Flexible stress sensor and its preparation method

A stress sensor and flexible technology, applied in the field of sensors, can solve the problems of small strain range, poor linearity, poor stability, etc., and achieve the effect of large strain range, strong environmental adaptability and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

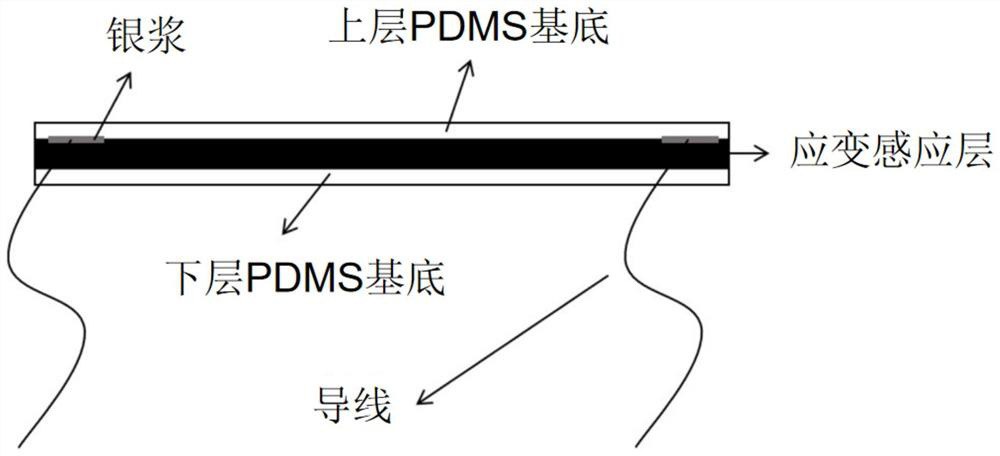

[0034] like figure 1 and figure 2 As shown, the present invention proposes a flexible stress sensor, which includes a strain sensing layer, an electrode and a flexible packaging layer, the strain sensing layer is electrically connected to the electrodes, and the flexible packaging layer includes an upper PDMS substrate and the underlying PDMS substrate, and cover the strain sensing layer and the electrodes.

[0035] The strain sensing layer is redox graphene with a prismatic network structure after laser reduction, and the redox graphene is a material after laser reduction twice.

[0036] The electrodes include silver paste and wires, one end of the wires is bonded to the strain sensing layer through the silver paste, and the other end is led t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com