A method for preparing flexible strain sensors using biaxial stretching technology

A strain sensor and biaxial stretching technology, applied in the field of sensors, can solve the problems of dispersion of conductive active nanomaterials, easy re-agglomeration plane orientation, etc., achieve large strain range, solve the problems of dispersion and re-agglomeration, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

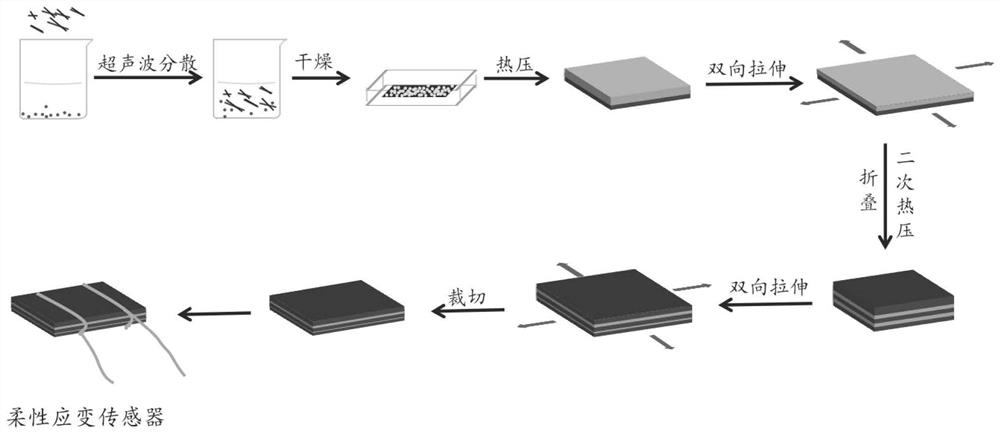

[0030] like figure 1 As shown, the present invention utilizes biaxial stretching technology to prepare high-performance flexible strain sensor, comprises the following steps:

[0031] Step S1: Disperse the mixture of 0.12 g of reduced graphene oxide and 0.28 g of multi-walled carbon nanotubes in 200 mL of N,N-dimethylformamide solvent for ultrasonic dispersion for 1 hour, and prepare the prepared nanocomposite The solution is poured into a mould, the size of which is 100×100×15 mm, and then the mold is moved into an oven at 80° C. to dry for 24 hours. After drying, a nano-filler composite film is obtained, and the side length of the composite film is 100 mm.

[0032] Step S2: Then spread 10g of polyurethane powder evenly on the composite film, and use a flat vulcanizer to heat press the composite film covered with polyurethane powder for 15 minutes at a temperature of 100°C and a working pressure of 10 MPa to obtain nano Composite sheet.

[0033] Step S3: Move the nanocompos...

Embodiment 2

[0037] The present invention utilizes biaxial stretching technology to prepare high-performance flexible strain sensor, comprises the following steps:

[0038] Step S1: Disperse the mixture of 0.12 g of reduced graphene oxide and 0.28 g of multi-walled carbon nanotubes in 200 mL of N,N-dimethylformamide solvent for ultrasonic dispersion for 1 hour, and prepare the prepared nanocomposite Pour the solution into a mold with a size of 100×100×15mm, and then move the mold into an oven at 80°C to dry for 24 hours. After drying, a nano-filler composite film is obtained, and the side length of the composite film is 100mm;

[0039] Step S2: Then spread 10g of polyurethane powder evenly on the composite film, and use a flat vulcanizer to heat press the composite film covered with polyurethane powder for 15 minutes at a temperature of 100°C and a working pressure of 10 MPa to obtain nano Composite sheets;

