Patents

Literature

101results about How to "Reduce the probability of rupture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

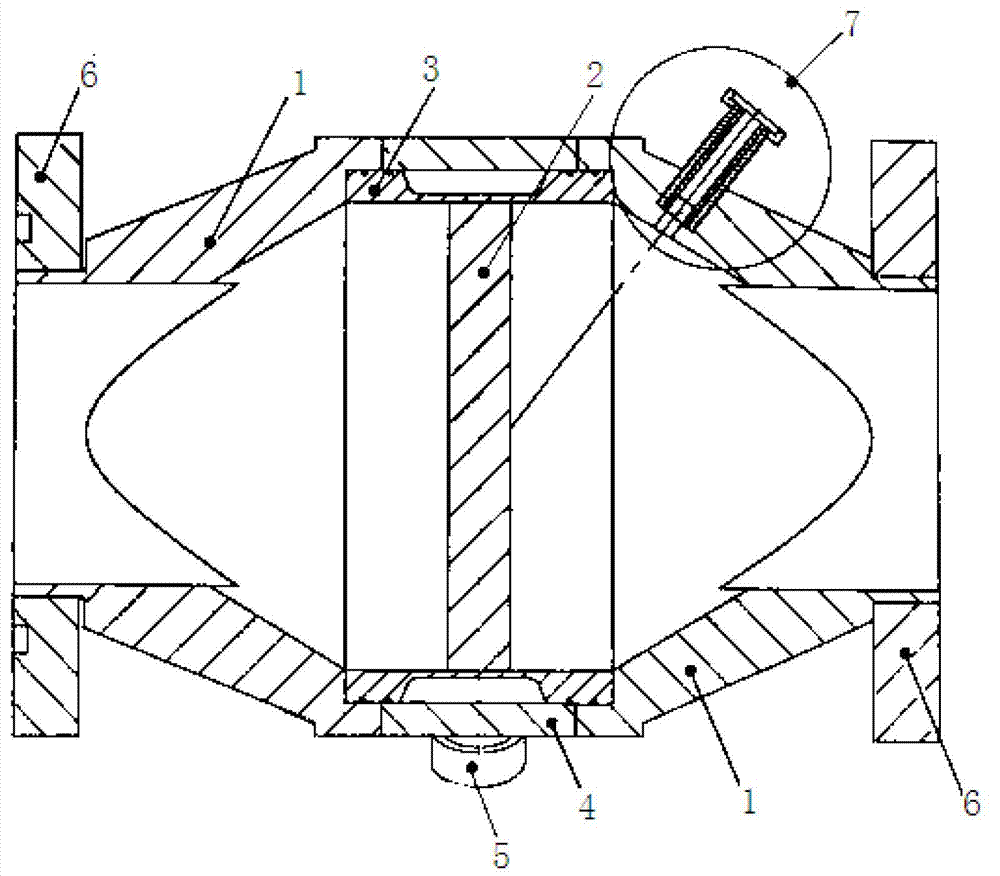

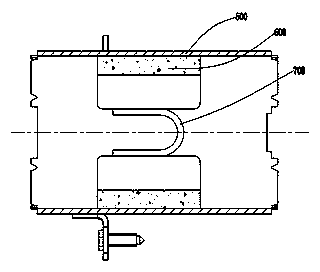

Novel high-power microwave vacuum ceramic window

ActiveCN103094645ASmall temperature differenceReduce the probability of ruptureWaveguide type devicesMicrowaveFlange

The invention discloses a novel high-power microwave vacuum ceramic window which comprises two cone-shaped window bodies which are symmetrically arranged in a left-and-right mode and a ceramic piece in a middle position. A circular waveguide window frame is arranged on the outer side of the ceramic piece, and the ceramic piece is arranged along the radial direction of the window frame. An outer water sleeve is sleeved on the outer side of the window frame, and a water inlet connector and a water outlet connector are welded in the outer water sleeve. The left and the right ends of the window frame and the outer water sleeve are respectively assembled and connected with round waveguides of the cone-shaped window bodies of the left side and the right side of the ceramic window. Rectangular waveguides of the cone-shaped window bodies are connected with flanges, a fire striking detecting device is arranged on the right window body, the rectangular waveguides are gradually transformed to be the round waveguides through the left window body, and the round waveguides are gradually transformed to be the rectangular waveguides through the right cone-shaped window body. The novel high-power microwave vacuum ceramic window has the advantages of being good in microwave performance, high in vacuum tightness, high in safety, high in reliability, not rigorous for machining requirements, capable of achieving one-off vacuum welding and the like, and is suitable for general application of vacuum systems.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

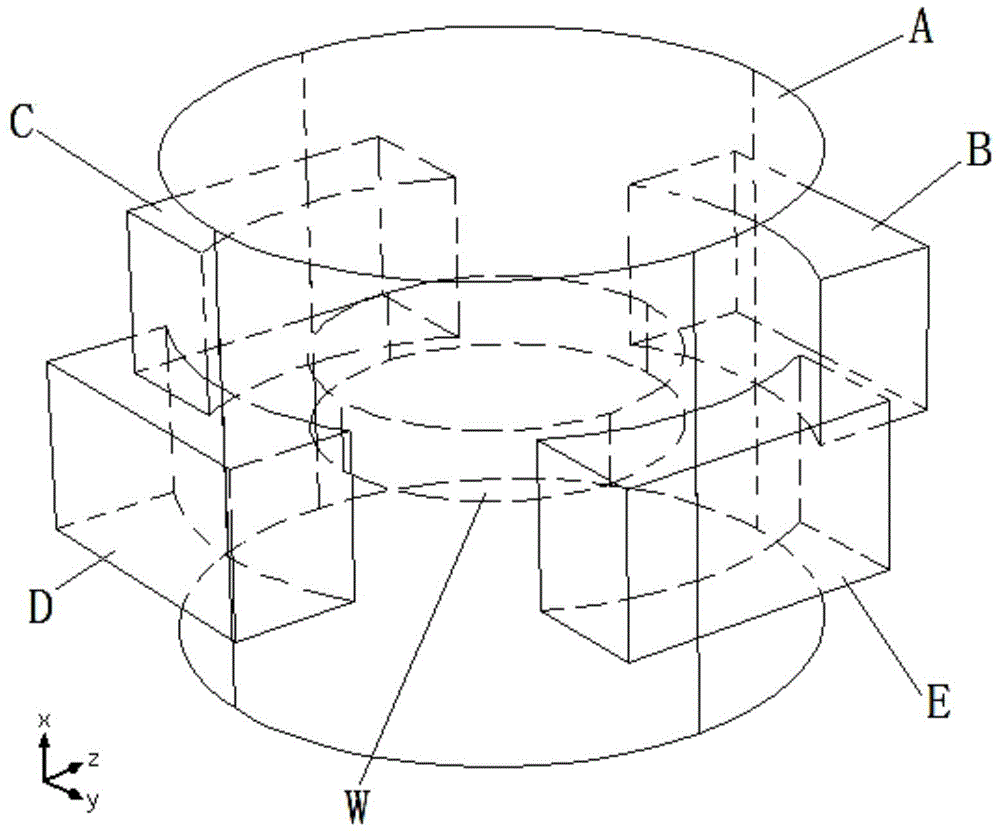

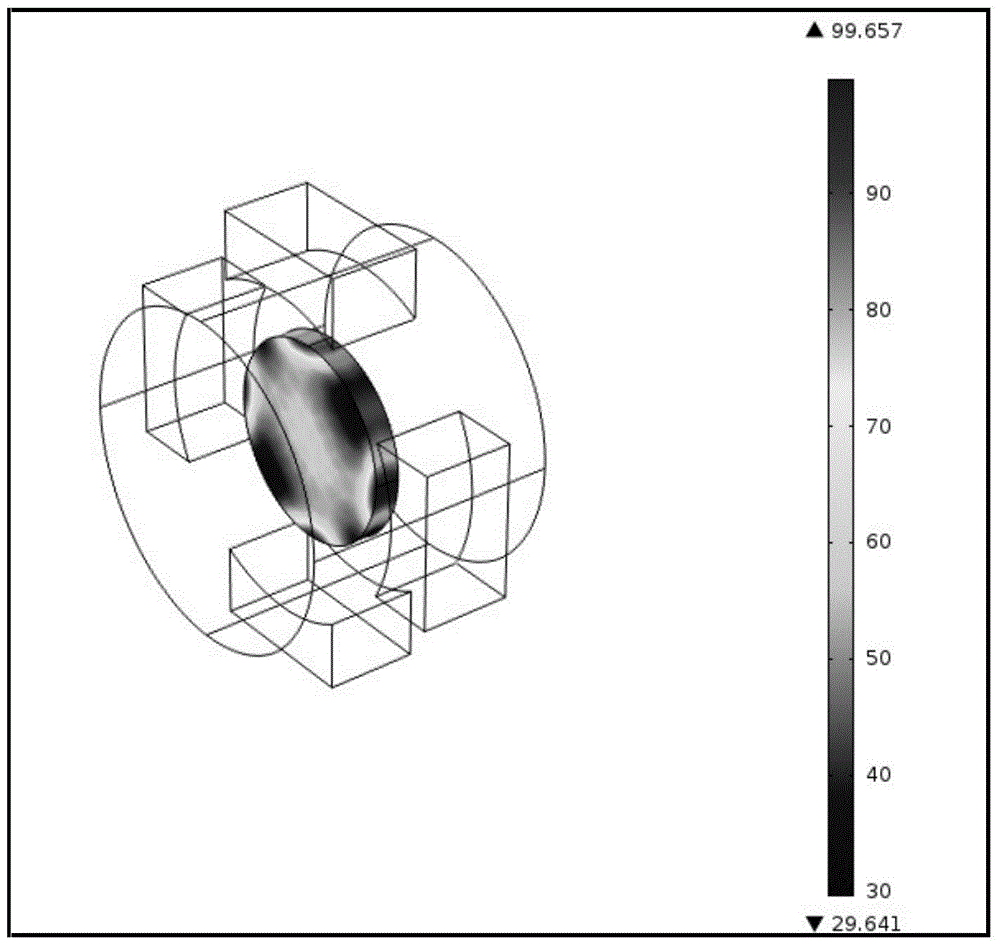

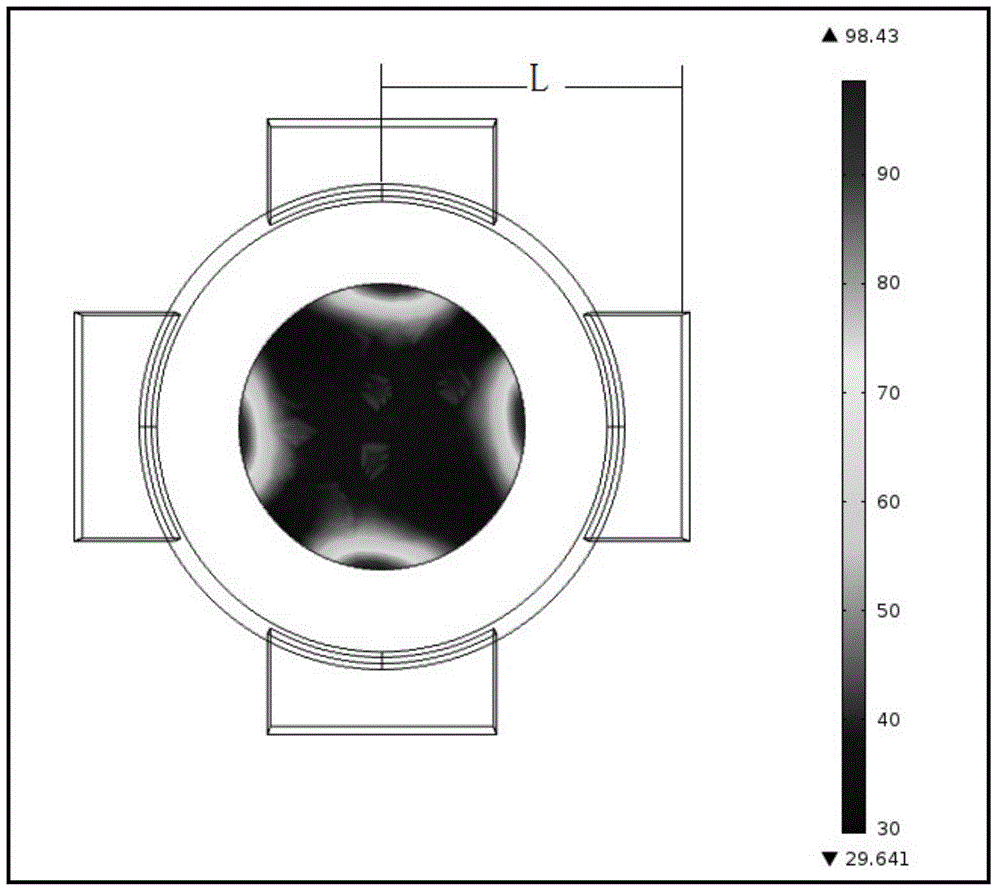

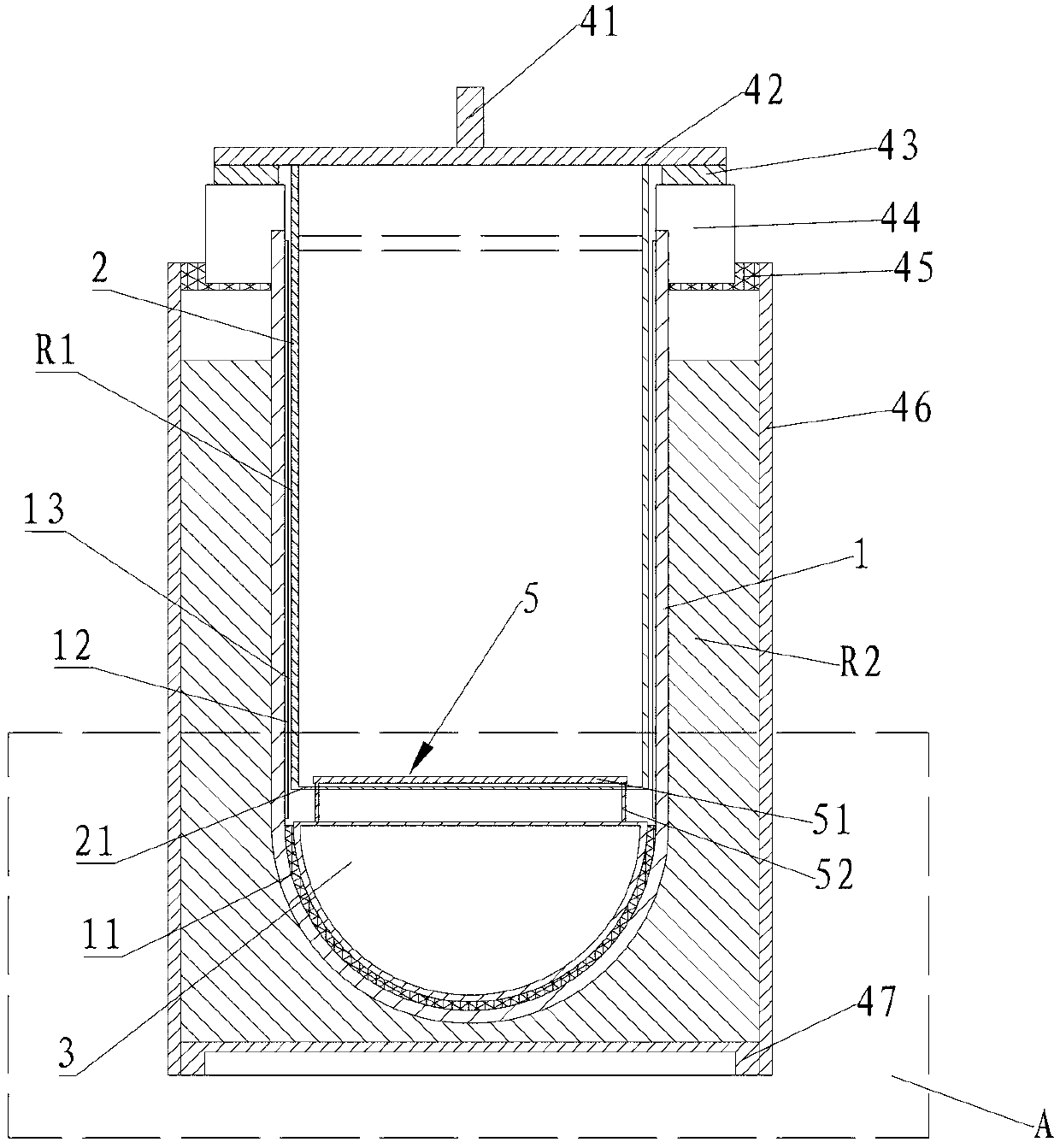

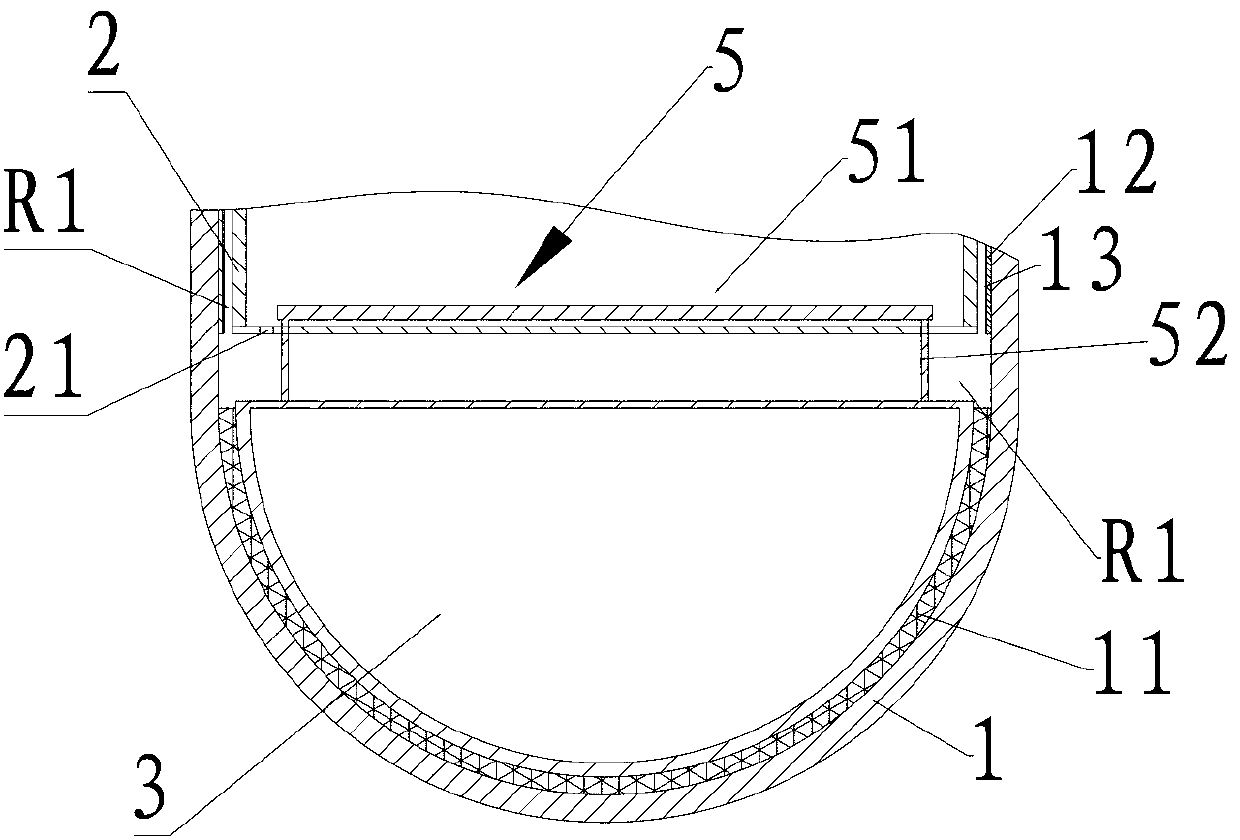

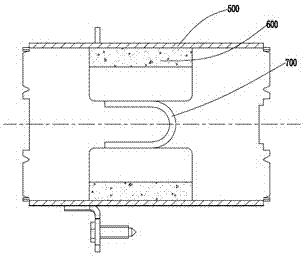

Resonant cavity for verifying wood microwave pretreatment temperature distribution

InactiveCN104797029ABreakage rateReduce the probability of ruptureMicrowave heatingHeating arrangementResonant cavityMicrowave

The invention discloses a resonant cavity for verifying wood microwave pretreatment temperature distribution. The resonant cavity for verifying wood microwave pretreatment temperature distribution comprises a main resonant cavity which is arranged horizontally; at least one fed-in waveguide is arranged on the main resonant cavity in the lateral direction; the main resonant cavity is connected with the fed-in waveguides; the fed-in waveguides are horizontally distributed along the direction from the center of the main resonant cavity to the outside; hollow-out openings are respectively formed in two end surfaces of each fed-in waveguide; the cross section of each fed-in waveguide is rectangular; the length direction of the rectangular cross section of each fed-in waveguide is a horizontal direction; the width direction of the rectangular cross section of each fed-in waveguide is a vertical direction; and the distance from the hollow-out opening of one end, which is far away from the center of the main resonant cavity, of each fed-in waveguide to the center of the main resonant cavity is 1.1 times greater than the length of the rectangular cross section of the fed-in waveguide. The resonant cavity for verifying wood microwave pretreatment temperature distribution has the advantages that wood microwave energy utilization rate is high, microwave energy is dispersed uniformly, temperature distribution uniformity is high, and wood breaking rate is low.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Glass for information recording media substrate, glass substrate for magnetic disk and magnetic disk

InactiveCN101417861ANot easy to peel offInhibited DiffusionWeather resistanceCondensed matter physics

To provide a glass for an information recording media substrate, which is excellent in weather resistance. A glass for an information recording media substrate, which comprises, as represented by mol % based on oxide, from 61 to 66% of SiO2, from 11.5 to 17% of Al2O3, from 8 to 16% of Li2O, from 2 to 8% of Na2O, from 2.5 to 8% of K2O, from 0 to 6% of MgO, from 0 to 4% of TiO2 and from 0 to 3% of ZrO2, provided that Al2O3+MgO+TiO2 is at least 12%, and Li2O+Na2O+K2O is from 16 to 23%, wherein in a case of where B2O3 is contained, its content is less than 1%. The above glass for an information recording media substrate, wherein when the glass is left under steam atmosphere at 120 DEG C. at 0.2 MPa for 20 hours, and the amount of Li, the amount of Na and the amount of K, which precipitate on a surface of the glass are represented as CLi, CNa and CK respectively, CNa is at most 0.7 nmol / cm2, and CLi+CNa+CK is at most 3.5 nmol / cm2.

