Preparation method of low-temperature-sintered PZT95-5 piezoelectric ceramics

A PZT95, low-temperature sintering technology, applied in the low-temperature field of ceramic materials, can solve the problems of high sintering temperature and low performance, and achieve the effects of high residual polarization strength, high electrical strength and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the PZT95 / 5 ferroelectric ceramic material of the present invention may include:

[0038] (1) Mixed raw materials: Pb in powder form 3 O 4 , ZrO 2 , TiO 2 , Nb 2 O 5 , CdO and Li 2 CO 3 As raw materials, the ratio is stoichiometric, using absolute ethanol, zirconia balls as the medium, and mixing the raw materials: zirconia balls: deionized water with a mass ratio of 1:2:0.85, and wet ball milling for 6-10 hours ;

[0039] (2) Synthesis of niobium doped and modified and contains CdO, Li 2 CO 3 PZT95 / 5 ferroelectric ceramic powder: Pour the raw material obtained in step (1) into a container, put it into an oven and dry it, then press it, and synthesize it at a temperature ranging from 760°C to 850°C for 2 to 4 hours. Grind and pulverize the synthesized block to obtain niobium-doped modified and contain CdO, Li 2 CO 3 PZT95 / 5 ferroelectric ceramic powder;

[0040] (3) Press molding of the powder: the powder described in (2) is wetted with deionized wat...

Embodiment 1

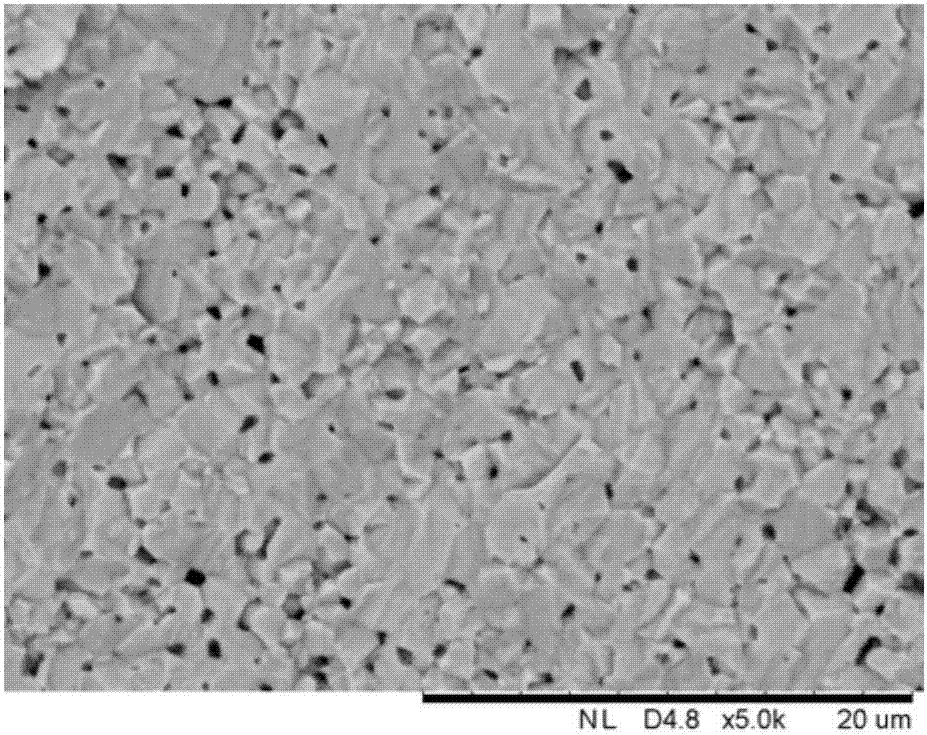

[0046] Take Pb 3 O 4 , ZrO 2 , TiO 2 , Nb 2 O 5 , CdO and Li 2 CO 3 As raw material, press (Pb 99.5 Cd 0.005 )(Zr 0.965 Ti 0.035 )O 3 +1%wtNb 2 O 5 +0.1%wt Li 2 CO 3 Use absolute ethanol and zirconia balls as the medium to mix the raw materials: zirconia balls: deionized water = 1:2:0.85, and wet ball mill for 8 hours; pour the mixed raw materials Put it into the container and put it in the oven for drying, then press the block, and synthesize. The synthesis temperature range is 850℃ and keep for 2~4h. Grind and pulverize the synthesized block to obtain niobium-doped modified and contain CdO, Li 2 CO 3 PZT95 / 5 ferroelectric ceramic powder; the obtained powder adopts deionized water and zirconia ball as the medium, and the mass ratio of material: zirconia ball: deionized water is 1:1.5:1 after wet ball milling for 24h , Discharging and drying, adding 6.75wt% PVA for granulation forming, and pressing the split body under a pressure of 150MPa to form; put the formed sample into a b...

