Mould for continuous extrusion production of high-width-thickness-ratio profiles

A width-to-thickness ratio, die technology, used in metal extrusion dies and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

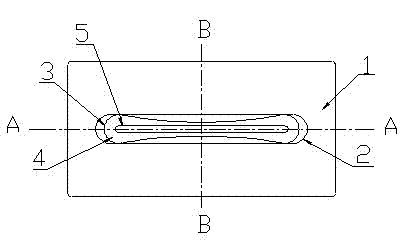

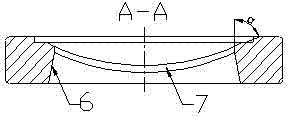

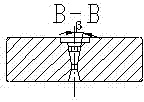

[0032] The mold structure has two diversion grooves and a unequal high resistance surface with flow resistance angle α and flow promotion angle β. The outlet of the expanded cavity is connected to the inlet of the mold. The opening of the mold 1 is provided with a diversion groove 2 with the same shape and size as the outlet of the expanded cavity. Behind the diversion groove is a "dumbbell-shaped" diversion groove 3 , the "dumbbell-shaped" diversion groove is transitioned to the unequal high-resistance surface 4 with a flow-resistance angle by using a circular arc radian, and a constant-diameter belt 5 is provided behind the flow-resistance surface, and a tool relief groove is opened at the exit of the mold 6 is connected with equal sizing belt. The overall dimension of the "dumbbell-shaped" diversion groove is to add 7mm to the width and length of the cross-sectional dimension of the product, and then according to the law of metal flow, at both ends of the cross-section of t...

Embodiment 2

[0035]The mold structure has two diversion grooves and a unequal high resistance surface with flow resistance angle α and flow promotion angle β. The outlet of the expanded cavity is connected to the inlet of the mold. The opening of the mold 1 is provided with a diversion groove 2 with the same shape and size as the outlet of the expanded cavity. Behind the diversion groove is a "dumbbell-shaped" diversion groove 3 , the "dumbbell-shaped" diversion groove is transitioned to the unequal high-resistance surface 4 with a flow-resistance angle by using a circular arc radian, and a constant-diameter belt 5 is provided behind the flow-resistance surface, and a tool relief groove is opened at the exit of the mold 6 is connected with equal sizing belt. The overall dimension of the "dumbbell-shaped" diversion groove is to add 5mm to the width and length of the cross-sectional dimension of the product, and then according to the metal flow law, at both ends of the cross-section of the "...

Embodiment 3

[0038] The mold structure has two diversion grooves and a unequal high resistance surface with flow resistance angle α and flow promotion angle β. The outlet of the expanded cavity is connected to the inlet of the mold. The opening of the mold 1 is provided with a diversion groove 2 with the same shape and size as the outlet of the expanded cavity. Behind the diversion groove is a "dumbbell-shaped" diversion groove 3 , the "dumbbell-shaped" diversion groove is transitioned to the unequal high-resistance surface 4 with a flow-resistance angle by using a circular arc radian, and a constant-diameter belt 5 is provided behind the flow-resistance surface, and a tool relief groove is opened at the exit of the mold 6 is connected with equal sizing belt. The overall dimension of the "dumbbell-shaped" diversion groove is to add 15mm to the width and length of the cross-sectional dimension of the product, and then according to the law of metal flow, at both ends of the cross-section of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com