Preparation method of high-purity copper target

A technology of high-purity copper and target material, which is applied in the field of sputtering target material, can solve problems such as abnormal grain structure, low deformation temperature, and large deformation resistance, and achieve the effects of fully and thoroughly deformed, reduced plastic deformation resistance, and uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

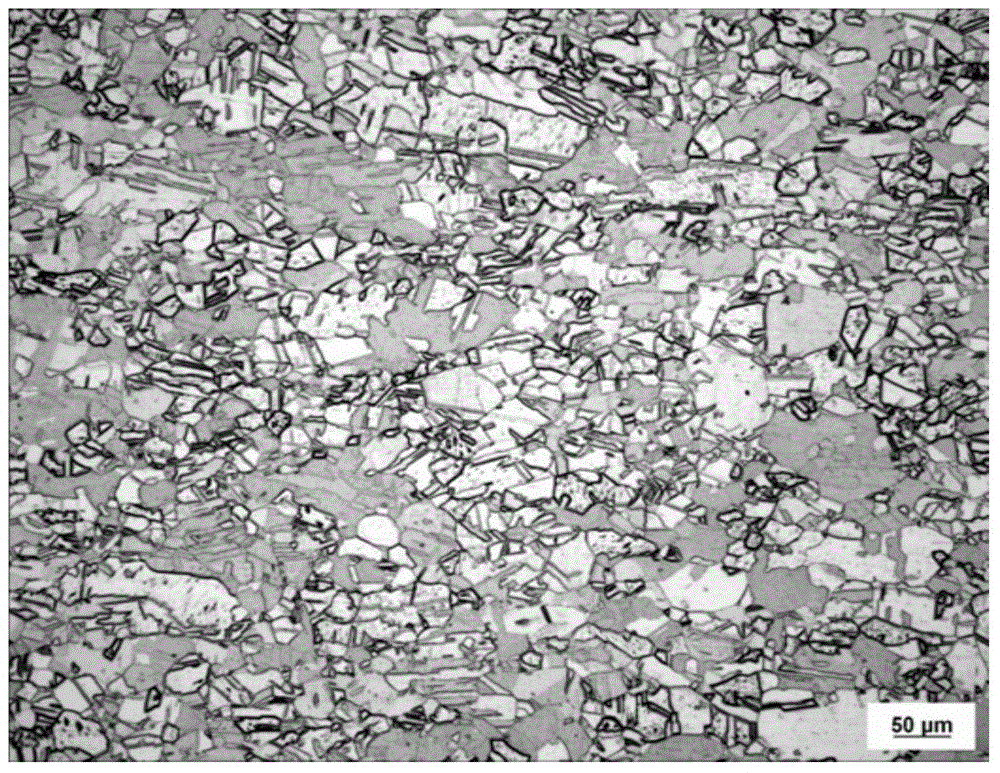

[0025] The size specification of high-purity copper ingot is Φ220×150mm, and the purity is 99.9999% (6N). The heating furnace uniformly heats the high-purity copper ingot to 450°C and keeps it warm for 3 hours. The air hammer is upsetting in the axial direction, and the size of the workpiece after upsetting is about Φ285×90mm; then the blank is laid flat along the axial direction, and then drawn out, the size of the workpiece after being drawn out is about Φ220×150mm, this is one round . The billet is forged one more round in the same way. The forged billet is subjected to 12 passes of reciprocating cold rolling on a two-roll mill, with a deformation of 12% in each pass and a total deformation of 80%. The size of the billet after rolling is about Φ490×30mm. The average grain size of the billet after rolling is 23 μm after being held at 350 ° C for 2 hours (such as figure 1 ).

