Preparation method of thorium-based mixed oxide ceramic microsphere

A technology of mixed oxides and ceramic microspheres, which is applied in the manufacture of reactors, reactors, and reduction of greenhouse gases. It can solve problems such as uneven distribution of thorium bases, and achieve the effects of reducing the rupture rate, ensuring uniformity, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

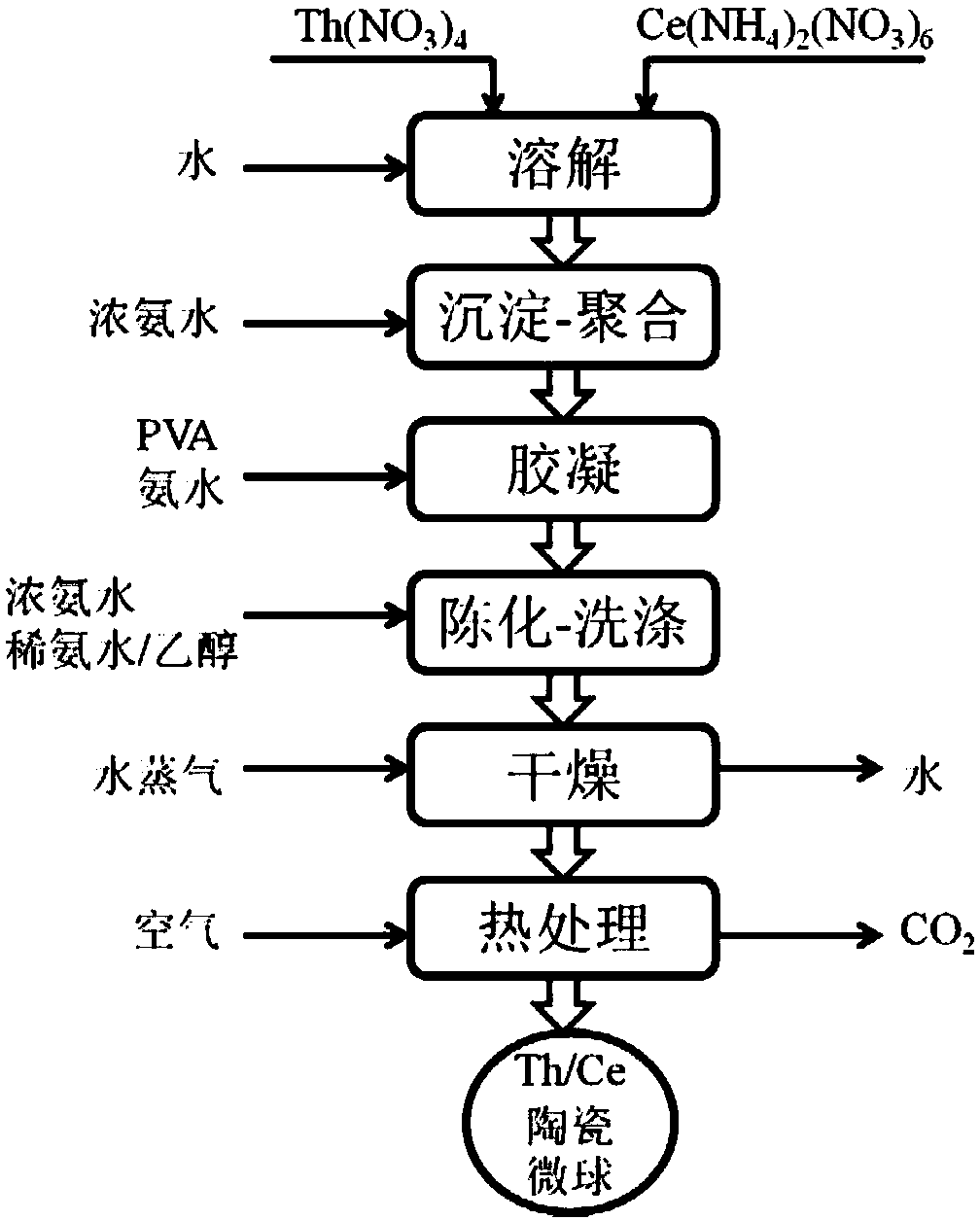

Method used

Image

Examples

Embodiment 1

[0026] S1, preparation of thorium-cerium mixed colloid: weighing 41.12g Th(NO 3 ) 4 ·6H 2 O was prepared into 50mL of 1.4mol / L thorium nitrate solution, heated up to 50°C, and slowly added 3.84g Ce(NH 4 )(NO 3 ) 6 Stir until completely dissolved, make a mixed solution of Th / (Th+Ce) (molar ratio) = 0.9, heat to 60°C, add concentrated ammonia water at a rate of 0.3mL / min to adjust the neutralization degree to 80%, and form a hydrolysis polycondensation Solution, after the solution is cooled to room temperature, add 9mL of polyvinyl alcohol with a concentration of 80g / L while stirring, stir until it is completely uniform, then let it stand, and ultrasonically eliminate bubbles to obtain a thorium-cerium mixed colloidal solution.

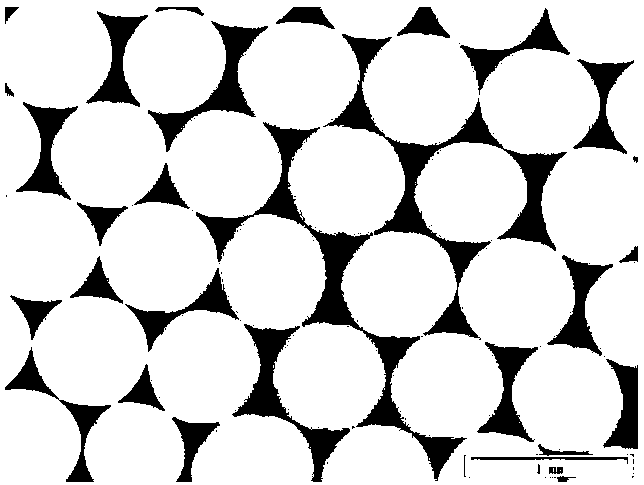

[0027] S2, Vibration dispersion forming: Transport the thorium-cerium mixed colloid solution into the pipeline through a constant flow pump, and then disperse it into liquid droplets through the vibrator, then pass through the air zone and ammonia z...

Embodiment 2