Owner:ASAHI GLASS CO LTD

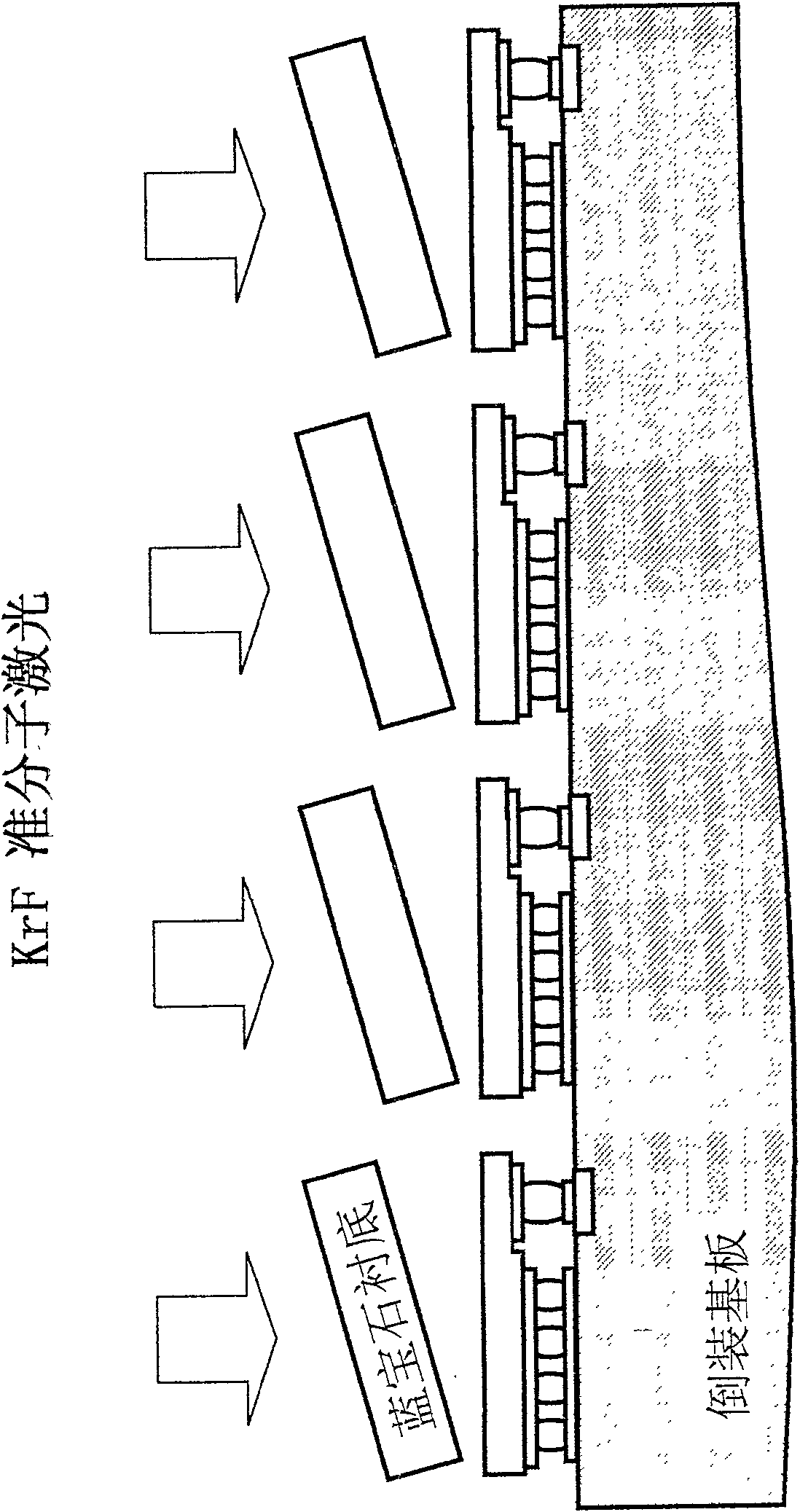

Film LED (light-emitting diode) chip device as well as manufacturing method and application thereof

ActiveCN102683517AReduce the probability of ruptureReduce the chance of deformationSemiconductor devicesFilm baseReflective layer

The invention provides a film LED (light-emitting diode) chip device, comprising a GaN-based epitaxial film base which is provided with an etching groove, and a fixed film which is coated on a GaN-based epitaxial film, wherein a metal reflection layer is attached to the surface of the P-shaped semiconductor layer of the GaN-based epitaxial film base, passive films are deposited on the metal reflection layer and the GaN-based epitaxial film base to form the GaN-based epitaxial film, the passive film on the surface of the metal reflection layer and the passive film on the bottom surface of the etching groove are respectively provided with a hollowed-out area, a P pole multilayer metal bonding layer and a N pole multilayer metal bonding layer are respectively arranged on the corresponding hollowed-out area, and a P pole conductive support thick metal layer and an N pole conductive support thick metal layer are respectively arranged on the P pole multilayer metal bonding layer and the N pole multilayer metal bonding layer. The invention also provides a manufacturing method and application of the film LED chip device. According to the invention, the occurrence rate of wafer fracture and the probability of wafer deformation in the subsequent laser stripping process are reduced, and the yield of products is improved.

