Method for preparing strontium-barium titanate/polymide dielectric adjustable composite material thick film

A technology of polyimide dielectric and barium strontium titanate, which is applied in the field of composite material manufacturing, can solve the problems such as the dielectric adjustability of polymer-based barium strontium titanate composite materials, and achieve excellent chemical stability, The effect of reducing the dielectric constant and smoothing the surface without cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1. Select ZKPI-305IID ordinary polyimide coating glue produced by Beijing Bomi Technology Co., Ltd. as the polyimide precursor.

[0061] 2. The chemical composition is prepared by conventional solid-state reaction method as Ba 0.6 Sr 0.4 TiO 3 Barium strontium titanate dielectric tunable ceramics. According to XRD detection, barium strontium titanate has a pure cubic perovskite structure without the formation of a second phase.

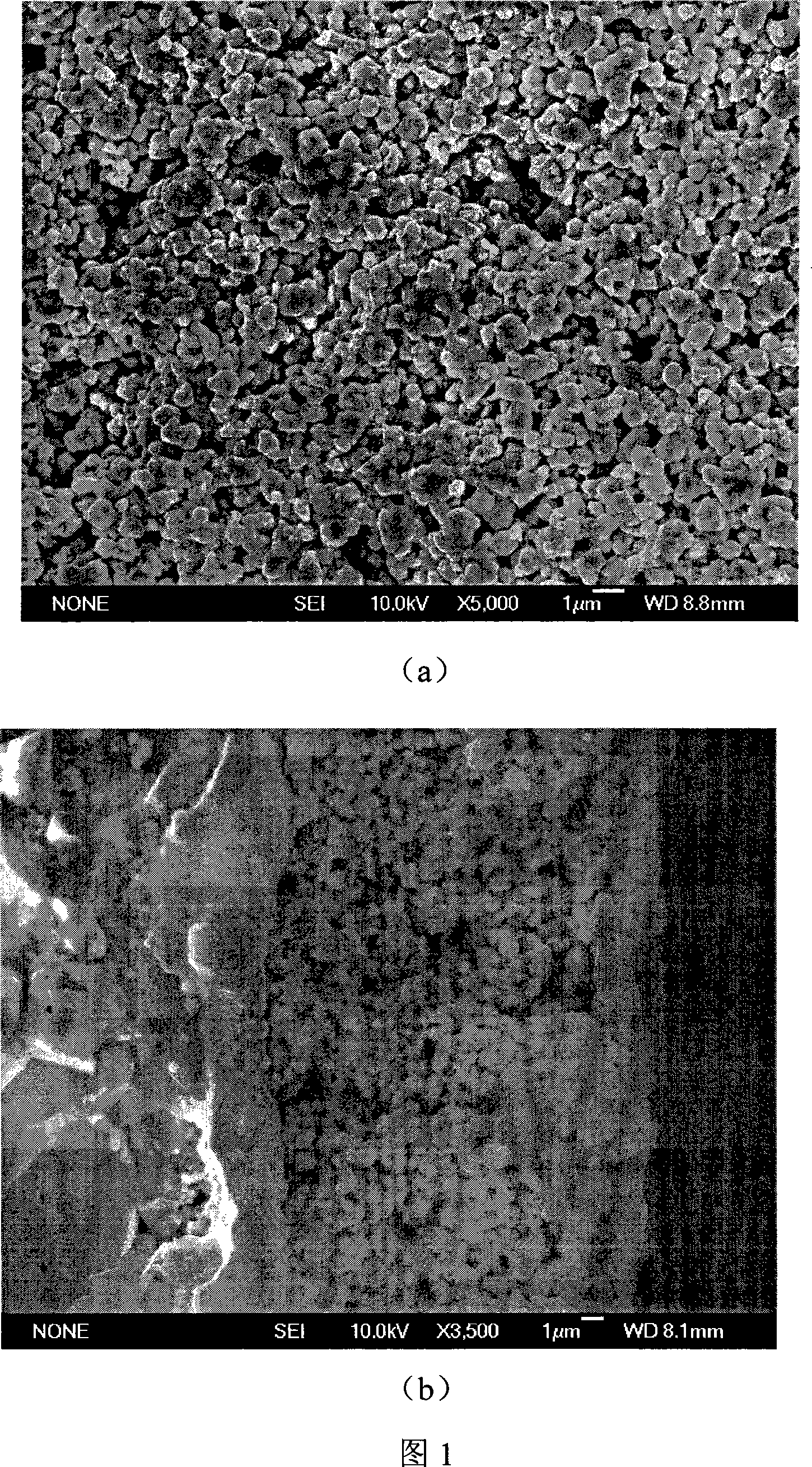

[0062] 3. Crushing by means of ordinary ball milling, the ball milling speed is 150 rpm, and the ball milling is continued for 4 hours. The central particle size of the prepared barium strontium titanate powder is 0.6um.

[0063] 4. Take 100g of crushed barium strontium titanate powder, dry at 110°C for 24 hours, then add 2-5g of acrylic acid solution, and ultrasonically treat it in 100ml of absolute ethanol for 1 hour, so that the surface of the ceramic powder is treated with acrylic acid.

[0064] 5. Mix 20g of the polyimide precursor and...

Embodiment 2

[0068] 1. Select ZKPI-305IID ordinary polyimide coating glue produced by Beijing Bomi Technology Co., Ltd. as the polyimide precursor.

[0069] 2. The chemical composition is prepared by conventional solid-state reaction method as Ba 0.6 Sr 0.4 TiO 3 Barium strontium titanate dielectric tunable ceramics. According to XRD detection, barium strontium titanate has a pure cubic perovskite structure without the formation of a second phase.

[0070] 3. Crushing by means of ordinary ball milling, the ball milling speed is 150 rpm, and the ball milling is continued for 4 hours. The central particle size of the prepared barium strontium titanate powder is 0.6um.

[0071] 4. Take 100g of crushed barium strontium titanate powder, dry at 110°C for 24 hours, then add 2-5g of acrylic acid solution, and ultrasonically treat it in 100ml of absolute ethanol for 1 hour, so that the surface of the ceramic powder is treated with acrylic acid.

[0072] 5. Mix 20g of the polyimide precursor and...

Embodiment 3

[0076] 1. Select ZKPI-305IID ordinary polyimide coating glue produced by Beijing Bomi Technology Co., Ltd. as the polyimide precursor.

[0077] 2. The chemical composition is prepared by conventional solid-state reaction method as Ba 0.6 Sr 0.4 TiO 3 Barium strontium titanate dielectric tunable ceramics. According to XRD detection, barium strontium titanate has a pure cubic perovskite structure without the formation of a second phase.

[0078] 3. Crushing by high-energy ball milling, ball milling for 4 hours, the central particle size of the prepared barium strontium titanate powder is 0.1um.

[0079] 4. Take 100g of crushed barium strontium titanate powder, dry at 110°C for 24 hours, then add 2-5g of acrylic acid solution, and ultrasonically treat it in 100ml of absolute ethanol for 1 hour, so that the surface of the ceramic powder is treated with acrylic acid.

[0080] 5. Mix 20 g of the polyimide precursor and 20 g of the surface-pretreated barium strontium titanate pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Central particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com