Embodiment 2

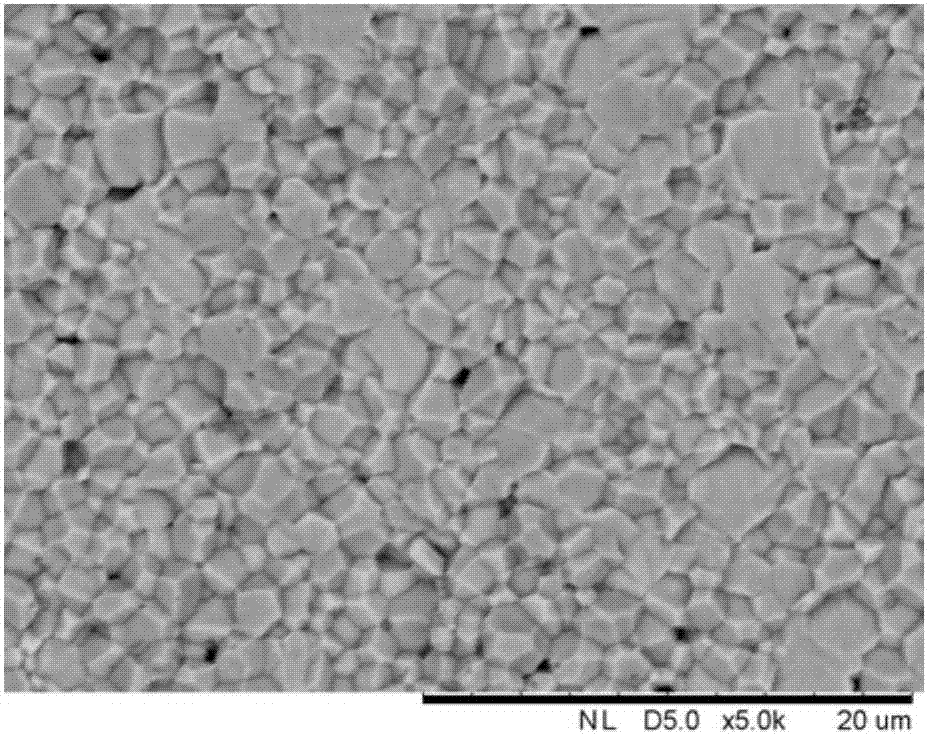

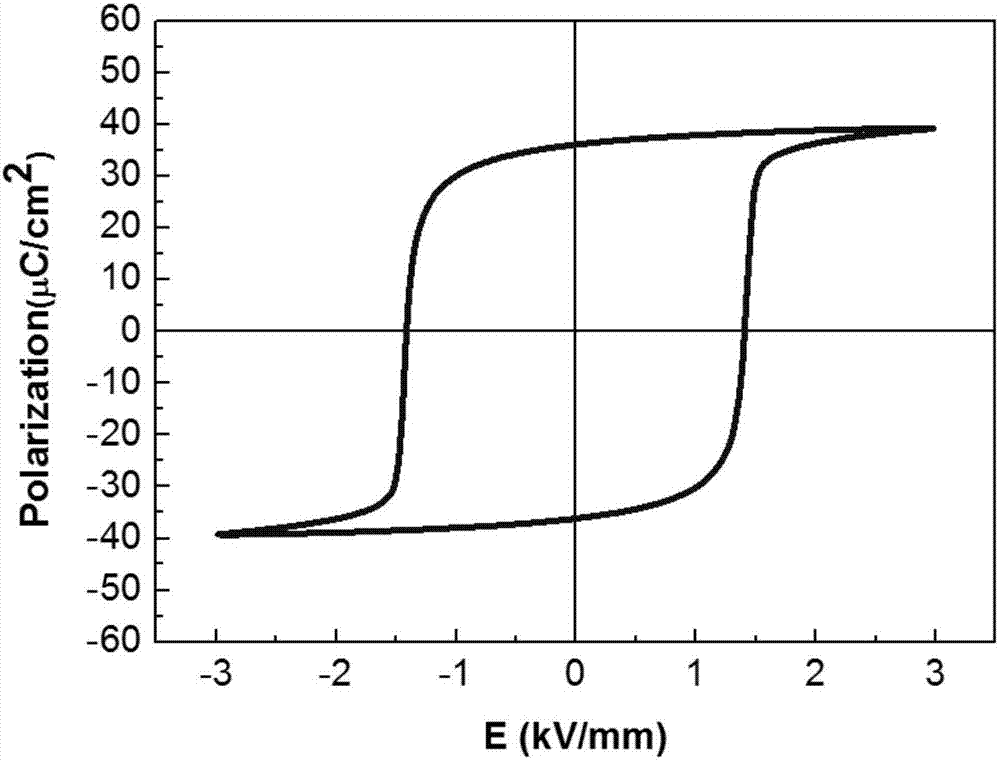

[0048] According to (Pb 99 Cd 0.01 )(Zr 0.965 Ti 0.035 )O 3 +1%wtNb 2 O 5 +0.15%wt Li 2 CO 3 The specific preparation process is as in Example 1. The main properties of the obtained standard tablets are: d 33 =67pC / N, Pr=46μC / cm 2 . figure 2 The microscopic morphology of the material described in this example is given, Figure 4 The hysteresis loop of the material in this example is given, Figure 5 The XRD diffraction pattern of the material in this example is given.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com