Thermoshrinking polyester and preparing method thereof

A technology of heat shrinkage and polyester, applied in the direction of single-component polyester rayon, rayon manufacturing, textiles and papermaking, etc., can solve the problems of low shrinkage rate and low shrinkage internal stress, and achieve low production cost and transparency High, multi-function effect

Inactive Publication Date: 2016-05-18

CHINA PETROLEUM & CHEM CORP +1

View PDF8 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

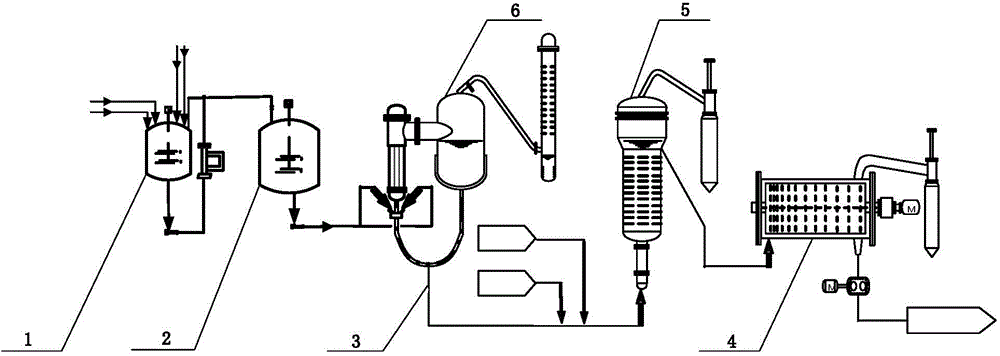

[0006] The purpose of the present invention is to address the shortcoming of low shrinkage rate caused by low shrinkage internal stress due to the high crystallinity of existing ordinary polyester during fiber spinning or uniaxially stretched film. Polyester process production line, providing a high-shrinkage polyester with effectively reduced polyester crystallinity, high heat resistance and antistatic properties and its preparation method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below according to specific embodiments. The protection scope of the present invention is not limited to the following examples, which are listed for illustrative purposes only and do not limit the present invention in any way.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

