Patents

Literature

53 results about "Thorium nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thorium nitrate can dissolve in several different organic solvents including alcohols, ketones, esters and ethers. This can be used to separate different metals such as the lanthanides. With ammonium nitrate in the aqueous phase, thorium nitrate prefers the organic liquid, and the lanthanides stay with the water.

Process for extracting and separating thorium and extracting rare earth chloride from sulfuric and phosphoric mixed acid system

InactiveCN1394971AReduce radioactive contaminationReduce negative impactRadium compoundsRare earth metal compoundsKeroseneFractionation

The present invention belongs to a process for extracting and separating thorium from sulfo-phosphoric mixed acid and extracting rare earth chloride. Said process adopts primary amine added mixed alcohol as extracting agent, and makes direct fractionation of rare earth slurry to extract thorium, and the thorium content in the separated rare earth slurry is ThO2 / REO is less than or equal to 5X10 to the minus sixth. Said invention utilizes the thorium being in organic phase and adopts countercurrent reextraction process by means of nitric acid to obtain thorium nitrate product, its purity is 99%, and thorium recovery is up to 99%. Said invention adopts magnesium oxide precipitation method to remove the iron and phosphorus in the rare earth reffinate, uses ammoniated P507-kerosene to extract organic phase.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for separating and recycling uranium, thorium and rare earth in rare earth mineral decomposition residue

ActiveCN104498739AEasy to separateEasy to industrializeProcess efficiency improvementSlagThorium nitrate

The invention discloses a method for separating and recycling uranium, thorium and rare earth in rare earth mineral decomposition residue. The method comprises the following steps: carrying out acid leaching, carrying out pressure filtration, absorbing and recycling uranium by using anion resin, separating and recycling thorium and rare earth by suing cationic resin. The method specifically comprises the following steps: leaching rare earth mineral decomposition residue by using inorganic acid; carrying out pressure filtration on the leached slag, washing the leached slag to obtain a clear material solution, absorbing uranium element of the leached material solution by using 201*7 type resin, separating elements thorium and rare earth of an uranium-removal material by using 001*7 type resin, separating and purifying uranium, thorium and rare earth, then washing, complexing, eluting, precipitating and concentrating to obtain products comprising heavy oleate, thorium nitrate and rare earth carbonate and obtain products which comprise high-purity uranium, thorium and rare earth. The extracting and recycling process is simple in device structure, low in investment, low in energy consumption and easy to operate; the industrialization is liable to implement; the direct recovery rate is 99%; precious resources can be recycled; the waste is reduced; the environment is protected.

Owner:YIYANG HONGYUAN RARE EARTH

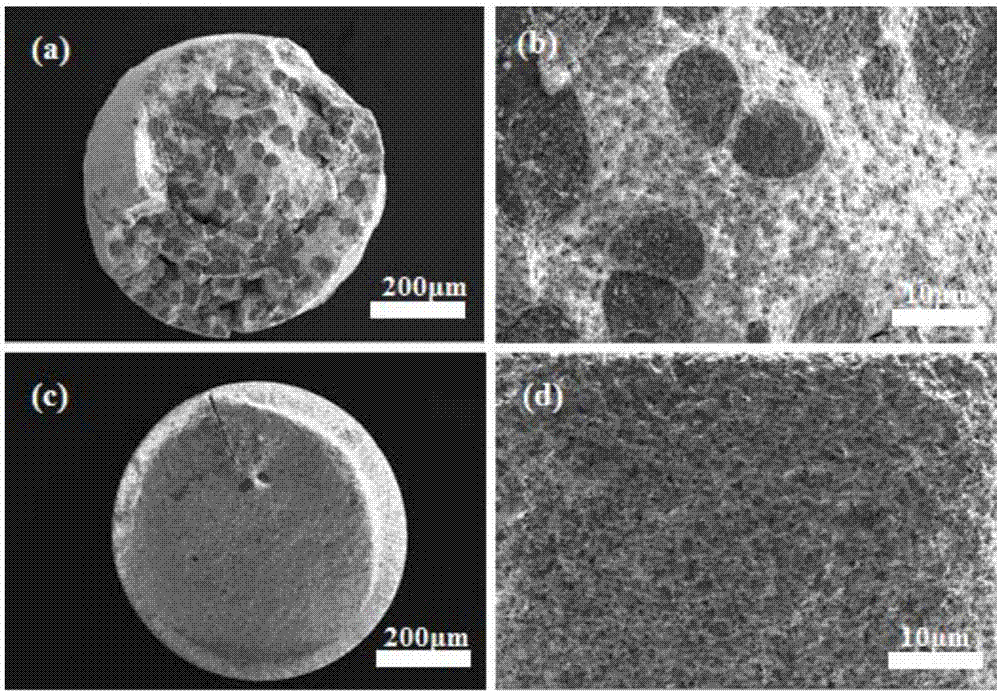

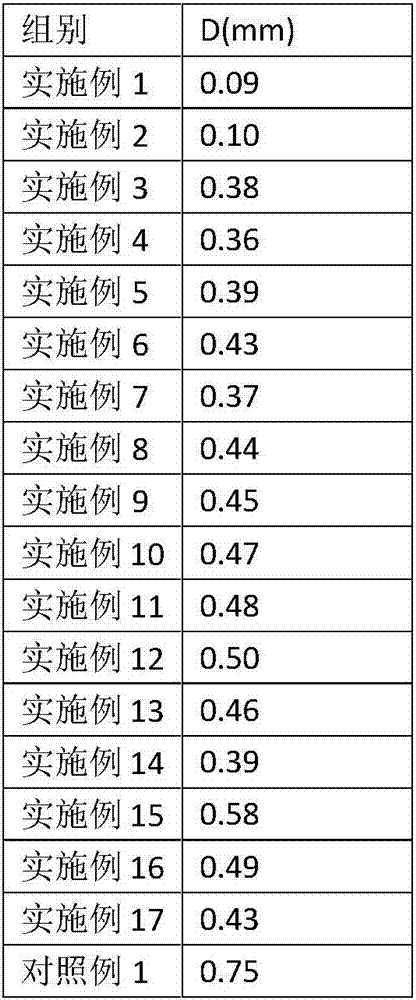

Preparation method of thorium-uranium mixed oxide ceramic microspheres

ActiveCN103165206ANo stringent requirementsFlat surfaceNuclear energy generationReactors manufactureOxide ceramicMixed oxide

The invention belongs to a preparation method of nuclear fuel, and concretely relates to a preparation method of thorium-uranium mixed oxide ceramic microspheres. The method uses an internal gelation method, and comprises using an acid-lacking uranyl nitrate solution and thorium nitrate as raw materials, preparing sol, dispersing gelling, washing, drying, calcining and reduction sintering to prepare ThO2-UO2 microspheres with a diameter of 0.05-0.20 mm. The ThO2-UO2 microspheres has outstanding advantages of smooth surface, good sphericity, compact inside, uniformly distributed thorium, and a density being greater than 96.8% TD; and the method is simple, and can prepare the thorium-uranium mixed oxide ceramic microspheres with different thorium contents.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Method for producing thorium-tungsten wire

InactiveCN101004995AUniform distribution of internal stressImprove the winding effectCold cathode manufactureThorium nitrateTungsten filament

The method includes following steps: adding certain quantity of solution of thorium nitrate into tungsten oxide so as to prepare doped powder of tungsten oxide; deoxidizing the obtained doped powder of tungsten oxide to obtain powder of thorium - tungsten; acid cleaning powder of thorium - tungsten to remove impurity, and producing sintered body of powder of thorium - tungsten; using press work to obtain thorium -tungsten filament with needed diameter, and content of thorium dioxide being 0.7-1.1 wt%, and enwinding thorium -tungsten filament by using wire coil; Finally, straightening filament. The invention raises the rate of finished products, and optimizes working performance of tungsten winding.

Owner:兆恒威勒(石门)钨业有限公司

Molten gold resisting high-temp sinter and its preparing process

A gold solution resisting high-temp sinter for ceramic decoration contains Au (10-15 wt.%), Th (2.2-3.0), Rh (0.1-0.3), Sb (0.1-0.8), Pb (0.3-0.4), Bi (1.0-1.4) and mixed solvent. It is prepared through preparing resinates of thorium nitrate, RhO3 and SbCl3, mixing them together; preparing gold ammonium percloride from AuCl3, reaction on balsam sulfide to obtain gold resinate; preparing resinatesof lead nitrate and bismuth nitrate, mixing them together; mixing said three components together, and diluting with mixed solvent.

Owner:NANJING UNIV

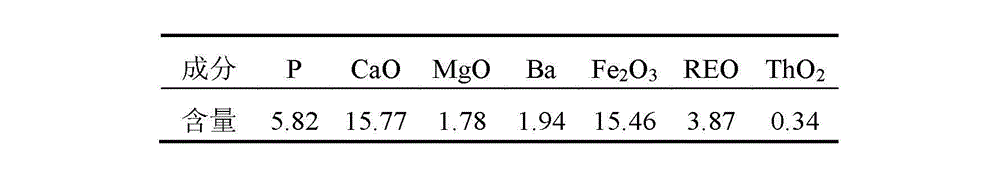

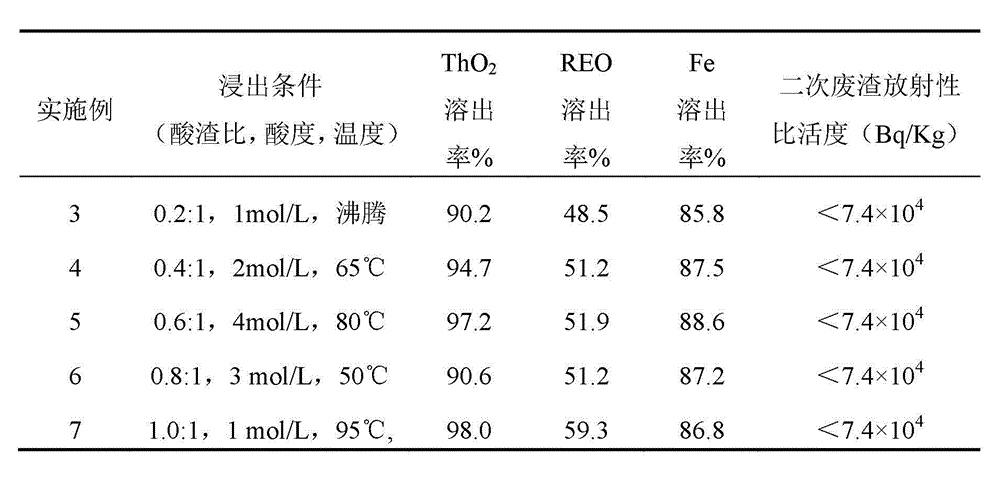

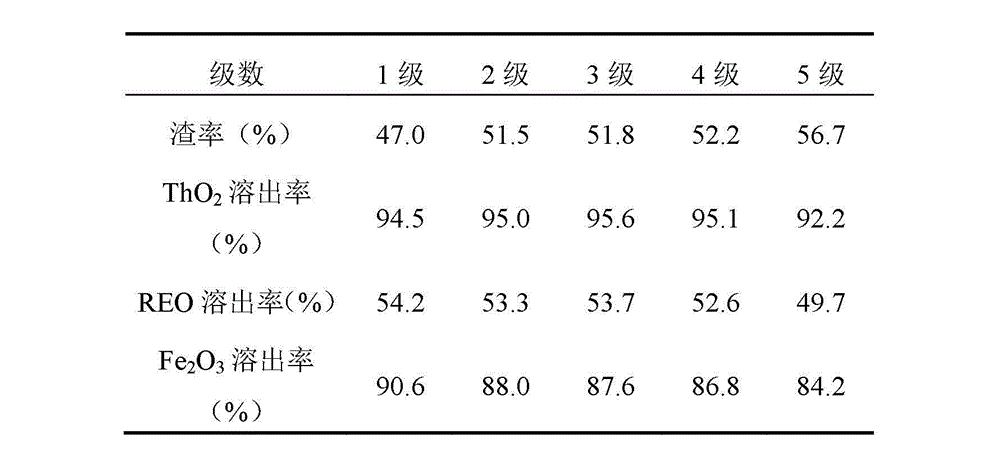

Method for recovering rare earth, thorium and iron in waste residue of rare earth acid technological process

InactiveCN103184343AAchieve leaching recoveryTo achieve the purpose of comprehensive recyclingProcess efficiency improvementLiquid productPregnant leach solution

The invention relates to a method for recovering rare earth, thorium and iron in waste residue of a rare earth acid technological process. The method is characterized by comprising the following steps: using the waste residue produced in the rare earth acid technological process as a raw material; according to the ratio of the acid to the residue of (0.2-1.0):1, mixing the waste residue of the rare earth acid technological process with one or more of HCl solution, H2SO4 solution and HNO3 solution with the concentration of 1mol / L-4mol / L; performing agitation leaching at a temperature of 60 DEG C to boiling temperature, wherein a leaching finishing point is determined based on the percentage content of ThO2 less than 0.05% and specific radioactivity small than 7.4*104 Bq / Kg in secondary waste residue; filtering and washing a filter cake to obtain a leaching solution and the secondary waste residue; enabling the leaching solution to be a thorium nitrate solution after being subjected to primary amine extraction and nitric acid reverse extraction; using alkali to adjust the pH value of surplus raffinate to be 4.5-5.5 so as to precipitate Fe(OH)3 by-products; and obtaining filter liquor namely rare feed liquid products. The method has the advantages that dissolving out of REO, ThO2 and Fe in the waster residue by water logging is realized; the amount of the secondary waste residue is reduced below 50 % of the amount of the original residue; and the content of the ThO2 is less than 0.05 percent and the specific radioactivity is small than 7.4*104 Bq / Kg in the secondary waste residue.

