High-temperature-resistant organic-solvent-resistant separating membrane material, separating membrane, and preparation method thereof

A technology resistant to organic solvents and high temperature, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of low cost, poor porosity, hydrophobicity, poor corrosion resistance to organic solvents, poor porosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

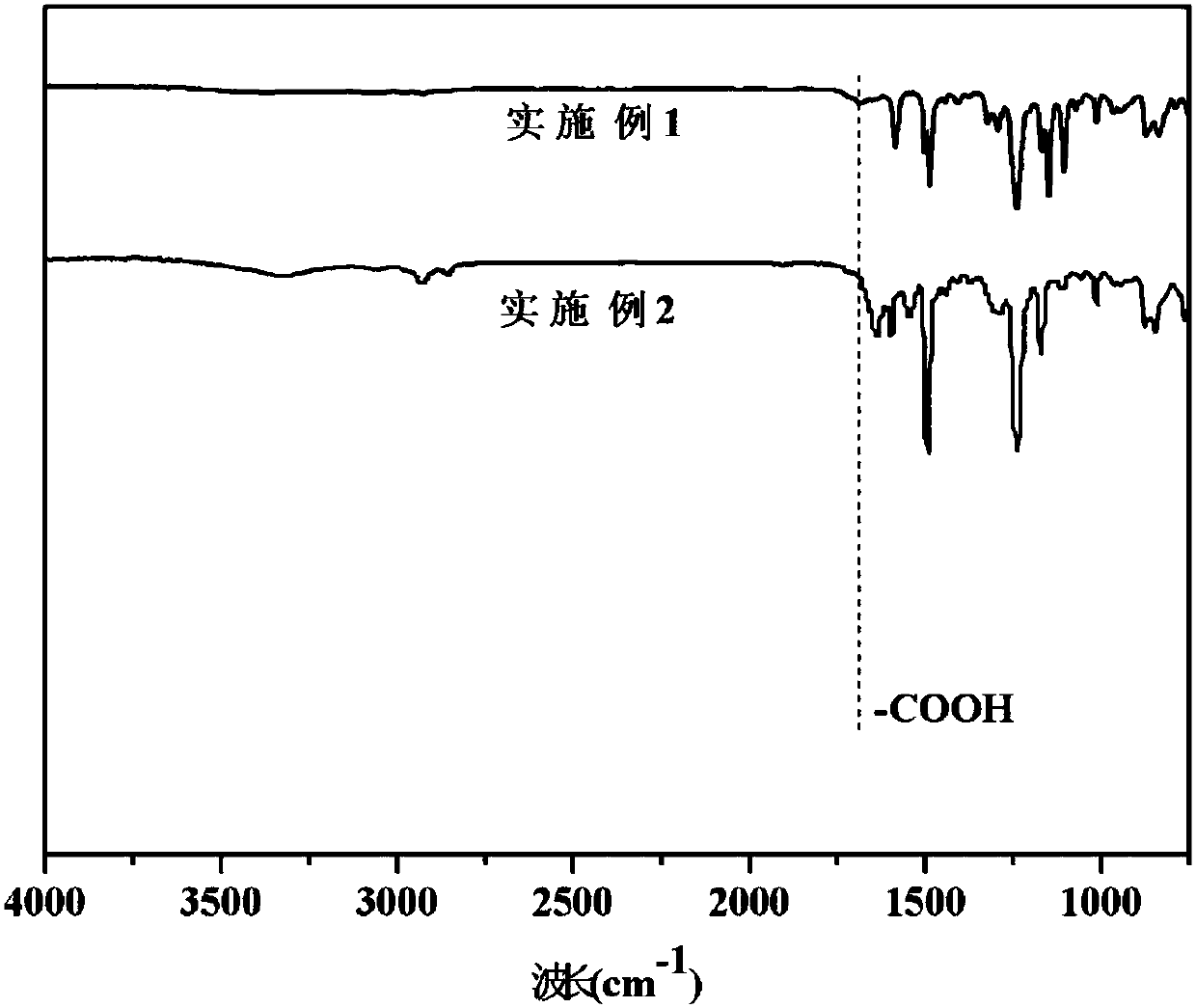

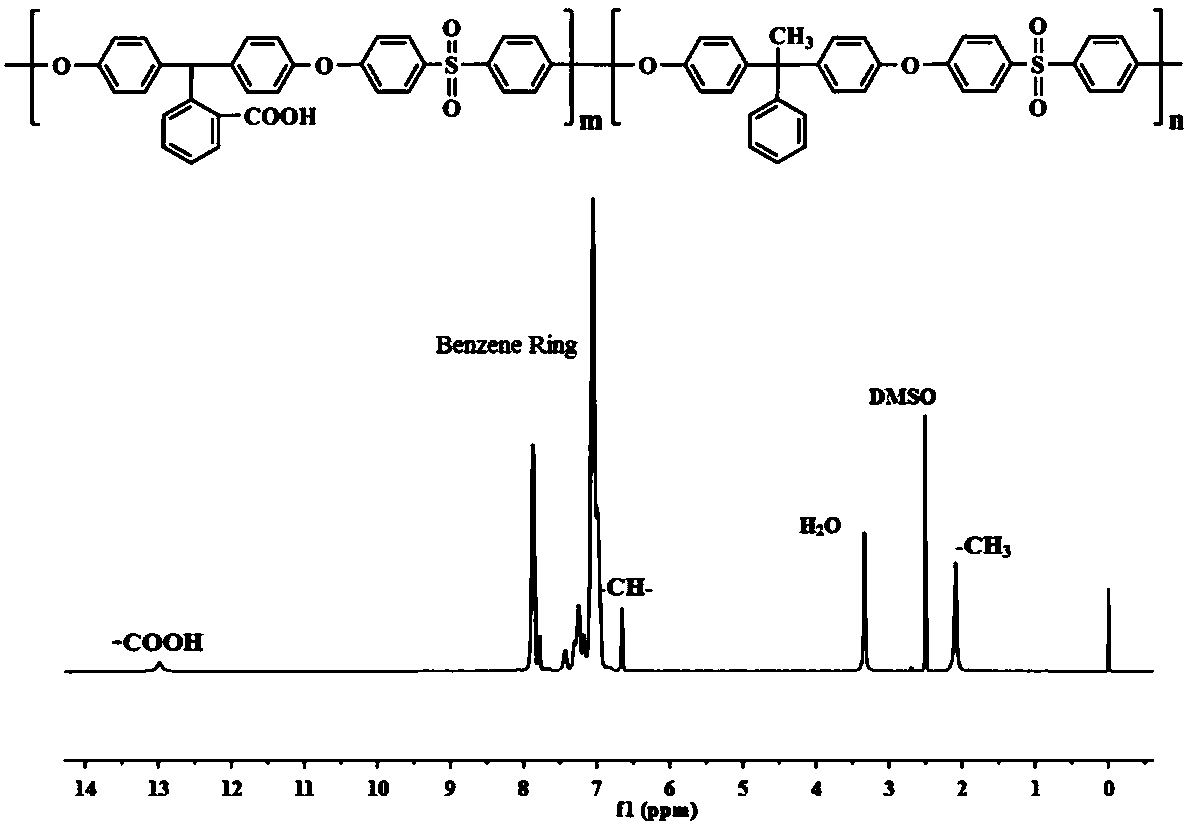

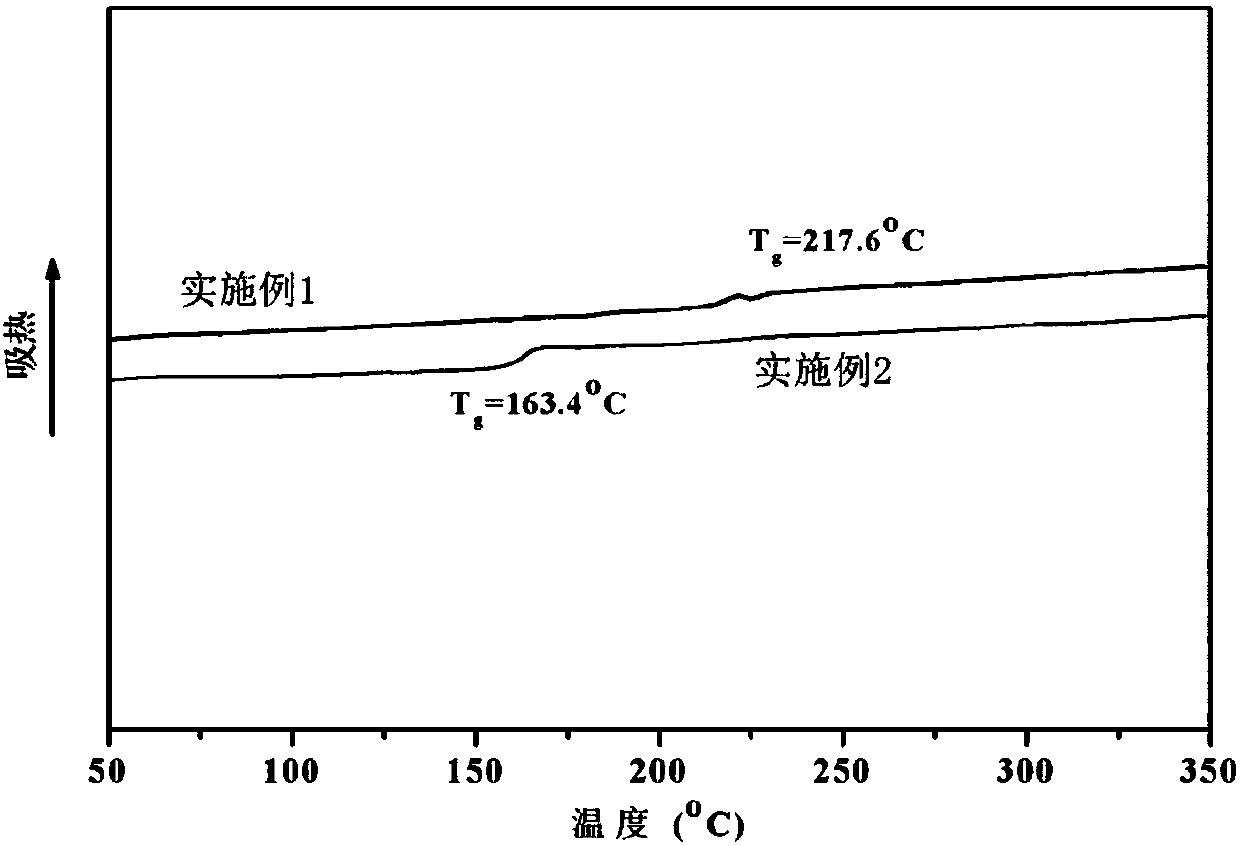

Embodiment 1

[0069] (1) Preparation of carboxyl-containing polymer crude product:

[0070] 28.7g of 4,4'-dichlorodiphenylsulfone, 1g of sodium oxalate, 5g of toluene, 2.9g of 1,1-bis(4-hydroxyphenyl)phenylethane, 2-(bis-(4- Add 28.8g of hydroxyphenyl)methyl)benzoic acid, 10.6g of sodium carbonate and 200g of 1,3-dimethyl-2-imidazolidinone into the reaction kettle, and dehydrate at 160°C for 0.5h under the protection of nitrogen , continue to react at a temperature of 190°C for 1 hour to obtain a viscous polymer solution, then cool the polymer solution to 25°C, pour it into water while stirring, and precipitate a crude polymer in a line shape;

