Mullite fiber preparation method

A kind of mullite fiber and mullite technology, which is applied in the field of green low-cost mullite fiber preparation, can solve the problems of large internal and external temperature gradient, low material consistency, and fiber grain growth, and achieve short holding time , Improve energy utilization, reduce fiber brittle fracture and pulverization ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, the chemical expression of mullite fiber is 3Al 2 o 3 2SiO2 2 , the specific preparation method is as follows:

[0033] (1) Weigh 241.5g aluminum chloride hexahydrate (AlCl 3 ·6H 2 (2), 135g aluminum powder, add 400ml deionized water, stir 20min with the rotating speed of 800rpm and make mixed solution A, then add 480ml silica sol (SiO 2 Content is 0.25g / ml), and 1% polyvinyl alcohol, heated to 80 ° C, and fully stirred, during the stirring process, 1mol / L of HCl was added dropwise to adjust the pH to 5±1. A sol was obtained after stirring for 12 h.

[0034] (2) The sol obtains colloidal fibers through spinning into fibers;

[0035] (3) The colloidal fiber was heated to 500°C at a heating rate of 2°C / min, and heat-treated for 2 hours to obtain an amorphous fiber;

[0036] (4) Put the amorphous fiber obtained in (3) into a professional microwave oven for heat treatment, the sintering atmosphere is air, and the temperature is raised to 1000°C at...

Embodiment 2

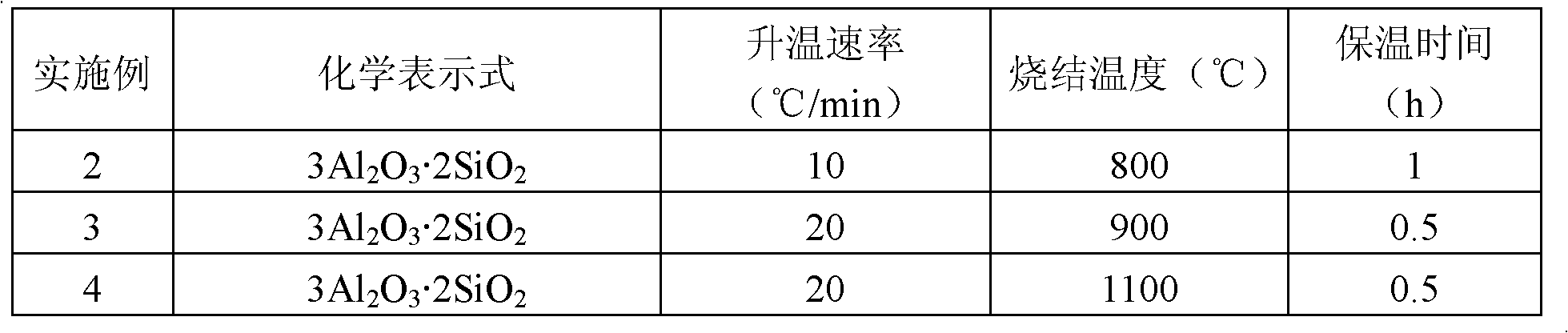

[0039] In Examples 2 to 8, the chemical expression of mullite fiber is the same as that of Example 1, and the specific preparation method is basically the same as that of Example 1, except that the heating rate, sintering temperature, and holding time are shown in Table 1 below. .

[0040] Chemical expression and process conditions of mullite fiber in Table 1 embodiment 2~8

[0041]

[0042]