[0032] S1, preparation of thorium-cerium mixed colloid: weigh 94.0g Th(NO 3 ) 4 ·6H 2 O was prepared into 100mL of 1.6mol / L thorium nitrate solution, heated to 80°C, and slowly added 26.31g Ce(NH 4 )(NO 3 ) 6 Stir until completely dissolved, make a mixed solution of Th / (Th+Ce) (molar ratio) = 0.7, heat to 60°C, add concentrated ammonia water at a rate of 0.5mL / min to adjust the neutralization degree to 85%, and form a hydrolysis polycondensation Solution, after the solution is cooled to room temperature, add 15mL of polyvinyl alcohol with a concentration of 80g / L while stirring, stir until it is completely uniform, then let it stand, and ultrasonically eliminate bubbles to obtain a thorium-cerium mixed colloidal solution.

[0033] S2, Vibration dispersion forming: Transport the thorium-cerium mixed colloid solution into the pipeline through a constant flow pump, and then disperse it into liquid droplets through the vibrator, then pass through the air zone and ammonia zone ...

Embodiment 3

[0037] S1, preparation of thorium-uranium mixed colloid: weighing 41.12g Th(NO 3 ) 4 ·6H 2 O was prepared into 50 mL of 1.4 mol / L thorium nitrate solution, heated to 50°C, and 6.90 g of UO was slowly added 2 (NO 3 ) 2 ·6H 2 Stir O until it is completely dissolved, make a mixed solution of Th / (Th+U) (molar ratio) = 0.8, heat to 60°C, add concentrated ammonia water at a rate of 0.4mL / min to adjust the neutralization degree to 80%, and form a hydrolyzed solution Polycondensation solution, after the solution is cooled to room temperature, add 8mL of polyvinyl alcohol with a concentration of 80g / L while stirring, stir until it is completely uniform, then let it stand, and ultrasonically eliminate bubbles to obtain a thorium-uranium mixed colloid solution.

[0038] S2, vibration dispersion forming: the thorium-uranium mixed colloid solution is transported into the pipeline through a constant flow pump, and then dispersed into droplets by a vibrator, then passes through the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com