Test sample and method for testing performance parameters of pipe under complex stress state

A complex stress and pipe technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve problems such as inability to accurately and comprehensively obtain pipe performance parameters, and affect the accuracy of pipe plastic forming process simulation analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

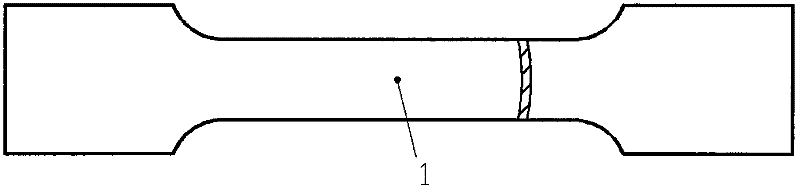

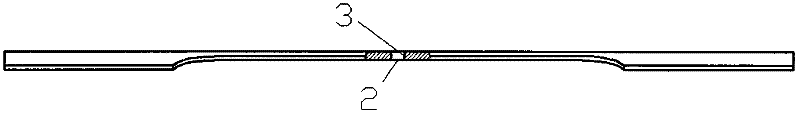

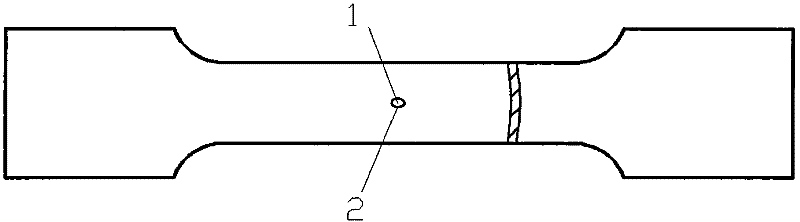

[0047] The invention is a sample used for testing the performance parameters of the pipe under the complex stress state, and the test of the performance parameters of the pipe under the complex stress state is realized through the arc tensile sample with the elliptical hole and the pipe compression sample. The arc-shaped tensile sample with an elliptical hole is obtained by improving the unidirectional tensile arc-shaped sample commonly used in the prior art; the pipe compression sample is taken along the axial direction of the pipe to be tested Pipe section. The pipe diameter D of the tested pipe material of the present invention is 30~200mm; An ellipse through hole is processed on the used uniaxial tensile arc sample, and the major axis of the ellipse through hole is 2.5~5mm, short The axis is 1.5-3mm; the pipe compression sample is a pipe section with a length of 100mm cut along the axial direction of the pipe to be tested. In the present invention, the pipe diameter D of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long axis | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com