[0071] (2) Purification of carboxyl-containing polymer crude product:

[0072] The crude polymer was boiled, drained, crushed, washed with deionized water and ethanol, filtered, and the filter cake was collected and dried at 150°C for 2 hours to obtain a purified carboxyl-containing polymer;

[0073] (3) Carboxylation of carboxyl-containing polyme...

Embodiment 2

[0085] (1) Preparation of carboxyl-containing polymer crude product:

[0086] 1,6-bis(4-fluorobenzoyl)hexamethylenediamine 36g, potassium sorbate 5g, xylene 50g, 1,1-bis(4-hydroxyphenyl)phenylethane 5.8g, 2-( 25.6g of bis-(4-hydroxyphenyl)methyl)benzoic acid, 8.2g of sodium hydroxide and 300g of N-methylpyrrolidone were added to the reaction kettle, and under the protection of nitrogen, the dehydration reaction was carried out at a temperature of 170°C for 1.5h. Continue the reaction at 200°C for 5 hours to obtain a viscous polymer solution, then cool the polymer solution to 150°C, pour it into water while stirring, and precipitate the crude polymer in line shape;

[0087] (2) Purification of carboxyl-containing polymer crude product:

[0088] The crude polymer was boiled, drained, crushed, then washed with deionized water and acetone, filtered, and the filter cake was collected and dried at a temperature of 100°C for 12 hours to obtain a purified carboxyl-containing polymer;...

Embodiment 3

[0104] (1) Preparation of carboxyl-containing polymer crude product:

[0105] 21.8g of 4,4'-difluorobenzophenone, 20g of sodium p-aminobenzenesulfonate, 60g of toluene, 4.56g of bisphenol A, 25.6g of 2-(bis-(4-hydroxyphenyl)methyl)benzoic acid g, 4.8g of lithium hydroxide and 250g of N-cyclohexylpyrrolidone were added to the reaction kettle, and under the protection of nitrogen, dehydration reaction was carried out at a temperature of 190°C for 4h, and the reaction was continued at a temperature of 230°C for 6h to obtain a viscous polymer solution. Cool the polymer solution to 60°C, pour it into water while stirring, and precipitate the crude polymer in line form;

[0106] (2) Purification of carboxyl-containing polymer crude product:

[0107] The crude polymer was boiled, drained, crushed, washed with deionized water and ethanol, filtered, and the filter cake was collected and dried at 150°C for 1 hour to obtain a purified carboxyl-containing polymer;

[0108] (3) Carboxyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com