Embodiment 2

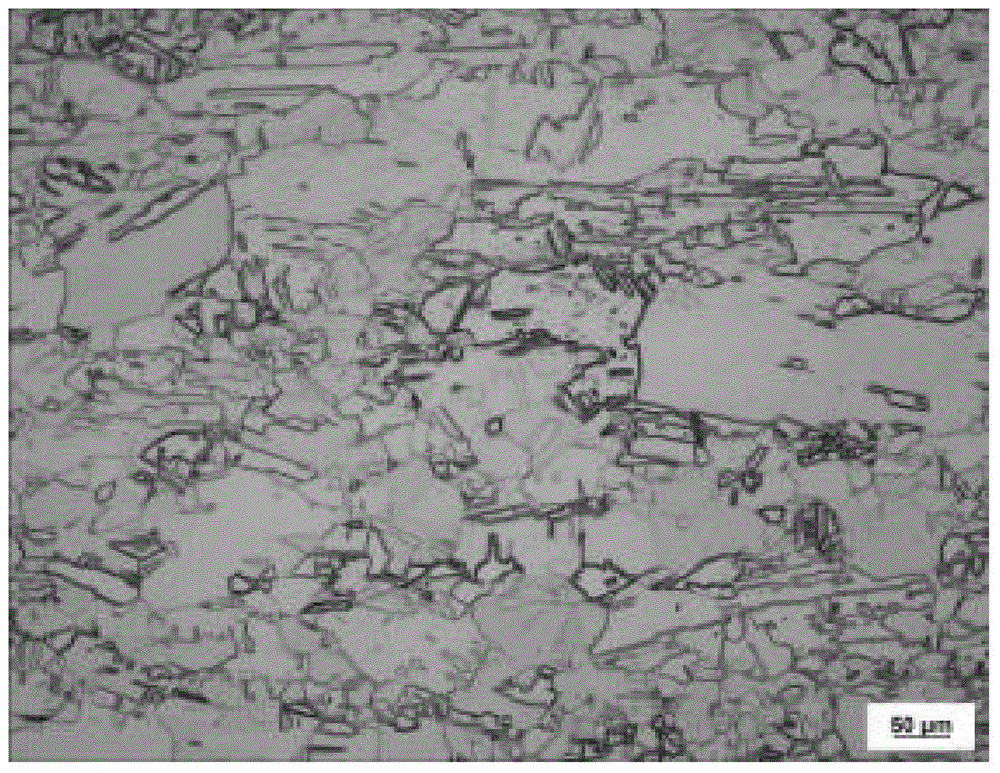

[0027] The size specification of the high-purity copper ingot is Φ150×150mm, and the purity is 99.999% (5N). The heating furnace uniformly heats the high-purity copper ingot to 500°C and keeps it warm for 1 hour. The air hammer is stretched along the axial direction, and the workpiece size after stretching is about Φ116×250mm; then the billet is erected along the axial direction, and then upset, the workpiece size after upsetting is about Φ150×150mm, this is one round . The billet was continuously forged for 3 rounds in the same way. The forged billet is subjected to 8 passes of reciprocating cold rolling on a two-roll mill, with a deformation of 20% in each pass and a total deformation of 85%. The size of the billet after rolling is about Φ390×22mm. The average grain size of the billet after rolling was 35 μm after being kept at 450° C. for 1 hour.

Embodiment 3

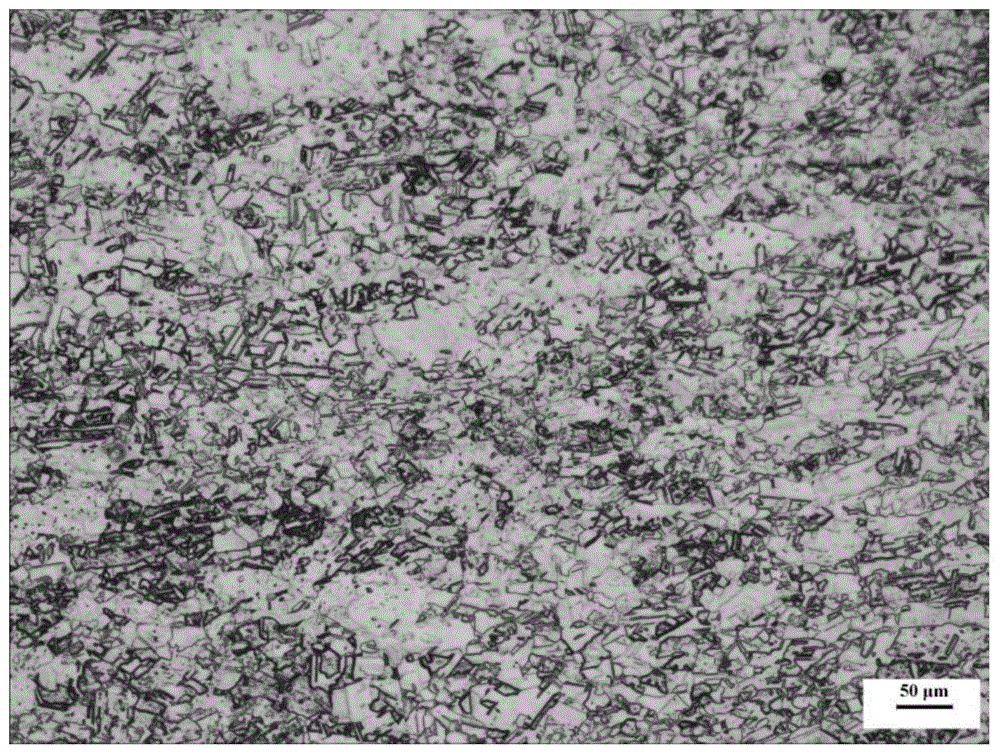

[0029] The size specification of high-purity copper ingot is Φ150×100mm, and the purity is 99.9999% (6N). The heating furnace uniformly heats the high-purity copper ingot to 400°C and keeps it warm for 3 hours. Air hammer upsetting along the axial direction, the size of the workpiece after upsetting is about Φ210×51mm, then the blank is laid flat along the axial direction, and then stretched, the size of the workpiece after being stretched is about Φ150×100mm, this is one round . The blank is continuously forged for 5 rounds according to the same method. After forging, the blank is subjected to 16 passes of reciprocating cold rolling on a two-roll rolling mill. The deformation of each pass is 10%, and the total deformation is 80%. The size of the blank after rolling is about Φ330× 20mm. The average grain size of the billet after rolling was 12 μm after being kept at 250° C. for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com