Owner:ELEC TECH PHOTOELECTRIC TECH DALIAN

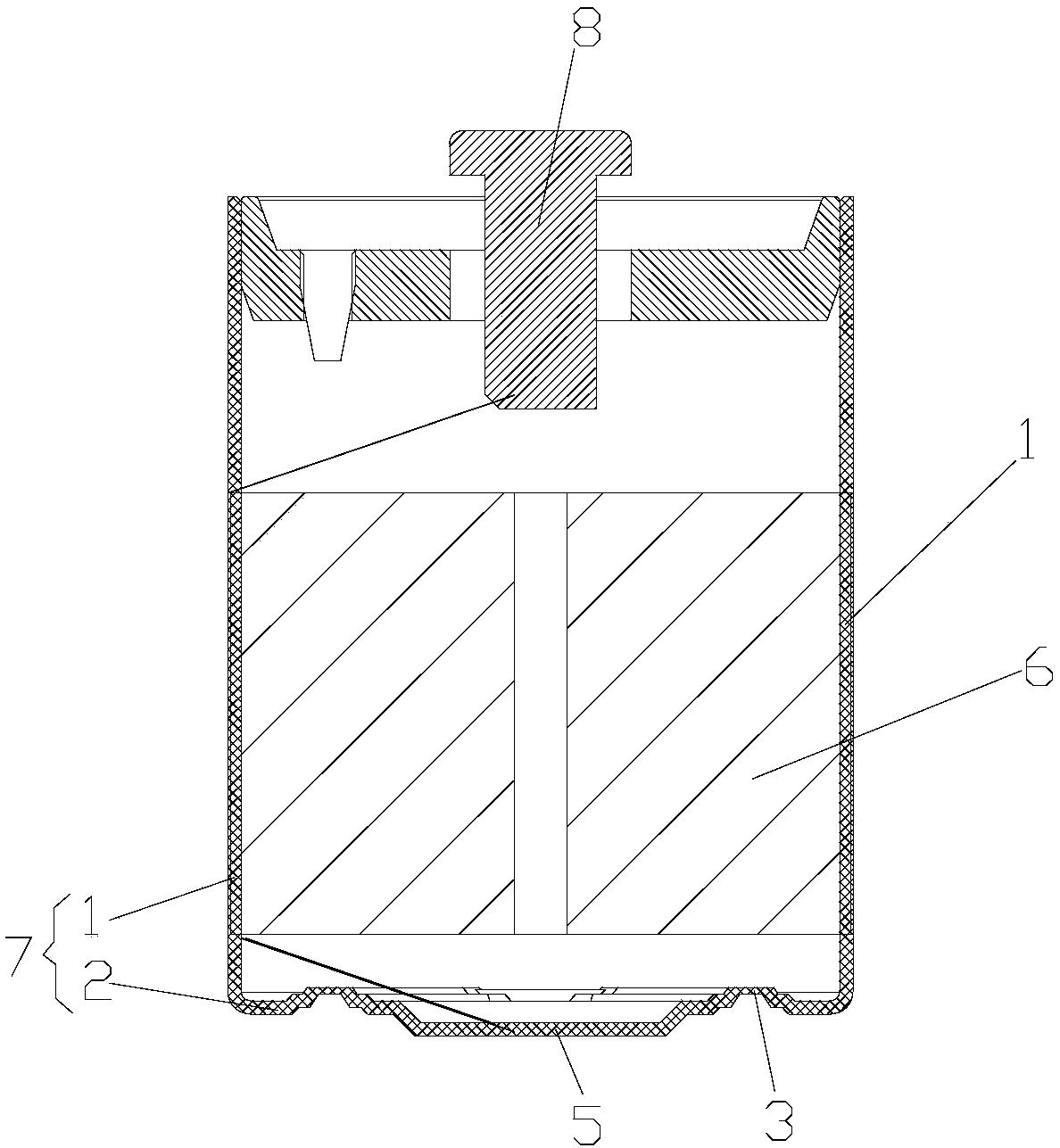

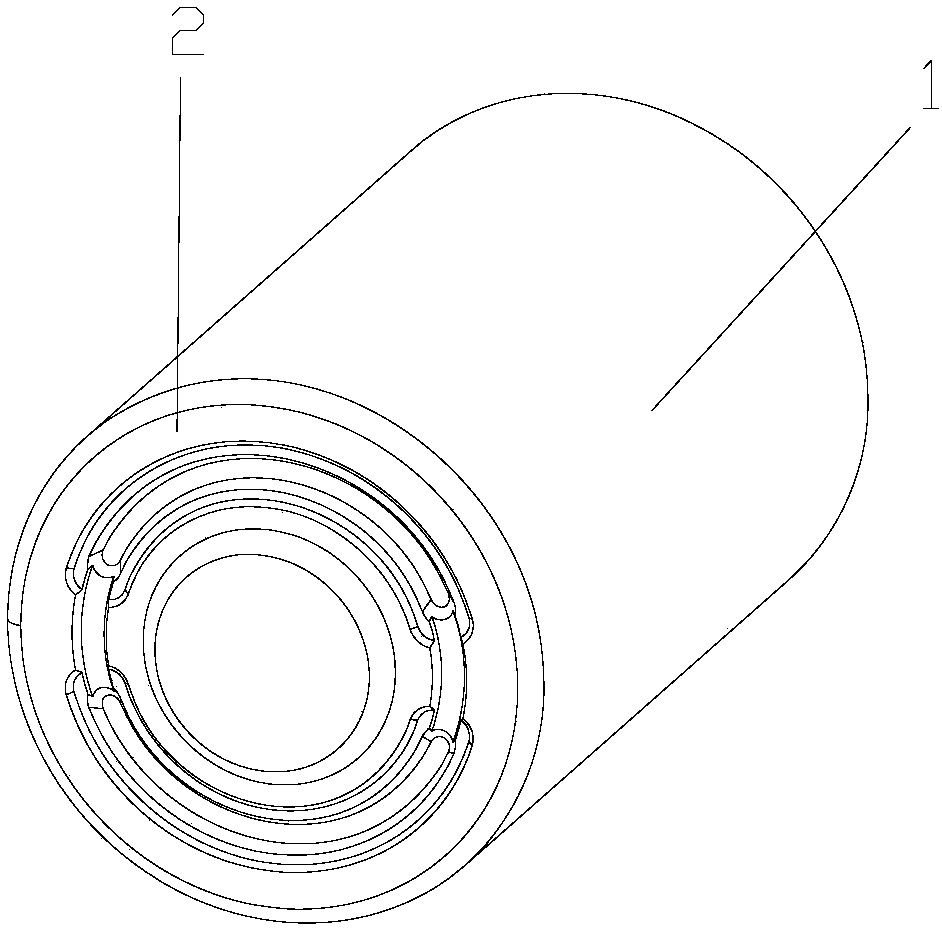

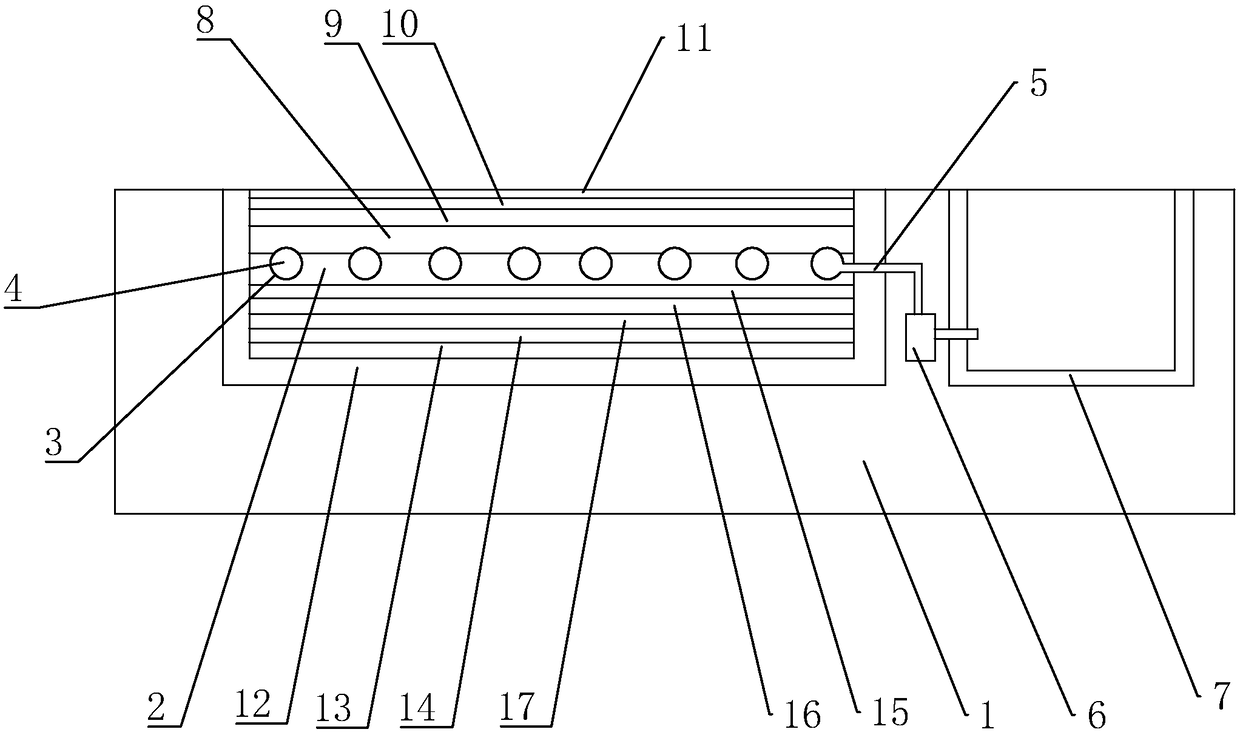

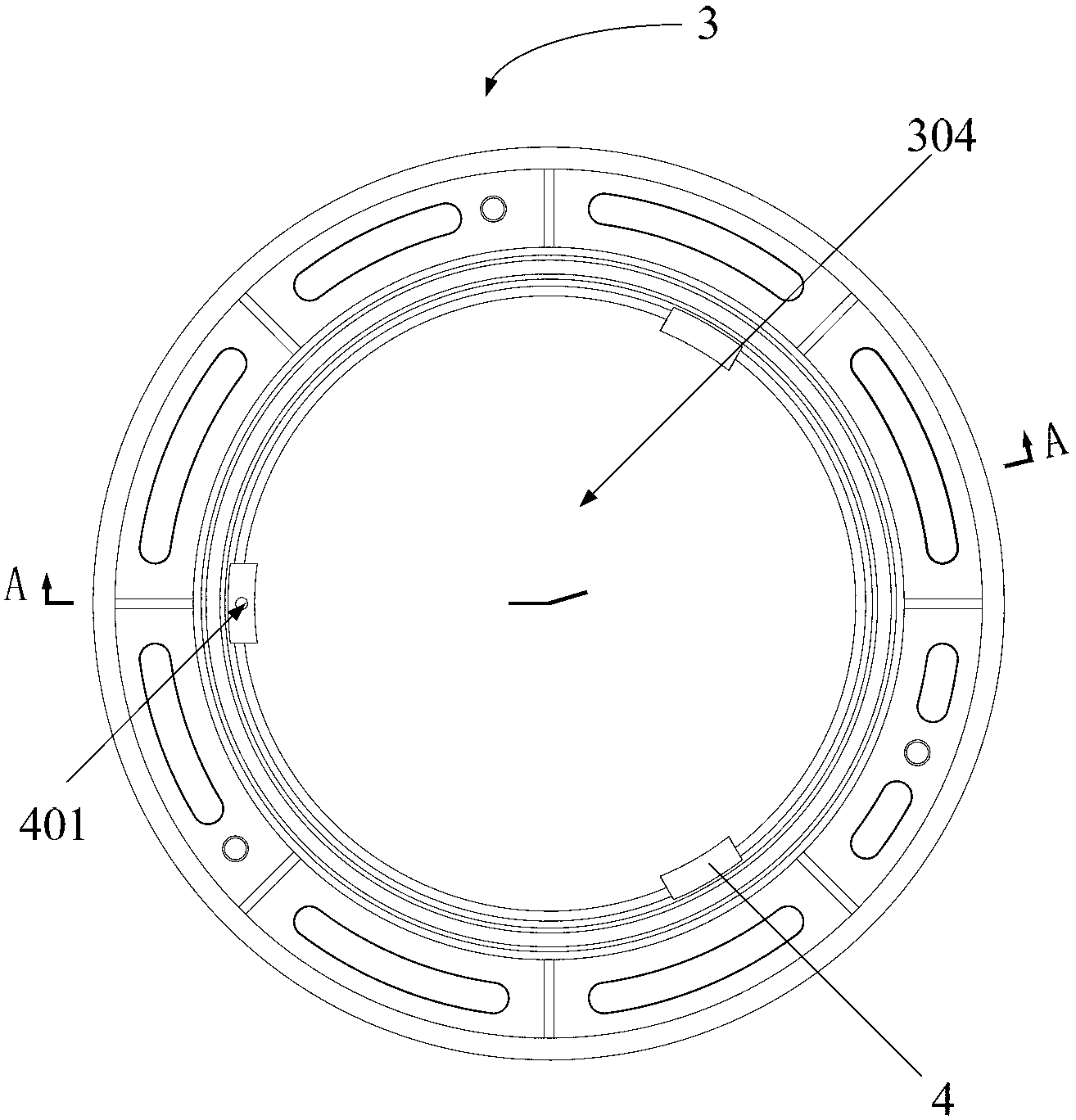

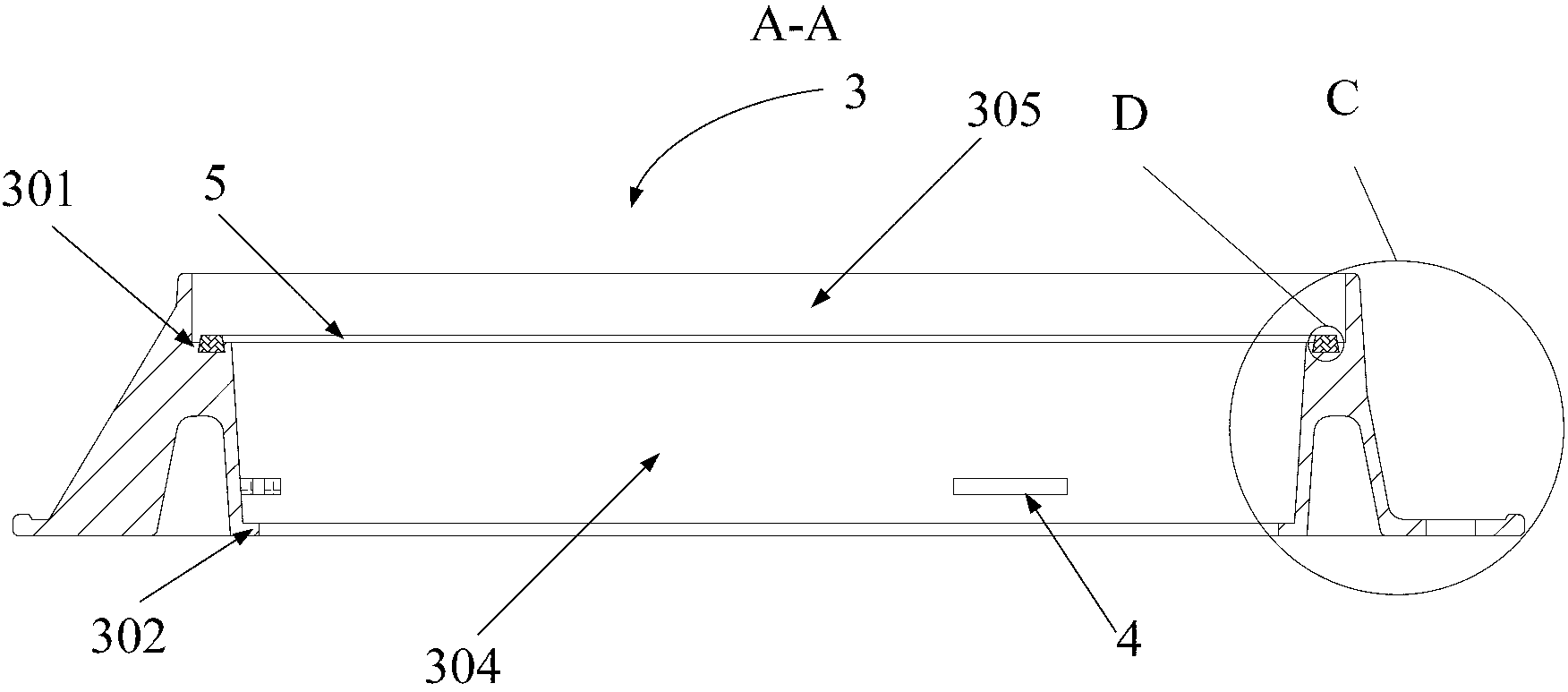

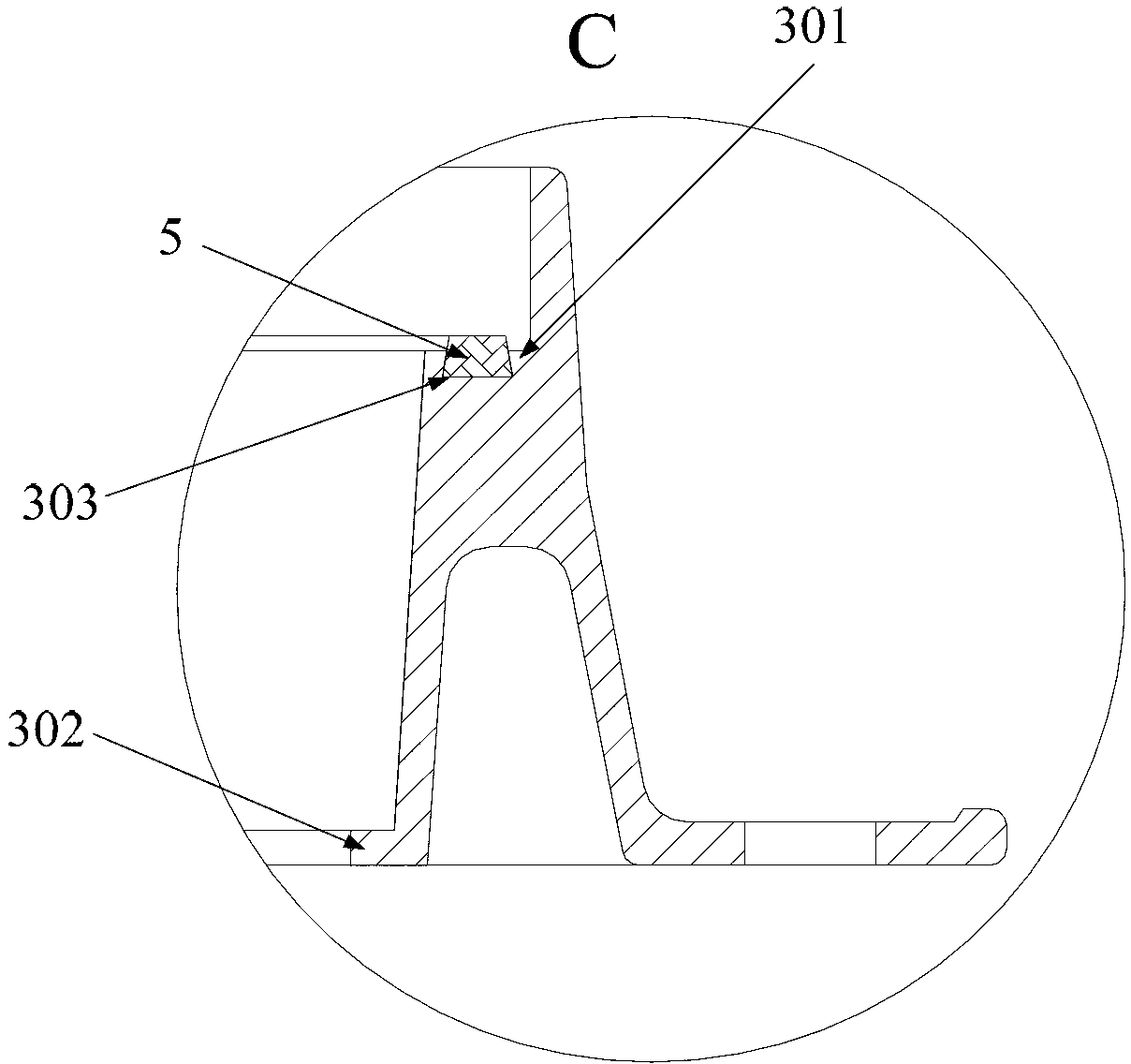

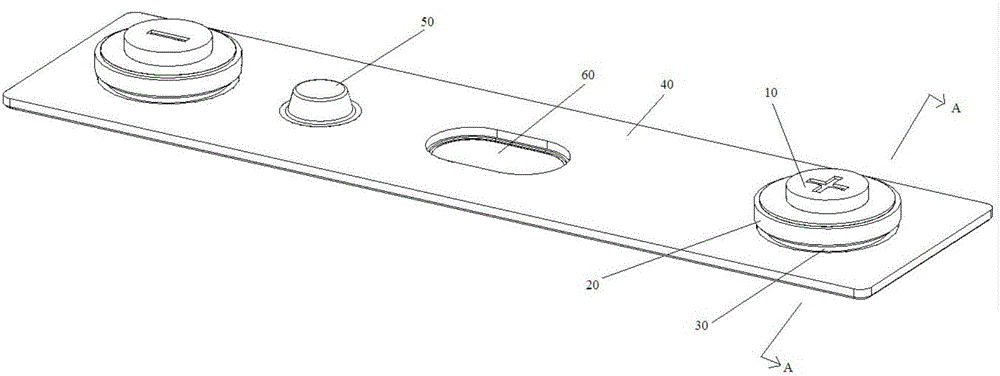

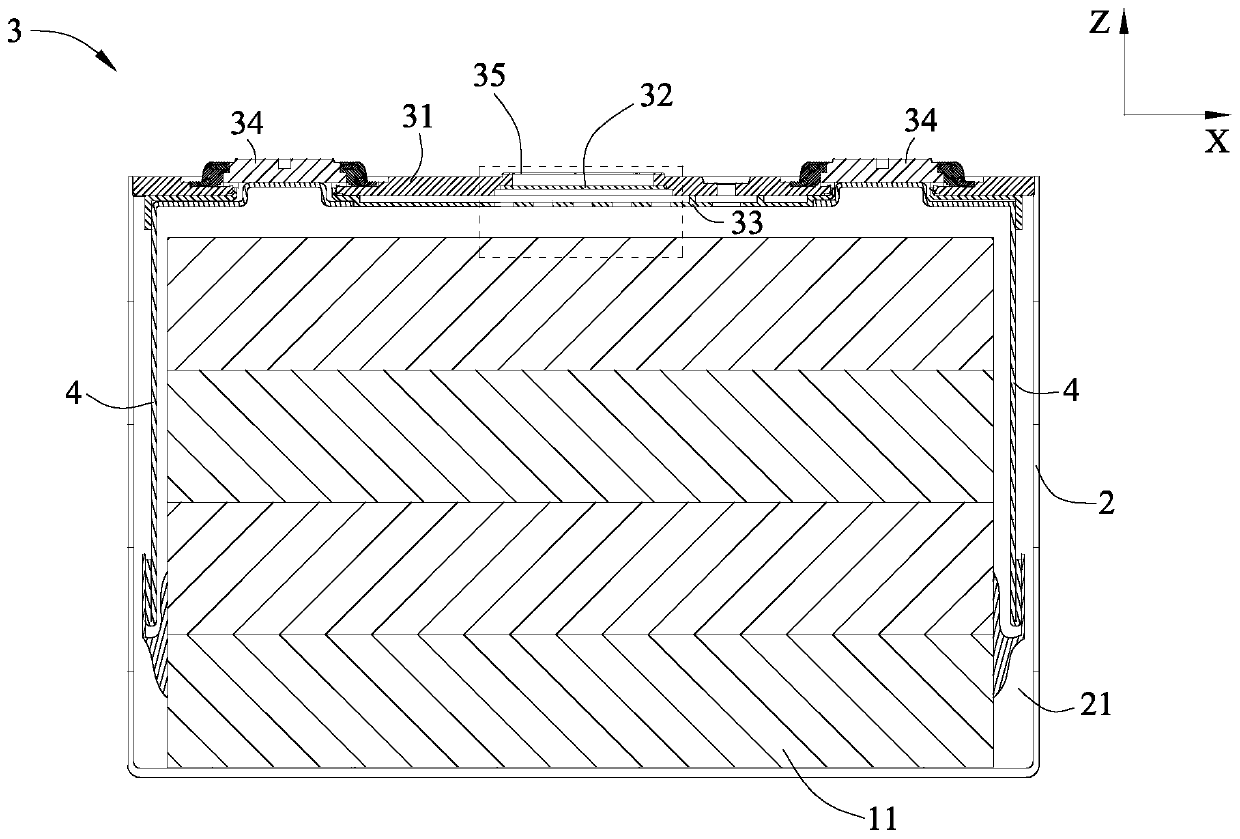

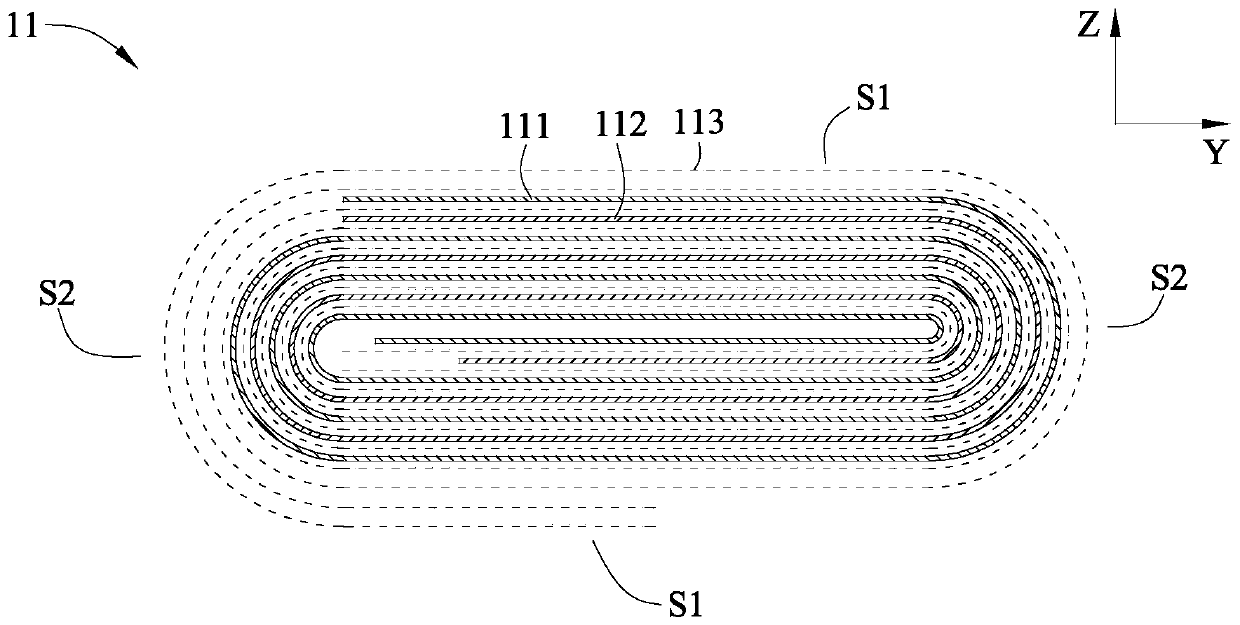

Lithium ion battery and case thereof

PendingCN108565492AEasy to processReduce the probability of ruptureFinal product manufactureSmall-sized cells cases/jacketsAtmospheric pressureLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and relates to a lithium ion battery and a case thereof. The lithium ion battery comprises the case, an upper cover and a roll core, wherein the upper cover covers the case; the roller core is positioned inside the case; a positive electrode of the roll core is connected with an electrode post through a guide foil strip; the electrode post is positioned in the center of the upper cover and is used for guiding out the positive electrode of the lithium ion battery; the case comprises a cylindrical case body and a case bottompositioned at the bottom of the cylindrical case body; a negative electrode of the roll core is connected with a center lug boss through a guide foil strip; the center lug boss is positioned in the center of the case bottom and is used for guiding out a negative electrode of the lithium ion battery; one section or a plurality of sections of arc-shaped safety valves are arranged on the base; the arc-shaped safety valve is an arc-shaped groove with the gradually reduced thickness in the circumference direction; the radius of the arc-shaped groove is 1 / 2 to 3 / 4 of the radius of the case bottom. Through the arrangement of the arc-shaped safety valve with the gradually reduced thickness on the case base, product service life reduction caused by occurrence of advanced opening of the safety valvecan be effectively avoided; meanwhile, the potential safety hazards caused when the safety valve is not opened at too high inside air pressure in the lithium ion battery can be avoided.

