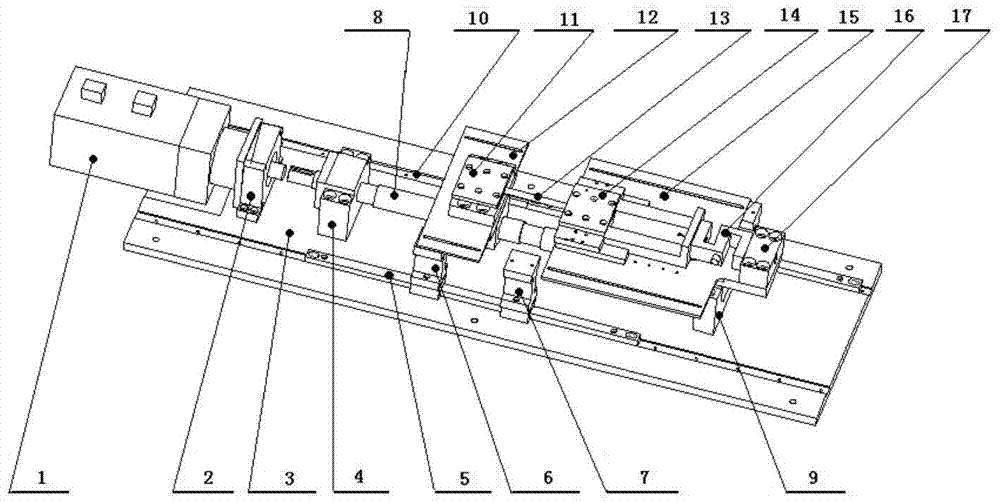

In-situ uniaxial tension observation device for mesoscale metal material

A metal material, uniaxial stretching technology, applied in the field of metal plastic forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

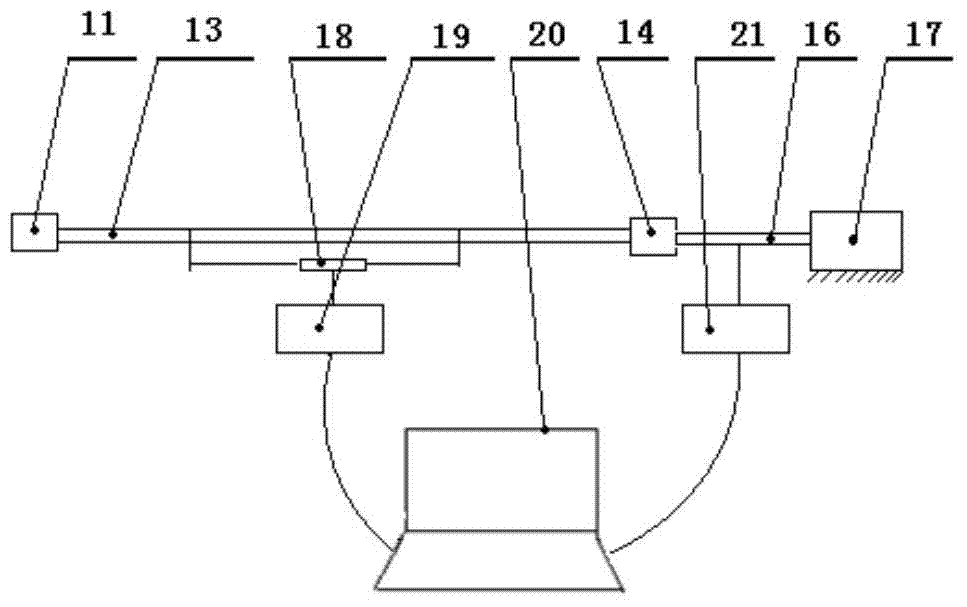

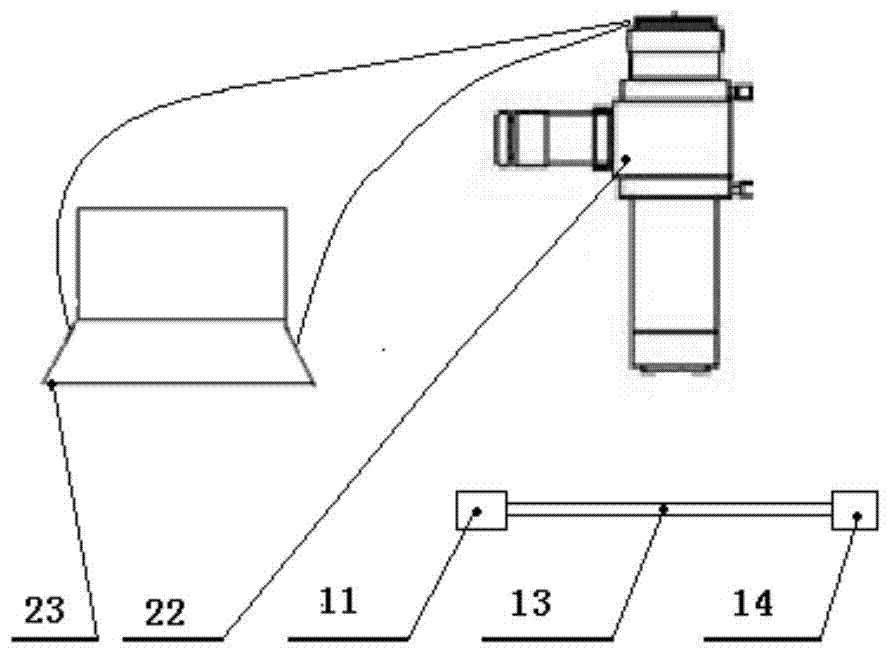

Method used

Image

Examples

Embodiment 1

[0056] Taking the DP590 steel plate with a thickness of 0.5mm as the research object, the working process of this embodiment is divided into the following steps:

[0057] (1) Sample preparation: DP590 steel plates with a thickness of 0.5 mm or more were cut to a thickness of 0.5 mm or more by wire cutting, and then ground to a thickness of 0.5 mm by a grinder, and metallographic corrosion was carried out using ordinary 5% Nital (alcohol nitric acid) solution.

[0058] (2) Preparation before the equipment experiment: start the DC servo motor 1, return the two oppositely moving chucks 11 and 2 14, and when the chucks are completely close together, use the middle of the sample grinding area as a reference. The reverse DC servo motor 1 moves the two chucks to the position where the sample can be clamped, and makes a mark on the sample 13.

[0059] (3) Sample clamping: open chuck one 11 and chuck two 14 respectively, clamp the sample 13 according to the pre-made marks of the sample...

Embodiment 2

[0062] Taking the TRIP590 steel plate with a thickness of 0.5mm as the research object, the working process of this embodiment is divided into the following steps:

[0063] (1) Sample preparation: wire-cut the TRIP590 steel plate above 0.5mm to be above 0.5mm, and then use a grinder to grind to a thickness of 0.5mm; the sample is mechanically polished after conventional inlay, rinsed with alcohol and dried with cold air, and immediately put into fresh Corrosion in 4% picric acid (2,4,6-trinitrophenol, C6H3N3O7) alcohol solution (picric alcohol) for 10-20s, add a few drops of hydrochloric acid to the bitter alcohol to sharpen the grain boundary (after confirming, Hydrochloric acid can also strengthen the contrast between the two tissues, see other people's literature on corrosion for details.), rinse with alcohol and dry with cold air; then immediately put it into fresh 1% Na2S2O5 aqueous solution for 10-20s coloring, Avoid shaking the sample to prevent the colorant from fallin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com