Clamp, device with clamp for testing mechanical property of hyper-elastic material and method

A testing device and a technology of material mechanics, which are applied in the direction of measuring devices, analyzing materials, and using stable tension/pressure to test the strength of materials, etc., can solve problems such as uneven stretching and low accuracy of test results, and achieve reliable mechanical performance parameters , Simplify the clamping and fixing and replacement operation procedures, and improve the effect of experimental accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

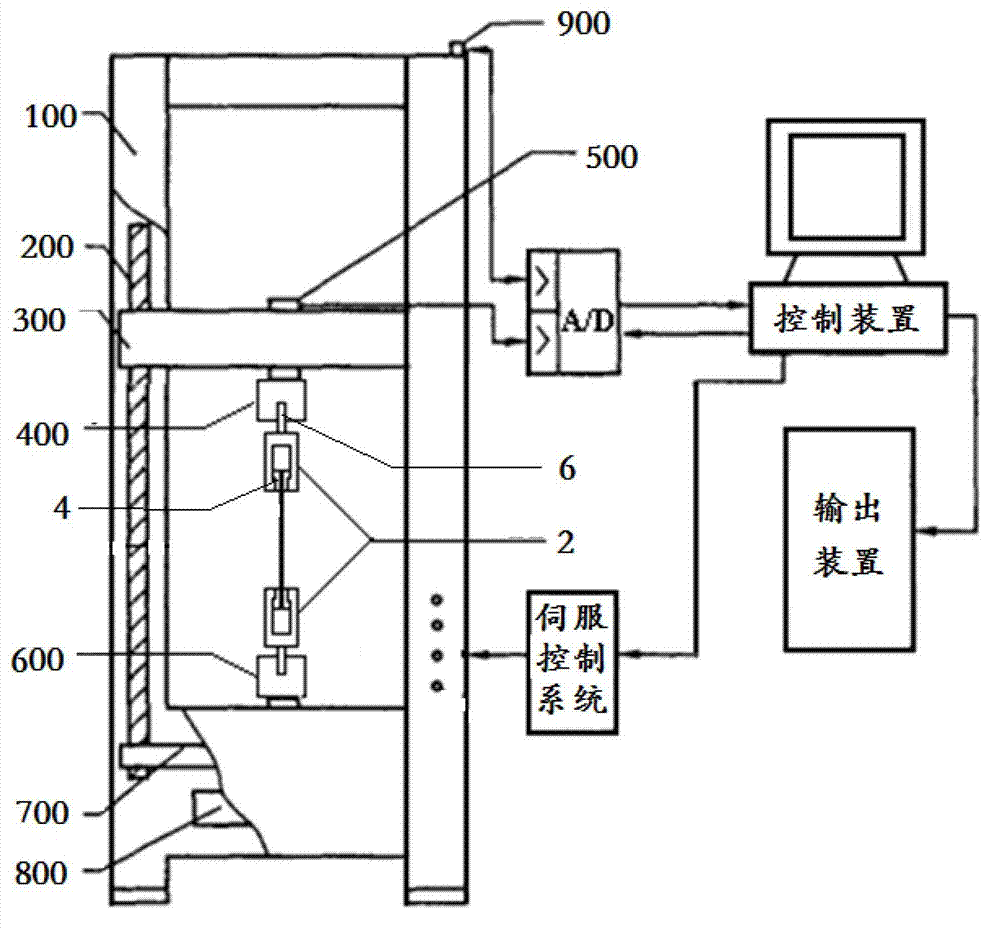

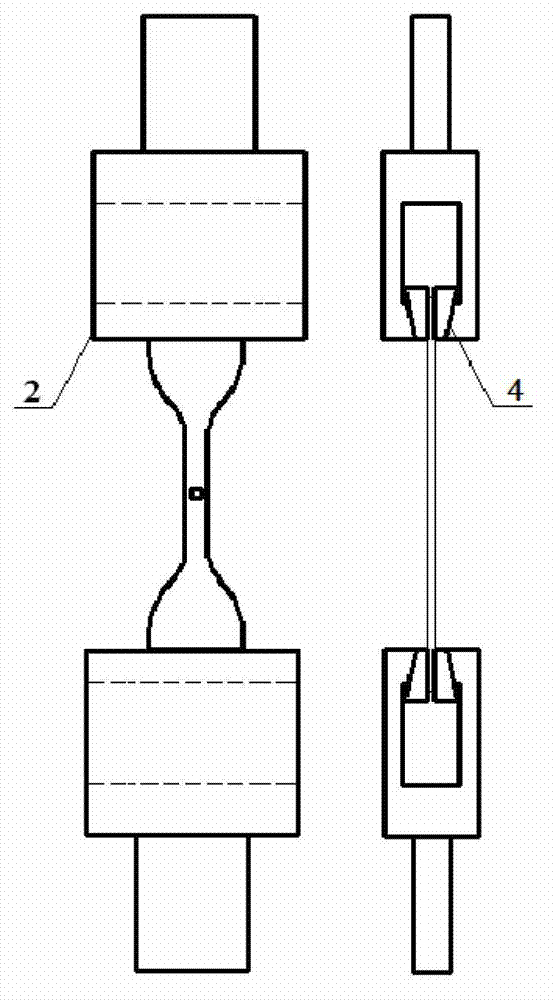

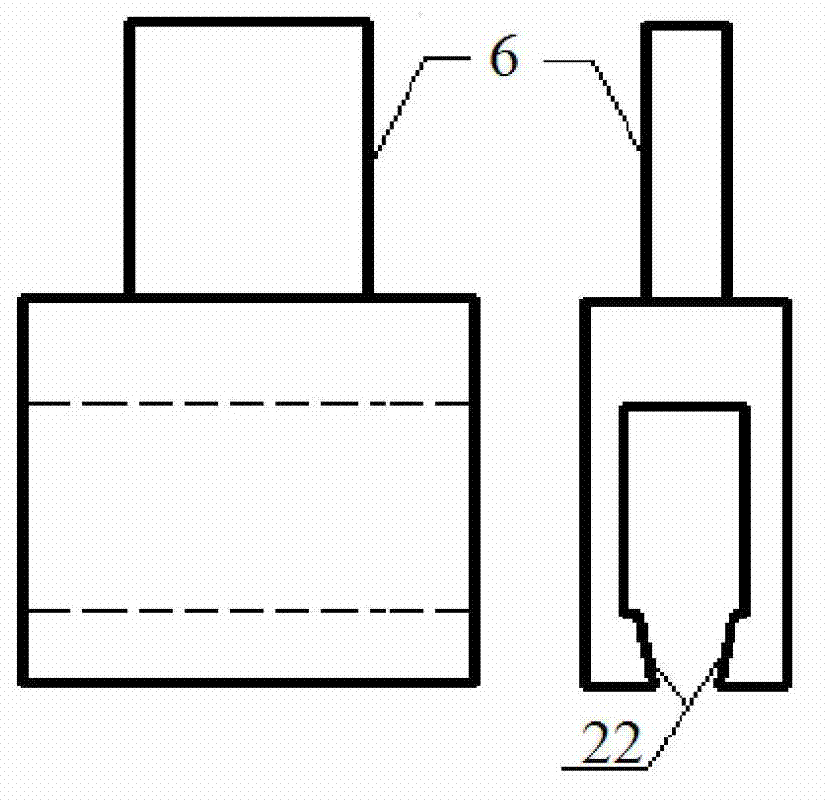

[0037] The superelastic mechanical performance testing device involved in the present invention is used for performing mechanical performance tests on thin-walled test specimens, such as uniaxial tension, equibiaxial tension and plane tension tests.

[0038] The testing device is, for example, a known electronic universal material testing machine, such as figure 1 shown. This testing machine adopts full digital control, and is equipped with sensors such as load sensors and photoelectric displacement encoders to detect force and deformation. The mechanical loading part uses a DC servo control system to control the prestressed ball screw to drive the beam to move. Combined testing machine. Due to the adoption of advanced measurement and control technologies such as sensing technology, automatic detection and microcomputer control, it can not only complete routine experiments such as tension, compression, bending and shearing, but also conduct research on fracture properties of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com