Owner:BAOTOU RES INST OF RARE EARTHS +1

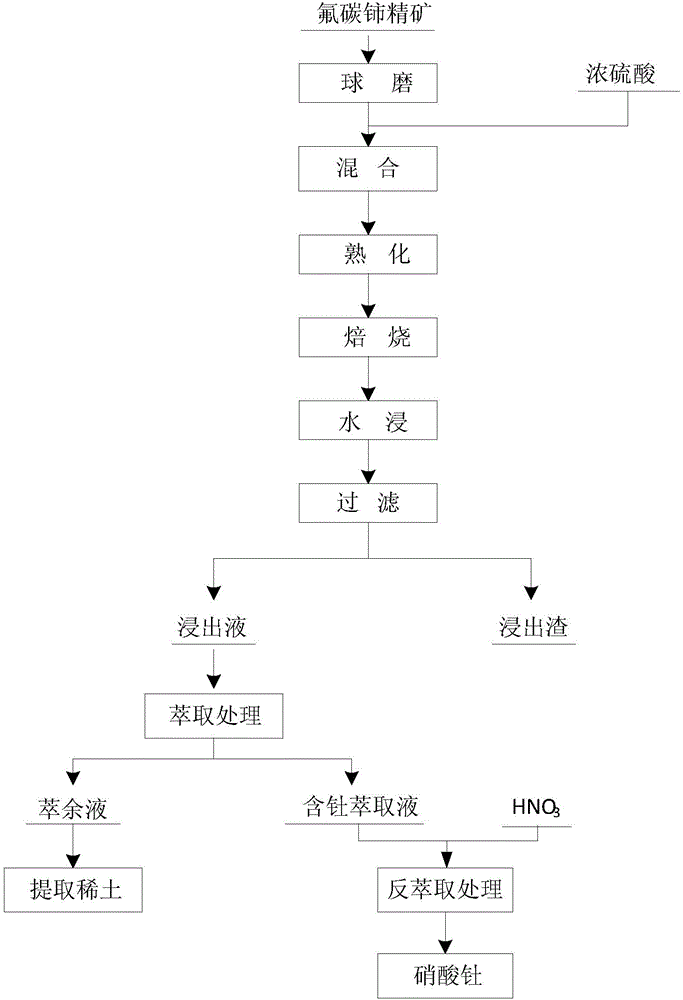

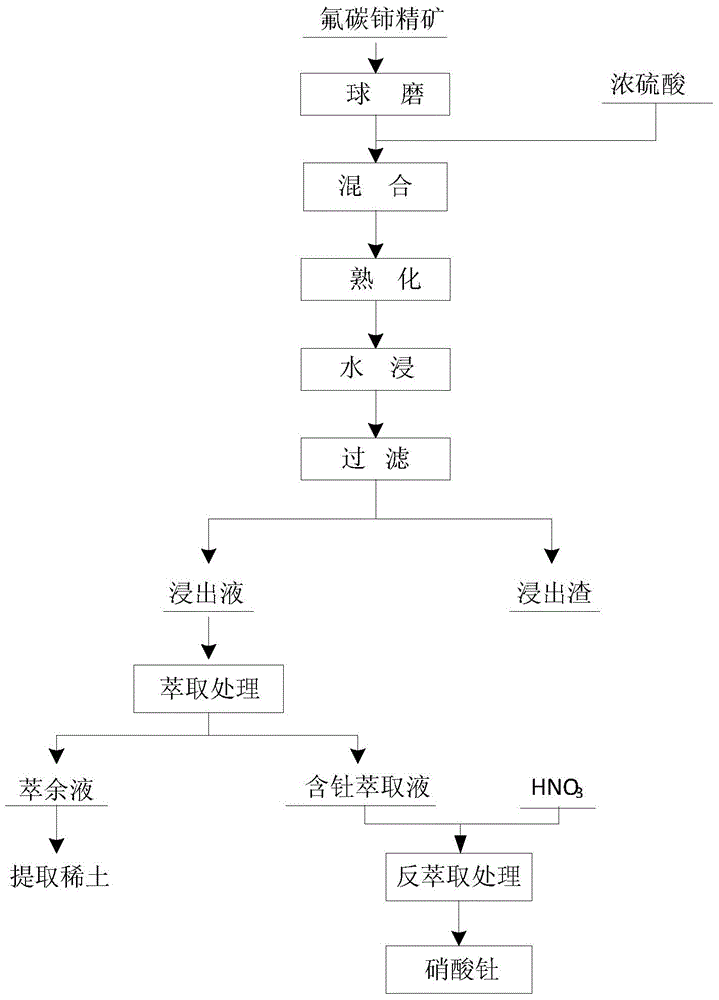

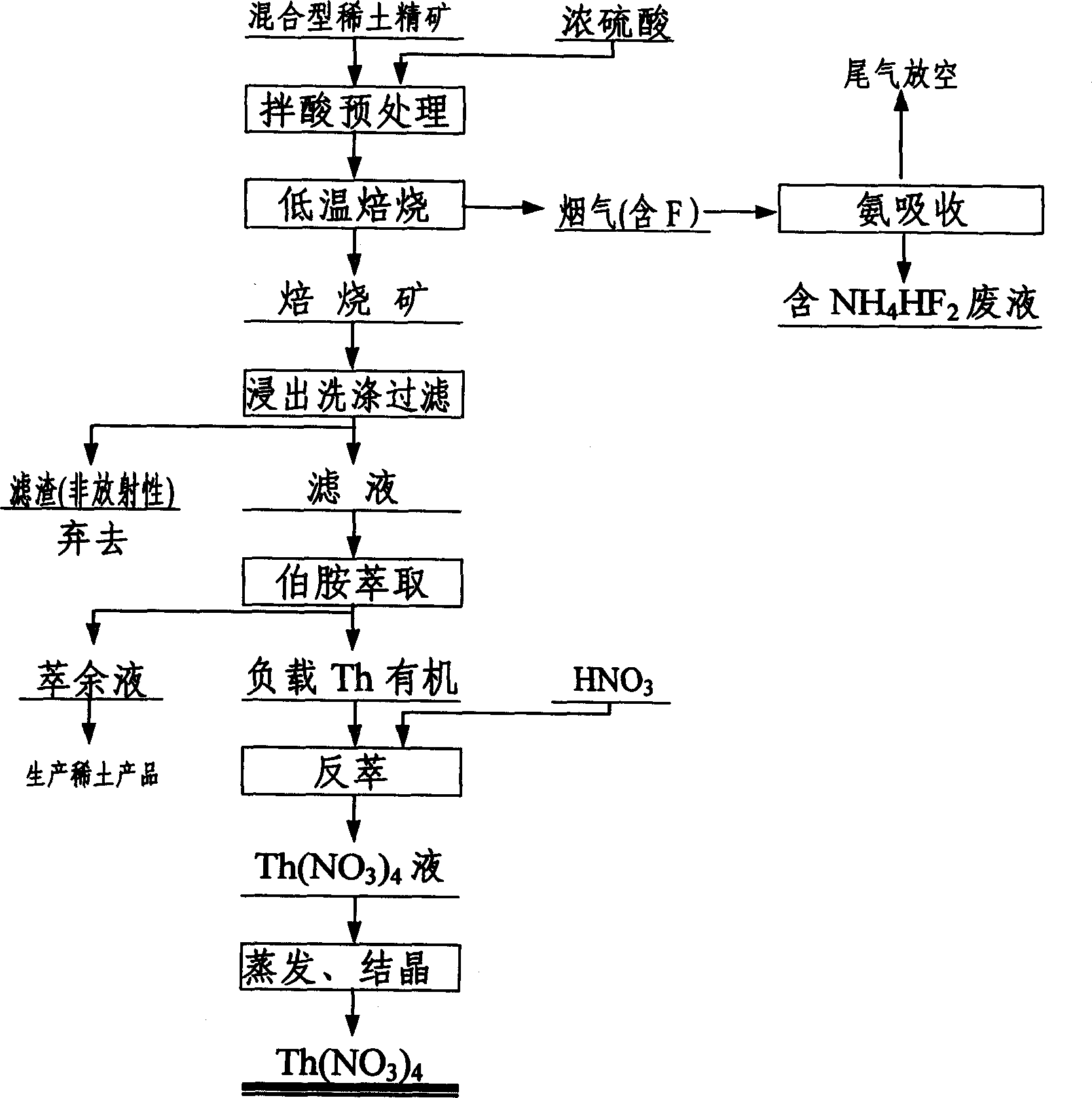

Processing method of fine bastnaesite

The invention discloses a processing method of fine bastnaesite. The processing method comprises the following steps: (1) carrying out ball-milling treatment on fine bastnaesite, so as to obtain fine bastnaesite particles; (2) mixing the fine bastnaesite particles with concentrated sulfuric acid, and curing, so as to obtain cured ores; (3) roasting the cured ores, so as to obtain roasted ores; (4) carrying out slurry mixing, water leaching and filtration on the roasted ores, so as to obtain leachate and leached slag; (5) extracting the leachate, so as to obtain rare earth and thorium-containing extraction liquid; (6) carrying out back extraction on the thorium-containing extraction liquid, so as to obtain thorium nitrate. By virtue of the processing method, Sichuan fine bastnaesite can be effectively processed, furthermore, the flow is simple, the REO leaching rate is high, the energy consumption is low, the consumption of auxiliary materials is low, meanwhile, the content of radioactive thorium is greatly decreased into a standard range, fluorine and radioactive thorium are not emitted in the whole process, the leached slag can be directly emitted after being washed, the environment is protected, furthermore, rare earth can be effectively separated, and fluorine and thorium resources can be comprehensively utilized, so that the processing method is a novel clean production process for metallurgical treatment of fine bastnaesite.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

Method for treating bastnasite concentrate

InactiveCN104946887ALess investmentReduce generationProcess efficiency improvementFiltrationWater immersion

The invention discloses a method for treating bastnasite concentrate. The method comprises the following steps: (1) conducting ball-milling treatment on the bastnasite concentrate to obtain bastnasite concentrate particles; (2) mixing the bastnasite concentrate particles with concentrated sulfuric acid to cure the bastnasite concentrate particles so as to obtain cured ore; (3) conducting slurry mixing on the cured ore, and conducting water immersion and filtration so as to obtain leach liquor and leach residue; (4) conducting extraction treatment on the leach liquor to obtain tombarthite and thorium containing extract liquor; (5) conducting reverse extraction treatment on the thorium containing extract liquor to obtain thorium nitrate. According to the method, Sichuan bastnasite concentrate can be effectively treated, the process is simple, the REO leaching rate is high, the energy consumption is low, the auxiliary material consumption is less, the radioactive thorium content is greatly reduced in the standard range, the fluorine and radioactive thorium emission in the whole process can be avoided, the leach residue can be directly discharged after being subjected to water washing, the environment can be protected, the tombarthite can be efficiently separated, the fluorine and thorium resources can be comprehensively utilized, and the method is a clean and new production process for metallurgical treatment of the bastnasite concentrate.