Owner:无锡凯帕德瑞科技有限公司

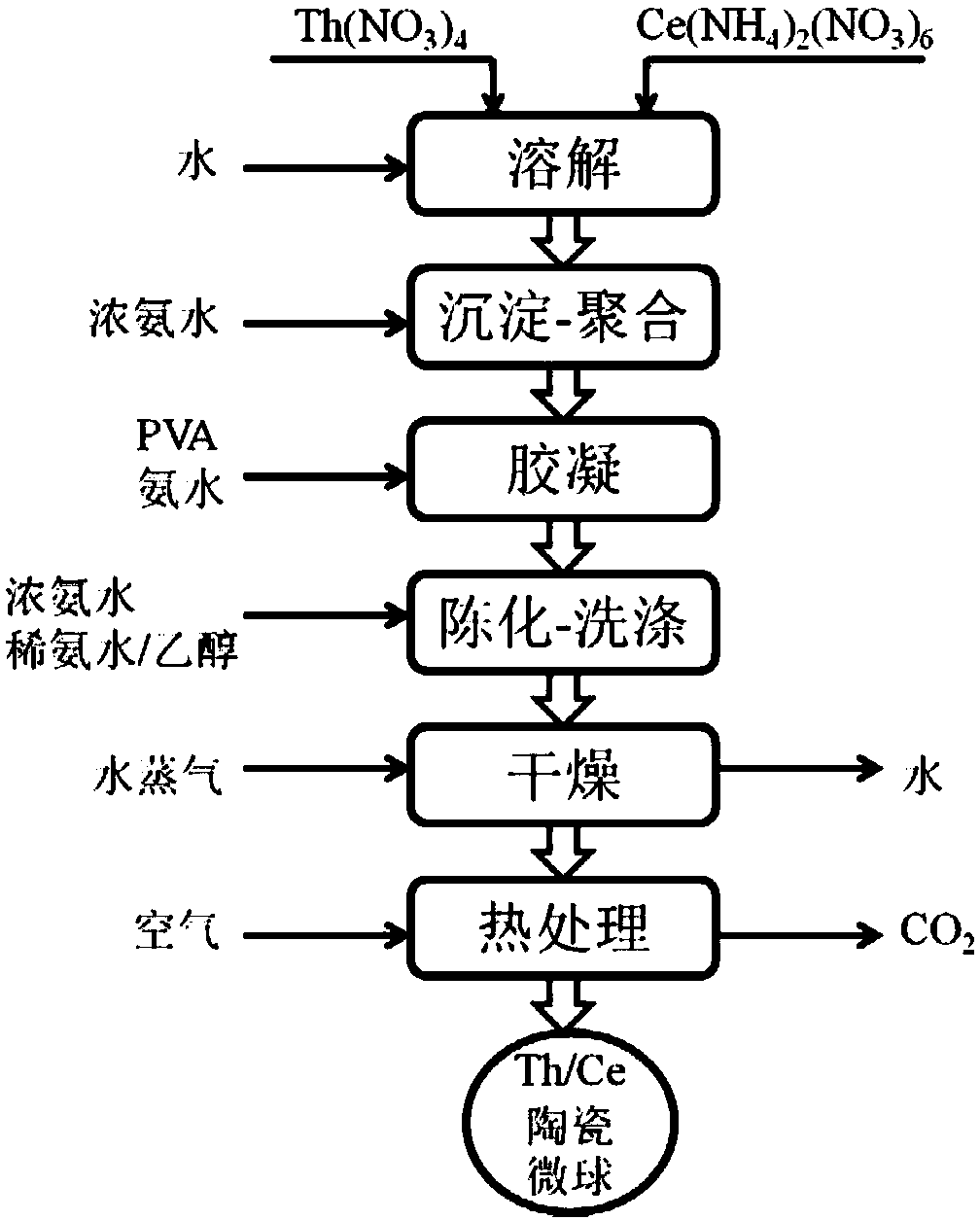

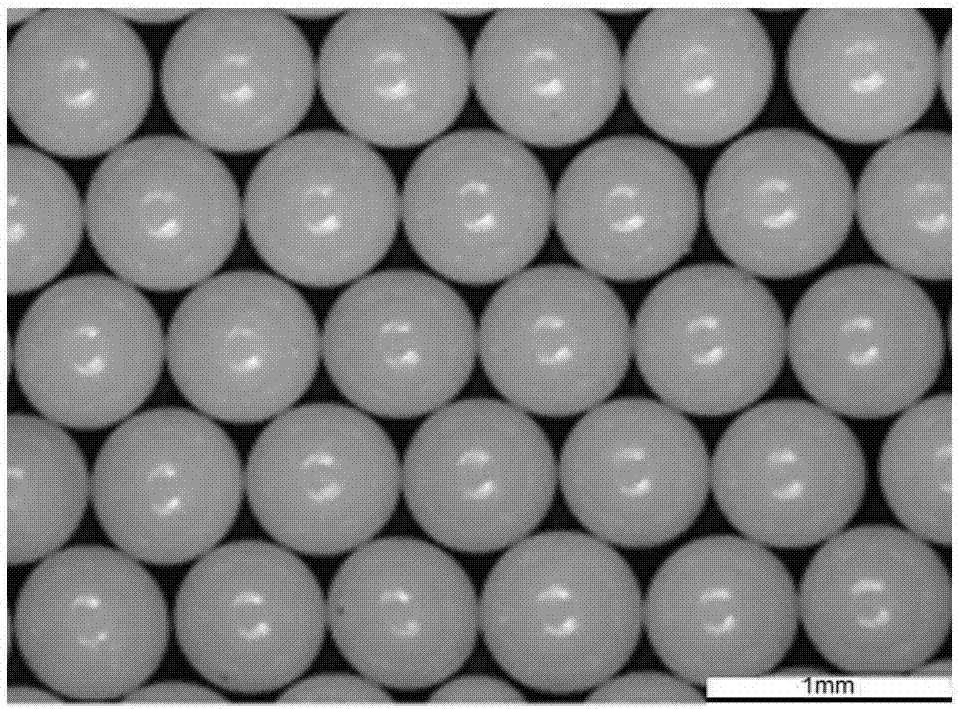

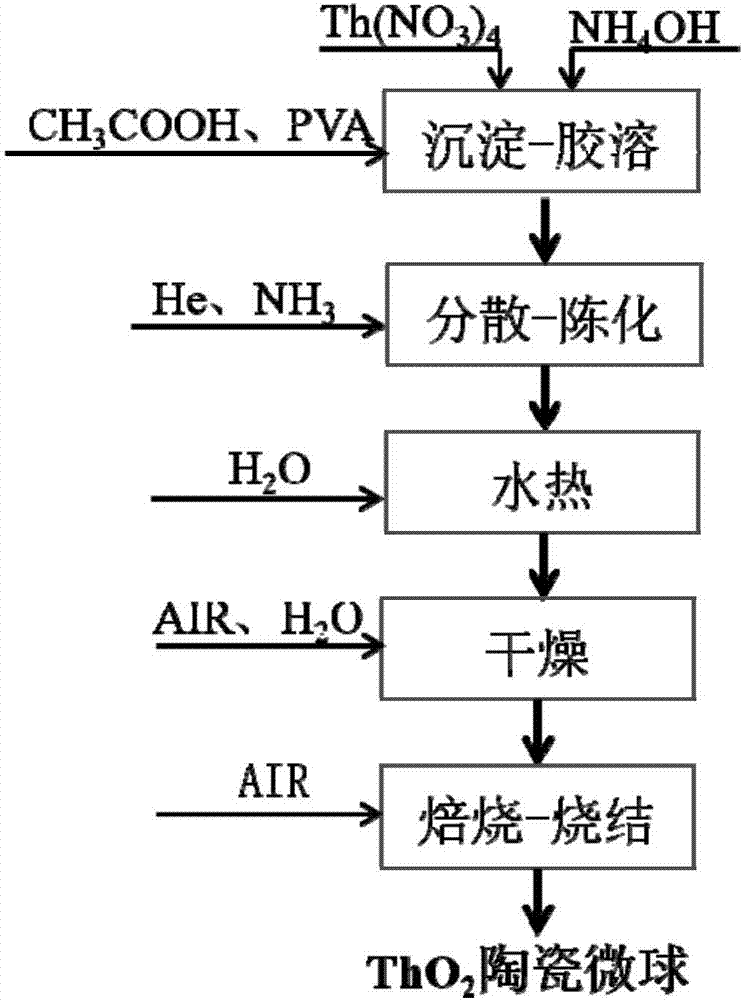

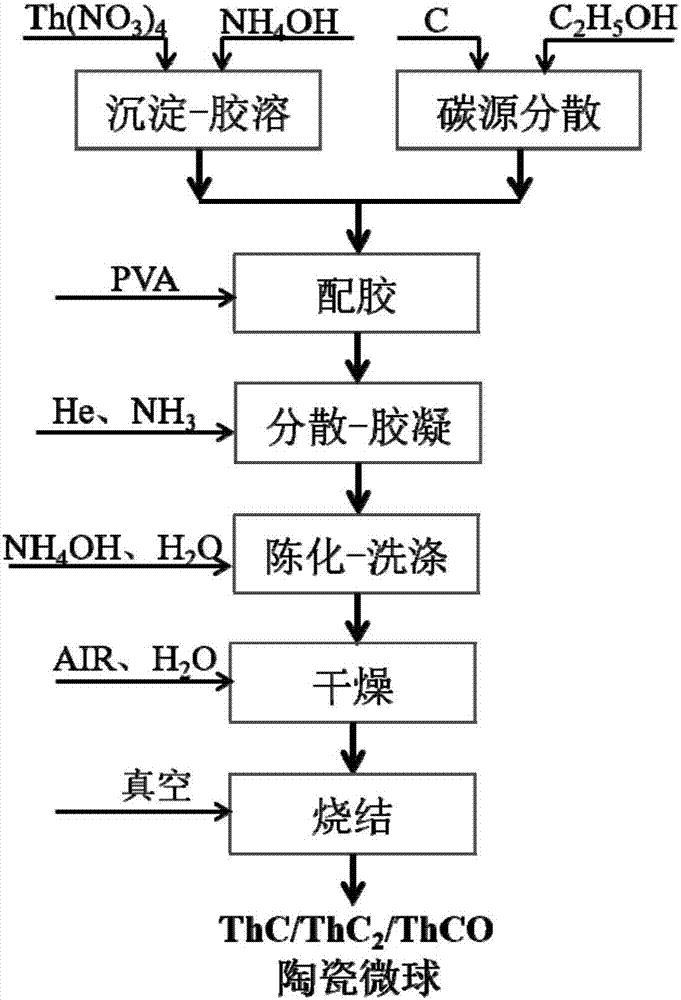

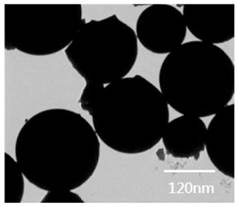

Preparation method of thorium-based mixed oxide ceramic microsphere

ActiveCN107833645AGuaranteed mechanical strengthAvoid deformationNuclear energy generationReactors manufactureAir atmospherePolyvinyl alcohol

The invention relates to a preparation method of a thorium-based mixed oxide ceramic microsphere. The preparation method comprises the following steps of under the conditions of heating and stirring,adding cerous ammonium nitrate or uranyl nitrate and plutonium nitrate solid into a thorium nitrate solution to form a mixed solution, using ammonium hydroxide to adjust the pH (potential of hydrogen)value to form a hydrolysis solution, adding a thickener (polyvinyl alcohol solution) into the hydrolysis solution, and stirring, so as to form a thorium-based mixed sol solution; enabling an exciterto disperse the thorium-based mixed sol solution into liquid droplets, sequentially sending into an air section and an ammonia gas section, and finally sending into the ammonium hydroxide to form a gel microsphere; heating and aging the gel microsphere in concentrated ammonium hydroxide, alternatively washing by ethyl alcohol and thin ammonium hydroxide, washing by deionized water, flatly paving the single layer of washed gel microspheres in a drying furnace, and leading water vapor to heat and dry, so as to obtain the dried gel microsphere; placing the gel microsphere into a sintering furnace, and heating and sintering in an air atmosphere, so as to obtain the mixed oxide ceramic microsphere. The preparation method has the advantage that the fuel with uniform distribution of elements canbe prepared.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Sodium-sulfur battery

ActiveCN103123988AReduce manufacturing costReduce the probability of ruptureSecondary cellsFiberSulfur

The invention discloses a sodium-sulfur battery in the field of energy storage. The sodium-sulfur battery comprises a ceramic electrolyte tube and a sodium storage tube which is sleeved inside the ceramic electrolyte tube, wherein the bottom surface of the sodium storage tube is provided with at least one through hole, a cathode chamber of the sodium-sulfur battery is formed between the sodium storage tube and the ceramic electrolyte tube, the bottom surface of the sodium storage tube is flat, a sodium storage tube hemispherical body is arranged right below the sodium storage tube, a gap is reserved between the sodium storage tube and the sodium storage tube hemispherical body, a fiber buffer layer is arranged between the bottom surfaces of the sodium storage tube hemispherical body and the inner wall of the ceramic electrolyte tube, and the fiber buffer layer is free from wetting liquid sodium. The sodium-sulfur battery has beneficial effects that under the situation that the through hole in the bottom surface of the sodium storage tube can be effectively sealed, the requirement on the dimensional precision of the ceramic electrolyte tube can be lowered, and the manufacturing cost of the sodium-sulfur battery can be reduced.

Owner:上海电气企业发展有限公司

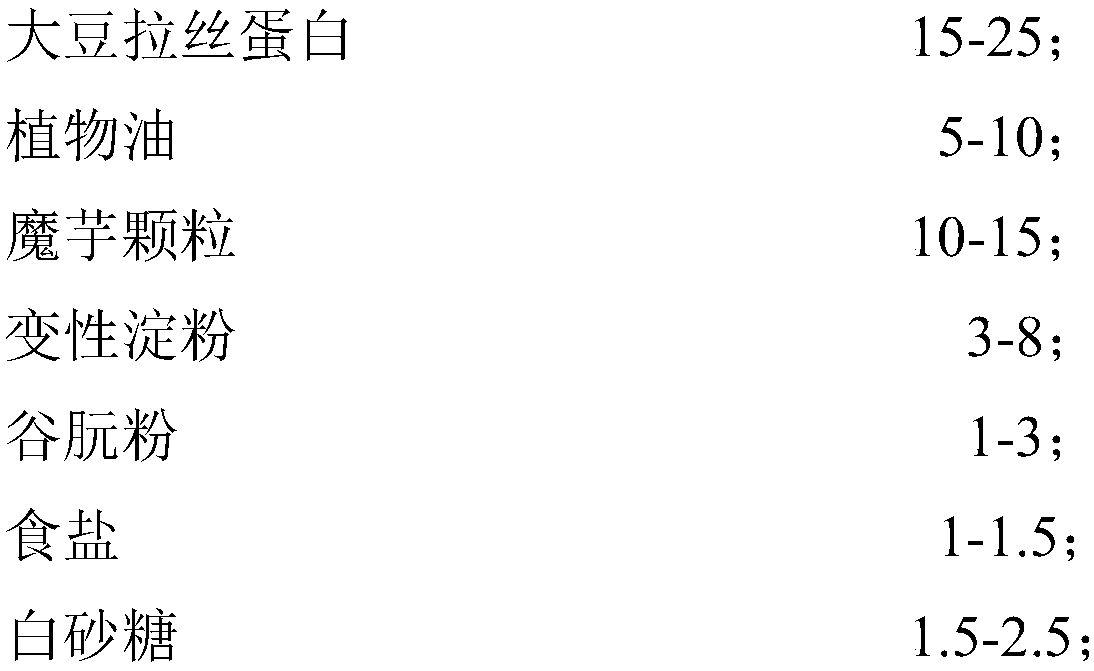

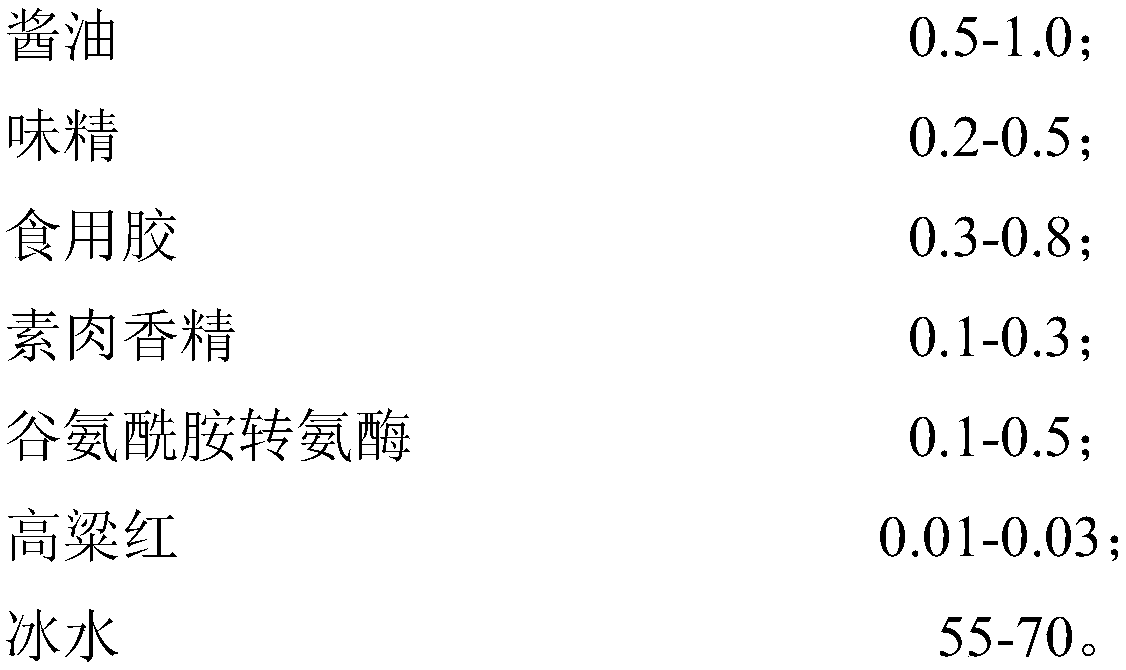

Soybean filament drawing protein vegetarian ham and preparation method thereof

The invention belongs to the fields of foods and food processing and particularly relates to a soybean filament drawing protein vegetarian ham and a preparation method thereof. The soybean filament drawing protein vegetarian ham is prepared from soybean filament drawing proteins, vegetable oil, konjak particles, modified starch, vital gluten, table salt, white granulated sugar, soy sauce, edible gum, a vegetarian meat essence, glutamine transaminase, a sorghum pigment and ice water through the processes of preparation of the konjak particles, pretreatment of the soybean filament drawing proteins, the raw material mixing and stirring, sausage filling and formation, hot air drying, stewing, freezing and the like. The raw material formula and production process of the soybean filament drawingprotein vegetarian ham are improved and optimized, the soybean filament drawing proteins are preprocessed in the earlier period, and the later-period stirring process is regulated and controlled, sothat the processed vegetarian ham has fine taste, good elasticity, tenacity and chewing feeling and does not have beany flavor, and a section is silky.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND

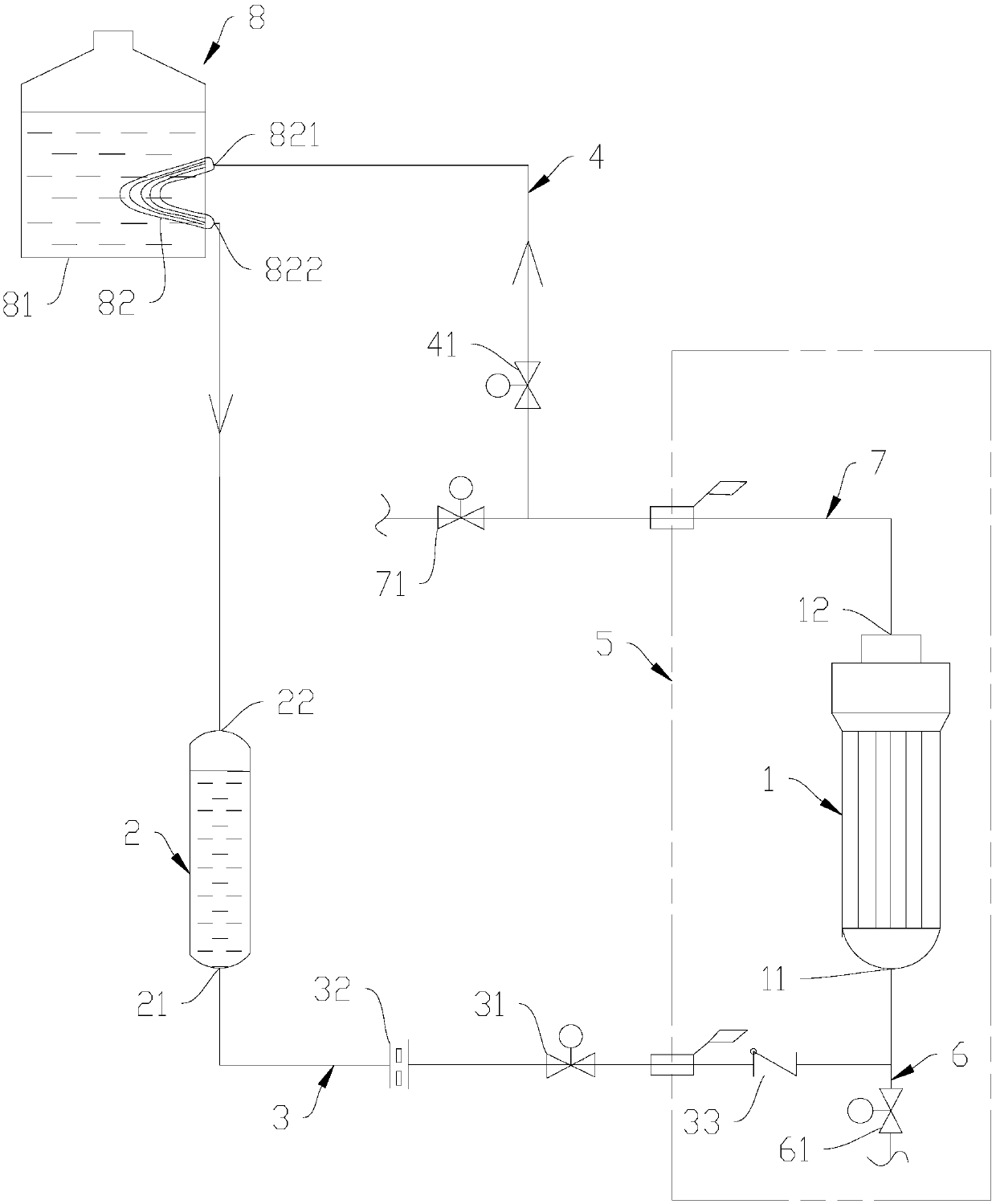

Marine reactor and once-through steam generator secondary side passive residual heat removal system

ActiveCN107644693ADischarge long termMeet the needs of waste heat removalNuclear energy generationCooling arrangementNuclear engineeringSecondary side

The invention relates to a marine reactor and once-through steam generator secondary side passive residual heat removal system, comprising: an once-through steam generator arranged in a containment and provided with a first inlet and a first outlet; a water supplement box that stores a coolant and is arranged outside the containment, wherein the water supplement box is provided with a second outlet and a second inlet, and the second outlet is positioned below the liquid level in the water supplement box; an incoming pipe connected between the first inlet and the second outlet; an outgoing pipeconnected between the first outlet and the second inlet. The liquid level in the water supplement box is higher than the first inlet, the coolant in the water supplement box is allowed to flow into the once-through steam generator via the second outlet and the first inlet, the once-through steam generator adsorbs atomized steam that flows out of the first outlet, condensate flows into the water supplement box via the second inlet. The system of the invention employs the passive residual heat removal technique, and the removal of residual waste when the reactor loses a normal heat removal pathis ensured; the water supplement box is communicated with the once-through steam generator, so that automatic water supplementing is achieved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

