Nylon 1111/ polyvinylidene fluoride ferroelectric composite film and preparation method thereof

A technology of polyvinylidene fluoride iron and polyvinylidene fluoride, which is applied in the field of preparation of polymer blended composite materials, can solve the problems of ferroelectric materials that have not been reported in literature, and achieve low overall cost, simple preparation method, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

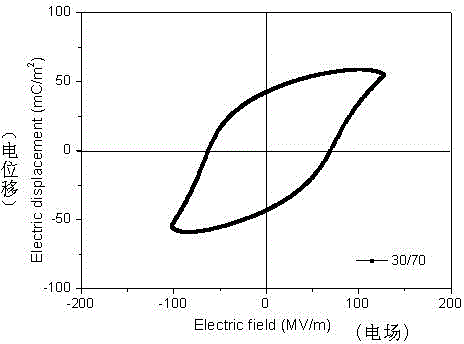

Embodiment 1

[0032] Nylon 1111 and polyvinylidene fluoride particles were vacuum-dried at 100°C for 24 hours, and 30 parts of nylon 1111 particles and 70 parts of polyvinylidene fluoride were added to the Haake rheometer according to parts by weight for blending, blending temperature 210°C, screw speed 60r / min, blending time 5min. The blended material is sandwiched between two aluminum foils, and hot-pressed on a hot press to form a film with a thickness of about 50 μm. Hot-pressing temperature is 210 ℃, hot-pressing pressure 6MPa, hot-pressing time 8min. Then quickly transfer the film in the molten state to an ice-water mixture for quenching, and dissolve the aluminum foil on both sides of the quenched film with a strong alkali solution of 5% sodium hydroxide at a temperature of 20°C to obtain an initial film and dry it naturally. Stretching at room temperature to obtain a stretched film sample with a thickness of 30 microns, the stretch ratio n =3.

Embodiment 2

[0034] Nylon 1111 and polyvinylidene fluoride particles were vacuum-dried at 80°C for 24 hours, and 50 parts of nylon 1111 particles and 50 parts of polyvinylidene fluoride were added to the Haake rheometer according to parts by weight for blending. The blending temperature was 210°C. The rotating speed is 60r / min, and the blending time is 5min. Take the blended material and sandwich it between two pieces of aluminum foil, and press it on a hot press to form a film with a thickness of about 50 μm. Hot-pressing temperature is 210 ℃, hot-pressing pressure 6MPa, hot-pressing time 8min. Then quickly transfer the film in the molten state to an ice-water mixture for quenching, and dissolve the aluminum foil on both sides of the quenched film with a strong alkali solution of potassium hydroxide with a mass concentration of 30% at a temperature of 10°C to obtain an initial film and dry it naturally. Stretch ratio at room temperature n =3, the ferroelectric composite thin film sample...

Embodiment 3

[0036] Nylon 1111 and polyvinylidene fluoride particles were vacuum-dried at 100°C for 24 hours, and 70 parts of nylon 1111 particles and 30 parts of polyvinylidene fluoride were added to the Haake rheometer according to parts by weight for blending, the blending temperature was 240°C, and the screw speed was 60r / min, blending time 5min. The blended material is sandwiched between two aluminum foils, and hot-pressed on a hot press to form a film with a thickness of about 50 μm. Hot-pressing temperature is 220 ℃, hot-pressing pressure 6MPa, hot-pressing time 8min. Then quickly transfer the film in the molten state to a mixture of ice and water for quenching. At 0°C, dissolve the aluminum foils on both sides of the quenched film with a strong alkali solution of 20% mass concentration of sodium hydroxide to obtain an initial film and dry it naturally. Stretched on a tensile machine at a temperature of 50°C, the stretch ratio n =3, the ferroelectric composite thin film sample wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com