Owner:CHINA ENFI ENGINEERING CORPORATION

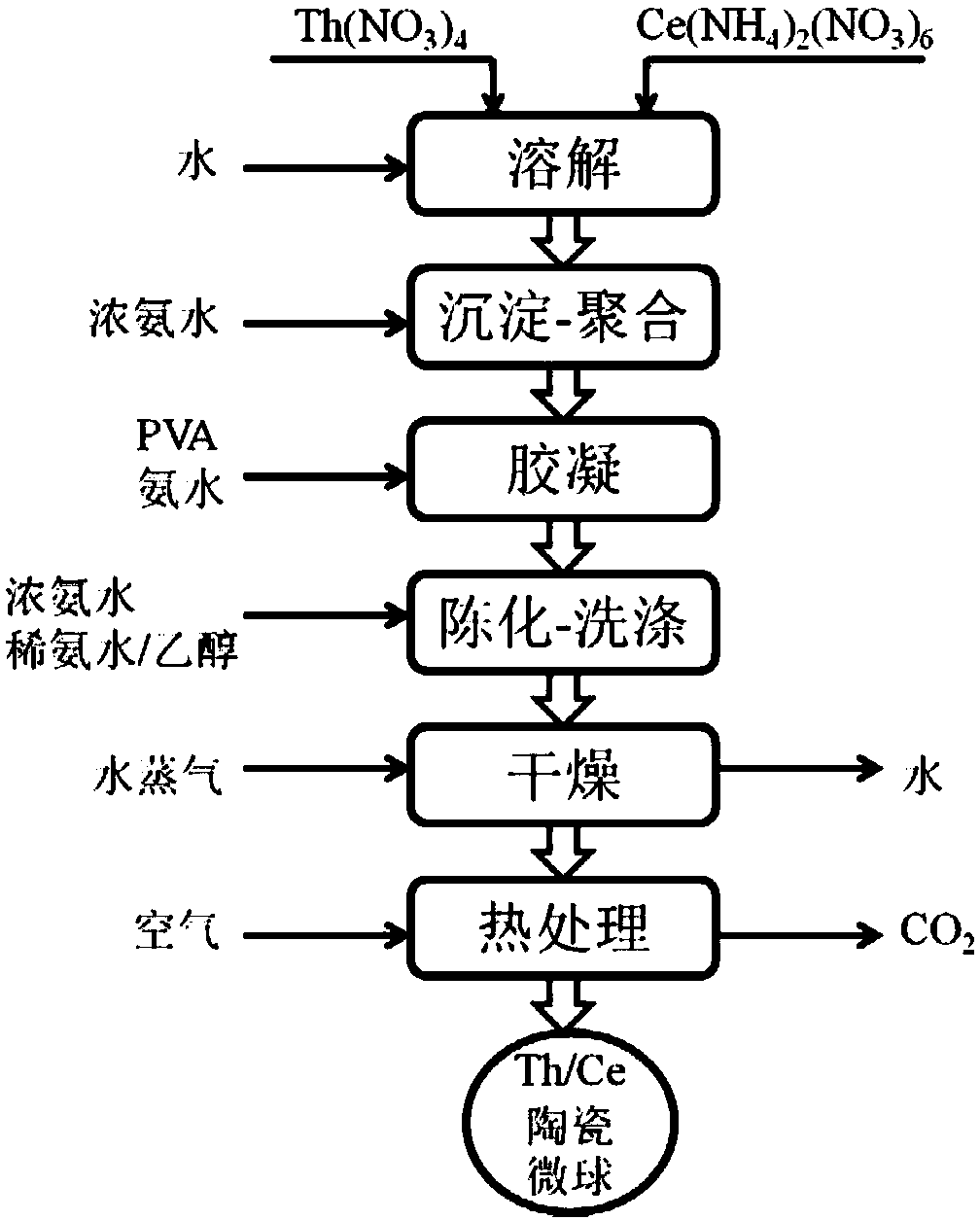

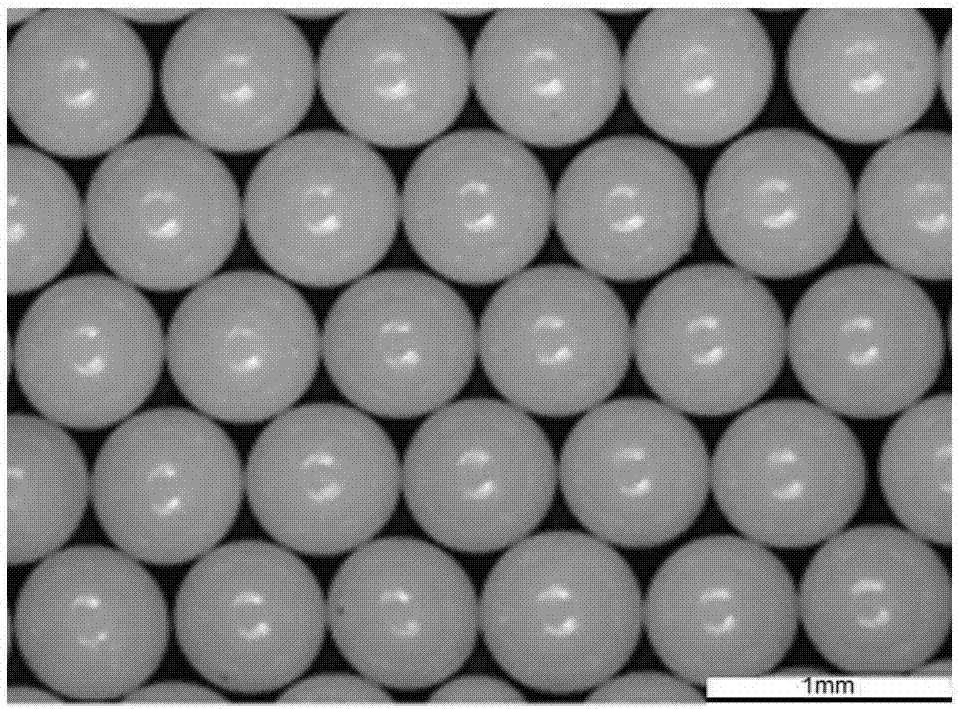

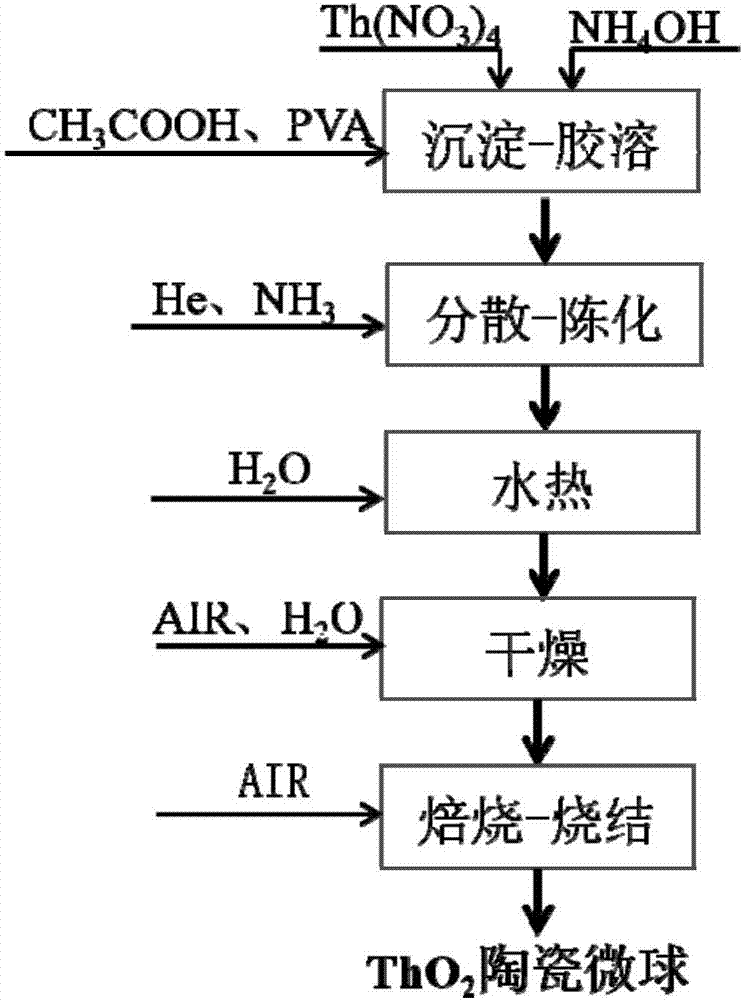

Preparation method of thorium-based mixed oxide ceramic microsphere

ActiveCN107833645AGuaranteed mechanical strengthAvoid deformationNuclear energy generationReactors manufactureAir atmospherePolyvinyl alcohol

The invention relates to a preparation method of a thorium-based mixed oxide ceramic microsphere. The preparation method comprises the following steps of under the conditions of heating and stirring,adding cerous ammonium nitrate or uranyl nitrate and plutonium nitrate solid into a thorium nitrate solution to form a mixed solution, using ammonium hydroxide to adjust the pH (potential of hydrogen)value to form a hydrolysis solution, adding a thickener (polyvinyl alcohol solution) into the hydrolysis solution, and stirring, so as to form a thorium-based mixed sol solution; enabling an exciterto disperse the thorium-based mixed sol solution into liquid droplets, sequentially sending into an air section and an ammonia gas section, and finally sending into the ammonium hydroxide to form a gel microsphere; heating and aging the gel microsphere in concentrated ammonium hydroxide, alternatively washing by ethyl alcohol and thin ammonium hydroxide, washing by deionized water, flatly paving the single layer of washed gel microspheres in a drying furnace, and leading water vapor to heat and dry, so as to obtain the dried gel microsphere; placing the gel microsphere into a sintering furnace, and heating and sintering in an air atmosphere, so as to obtain the mixed oxide ceramic microsphere. The preparation method has the advantage that the fuel with uniform distribution of elements canbe prepared.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Doping method for powder for magnetic control coil

The invention provides a doping method for powder for a magnetic control coil, belonging to the field of powder metallurgy manufacturing. The process of the invention comprises the steps of doping, stirring, steam drying and the like and is characterized by comprising the following concrete steps of: adding neutral additive of aqueous ammonia NH3.H2O to a thorium nitrate solution; evenly sprayingthe prepared mixed solution to the surface of blue tungsten WO2.9 in a doping pot and stirring; vacuumizing the doping pot and heating by water, and stirring while heating; and drying the powder by adopting a steam heating method under the vacuum state to finally obtain thorium-doped tungsten powder with even doping and low impurity content.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

Method for preparing ceramic micro-spheres of thorium oxide

ActiveCN107010955AReduce the probability of ruptureAvoid breakingNuclear energy generationReactors manufacturePolyvinyl alcoholThorium oxide

The invention relates to a method for preparing ceramic micro-spheres of thorium oxide. The method includes dropwise adding ammonia water into thorium nitrate solution to form hydrolysis solution, dropwise adding glacial acetic acid into the hydrolysis solution to regulate the pH (potential of hydrogen) of the hydrolysis solution, and adding polyvinyl alcohol into the hydrolysis solution under stirring conditions to form thorium oxide colloidal solution; dispersing the thorium oxide colloidal solution to obtain liquid drop and allowing the liquid drop to sequentially flow through helium zones, ammonia gas zones and ammonia water zones; arranging dispersed gel particles in strong ammonia water and aging the dispersed gel particles; adding the aged gel particles and deionized water into a hydrothermal reaction kettle and carrying out temperature reaction; placing gel particles into a drying furnace after hydrothermal reaction is carried out on the gel particles, and heating and drying the gel particles under humidity control to form dried gel particles; placing the dried gel particles in a calcination furnace, filling the calcination furnace with air and heating and calcining the gel particles to obtain calcined gel particles; placing the calcined gel particles in a sintering furnace, filling the sintering furnace with air and heating and sintering the calcined gel particles to obtain the ceramic micro-spheres. The method has the advantage that the ceramic micro-spheres of the thorium oxide can be prepared by the aid of simple technologies.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Mixed rare earth concentrate decomposition method

ActiveCN1286995CPromote decompositionImprove decomposition rateDispersed particle separationProcess efficiency improvementRare earthThorium nitrate

This invention provides a rare earths finished ore decomposition method. It includes following procedures (1) rare earths finished ore and concentrated oil of vitriol are blending as weight rate 1:1.1~1.7. (2) The rare earths finished ore after blending is slaked at 40~1800C. (3) The terrae rare finished ore after slaking is baked 1~8 hours at 150~3300C. (4) Baking ore is dunked by water to make 95% of rare earths and thorium entering solution, then they are separated by extraction, thorium nitrate product is got after scrubbing and reverse extraction, rare earths product not contain thorium is got after the solution extracted precipitating. (5) Fume generated by baking is discharged after defluorinated by ammonia or water scrubbing. (6) The residue from dunking is discharged after water scrubbing. Radioactive waste residue, waste water and waste gas contain fluorin and other problem brought by rare earths extraction can be solved by taking this invention to propose rare earths finished ore. It reaches country discharge standard and can realize cleaning production.

Owner:中国有色工程设计研究总院 +1

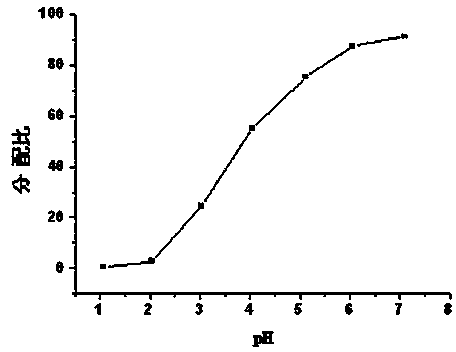

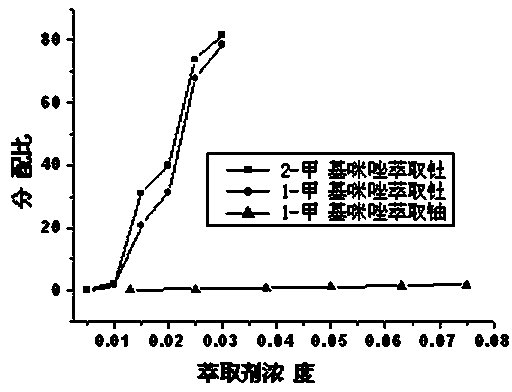

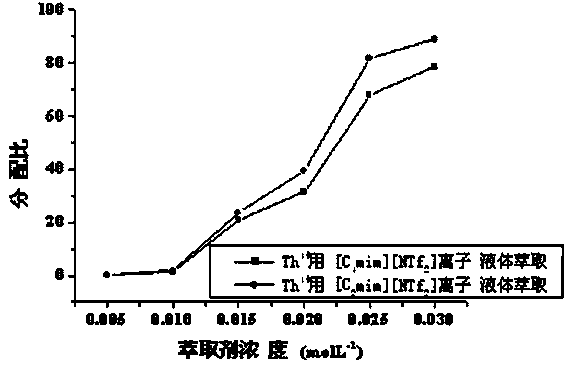

Method for separating uranium and thorium and reagent used for separation

InactiveCN103451426AAvoid adjustmentAvoid Co-Extraction Reagent InsufficiencyIonic liquidMethyl palmoxirate

The invention discloses a method for separating uranium and thorium and an extraction agent used for separation. According to the method, uranium and thorium nitrate mixed aqueous solution is placed in imidazolyl ionic liquid diluent in which the reagent is dissolved or n-amyl alcohol diluent in which the reagent is dissolved, thorium is extracted, and uranium stays in an aqueous phase. The extraction agent used for separation is1-methylimidazole showed in a first formula or 2-methylimidazole showed in a second formula. The method and the reagent have the advantages that the extraction agent is cheap and can be obtained easily, an extraction system is simple, extraction efficiency is high, the number of used extraction agents is small, and specificity is strong.