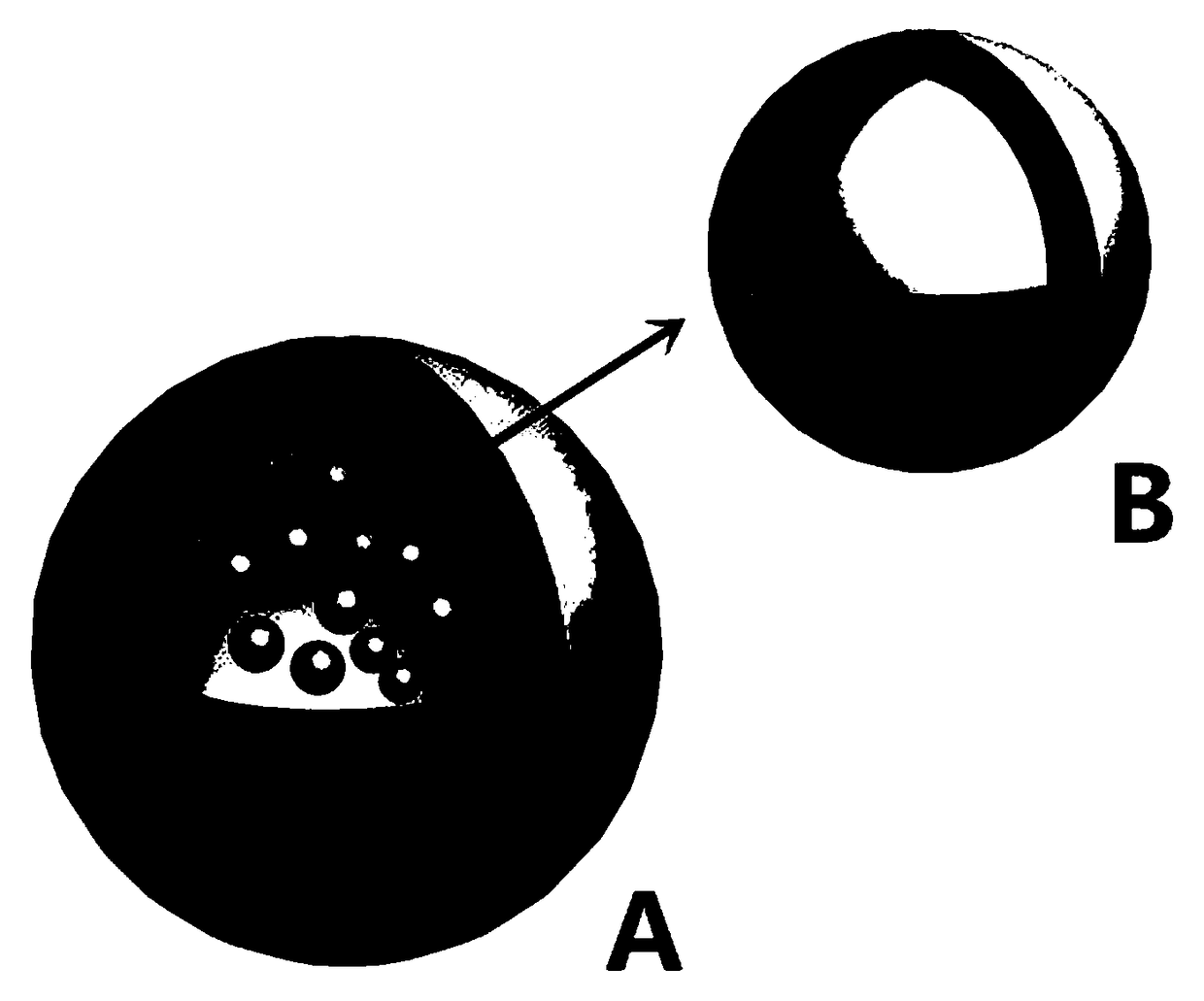

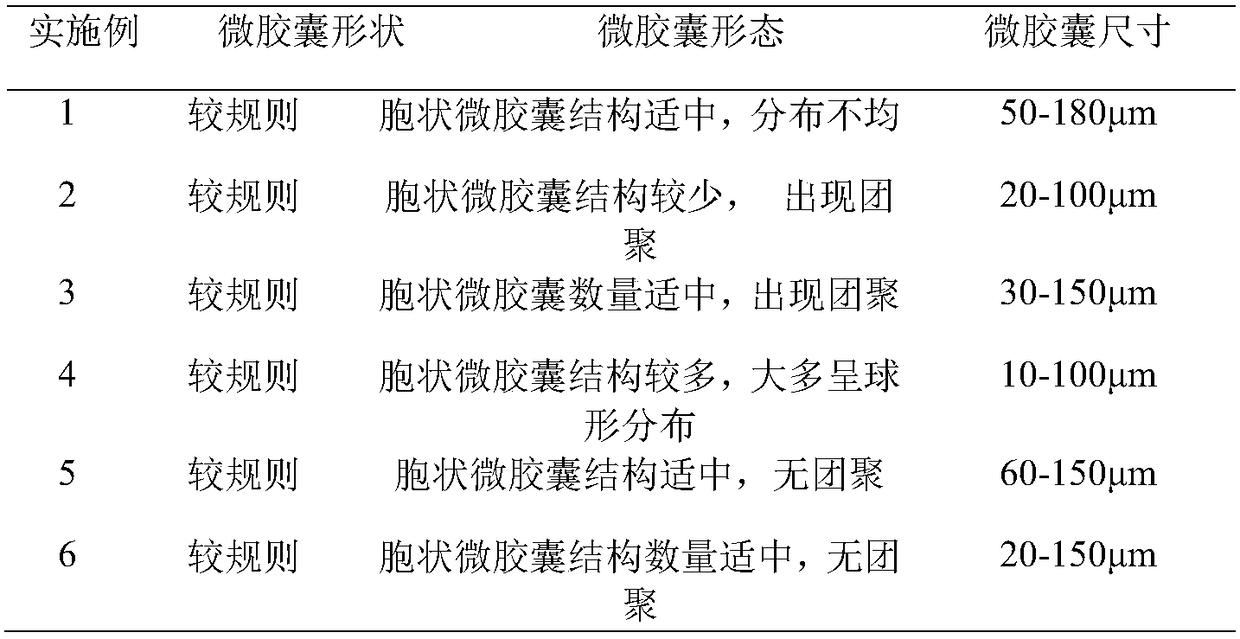

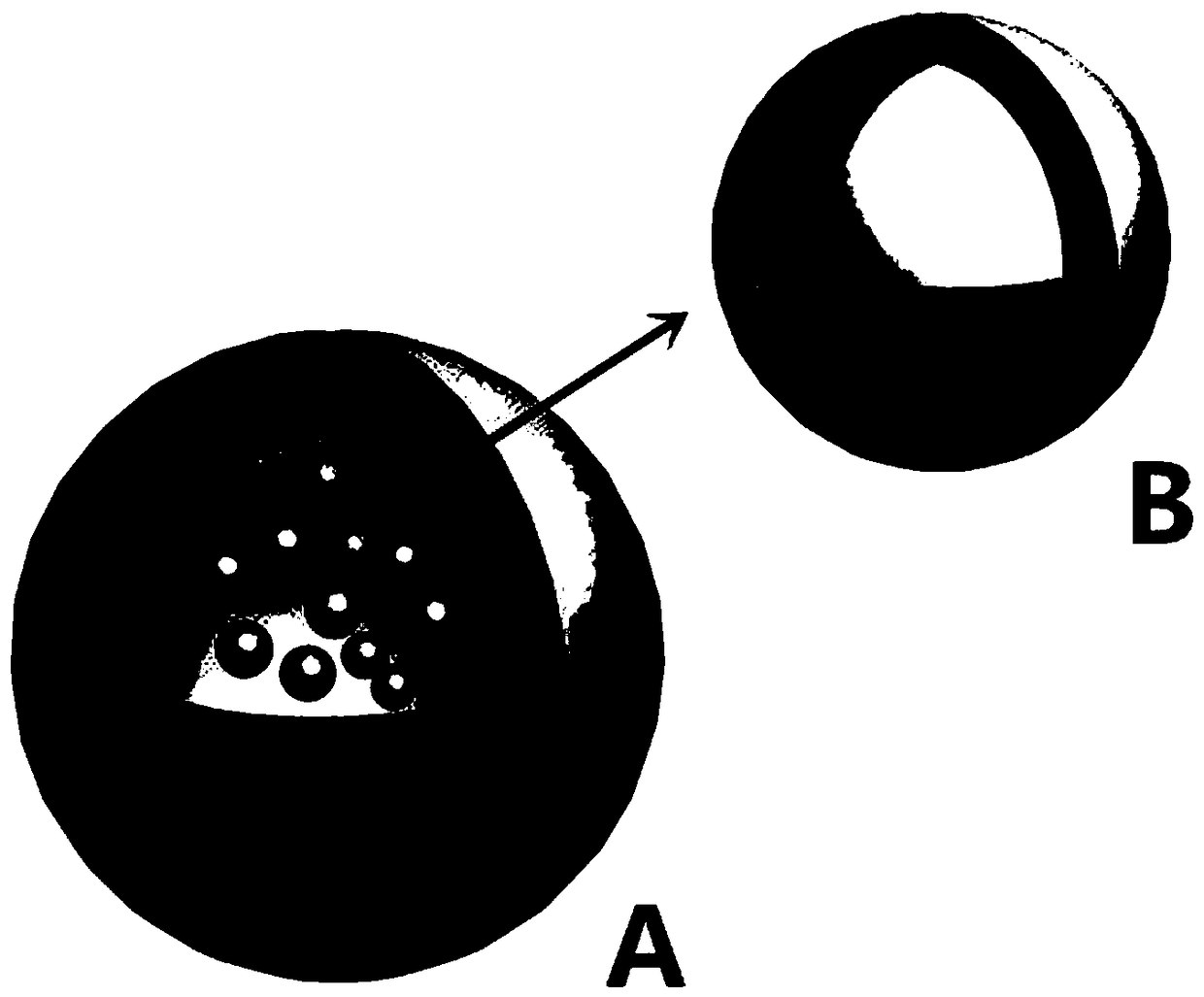

Graphene functional self-repairing microcapsule with a cellular structure and a preparation method thereof

The invention provides a graphene functional self-repairing microcapsule with a cellular structure and a preparation method thereof, aiming at the problems in a self-repairing system in the prior art,The internal repairing and external fixing graphene functional self-repairing microcapsule with the cellular structure consists of a capsule wall and a curing agent with which the capsule wall is covered, wherein graphene is dispersed in the capsule wall; a series of microcapsules of a micro-nano scale are dispersed in the curing agent to form a cellular structure; the insides of the microcapsules of the micro-nano scale are covered with a repairing agent. The self-repairing microcapsule system has a multi-core coating structure of a micro-nano scale, thereby improving the stability of the microcapsules, increasing the probability of contact between the repairing agent and the curing agent at the same time, and improving the repairing efficiency. In addition, the capsule wall of the self-repairing microcapsule system is modified by silane, an unhydrolyzed silane emulsion left after rupture of the microcapsules can form a hydrophobic film inside concrete capillary holes to prevent further diffusion of moisture, and the hydrolyzed silane emulsion can also participate in the synthesis of a wall material to improve the performance of the microcapsules.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

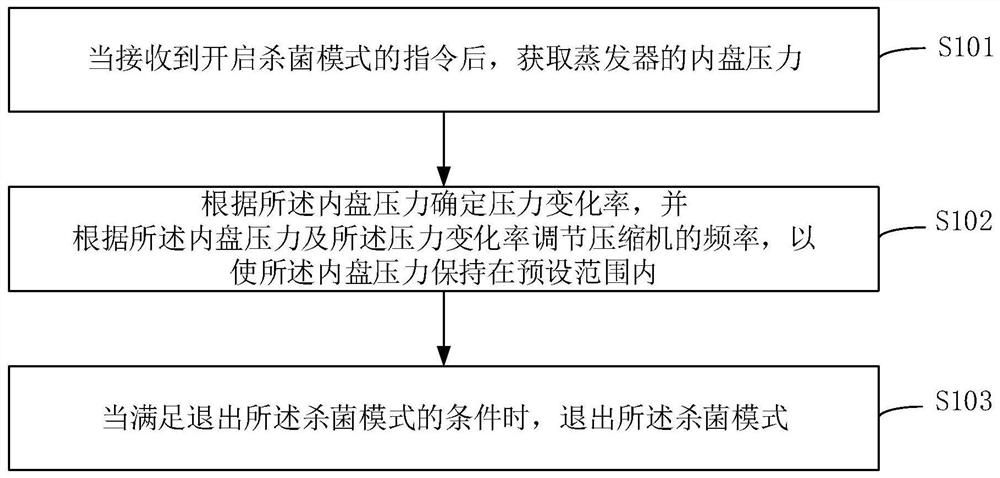

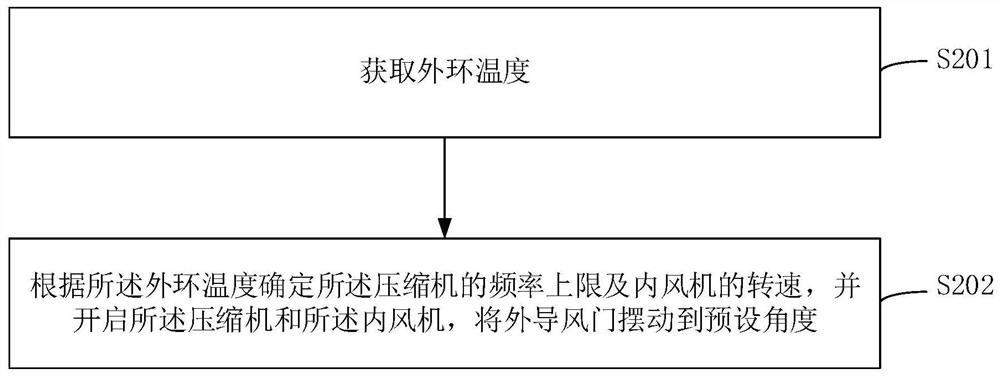

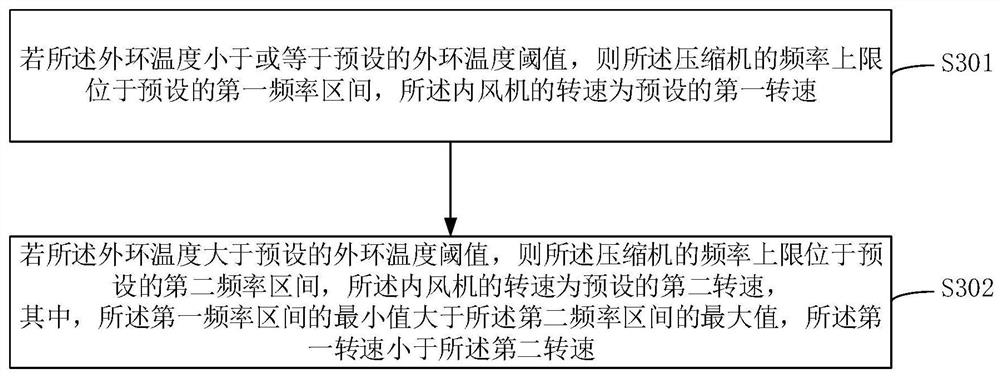

Air conditioner high-temperature sterilization control method and device, storage medium and air conditioner

ActiveCN111692701AReduce the probability of ruptureMonitor pressureMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsEngineering

The invention provides an air conditioner high-temperature sterilization control method and device, a storage medium and an air conditioner, and relates to the technical field of air conditioners. Themethod comprises the steps that after an instruction for starting a sterilization mode is received, inner disc pressure of an evaporator is obtained; pressure change rate is determined according to the inner disc pressure, and compressor frequency is adjusted according to the inner disc pressure and the pressure change rate, so that the inner disc pressure is kept within a preset range; and whena condition of exiting the sterilization mode is met, the sterilization mode is exited. By directly obtaining the inner disc pressure of the evaporator and the pressure change rate, the inner disc pressure and the pressure change rate can be monitored in real time, so that the problem of poor real-time performance caused by hysteresis of inner disc temperature detection is effectively avoided, theprobability that pressure in an evaporator copper pipe is too large is reduced, and then the probability that the copper pipe is broken is reduced.

Owner:NINGBO AUX ELECTRIC +1

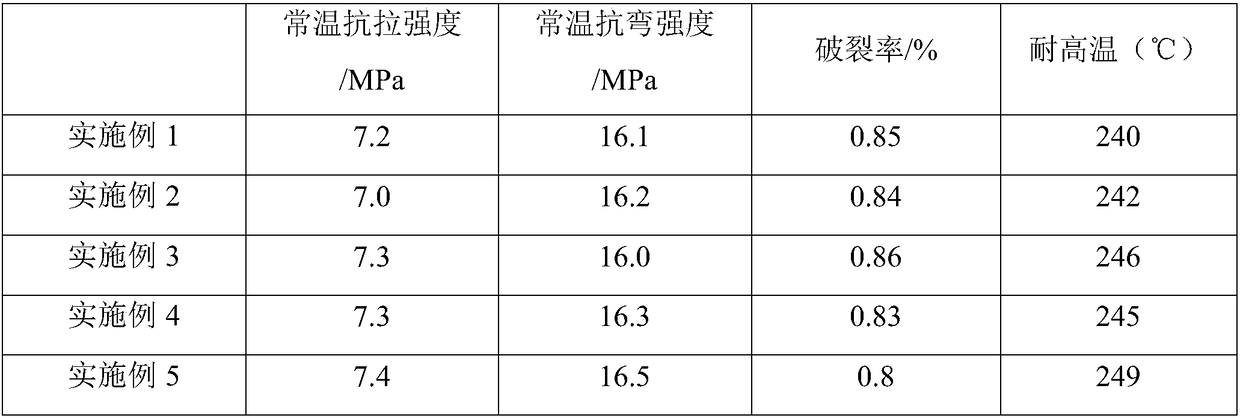

Method for preparing high-temperature-resisting anti-crack precoated sand through composite resin

InactiveCN106734854ALow gas productionHigh heat intensityFoundry mouldsFoundry coresOXALIC ACID DIHYDRATEFreeze-drying

The invention discloses a method for preparing high-temperature-resisting anti-crack precoated sand through composite resin, and belongs to the technical field of preparation of precoated sand. The method for preparing the high-temperature-resisting anti-crack precoated sand through the composite resin comprises the steps that quartz sand and waste ceramic are ground in a mixed mode, sieved and then mixed with pulp prepared from sticky rice and water, an obtained mixture is freeze-dried and sieved through wet ball-milling, and thus dry powder is obtained; afterwards, a formaldehyde solution reacts with phenol and oxalic acid, so that phenolic resin is obtained; the phenolic resin is dissolved in absolute ethyl alcohol, so that a phenolic resin-ethanol solution is obtained; and the dry powder, gypsum powder, simethicone and the like are poured into a sand mixer so as to be mixed, a urotropin solution and epoxy resin E-51 are added for a stirring reaction, the phenolic resin-ethanol solution and dibromotoluene glycidyl ether are added dropwise for a curing reaction, cooling is conducted till the room temperature is reached after curing, sand discharging is conducted, and thus the high-temperature-resisting anti-crack precoated sand is obtained. The precoated sand prepared through the method is good in curing effect and high in strength, has the excellent performance of low gas evolution and high temperature resistance, is good in material coordination and not prone to breakage when a casting is cast, and can meet production requirements of various complex precision castings.

Owner:丁玉琴

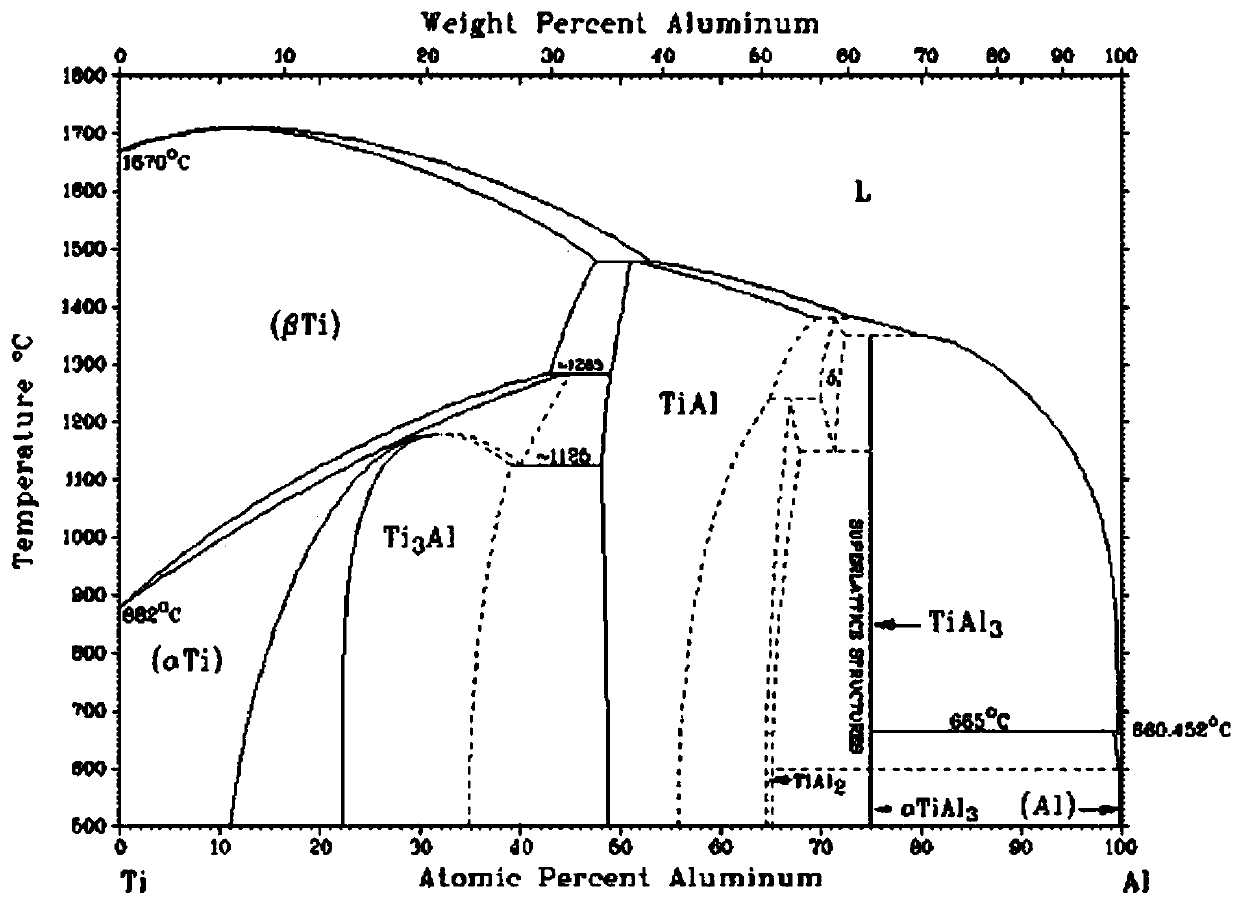

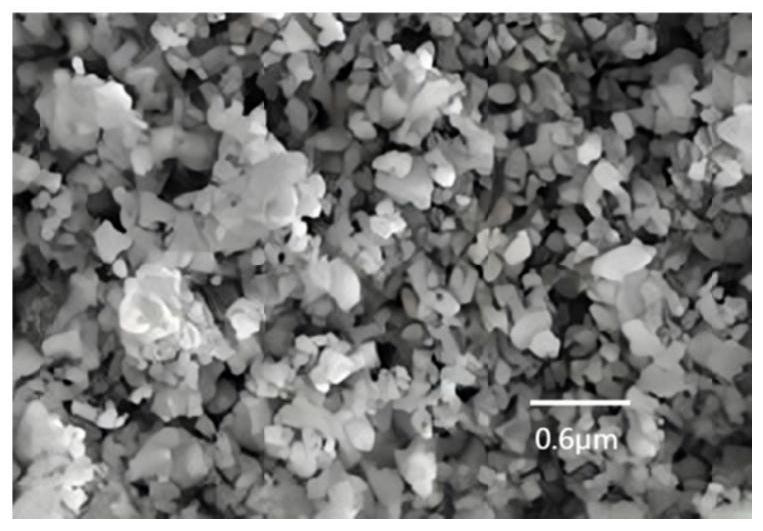

Preparation method of titanium-aluminum alloy target material

ActiveCN111101105AReduce manufacturing costSimple production process controlTransportation and packagingMetal-working apparatusTitaniumHot isostatic pressing

The invention discloses a preparation method of a titanium-aluminum alloy target material. The preparation method comprises a powder mixing step, a filling step, a cold isostatic pressing step, a welding sheath degassing step, a hot isostatic pressing step, a slitting step, an alloying diffusion heat treatment step and a machining finishing step. The preparation method is simple in control, low inprocessing cost and high in processing efficiency.