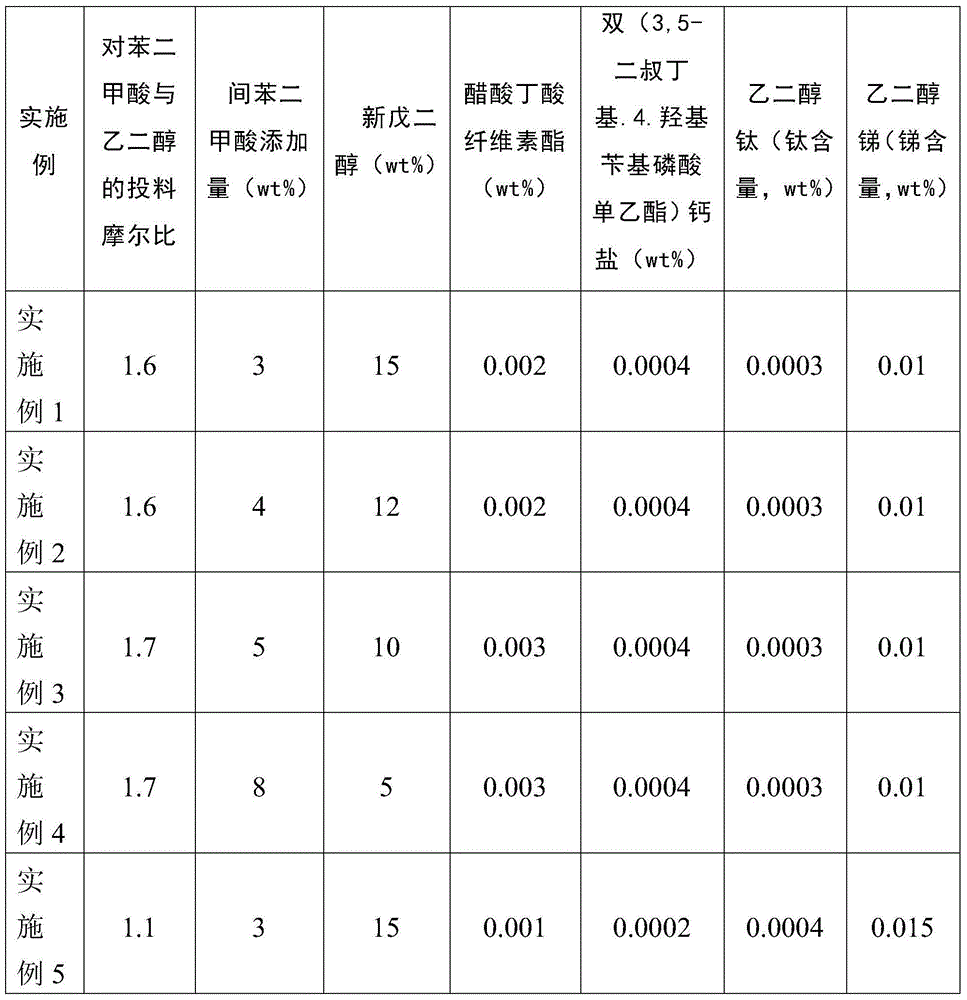

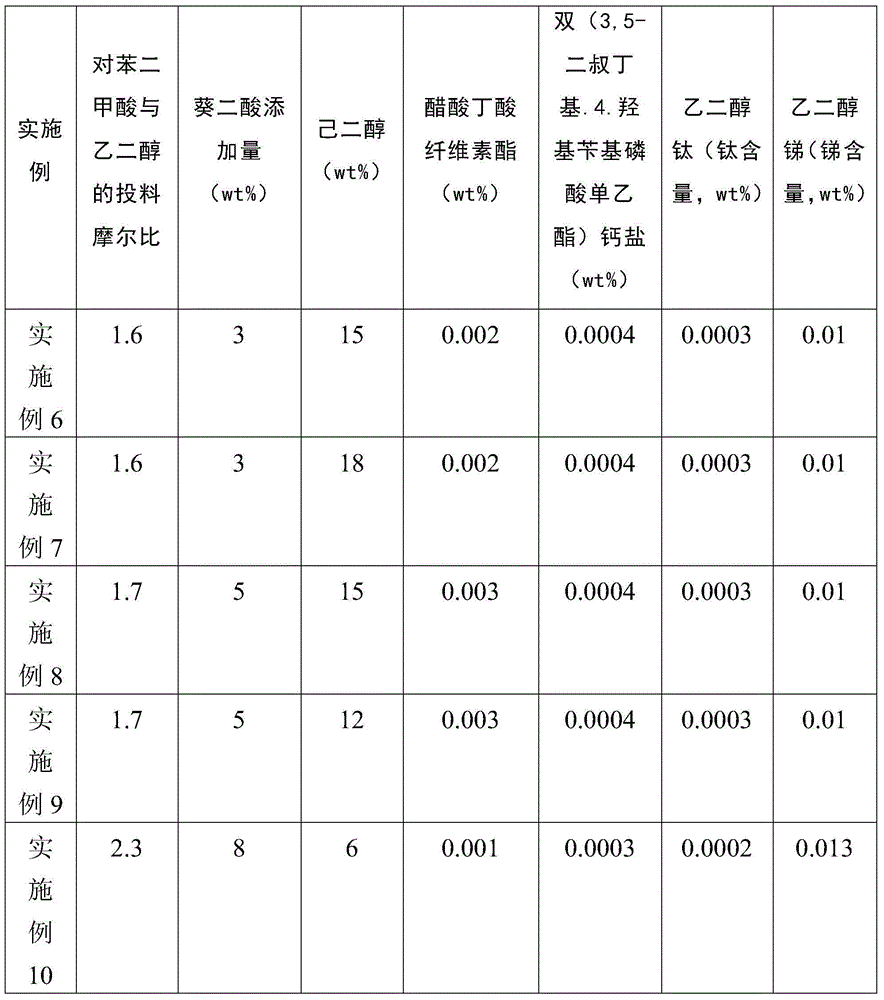

Thermoshrinking polyester is disclosed. Raw materials of the thermoshrinking polyester comprise terephthalic acid, ethylene glycol and a modifying agent. The modifying agent comprises 3-8 wt% of a dicarboxylic acid, 5-15 wt% of an aliphatic dihydric alcohol, 0.001-0.003 wt% of a hydrophilicity modifying agent and 0.0001-0.0005 wt% of an antioxidant heat stabilizer, with the amount of the modifying agent being calculated based on the theoretical weight of the polyester. The degree of crystallinity of the polyester is effectively reduced so that thermal degradation and oxidative degradation in subsequent processing steps can be prevented, thus preparing the thermoshrinking polyester with high heat resistance and an antistatic property. The thermoshrinking polyester can be used for high-shrinkage fiber spinning, uniaxial tension high-shrinkage film or other fields needing high-shrinkage polyester. A preparing method of the thermoshrinking polyester is also disclosed.

Description

technical field [0001] The invention relates to the technical field of polymer materials, in particular, the invention relates to a heat-shrinkable polyester and a preparation method thereof. Background technique [0002] PET polyester is a crystalline polymer, and the thermal shrinkage rate of fibers obtained by spinning or uniaxially stretched film is relatively low in the later stage. Even after special processing, only a thermal shrinkage rate of less than 30% can be obtained. In order to prepare fibers or films with high shrinkage rate, ordinary polyester needs to be modified by copolymerization. After copolymerization, the thermal shrinkage rate of fibers can reach more than 50%, and the highest thermal shrinkage rate of films can reach more than 70%. Copolymerization modification is mainly to add the third component or even the fourth component to participate in the copolymerization, change the regularity of the polyester chain segment, and make it produce an asymmetr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G63/91C08G63/183C08G63/85C08G63/86C08K5/523D01F6/92D01F1/10

Inventor 王鸣义程川吴一平陆慧良钱军任明利

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com