Owner:LANZHOU UNIVERSITY

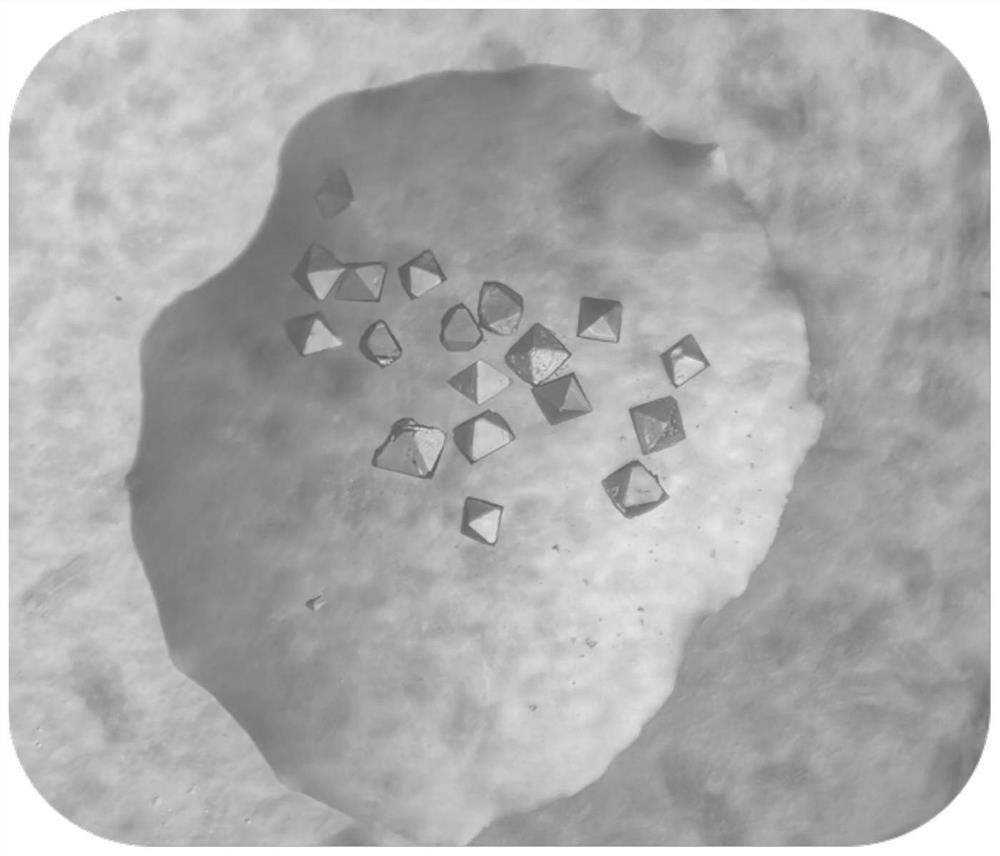

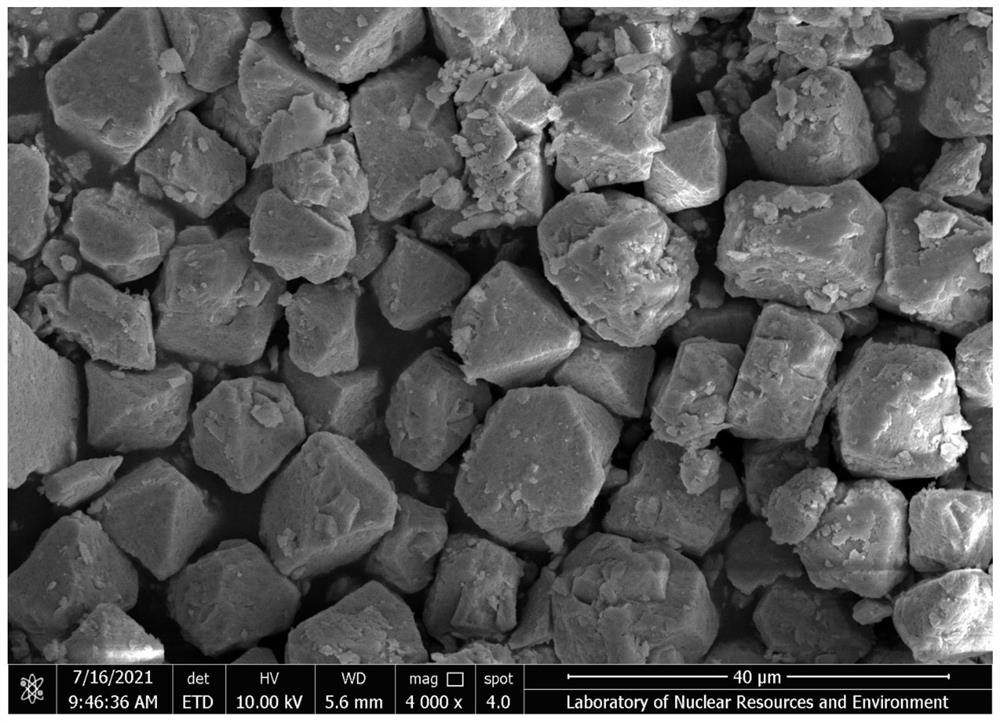

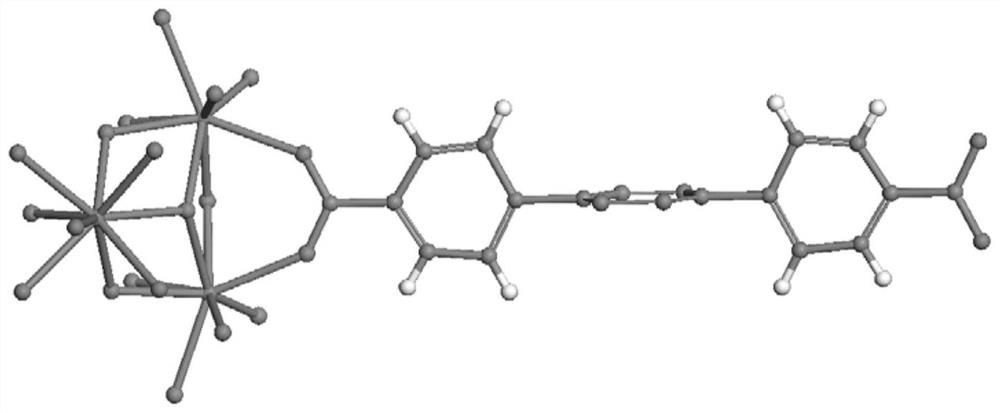

Thorium-based metal organic framework material and preparation method and application thereof

The invention discloses a thorium-based metal organic framework material and a preparation method and application thereof. The structural unit of the material is [Th6O4(OH)4(tpda)6], and tpda represents terphenyl dicarboxylic acid anions without two hydroxyl H atoms. The method comprises the following steps: uniformly mixing terphenyl dicarboxylic acid ligand, thorium nitrate tetrahydrate metal salt and tetramethylguanidine chloride ionic liquid step by step, and reacting under a heating condition through self-generated pressure to obtain crystals of the thorium-based metal organic framework material. The preparation method is simple and rapid, metal thorium is not agglomerated with the polydentate carboxylic acid ligand tpda, abundant coordination geometric structures and more leading-edge electron orbits can be formed, formation of different secondary building units and topology types is promoted, and the prepared thorium-based metal organic framework material is clear and stable in crystal structure, high in purity and suitable for industrial production. The method can be better applied to analysis and research of MOFs crystal structures, and has a wide application prospect in the field of adsorption and separation of radionuclides.

Owner:EAST CHINA UNIV OF TECH

Technology for extraction and separation of thorium and rare earth

ActiveCN106381406AHigh separation factorImprove separation efficiencyProcess efficiency improvementHigh concentrationResource utilization

The invention provides a technology for extraction and separation of thorium and rare earth, wherein the technology comprises the steps: firstly, dissolving prior dissolved slag produced in a monazite treatment alkaline-process technology by using hydrochloric acid to obtain a material liquid containing thorium, rare earth and uranium; taking P350 as an extractant, extracting and separating thorium and rare earth in the material liquid containing thorium and rare earth in a high-acidity hydrochloric acid system, to obtain a thorium-loaded organic phase and a raffinate; washing the thorium-loaded organic phase with high-acidity HCl, then carrying out back extraction by using a solution containing HNO3 and NaNO3 to obtain Th(NO3)4 back-extracted solution; and allowing the raffinate containing rare earth and high-concentration hydrochloric acid and obtained from extraction and separation to return to a prior dissolving process. The separation coefficient of thorium and rare earth can be effectively improved in the high-acidity extraction system, the separation efficiency is improved, the separation effect of rare earth and thorium is improved, high-purity thorium nitrate is obtained, rare earth and other valuable elements in the raffinate are comprehensively recycled, the hydrochloric acid in the raffinate is comprehensively utilized, the utilization rate of resources is improved, the postprocessing process is reduced, environment pollution is reduced, and the comprehensive utilization of the resources is achieved.

Owner:永州市湘江稀土有限责任公司

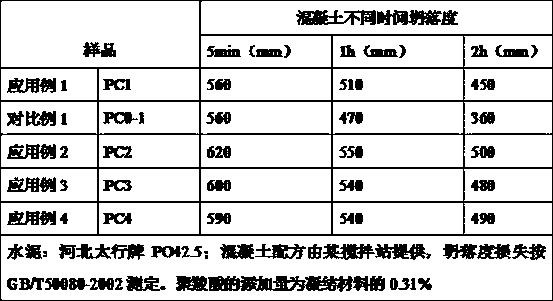

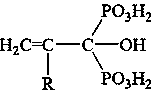

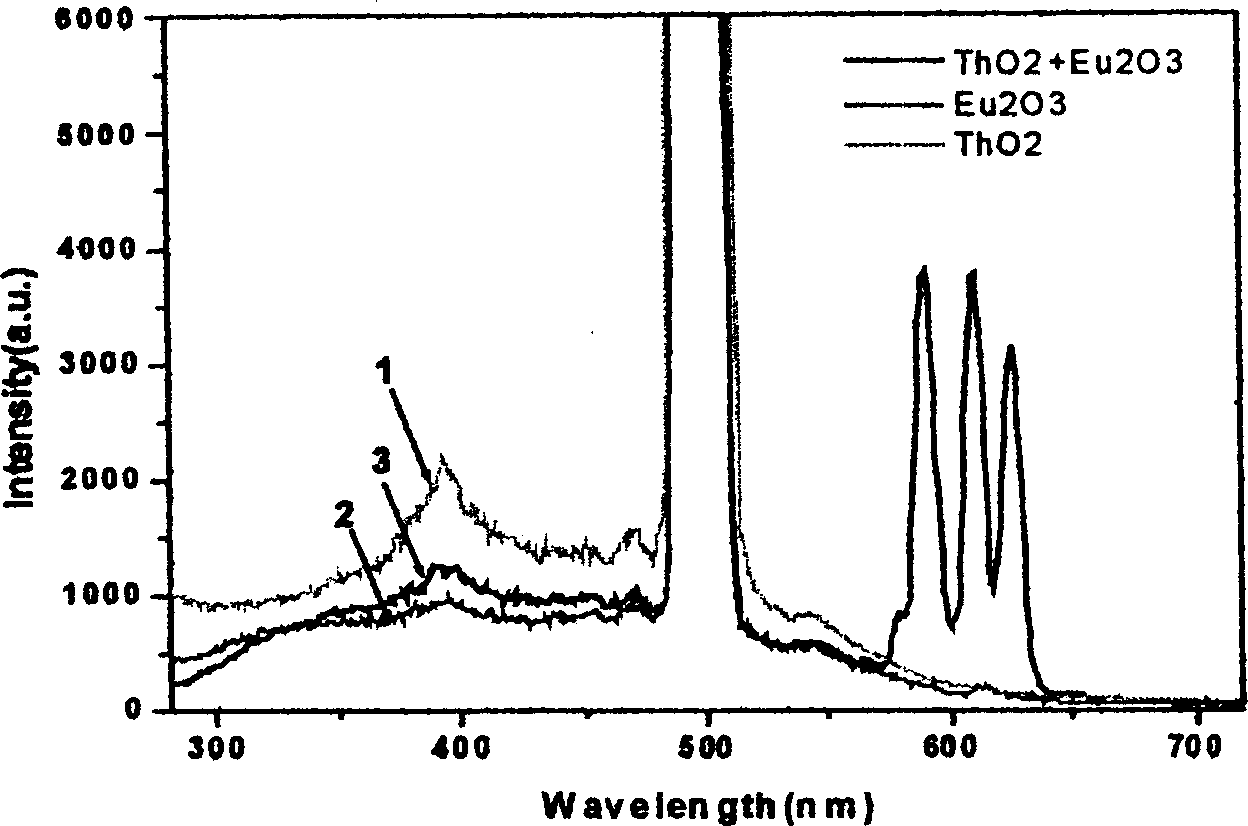

A kind of terminal ethylenically unsaturated phosphonic acid monomer and its preparation method