Owner:东莞市欧莱溅射靶材有限公司

3D printing precoated sand molding process

ActiveCN108296442AHigh strengthImprove high temperature resistanceFoundry mouldsFoundry coresWork in processUltimate tensile strength

The invention discloses a 3D printing precoated sand molding process. The 3D printing precoated sand molding process comprises the following steps: (A) raw sand is washed by water; (B) the raw sand iswashed by acid; (C) the raw sand is mixed with an auxiliary to obtain mixed sand; (D) the mixed sand is injected into a mold through a core injector; (E) steam is introduced into the mold to obtain a3D printing precoated sand semi-finished product; and (F) the 3D printing precoated sand semi-finished product is put in a hot air drying box for hot air drying curing to obtain molded 3D printing precoated sand. The 3D printing precoated sand molding process is simple; and the obtained precoated sand is high in strength and excellent in high-temperature resistance, so that the quality of 3D printing workpieces can be improved, no environmental pollution is caused, and energy conservation and environmental protection are achieved. The steam introduction step can be adopted to improve the filmcoating uniformity of the raw sand; and then, the hot air drying is performed for drying curing of sand models, so that the hardening speed is high, and the rupture rate of the precoated sand is reduced.

Owner:LIUZHOU LIUJING TECH CO LTD

Method for extracting vanadium from vanadium-containing solution

InactiveCN106222412AOvercoming extractionOvercoming long stripping stagesProcess efficiency improvementPhase splittingEmulsion

The invention relates to a method for extracting vanadium from a vanadium-containing solution. According to the technical scheme, a surfactant, a carrier, liquid paraffin and a membrane solvent are mixed evenly, and an evenly-mixed organic phase is obtained; then a back-extractant is added into the evenly-mixed organic phase, stirring is conducted, and an emulsion is obtained; the vanadium-containing solution and the emulsion are mixed, stirred and subjected to standing and phase splitting, and a vanadium-loaded solution and primary raffinate are obtained; the vanadium-loaded solution is subjected to demulsification and phase splitting, and a lean organic phase and a vanadium-rich solution are obtained; and the lean organic phase and the primary raffinate are mixed, stirred and subjected to standing and phase splitting, a vanadium-loaded organic phase and secondary raffinate are obtained, and the vanadium-loaded organic phase is directly returned to make an emulsion again. The method has the characteristics of being small in extractant usage quantity, short in technological process and high in vanadium recovery rate, production efficiency and continuous productbility.

Owner:WUHAN UNIV OF SCI & TECH +1

Outer-repairing and inner-curing type graphene functionalization self-repairing microcapsule with cellular structure and preparation method of self-repairing microcapsule

ActiveCN108993330AImprove stabilityImprove performanceCoatingsMicroballoon preparationMicro nanoEmulsion

The invention provides a graphene functionalization self-repairing microcapsule with a cellular structure and a preparation method of the self-repairing microcapsule for the problem existing in a self-repairing system in the prior art. The outer-repairing and inner-curing type graphene functionalization self-repairing microcapsule comprises a capsule wall and a repairing agent coated by the capsule wall, wherein graphene is dispersed in the capsule wall; a series of micro-nano microcapsules are dispersed into the repairing agent, so as to form a cellular structure; a curing agent is coated ineach of the micro-nano microcapsules. The self-repairing microcapsule system has a micro-nano multinuclear coating structure, so that the stability of the microcapsule is enhanced, meanwhile, the contact probability of the repairing agent and the curing agent are increased, and the repairing efficiency is improved. Additionally, the capsule wall of the self-repairing microcapsule system is modified by silane, silane emulsion which is not hydrolysed after the microcapsule is ruptured can form a hydrophobic membrane in a capillary hole of concrete, and the water content can be prevented from being diffused further; in addition, silane emulsion which is hydrolysed can participate in the synthesis of a wall material, so that the property of the microcapsule is improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

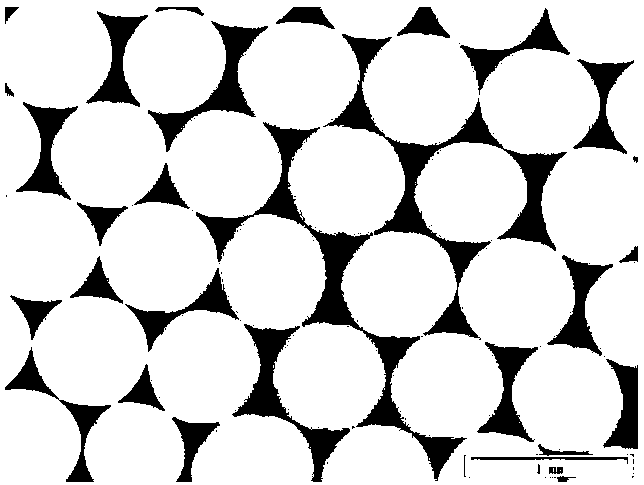

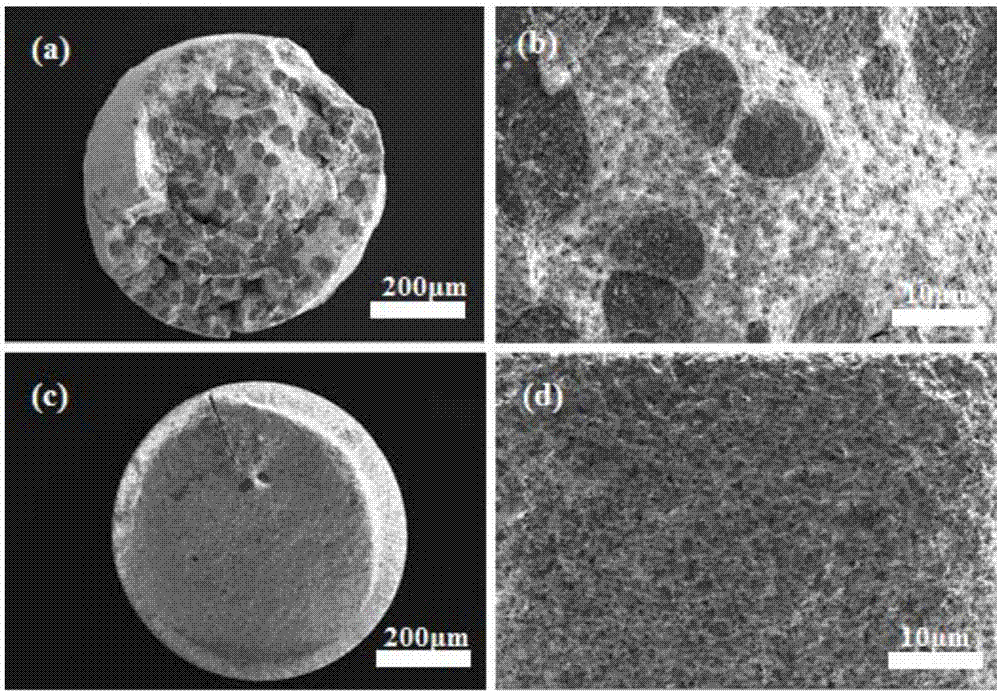

Method for preparing ceramic micro-spheres of thorium oxide

ActiveCN107010955AReduce the probability of ruptureAvoid breakingNuclear energy generationReactors manufacturePolyvinyl alcoholThorium oxide

The invention relates to a method for preparing ceramic micro-spheres of thorium oxide. The method includes dropwise adding ammonia water into thorium nitrate solution to form hydrolysis solution, dropwise adding glacial acetic acid into the hydrolysis solution to regulate the pH (potential of hydrogen) of the hydrolysis solution, and adding polyvinyl alcohol into the hydrolysis solution under stirring conditions to form thorium oxide colloidal solution; dispersing the thorium oxide colloidal solution to obtain liquid drop and allowing the liquid drop to sequentially flow through helium zones, ammonia gas zones and ammonia water zones; arranging dispersed gel particles in strong ammonia water and aging the dispersed gel particles; adding the aged gel particles and deionized water into a hydrothermal reaction kettle and carrying out temperature reaction; placing gel particles into a drying furnace after hydrothermal reaction is carried out on the gel particles, and heating and drying the gel particles under humidity control to form dried gel particles; placing the dried gel particles in a calcination furnace, filling the calcination furnace with air and heating and calcining the gel particles to obtain calcined gel particles; placing the calcined gel particles in a sintering furnace, filling the sintering furnace with air and heating and sintering the calcined gel particles to obtain the ceramic micro-spheres. The method has the advantage that the ceramic micro-spheres of the thorium oxide can be prepared by the aid of simple technologies.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