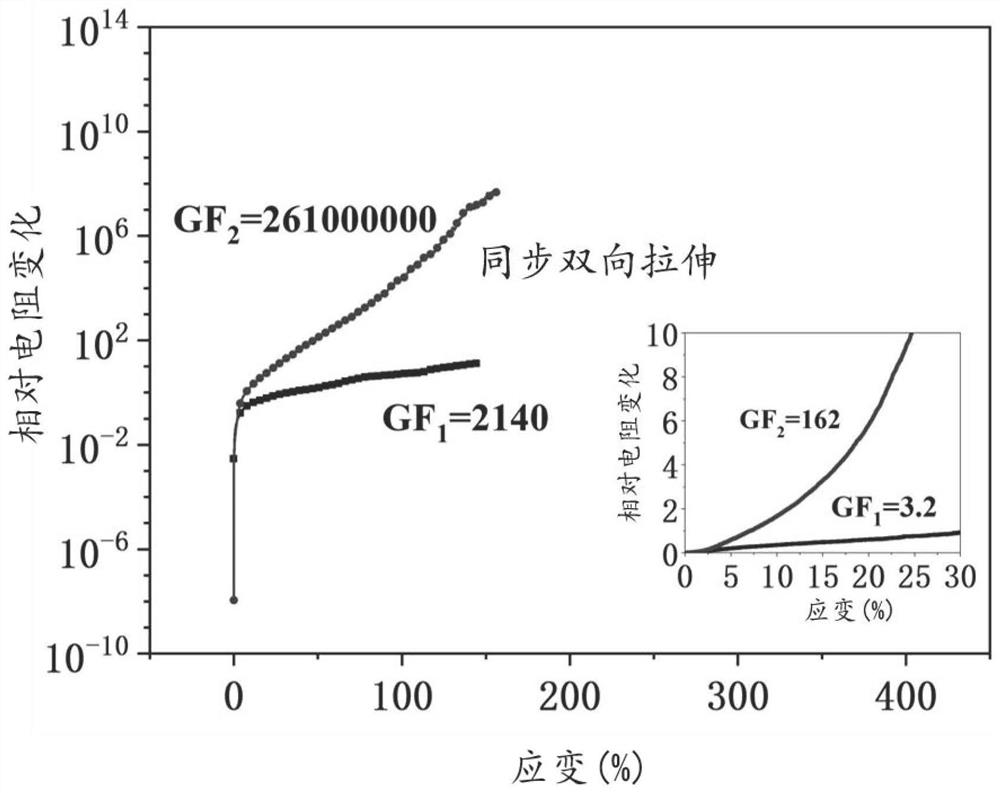

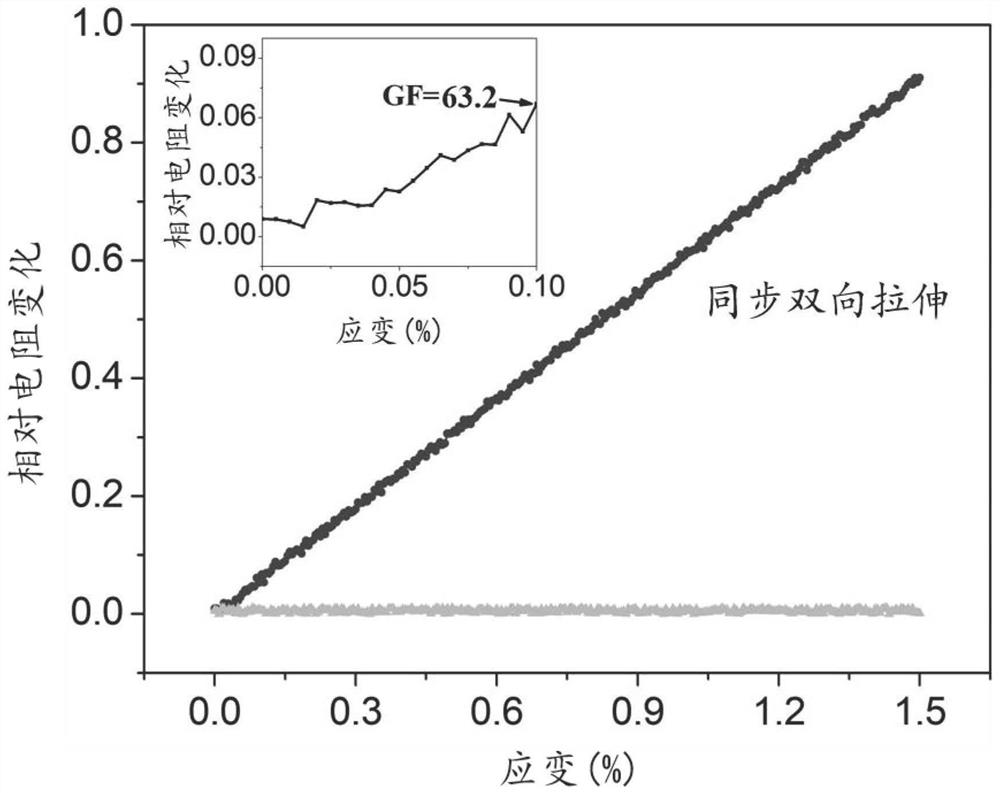

[0040]Step S3: Move the nanocomposite sheet into a biaxial tensile testing machi...

Embodiment 3

[0044] The present invention utilizes biaxial stretching technology to prepare high-performance flexible strain sensor, comprises the following steps:

[0045] Step S1: Disperse the mixture of 0.12 g of reduced graphene oxide and 0.28 g of multi-walled carbon nanotubes in 200 mL of N,N-dimethylformamide solvent for ultrasonic dispersion for 1 hour, and prepare the prepared nanocomposite Pour the solution into a mold with a size of 100×100×15mm, and then move the mold into an oven at 80°C to dry for 24 hours. After drying, a nano-filler composite film is obtained, and the side length of the composite film is 100mm;

[0046] Step S2: Then spread 10g of polyurethane powder evenly on the composite film, and use a flat vulcanizer to heat press the composite film covered with polyurethane powder for 15 minutes at a temperature of 100°C and a working pressure of 10 MPa to obtain nano Composite sheets;

[0047] Step S3: Move the nanocomposite sheet into a biaxial tensile testing mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com