ActiveCN106905362BHigh polymerization activityGood dispersionGroup 5/15 element organic compoundsPhosphateDistillation

The invention relates to an alkenyl-terminated unsaturated phosphonic acid monomer and a preparation method thereof. The monomer has the structure shown in the following formula, wherein R represents -H or -CH3. The method comprises the steps as follows: unsaturated carboxylic acid and a polymerization inhibitor are added to a reaction flask, then phosphorus trichloride is dropwisely added, the mixture is stirred continuously to react at the controlled temperature, the obtained system is heated slowly for a reflux reaction, the obtained system is slowly heated and reacts at the constant temperature, a lower layer product is subjected to reduced pressure distillation after the reaction ends, unsaturated carboxylic acid and residual HCl are removed, the content of the product is analyzed with a rapid thorium nitrate titration method, the yield is calculated, and an aqueous solution is prepared. A phosphate group is introduced while the high polymerization activity of double bonds of unsaturated acid is reserved, and a polycarboxylate superplasticizer with high dispersibility, high slump retention and high adaptability is acquired through polymerization with acrylic acid and alkenyl polyoxyethylene ether macromonomers.

Owner:河北凯瑞化工有限公司

Process for preparing europium oxide doped inorganic lighting material

InactiveCN1752178AEasy to operateConditions are easy to controlLuminescent compositionsRare earthThorium nitrate

Owner:XIAMEN UNIV

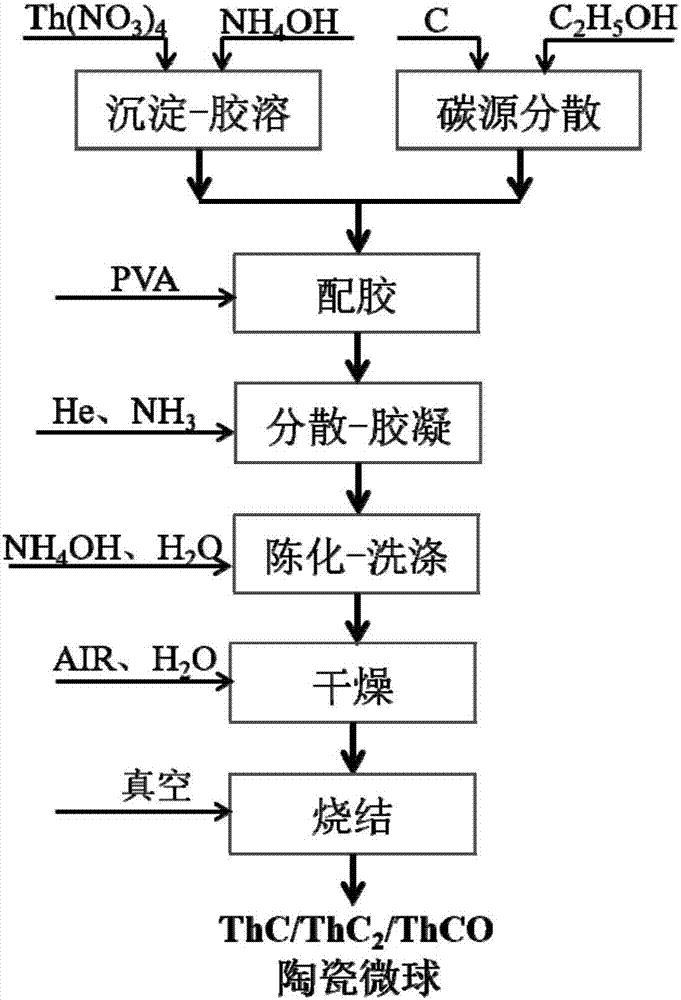

Method for preparing ceramic microspheres of thorium-based carbides and/or thorium-based oxycarbides

ActiveCN107134299AReduce the probability of ruptureNo crackNuclear energy generationReactor fuel susbtancesMicrosphereHydrolysis

The invention relates to a method for preparing ceramic microspheres of thorium-based carbides and / or thorium-based oxycarbides. The method comprises the following steps: dripping a thorium nitrate solution into ammonium hydroxide so as to form a hydrolysis solution; adding polyvinyl alcohol while stirring the hydrolysis solution so as to form sol; dispersing carbon powder by utilizing an organic reagent which is mutually soluble with water so as to form pre-dispersed carbon powder; adding the sol into the pre-dispersed carbon powder so as to form a carbon-containing colloidal solution; dispersing the carbon-containing colloidal solution into liquid drops, and enabling the liquid drops to sequentially pass through a helium area, an ammonia gas area and an ammonium hydroxide area so as to form gel particles; ageing the gel particles in stronger ammonia water, washing with deionized water, adding the washed gel particles into a drying furnace, controlling the humidity, heating and drying so as to form the dried gel particles; and adding the dried gel particles into a sintering furnace, heating and sintering under vacuum conditions, thereby obtaining the ceramic microspheres. According to the preparation method disclosed by the invention, the ceramic microspheres of thorium-based carbides and / or thorium-based oxycarbides are prepared through a simple process.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Method for preparing aqueous solution of neutral negative oxygen ions

PendingCN110272064AImprove sustained releaseResolve Material EffectsOther chemical processesRadium compoundsThermal insulationThorium nitrate

The invention discloses a method for preparing an aqueous solution of neutral negative oxygen ions. The method comprises the steps: performing a reaction on monazite concentrate and a sodium hydroxide aqueous solution of 45-55% at a temperature of 130-150 DEG C for 4.5-5.5 h so as to obtain a reactant with a mass ratio of alkaline to ore at (1:1)-(1:1.5), then diluting the reactant by using hot water of 80-100 DEG C, performing thermal insulation aging at 60-80 DEG C, performing separation so as to obtain a monazite alkali-soluble cake, then dissolving the alkali-soluble cake completely by using nitric acid, then extracting uranium thorium by using tributyl phosphate of 25-35%, performing reverse extraction by using pure water after introduction of uranium thorium into an organic phase so as to obtain a strip liquid of uranium thorium, performing concentration, then extracting uranium by using tributyl phosphate of 5.5-6.5%, extracting thorium by using a TBP kerosene liquid of 35-45%, and then performing reverse extraction, concentration and crystallization so as to obtain thorium nitrate. Through the colorless transparent neutral aqueous solution of the negative oxygen ions, influence and damage of an original acidic solution on the material of an attached substance are avoided.