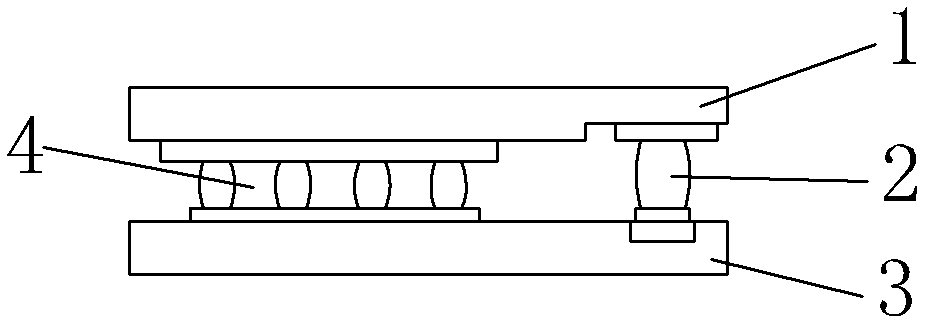

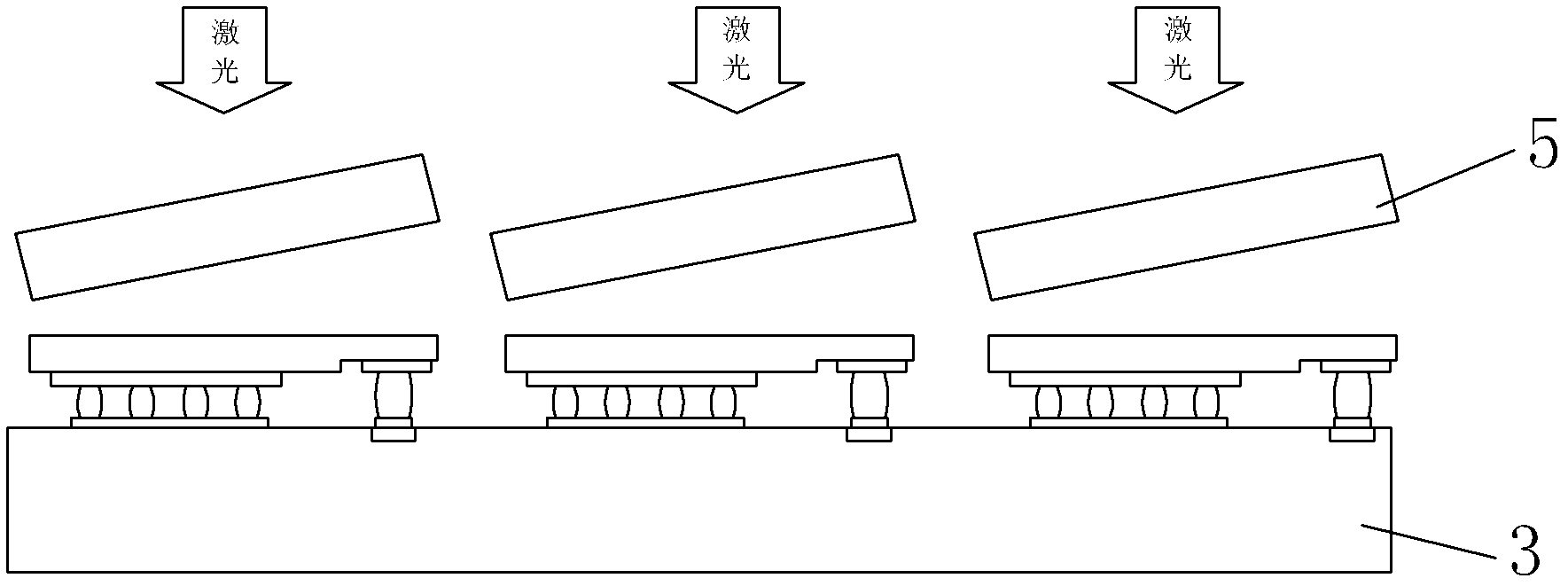

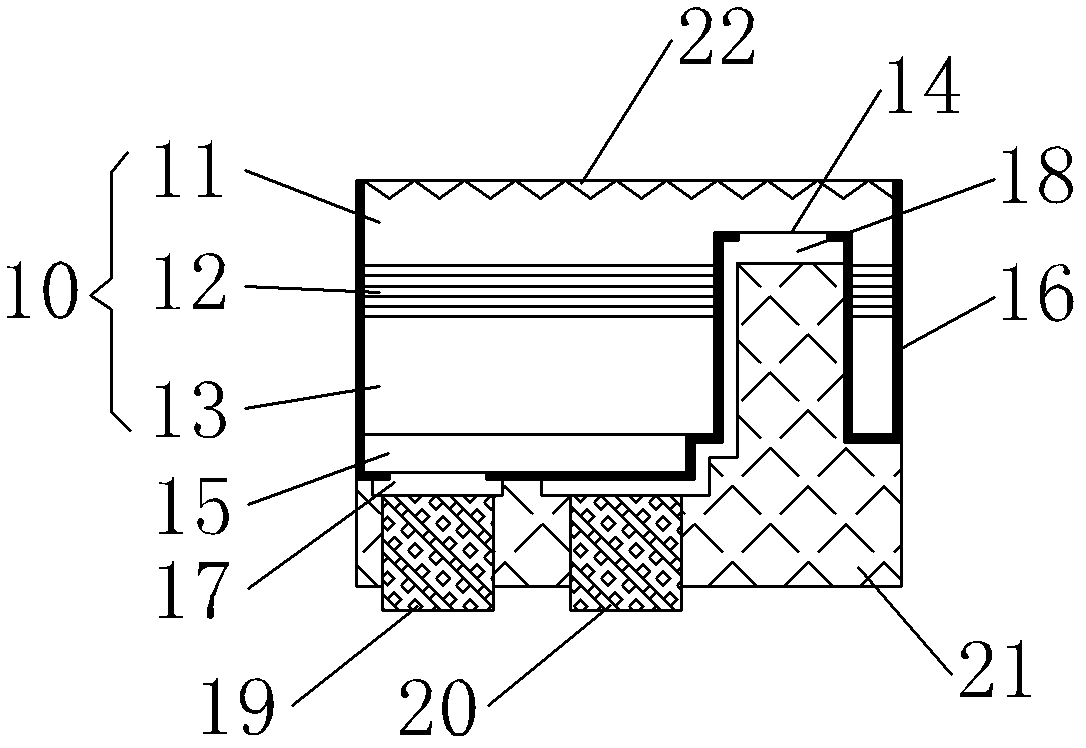

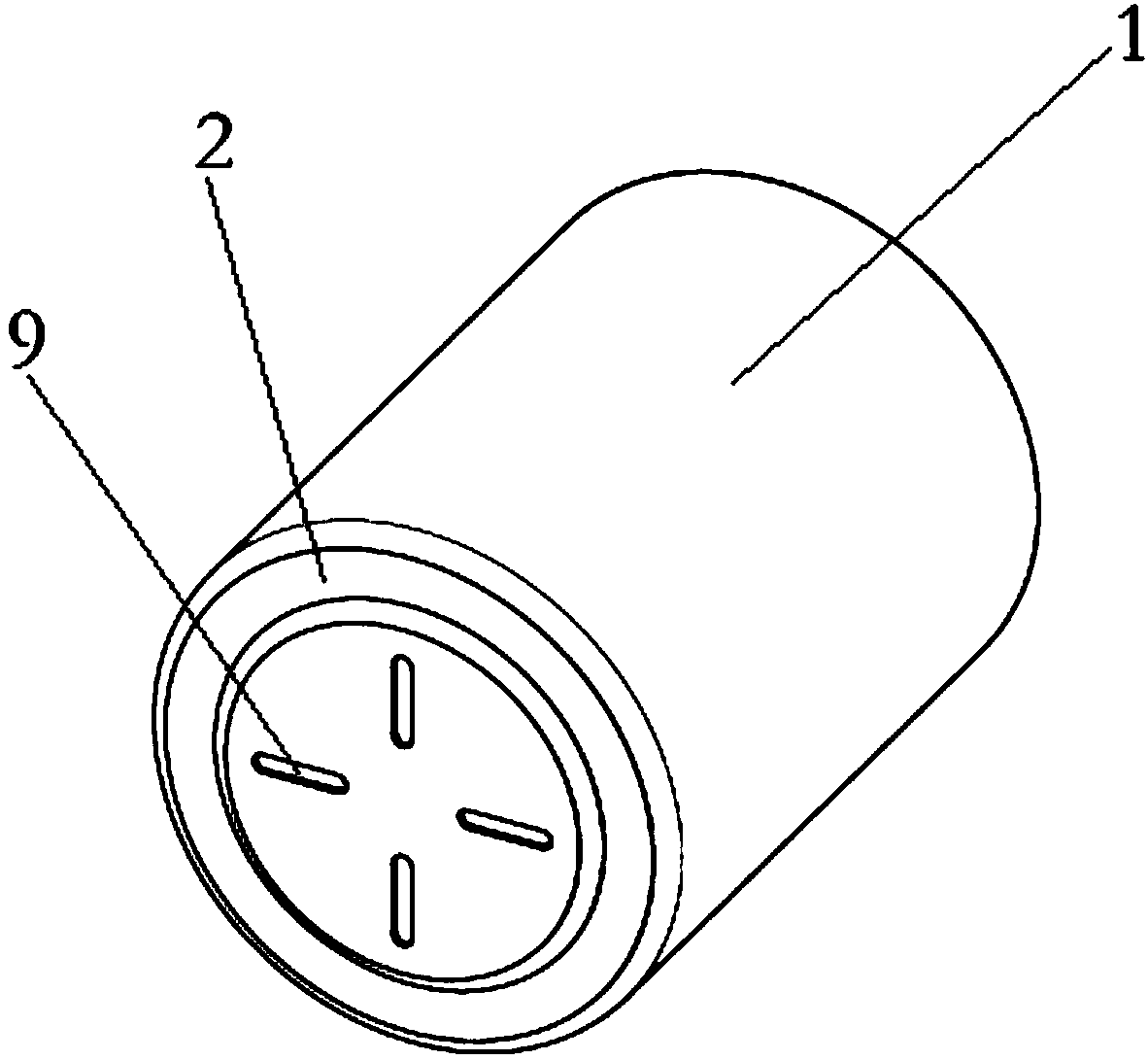

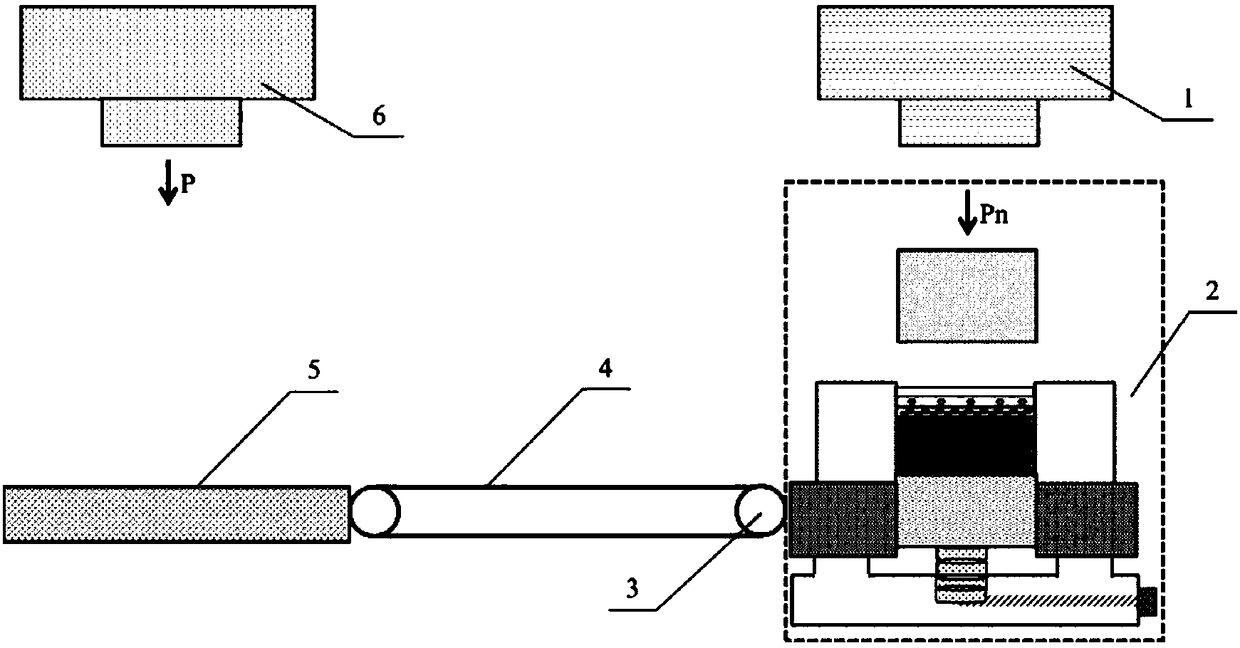

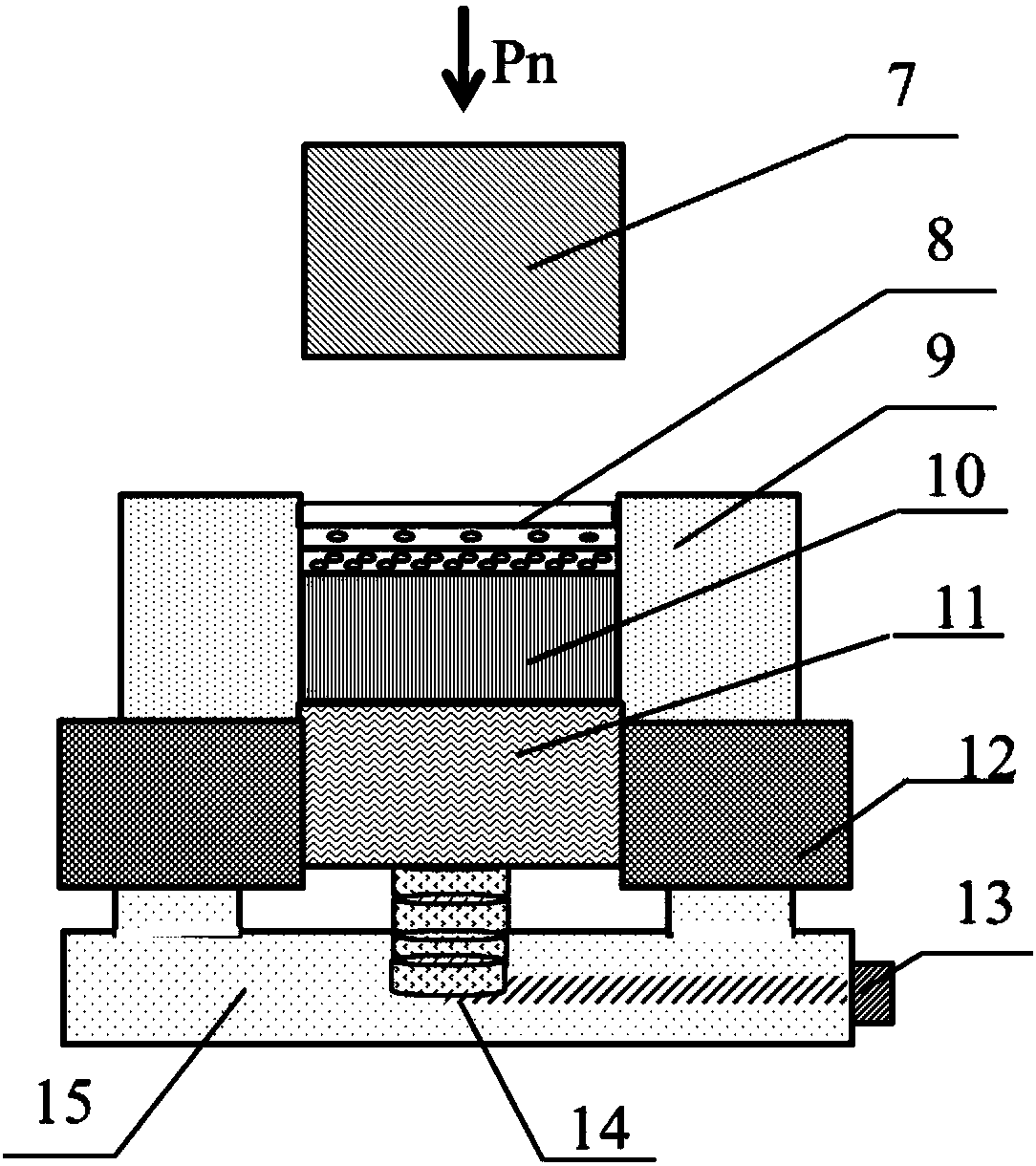

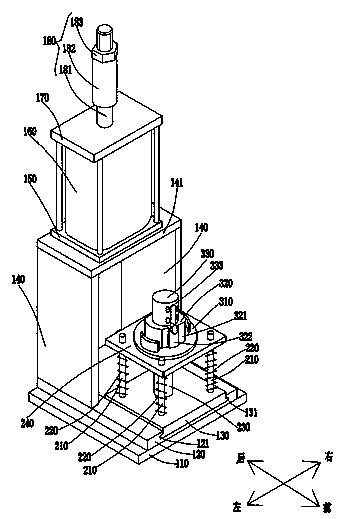

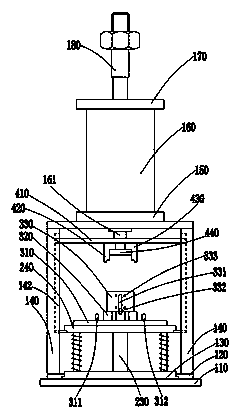

Forming device and application of large-size ultra-thin powder metallurgy gradient material

PendingCN108326297AImprove bindingPrecise control of lifting heightGradient materialMeasuring instrument

The invention belongs to the field of powder metallurgy forming equipment, and particularly relates to a forming device and application of a large-size ultra-thin powder metallurgy gradient material.The forming device of the large-size ultra-thin powder metallurgy gradient material comprises a pre-pressing forming system and a laminating powder laying forming system; and the laminating powder laying forming system is composed of a mold upper pressing head, a mold sleeve, a mold lower pressing head, a spiral height control instrument lifting table, a spiral height control instrument platform,a spiral rotary knob, a lifting screw rod and a height control instrument base. The laminating powder laying forming system of the forming device of the large-size ultra-thin powder metallurgy gradient material organically combines a spiral height measuring instrument and mold pressing forming, laminating powder laying with the descending height at the micron level is achieved, laying uniformity of each layer of power is guaranteed, and due to the fact that a mold can be replaced at any time, it can be achieved that sample forming blank bodies in different sizes are prepared. The forming device of the large-size ultra-thin powder metallurgy gradient material achieves integration of multi-layer powder laying, prefabricating forming and final forming in the powder metallurgy technology, thepressing forming performance is good, and thickness control of each layer is accurate.

Owner:CENT SOUTH UNIV

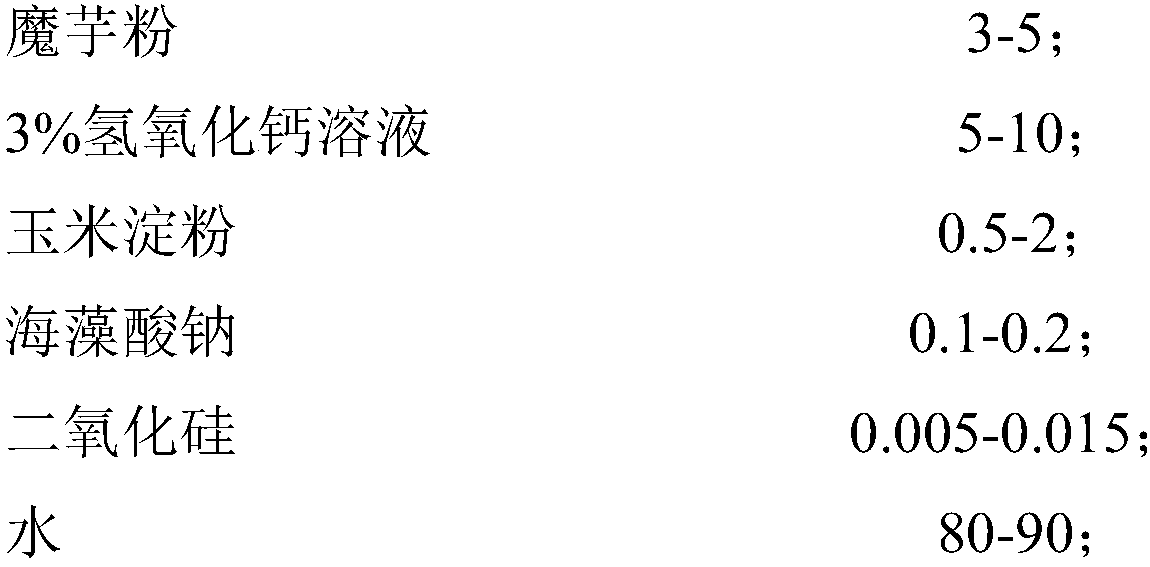

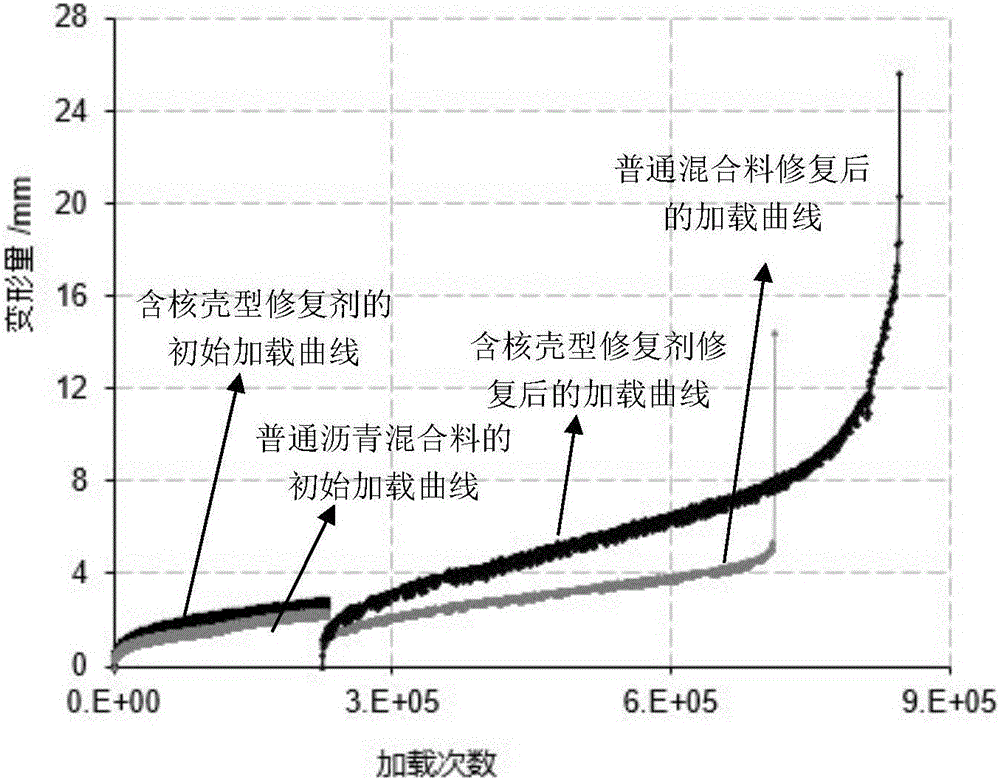

Core-shell type asphalt self-repairing agent and preparation method thereof

ActiveCN106117632AHigh mechanical strengthReduce the probability of ruptureBuilding insulationsMaleic anhydrideCore shell

The invention discloses a core-shell type asphalt self-repairing agent and a preparation method thereof, wherein calcium alginate is adopted as a wall material, an asphalt regeneration agent is adopted as a core material, a mass ratio of the wall material to the core material is 1:1-1:1.5, and the particle size of the shell is 1-3 mm. The preparation method comprises: 1) adding an asphalt regeneration agent to a polyethylene maleic anhydride copolymer aqueous solution, and carrying out stirring mixing; 2) carrying out shear mixing on the liquid obtained in the step 1) and a calcium alginate solution by using a high-speed shearing machine, wherein the shearing rate is 2000-3000 rpm, and the shearing time is 3-5 min; 3) slowly adding the liquid obtained in the step 2) into a calcium chloride solution, carrying out a stirring for 1.5-2.5 h at a temperature of 75-85 DEG C, washing with distilled water, and drying to obtain the core-shell type asphalt regeneration agent. According to the present invention, the shell calcium alginate has characteristics of good thermal stability and high mechanical strength, and has the breaking rate of less than 10% during the stirring of the asphalt mixture, the coverage rate of the asphalt regeneration agent is high, and the sufficient regeneration agent can be provided for the asphalt self-repair.

Owner:WUHAN UNIV OF TECH

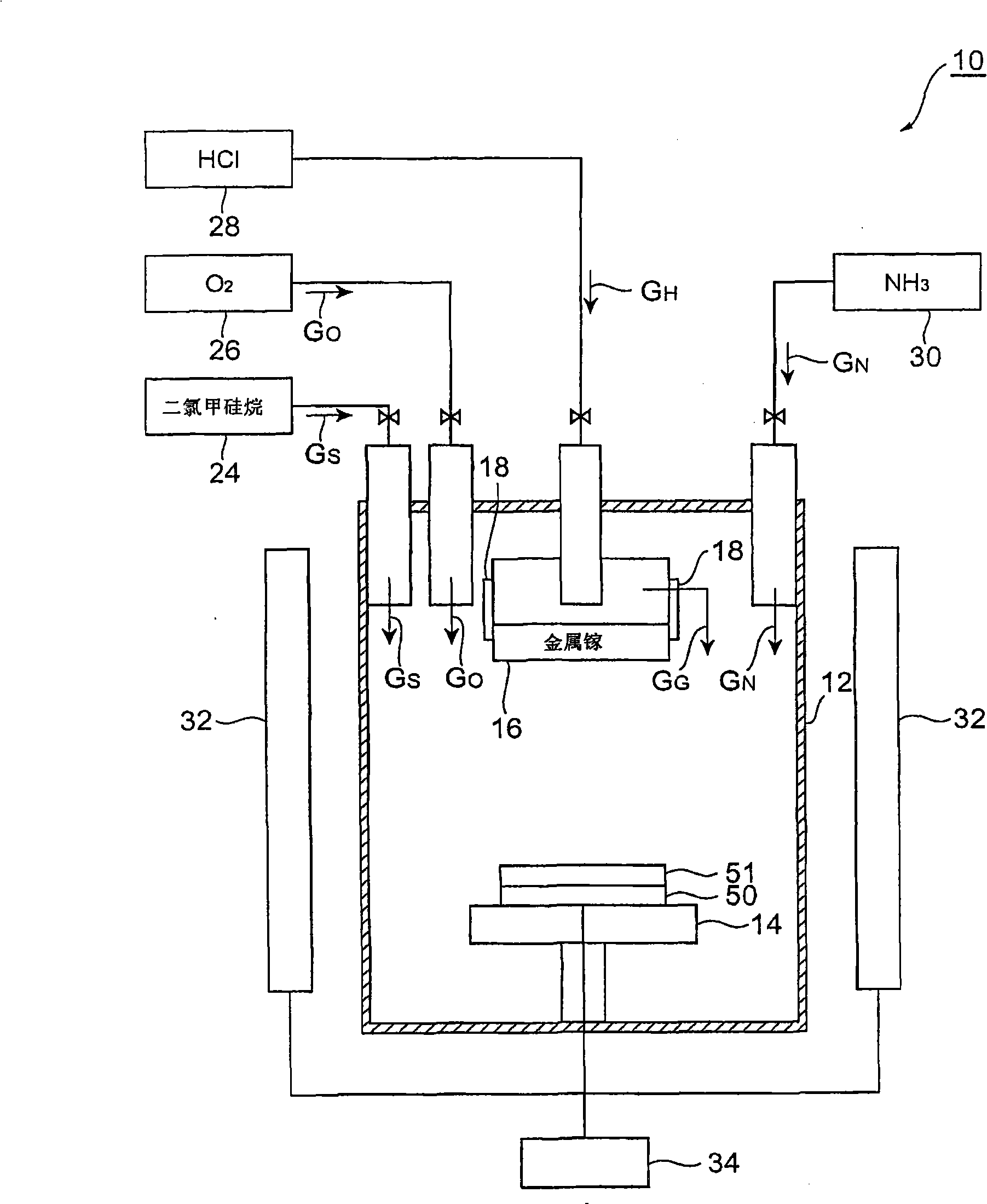

Gallium nitride substrate and gallium nitride film deposition method

InactiveCN101311379AIncrease the carrier concentrationReduce the probability of rupturePolycrystalline material growthSemiconductor/solid-state device manufacturingDopantCharge carrier

Provided is a gallium nitride substrate for advancing carrier concentration and lowing breaking incidence rate and a method of forming gallium nitride film (52), which is generated with carrier concentration more than 1*10<17> cm<3>. Firstly, a gallium nitride layer (51) including n-type dopant is formed on a substrate (51). Then gallium nitride film (52) is formed by heating the gallium nitride layer (51) on the substrate (50).

Owner:SUMITOMO ELECTRIC IND LTD

Football field construction process

ActiveCN108914744AAvoid Waterlogging ProblemsTake advantage ofSeed and root treatmentHops/wine cultivationSoil scienceWater resources

The invention discloses a football field construction process. The football field construction process comprises following steps: 1, earth excavation and original soil ramming; 2, square grid laying;3, gradient adjusting; 4, sodium bentonite waterproofing carpet laying; 5, backfilling and soil ramming; 6, blind drain excavation and spraying water supply system installation; 7, graded broken stonelayer laying; 8, loess coarse sand layer laying; 9, planting soil coarse sand layer laying; and 10, natural grass layer plantation. When rain is too heavy, a double way water pump is turned on, rainin the blind drains and rain on football field surface are pumped into a spraying main pipe through a pipe network and nozzles, and is discharged into a water reservoir, so that football field draining speed is accelerated, and water accumulation of football fields is avoided. In drought days, water in the water reservoir can be conveyed into the pipe network, and sprayed onto lawn through the nozzles, so that water recycling is realized, water resource is saved. Under the action of single-way membrane, rainwater can be pumped into the pipe network, and flowing out from the pipe network is prevented, so that water and soil loss of a second base layer is reduced.

Owner:北京泛华新兴体育产业股份有限公司

Well lid support, inner well lid of inspection well and well lid component of inspection well

ActiveCN103306308AAchieve supportAvoid falling intoArtificial islandsUnderwater structuresEngineeringMechanical engineering

Owner:保定市华光市政建材有限公司

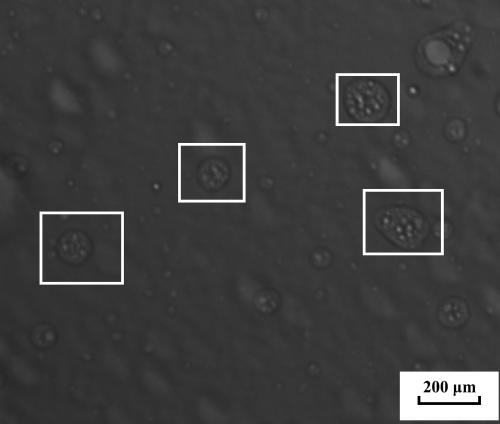

Method for preparing ceramic microspheres of thorium-based carbides and/or thorium-based oxycarbides

ActiveCN107134299AReduce the probability of ruptureNo crackNuclear energy generationReactor fuel susbtancesMicrosphereHydrolysis

The invention relates to a method for preparing ceramic microspheres of thorium-based carbides and / or thorium-based oxycarbides. The method comprises the following steps: dripping a thorium nitrate solution into ammonium hydroxide so as to form a hydrolysis solution; adding polyvinyl alcohol while stirring the hydrolysis solution so as to form sol; dispersing carbon powder by utilizing an organic reagent which is mutually soluble with water so as to form pre-dispersed carbon powder; adding the sol into the pre-dispersed carbon powder so as to form a carbon-containing colloidal solution; dispersing the carbon-containing colloidal solution into liquid drops, and enabling the liquid drops to sequentially pass through a helium area, an ammonia gas area and an ammonium hydroxide area so as to form gel particles; ageing the gel particles in stronger ammonia water, washing with deionized water, adding the washed gel particles into a drying furnace, controlling the humidity, heating and drying so as to form the dried gel particles; and adding the dried gel particles into a sintering furnace, heating and sintering under vacuum conditions, thereby obtaining the ceramic microspheres. According to the preparation method disclosed by the invention, the ceramic microspheres of thorium-based carbides and / or thorium-based oxycarbides are prepared through a simple process.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

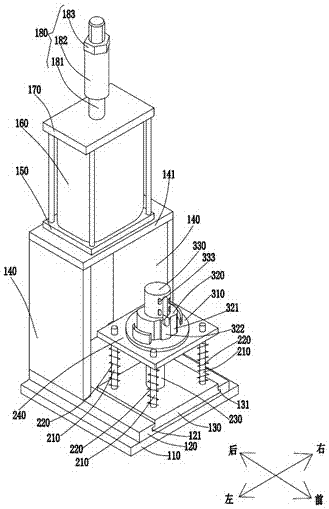

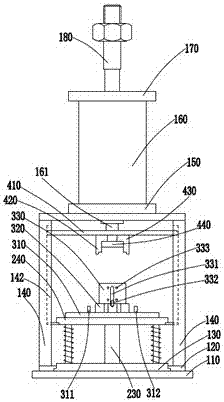

Motor magnetic tile assembly device

InactiveCN104967261AImprove stabilityEven by forceManufacturing stator/rotor bodiesMechanical engineeringStator

The invention discloses a motor magnetic tile assembly device, which comprises a base component, a gantry frame, a cylinder component, a guide component and an assembly component. According to the invention, the whole operating process is quick and convenient; as a stator housing, a magnetic tile and a magnetic tile clamp which are to be assembled are effectively limited, the whole assembly process is highly operable and the assembled stator housing is highly stable; the working efficiency is greatly improved as compared with the manual installation; and meanwhile, in the assembly of a cylinder, the magnetic tile to be assembled bears uniform force, the probability of the break of the magnetic tile is small, and the pass rate of the product is effectively increased. In addition, the guide component is also arranged in such a way that in the moving process of the cylinder component, a second guide post in a second guide assembly can effectively guide the movement of the cylinder component to make the whole assembly process more stable and reliable.