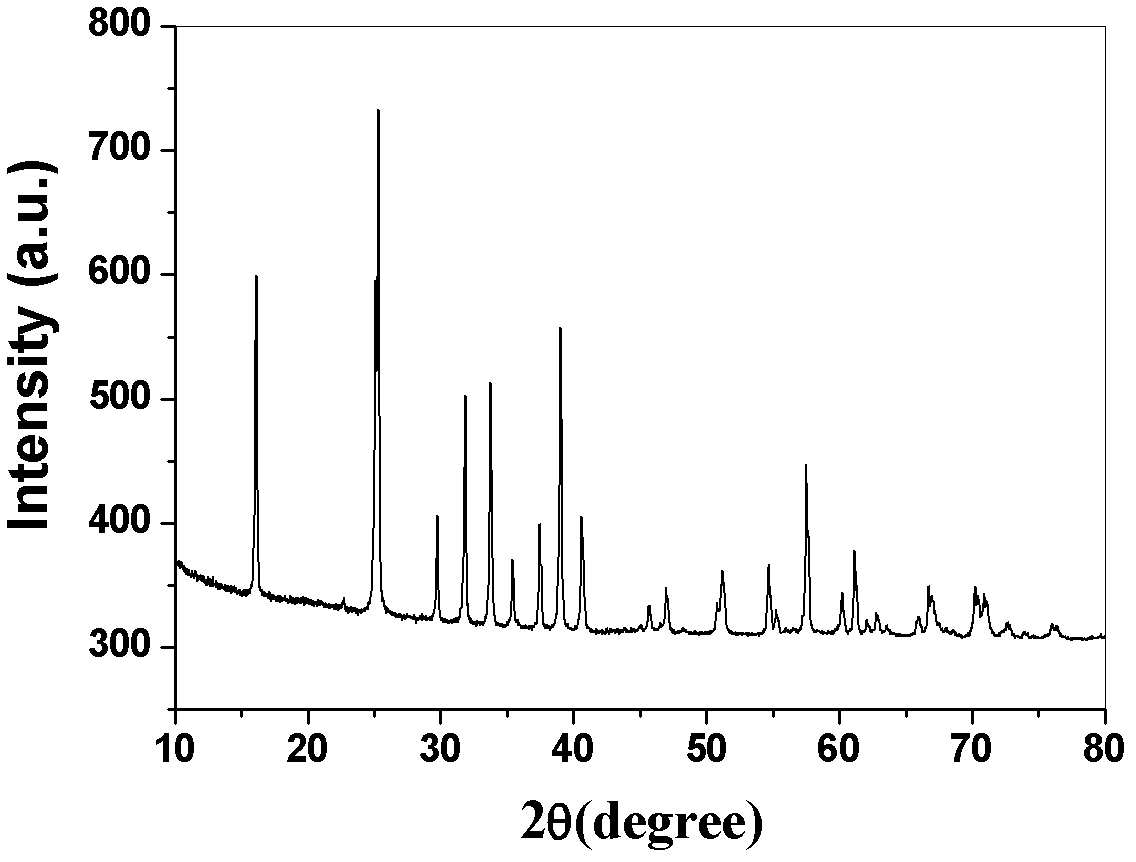

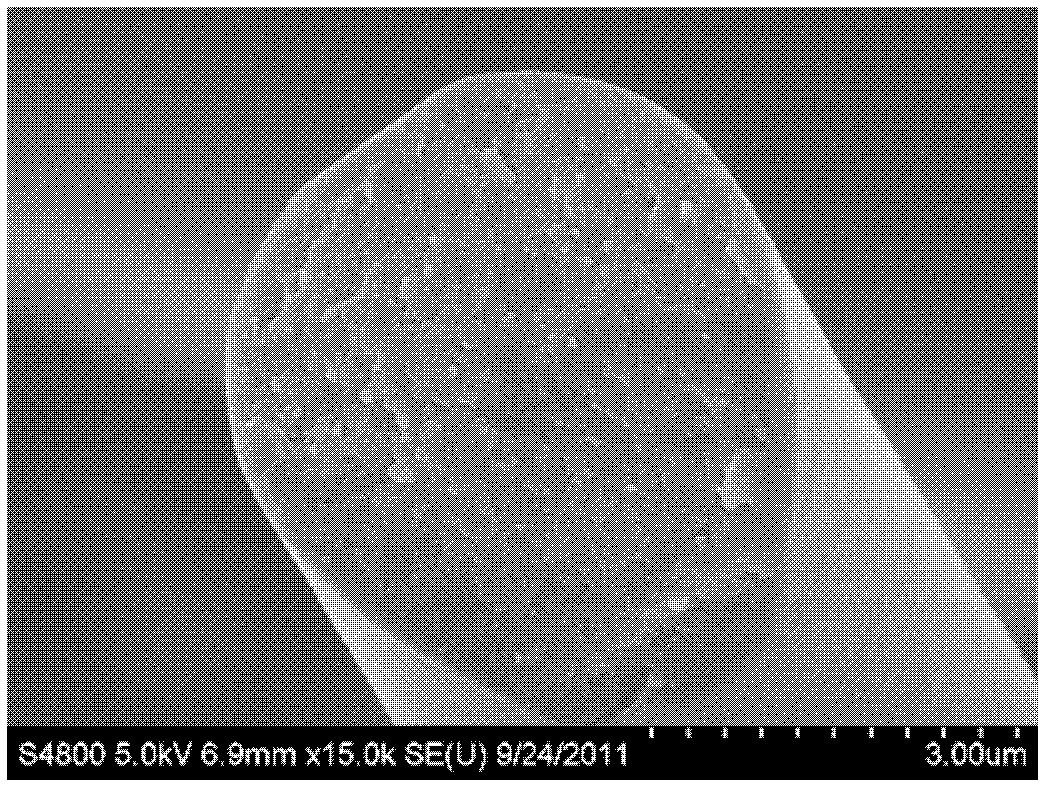

[0043] The polycrystalline mullite fiber sample prepared above was measured and analyzed, and the phase of the sample was analyzed by an X-ray diffractometer. figure 1 As shown, it is shown that the fiber is in the mullite phase at the microwave treatment temperature shown in Table 1; the fracture morphology, grain size, and structural characteristics of the sample are observed with a scanning electron microscope, and similar figure 2 In the image shown, the grain size is 30-60nm, the fiber diameter is 6-10μm, and the fiber section is dense.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com