Owner:广州曜科环保科技有限公司

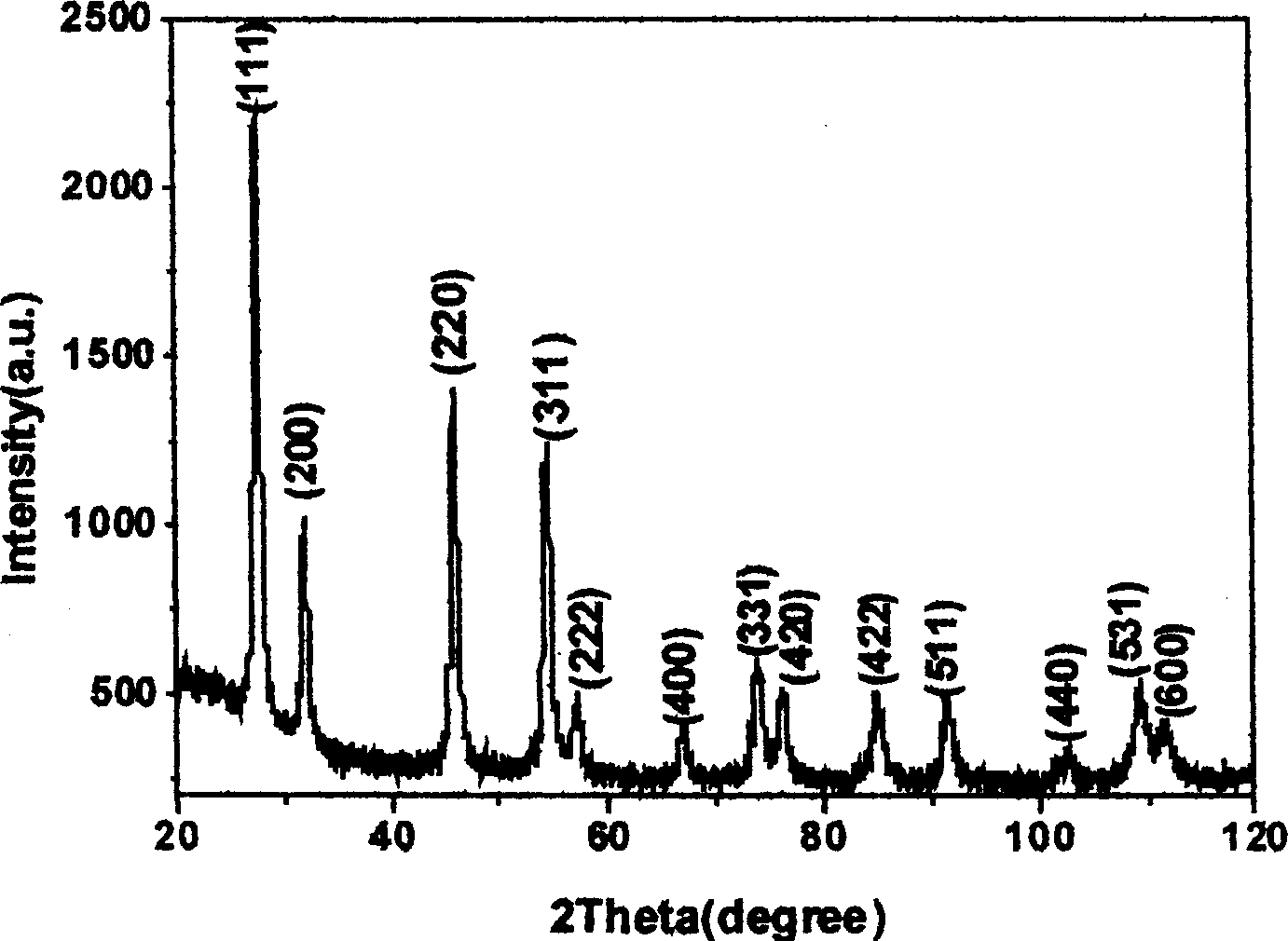

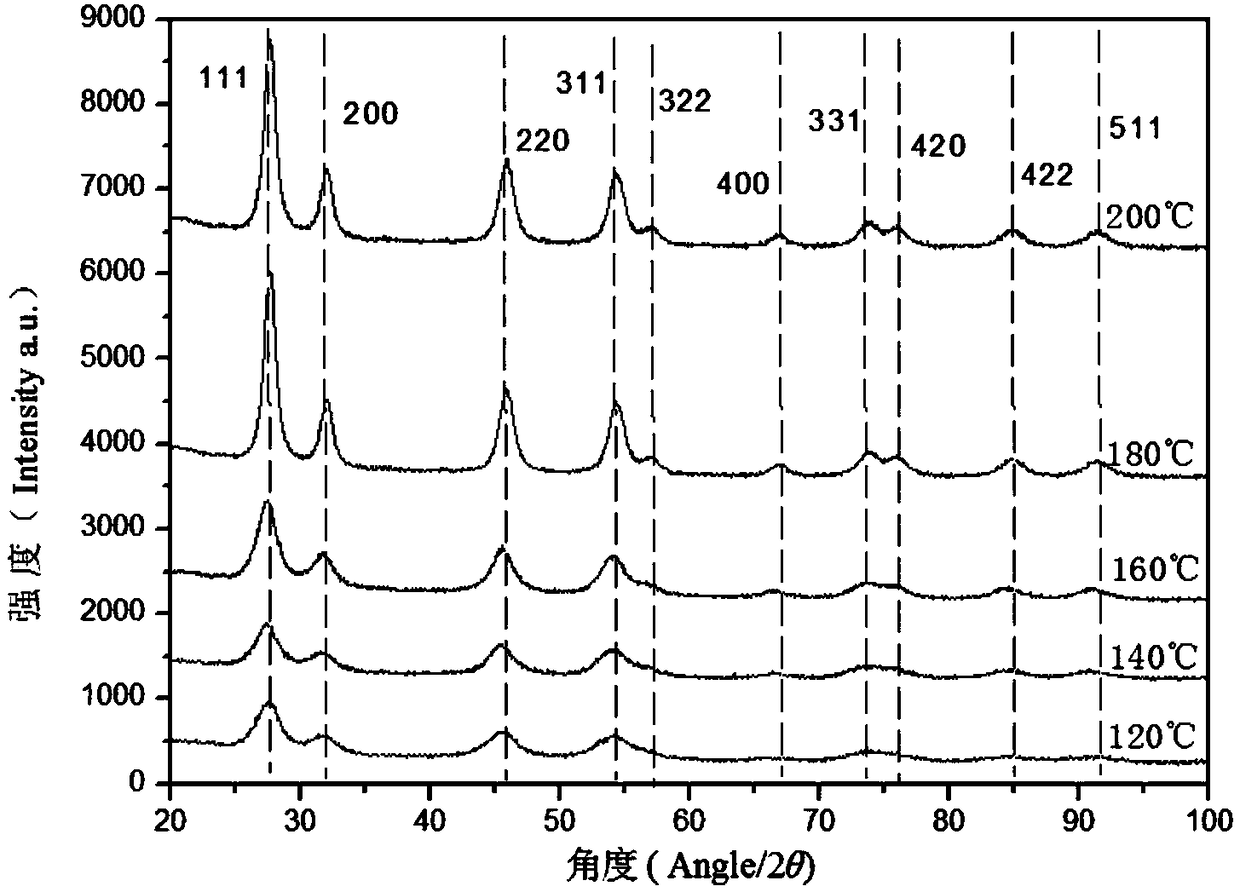

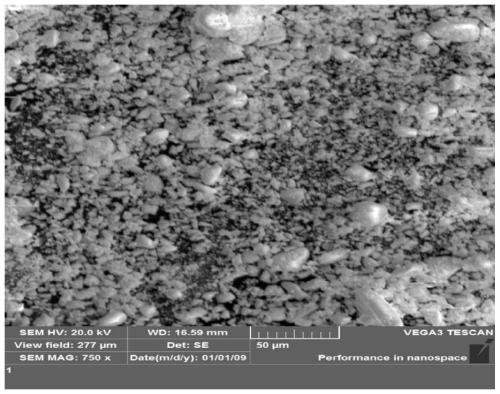

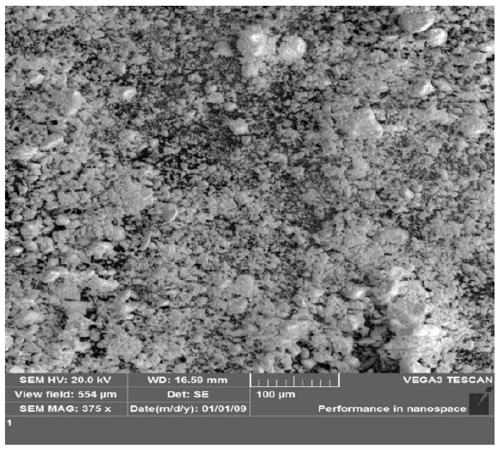

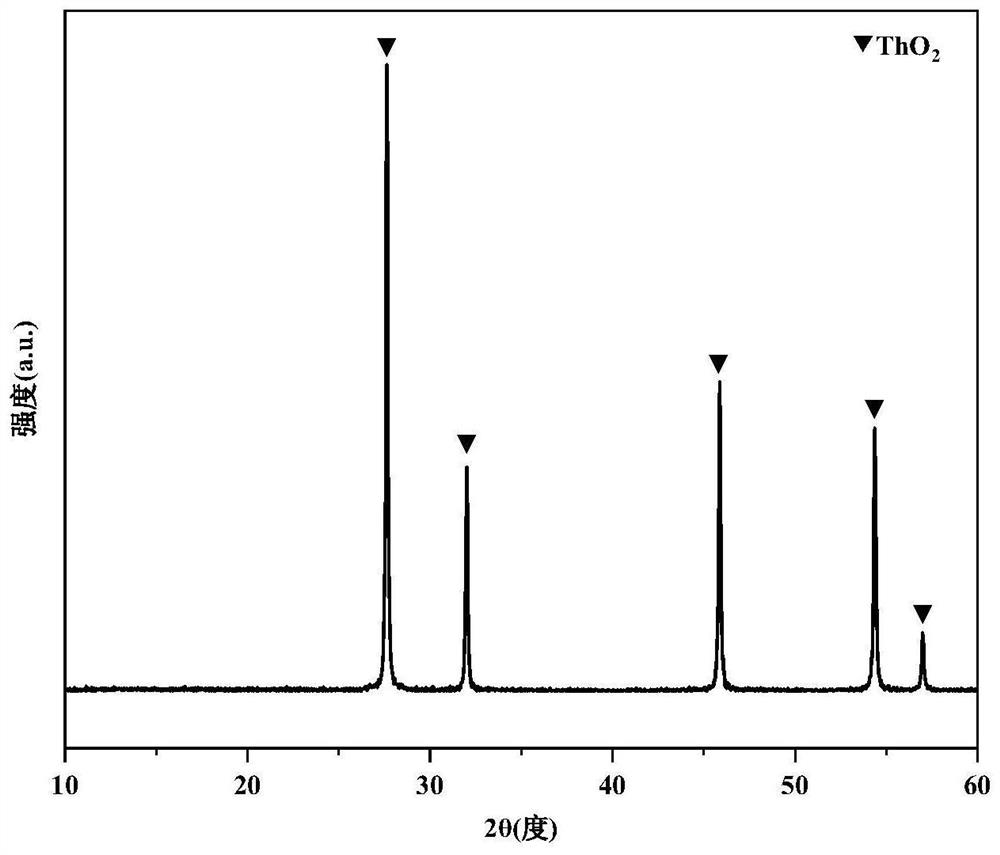

Preparation method for spherical thorium dioxide nano material with sheet-shaped surface structure and spherical thorium dioxide particles obtained from preparation method

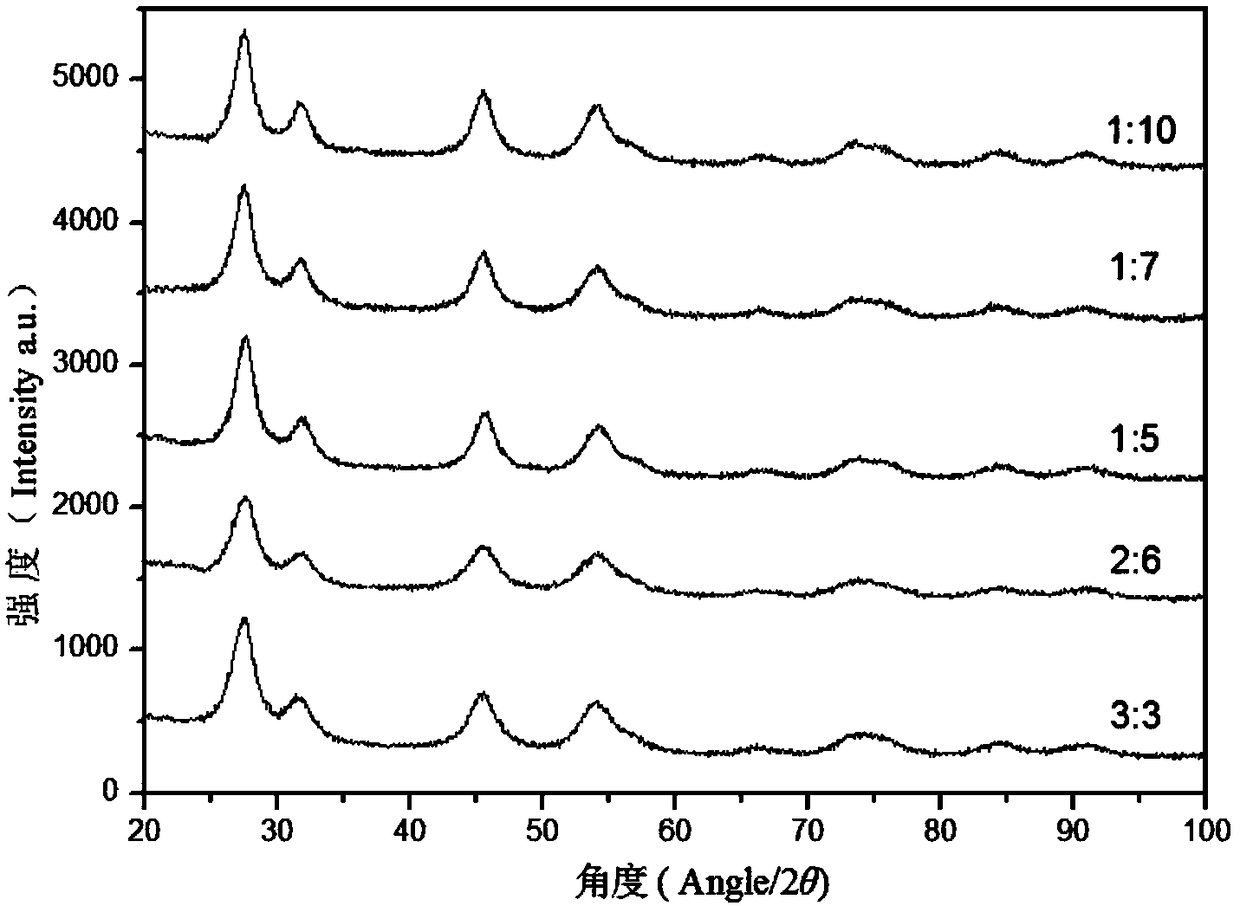

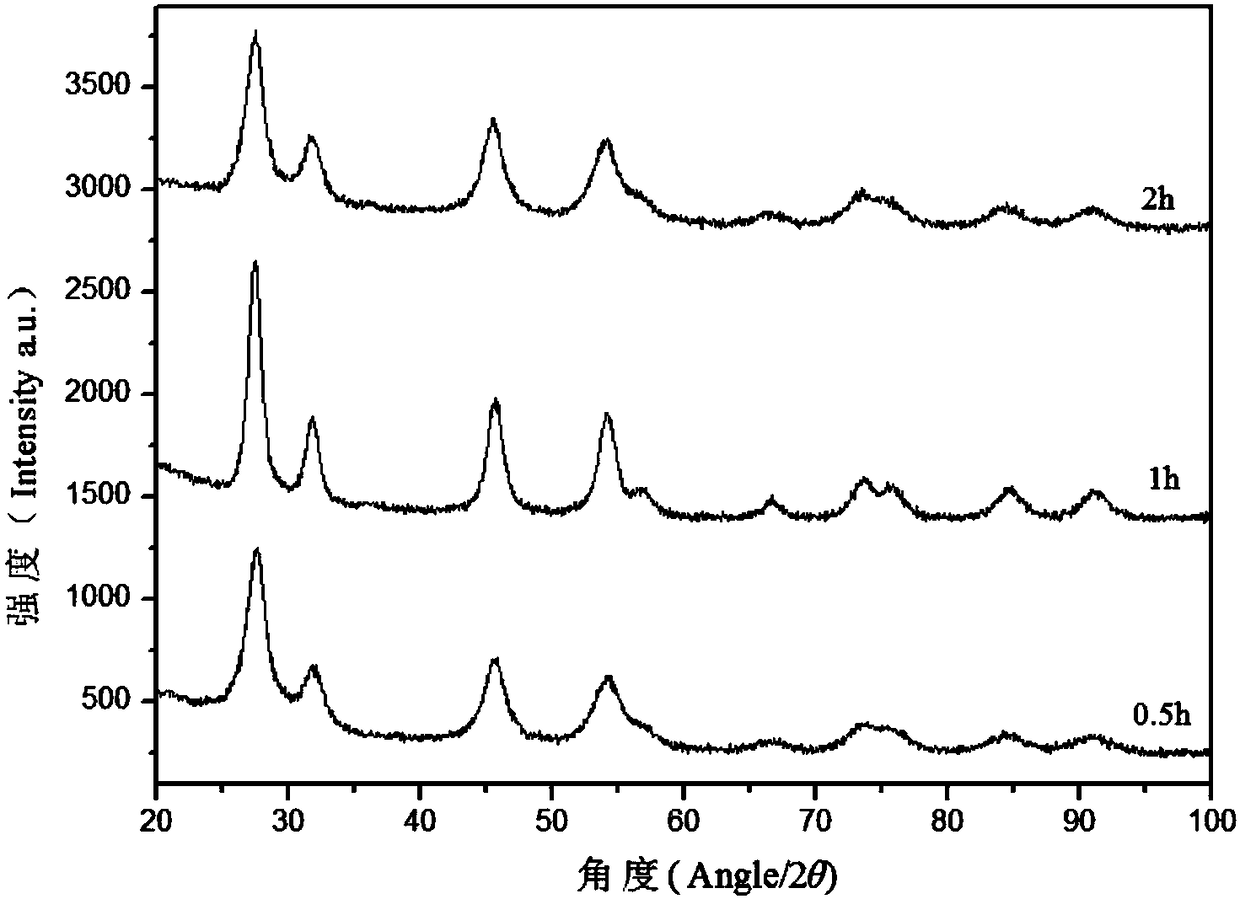

ActiveCN108083315ASimple processGood reproducibilityRadium compoundsNanotechnologyMicrowaveReaction temperature