Owner:岳阳瑞思达贸易有限公司

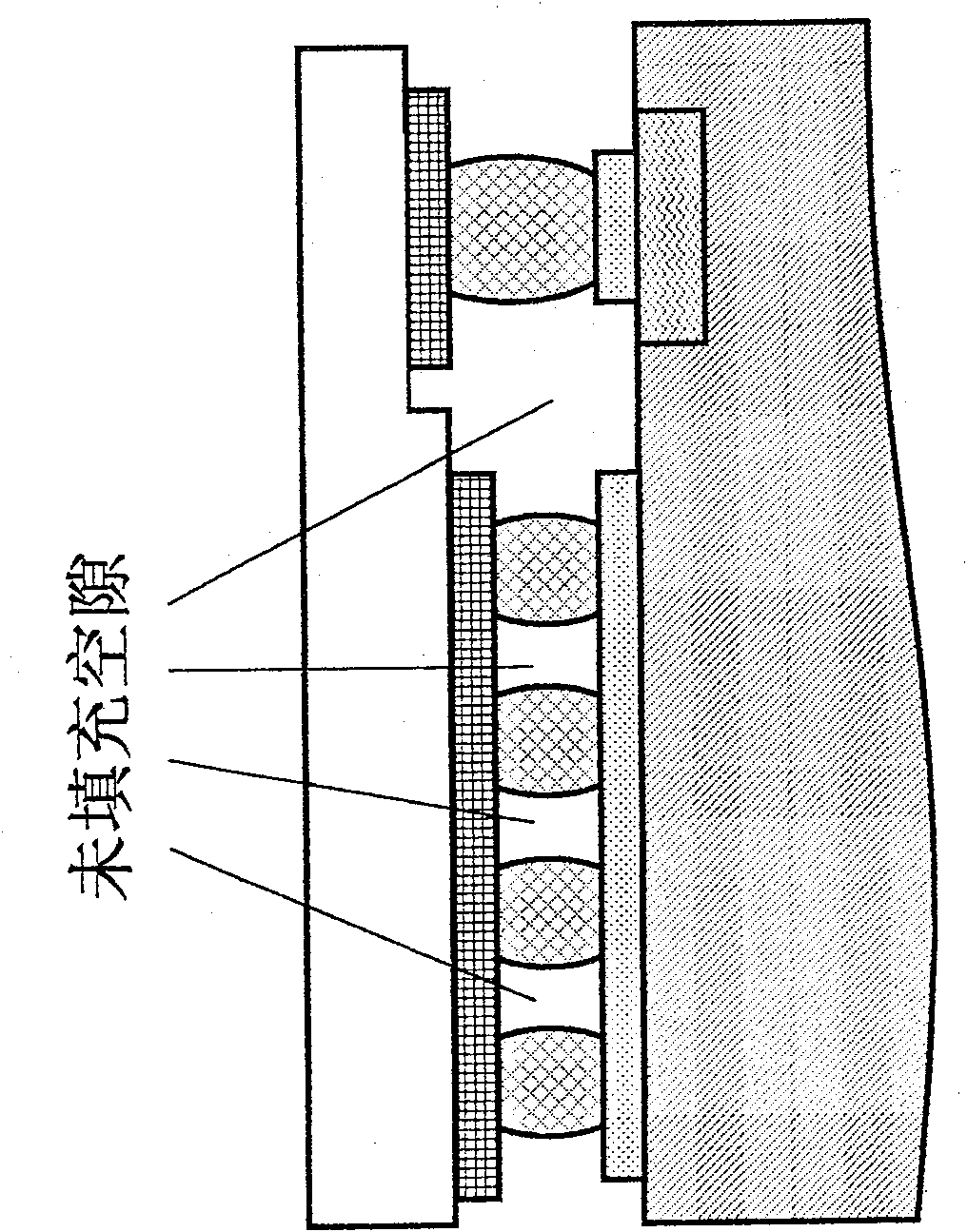

Film LED chip device based on compound low-resistance buffer structure and its making method

ActiveCN100580965CPadding achievedTo achieve electrical connectionSemiconductor devicesEngineeringLow resistance

The present invention provides a film LED chip device basing on the combined low-resistance buffer structure and the manufacturing method thereof, the insulating buffer film is packaged on side wall of all metal structures and is filled in all non-electrical connected areas, with filling in insulating buffer film between all metal convex points which connects the GaN base illuminating device and the electric polarized substrate, the filling-in thickness is a little under or even with the height of the metallic convex points, and with directly liking the GaN base illuminating device crystal disc with the whole surface of the electric polarized inversely mounted substrate with the mode of whole surface linking of the wafer, the metallic convex point of the conductive supporting thick metal layer and the insulating buffer film form the combined low-resistance buffer structure of the invention together, not only the electric connection between the GaN base illuminating device and the electric polarized inversely mounted substrate is realized, but also the buffer layer filling is realized thereby reducing the wafer rupture incidence rate of the subsequent laser stripping technique in order to increase the good product ratio, besides the stripped sapphire substrate disc which can execute finishing to the sapphire substrate and is obtained after stripped operation can be recovered for reusing, the production cost is reduced.

Owner:QUANZHOU SANAN SEMICON TECH CO LTD

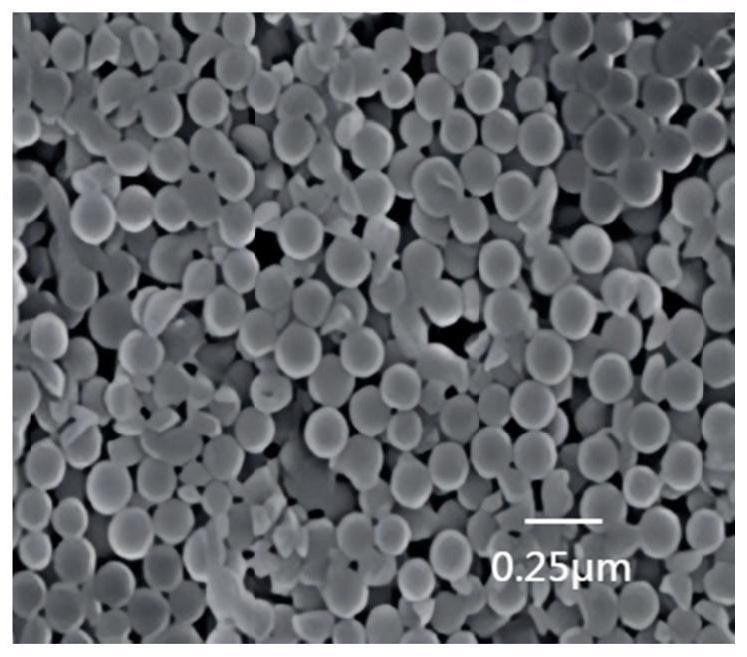

Ligand-coated doped lithium iron phosphate as well as preparation method and application thereof

PendingCN114373911AHigh discharge specific capacitySimple structureSecondary cellsPositive electrodesLithium iron phosphateElectrical conductor

The invention belongs to the technical field of lithium ion batteries, and discloses ligand-coated doped lithium iron phosphate as well as a preparation method and application thereof, and the general formula of the ligand-coated doped lithium iron phosphate is LiFePO4 (at) Mn-T-C / N, and T is at least one of zinc, nickel, copper, iron, cobalt, zirconium, aluminum, gallium and chromium. According to the ligand-coated doped lithium iron phosphate, doping is performed by the composite load type micro-carbon sphere conductor, the particle size of the composite load type micro-carbon sphere conductor reaches 80-150nm level, so that the ligand-coated doped lithium iron phosphate can bear stress with higher strength and reduce the probability of fracture, and the spherical lithium iron phosphate doped by the composite load type micro-carbon sphere conductor has the advantages that the service life of the ligand-coated doped lithium iron phosphate is prolonged, and the service life of the ligand-coated doped lithium iron phosphate is prolonged. And the material structure integrity is easier to control.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

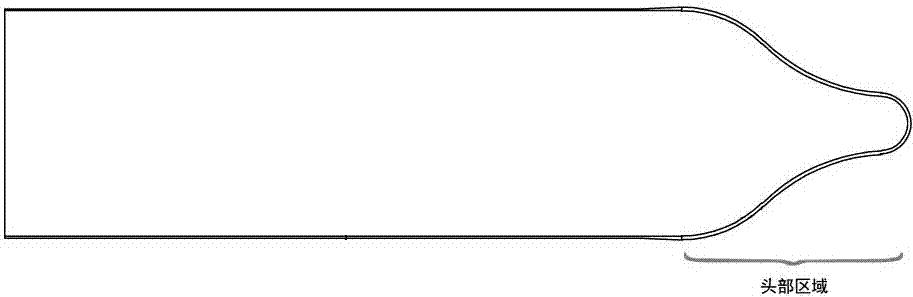

Condom with thickened head and manufacturing method thereof

InactiveCN103190978AReduce the probability of ruptureDecreased sexual arousalMale contraceptivesCoatingsEngineeringSexual life

The invention belongs to the technical field of birth control and particularly relates to a condom and a manufacturing method thereof. The head area of the condom is thicker than other areas. The head area of the condom is a 30-40 mm area from the top end of a condom sperm storage bag. The manufacturing method includes: an overall impregnation area of a condom die passes through a hot water tank to arrive at impregnation temperature, the head of the condom die passes through a hot water tank with higher temperature, and then the condom die enters natural rubber whey of a first tank to be soaked and then is soaked in natural rubber whey of a second tank. The condom with the thickened head can effectively reduce man sexual excitation through a screen hindering method and prolong sexual life time. The thickened head can increase bearing capacity of the head end of the condom so as to reduce probability of fracture of the head in a using process of the condom.

Owner:SHANGHAI MINGBANG RUBBER PROD

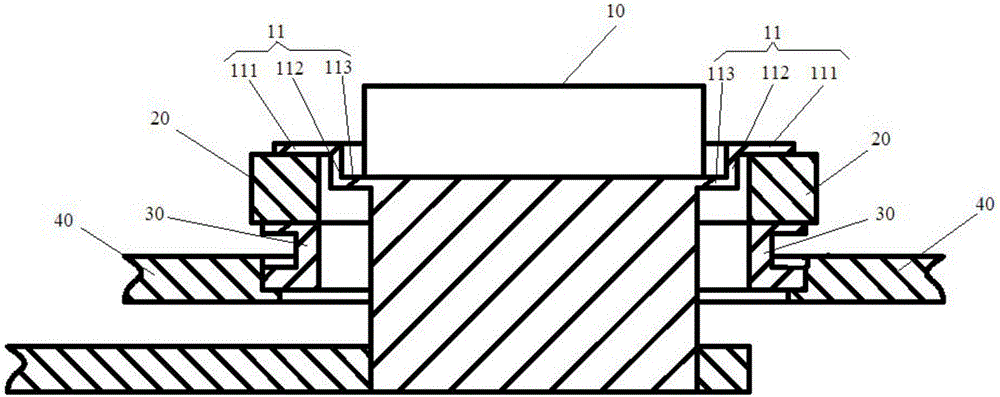

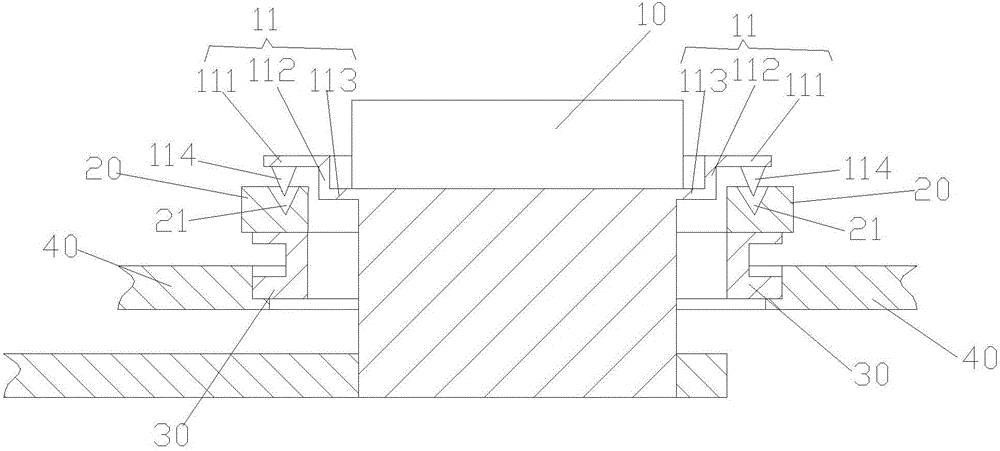

Cover board assembly for power battery and power battery

PendingCN105702887AImprove the safety of useReduce the probability of ruptureCharging stationsSmall-sized cells cases/jacketsPower batteryEngineering

The invention discloses a cover board assembly for a power battery and the power battery. The power battery comprises poles, insulators, composite ring flanges and a cover board body, wherein a welding part which protrudes to surround each pole is arranged on the pole between the top end and the bottom end; each welding part comprises a lower terrace, a buffer wall and an upper terrace; each lower terrace is connected with the corresponding pole; one side, far away from the corresponding pole, of each lower terrace is connected with the corresponding buffer wall; each buffer wall is also connected with the corresponding upper terrace; and the distance from each upper terrace to the plane in which the top end of the corresponding pole is located is smaller than that from the corresponding lower terrace to the plane in which the top end of the corresponding pole is located; a pole installation hole is formed in each insulator; the bottom end of each pole extends along the corresponding pole installation hole and penetrates through the corresponding insulator; each upper terrace is in contact with the upper surface of the corresponding insulator to prevent the corresponding pole from further sliding towards the inside of the corresponding pole installation hole; the lower surface of each upper terrace and the upper surface of the corresponding insulator are hermetically welded; and each composite ring flange is connected with the corresponding insulator and the cover board body respectively. According to the cover board assembly of the power battery and the power battery, the use safety is improved; and the service lifetime is prolonged.

Owner:SHENZHEN 3SUN ELECTRONICS

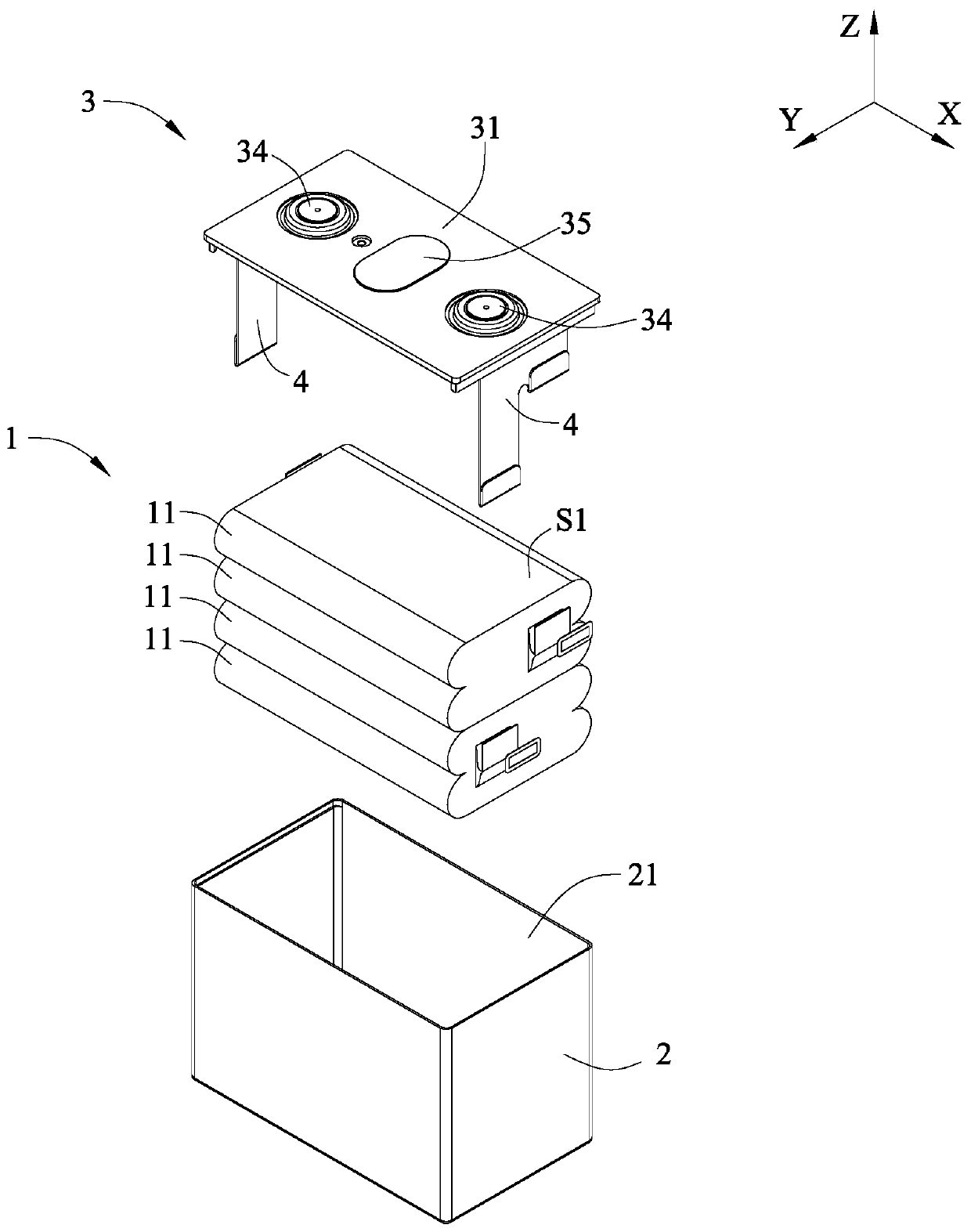

Secondary battery and battery module

PendingCN111384348APrevent crushingGuaranteed performanceCurrent conducting connectionsFinal product manufactureStructural engineeringMechanical engineering

The invention provides a secondary battery and a battery module. The battery module comprises a plurality of secondary batteries arranged in sequence. The secondary battery includes an electrode assembly, a case, and a top cover assembly. The shell is provided with a containing cavity; the electrode assembly is contained in the containing cavity. The electrode assembly comprises a plurality of electrode units, wherein the electrode units are arranged in a stacked mode in the axial direction of the containing cavity. The top cover assembly comprises a top cover plate and an explosion-proof sheet, wherein the top cover plate is connected to the shell and located on one side of the electrode assembly in the axial direction. The top cover plate is provided with a through hole, and the explosion-proof sheet is connected to the top cover plate and covers the through hole. One side, close to the electrode assembly, of the top cover plate is provided with a first inner surface; one side, closeto the electrode assembly, of the explosion-proof piece is provided with a second inner surface, and the distance between the first inner surface and the electrode assembly is smaller than that between the second inner surface and the electrode assembly. In the battery module, the arrangement direction of the plurality of secondary batteries is perpendicular to the axial direction.

Owner:CONTEMPORARY AMPEREX TECH CO

A motor magnetic tile assembly device

InactiveCN104967261BEffectively fixedImprove stabilityManufacturing stator/rotor bodiesEngineeringMechanical engineering

Owner:岳阳瑞思达贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com