Rolling technology for stainless steel wire rod

A technology of stainless steel plate and process, applied in the direction of metal rolling, etc., to achieve the effect of diversified size, uniform degree of deformation, and expanded range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

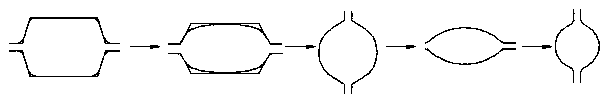

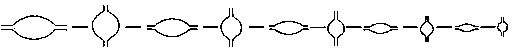

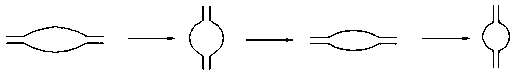

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0023] A stainless steel wire rod rolling process, comprising the following process steps:

[0024] S1: Billet preparation, stack the square steel billets according to the layers, in a well-shaped shape, and check the surface quality of the billets at the same time, and polish the thicker oxide layer;

[0025] S2: heat treatment, the steel billet is hoisted into the heating furnace for heat treatment, the temperature in the preheating section is less than 800°C, the temperature in the high temperature section is 830-1280°C, and the heating time is 120-180min;

[0026] S3: Pass rolling, through rough rolling, intermediate rolling and second inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com