The invention provides a preparation method for a spherical thorium dioxide nano material with a sheet-shaped surface structure. The preparation method comprises the following steps: dissolving thorium nitrate into water to form a thorium nitrate solution; dissolving urea into water to form a urea solution; transferring the thorium nitrate solution and the urea solution into a reaction kettle, wherein a molar ratio of thorium to urea is 1 to (1-10); putting the reaction kettle into a microwave reactor, selecting a reaction temperature of 120-200 DEG C to perform heating reaction for 30-60 minutes, centrifugally separating microwave products obtained in the reaction kettle to obtain precipitates; and drying the precipitates to obtain the spherical thorium dioxide nano material with the sheet-shaped surface structure. The invention further provides spherical thorium dioxide particles prepared from the method. In a word, the preparation method provided by the invention is simple in process and is good in reproducibility; and moreover, used raw materials are inorganic compounds, are cheap and easily available, are relatively low in cost, are environmentally friendly, and are easy for industrial production.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

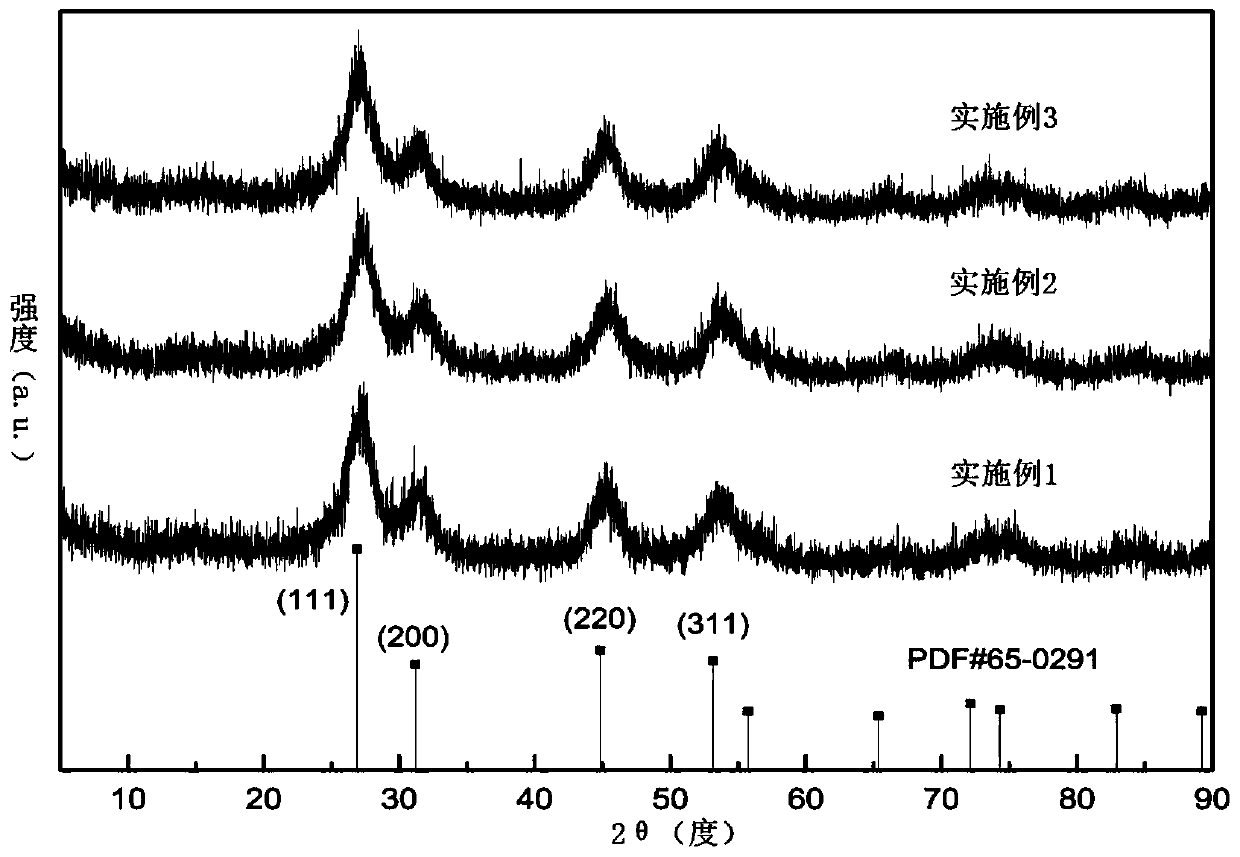

Preparation method of thorium dioxide nano material

PendingCN111439772AShape is easy to controlReunion smallRadium compoundsNanotechnologyThorium oxidePhysical chemistry

The invention belongs to the technical field of nano materials, and relates to a preparation method of a thorium dioxide nano material. The preparation method comprises the following steps: uniformlymixing a thorium nitrate solution and a sodium hydroxide solution, adding the mixture into a reaction kettle for hydrothermal reaction, cooling the reaction product to room temperature, washing the reaction product with water until the pH value is 7.5-8.5, drying and grinding to obtain the thorium dioxide nano material. With application of the preparation method of the thorium dioxide nano material, ThO2 ceramic nano-powder with controllable morphology, light agglomeration, uniform particle size, high specific surface area and good catalytic activity can be prepared on a large scale.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

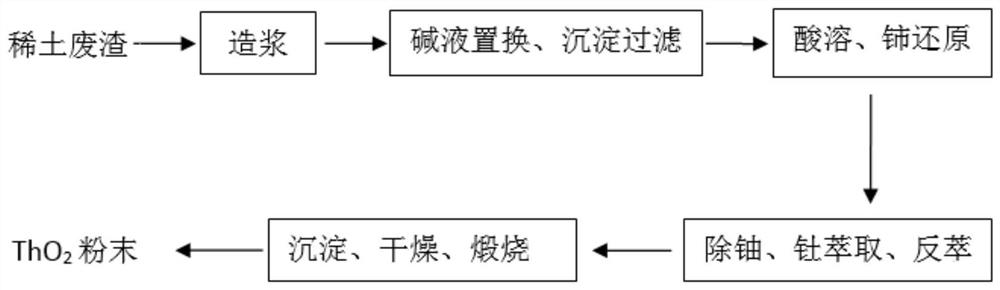

Method for extracting and preparing nuclear-grade ThO2 powder from rare earth waste residues

PendingCN112593099AReduce dosageEasy extractionProcess efficiency improvementRare-earth elementEngineering

The invention belongs to the technical field of radioactive waste treatment, and particularly relates to a method for extracting and preparing nuclear-grade ThO2 powder from rare earth waste residues.The method is used for alkalization treatment of the rare earth waste residues, not only can realize preliminary separation of thorium elements and part of impurity elements, but also can effectivelysolve the problem of equipment corrosion, meanwhile, the generated thorium hydroxide is easily converted into a thorium nitrate solution, and the next extractive purification process is carried out.According to the method, the thorium nitrate is extracted and purified by adopting a centrifugal extraction technology, the method has the characteristics of high recovery rate, continuous operation,low energy consumption and the like, the thorium elements are efficiently separated from other rare earth elements, and therefore the method has important significance in extracting and preparing nuclear-grade ThO2 powder from the rare earth waste residues.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Nano modified material contained plant oil based lubricating oil preparation method

InactiveCN107151577AGood physical propertiesEvenly distributedLubricant compositionMicrowaveCoupling

The invention discloses a nano modified material contained plant oil based lubricating oil preparation method. According to the method, plant oil synthesized lubricating oil which contains modified materials such as nano thorium nitrate is prepared from castor oil, nano thorium oxide, nano zinc oxide, surfactant sodium alkyl sulfate, ion exchange resin and the like by modification means of acid treatment, coupling, magnetic stirring, microwave treatment and the like.

Owner:长乐净能新材料科技有限公司

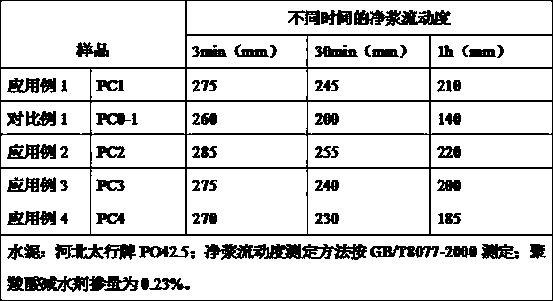

Preparation method of europium oxide luminescent material

InactiveCN101967377AEasy to operateConditions are easy to controlLuminescent compositionsRare earthThorium nitrate

The invention discloses a preparation method of europium oxide luminescent material, which relates to the preparation method of a rare earth luminescent material. In the preparation method, the mass ratio of thorium nitrate tetrahydrate to europium oxide powder is 1:0.01-0.02; the thorium nitrate tetrahydrate and the europium oxide powder are uniformly mixed together, and then the mixture is calcined in a container for 1 to 12 hours at the temperature of between 400 and 1,000 DEG C; and the mixture is cooled to obtain a target product. The preparation method has strong operability, the reaction process is convenient to operate, the condition is easy to control, and the reaction efficiency is high, so the preparation method is convenient for industrial production.

Owner:苏振彪

Method for preparing thorium dioxide nano material based on molten salt method and thorium dioxide nano material obtained by method

PendingCN113860350AIncrease heating capacityImprove ionic conductivityRare earth metal oxides/hydroxidesMaterial nanotechnologyLithium chlorideThorium oxide

The invention relates to a method for preparing a thorium dioxide nano material based on a molten salt method, wherein the method comprises the steps: forming molten salt from lithium chloride and potassium chloride according to a molar ratio of thorium nitrate hexahydrate to the molten salt of 1:5-1:80 to form raw materials; uniformly stirring and mixing the raw materials to obtain a mixture; heating the mixture to 400 DEG C-800 DEG C, calcining for 1-8 hours, and completely cooling to obtain a reaction product; adding water into the reaction product, and performing ultrasonic treatment to obtain a milky white suspension; and carrying out suction filtration on the milky white suspension by using a suction filtration device, then repeatedly carrying out suction filtration and washing by using pure water to remove unreacted raw materials, and then drying to obtain the thorium dioxide nano material. On the other hand, the invention provides the thorium dioxide nano material prepared by the method. According to the method disclosed by the invention, the preparation of monodisperse nanoscale thorium dioxide can be realized, and the thorium dioxide is low in price, clean, expandable and easy to scale.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

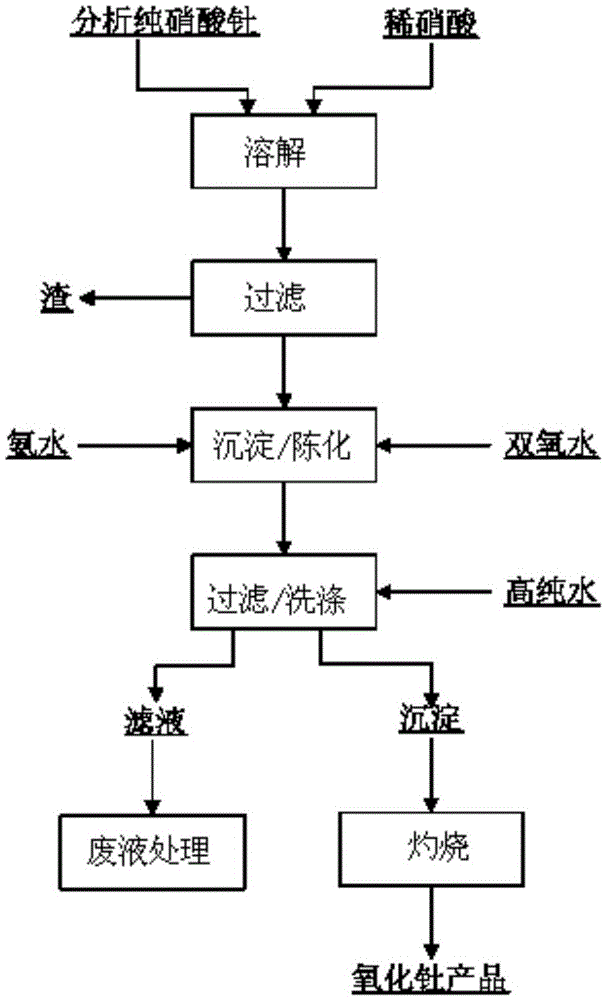

Preparation method of nuclear pure grade thorium

The invention provides a preparation method of nuclear pure grade thorium. The method includes the steps of dissolution, filtration, precipitation, ageing, burning and the like. The method provided by the invention can effectively lower the content of impurity elements in analytically pure thorium nitrate to less than 10<-6>ug / g content level to reach the nuclear pure grade. And the whole process is easy to operate, the cycle is short, the cost is low, the product purity is high and can reach more than 99.999%, the yield is greater than 97%, and the content of thorium in the filtrate is less than 0.5g / L. The process can effectively reduce the impurity elements of the product, and the prepared thorium product can reach the relevant standards of the state or industry.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Method for testing fluorine ions in industrial sewage

InactiveCN109580602ASimple methodFast wayMaterial analysis by observing effect on chemical indicatorFiltrationChemistry

The invention relates to environmental science, and specifically provides a novel detection method for analyzing fluorine ions in industrial sewage. The method comprises the following steps: taking proper amount of water samples in a triangular flask; dropping a NaOH solution to adjust the solution pH value to be 7 to 8; after dropping an AgNO3 solution, adjusting the solution pH value to be 6 to7; after that, performing dry filtration on a test solution, retaining whole filtrate, and adding a few drops of sodium alizarin sulfonate to the filtrate, and the solution is red; after that, dropping dilute HNO3 until the solution is just yellow, after adding a buffer solution, titrating with a thorium nitrate standard solution until the solution is red (without yellow), and taking the solutionas an end point; and finally, an analysis result of the fluoride ions in the sewage is obtained by calculation. The method of the invention is simple and rapid, an analysis period can be controlled within one hour, and the method is easily promoted in general sewage treatment laboratories.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

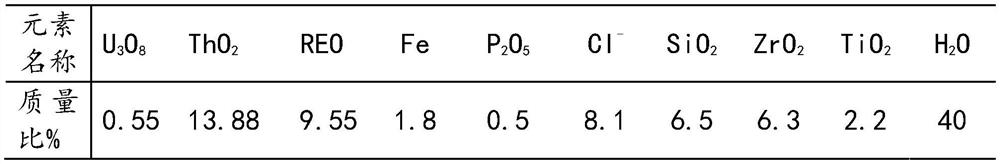

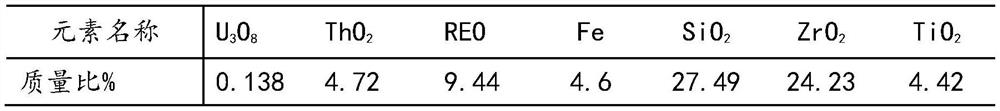

Method for preparing thorium nitrate by utilizing monazite excellent molten slag

ActiveCN114164351ASolve the problem of low extraction efficiencyProcess efficiency improvementPhysical chemistryThorium nitrate

The invention discloses a method for preparing thorium nitrate by using monazite excellent molten slag, which comprises the following steps: (1) slurry pretreatment: mixing the monazite excellent molten slag into slurry, adding nitric acid, heating and stirring to obtain feed liquid A; (2) titanium removal treatment: carrying out titanium removal treatment on the feed liquid A, and filtering to obtain filtrate B; (3) uranium extraction: extracting the filtrate B to obtain a uranium-containing organic phase, heating with a nitric acid solution for back extraction, and carrying out precipitation treatment to obtain raffinate C; (4) thorium extraction: extracting the raffinate C to obtain a thorium-containing organic phase and raffinate D, and heating the thorium-containing organic phase with a nitric acid solution for back extraction to obtain thorium back extraction liquid E; and (5) thorium nitrate crystallization: carrying out concentration treatment on the thorium strip liquor E, carrying out uranium extraction operation in the step (3) on the obtained concentrated liquor to obtain raffinate F, carrying out crystallization treatment on the raffinate F, and continuously carrying out solid-liquid separation to obtain high-purity thorium nitrate. The invention aims to improve the extraction efficiency of the superior monazite slag.

Owner:湖南中核金原新材料有限责任公司

Preparation method of high-purity thorium nitrate

InactiveCN106480329AHigh stripping rateFacilitate strippingProcess efficiency improvementSalting outKerosene

The invention provides a preparation method of high-purity thorium nitrate. The preparation method comprises the steps that HNO3 and NaNO3 are used as salting-out agents for allocating a Th(NO3)4 solution to form a mixed solution, and a P350-sulfonated kerosene organic phase is used for extracting the mixed solution; a NaNO3 solution is adopted for washing the obtained organic phase loaded with Th; and a fluorine-containing water solution is adopted for reversely extracting the washed organic phase loaded with Th. The process has the advantages that when high-purity water is adopted for thorium reverse extraction, F<-> in an added HF or NaF solution can be easily coordinated with Th<4+> to form [ThFx]<4>-x, so that reverse extraction of a P350 system with Th<4+> loaded is promoted, and the reverse extraction rate of thorium can be improved; and the product quality can reach the standards that ThO2 / Th(NO3)4.6H2O is larger than or equal to 46%, and the ThO2 purity is larger than 99.9995%.

Owner:永州市湘江稀土有限责任公司

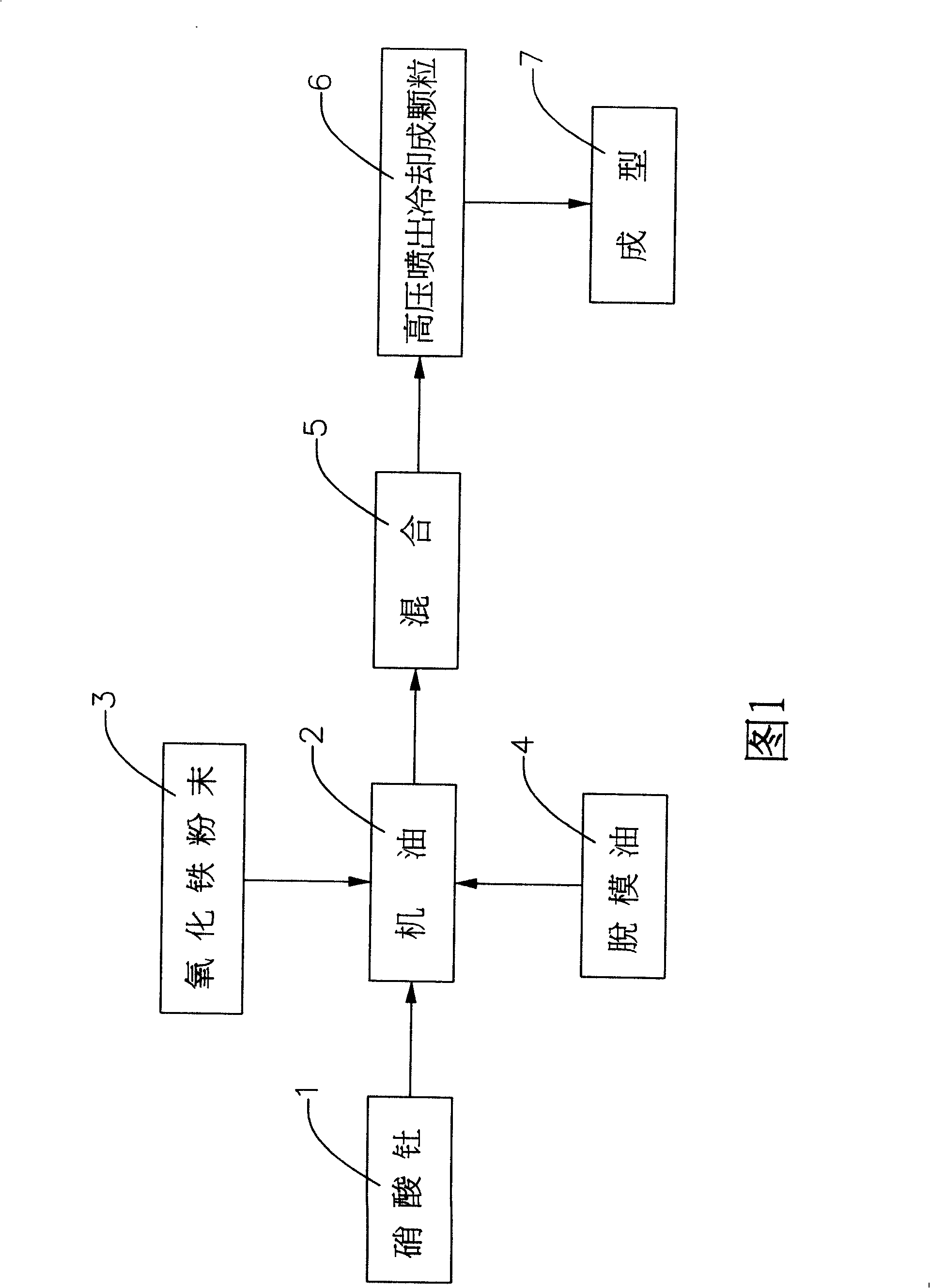

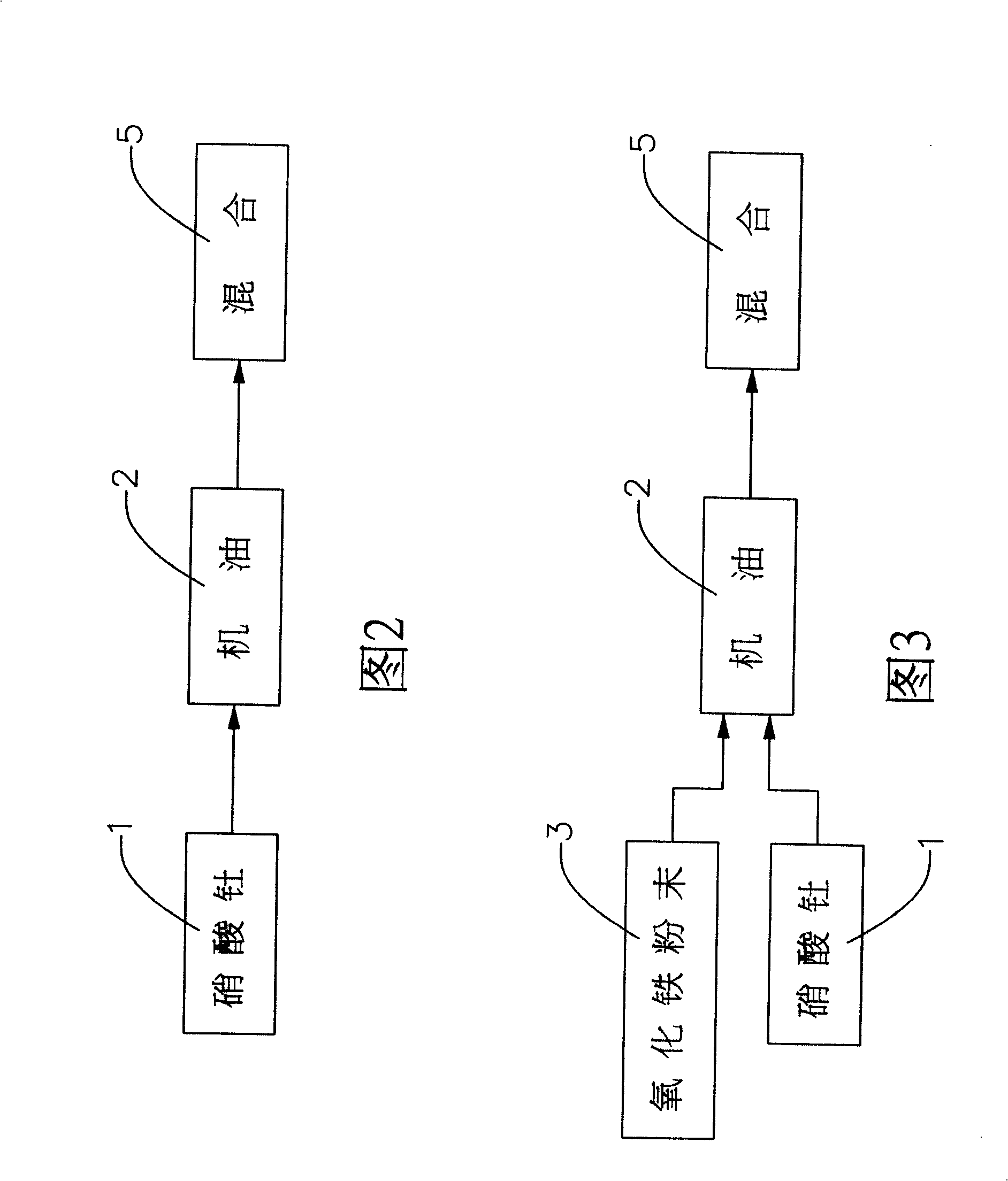

Fuel additive for increasing fuel oil efficiency and manufacturing method thereof

InactiveCN101265423AReduce pollutionImprove fuel efficiencyLiquid carbonaceous fuelsOil additiveFuel efficiency

The invention relates to a fuel additive for improving the fuel efficiency and a preparation method thereof. The invention mainly comprises the following steps: 500 gram of thorium nitrate and 1000 gram of motor oil are mixed; during the mixing process, 200 gram of mould oil is added and uniformly mixed; 10000 gram of ferric oxide powder (iron powder) is added and mixed to the uniform state, then is sprayed out with high pressure, the production is momentarily cooled and granular material is formed, the formed granular material is put into a forming machine for pressurization, in order to form the granule with required size, therefore the required fuel additive is formed, and the far infrared radiation generated through the thorium nitrate can produce catalytic action to the fuel, enable the fuel molecule to be fine, improve the octane quality, and achieve the purpose of improving the fuel efficiency.

Owner:吴为禾

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com