Method for treating bastnasite concentrate

A treatment method, bastnasite technology, applied in the field of metallurgy, can solve the problems of low decomposition rate and long process of carbonate decomposition of rare earths, and achieve the effects of reducing the generation of polluting gases, high leaching rate, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

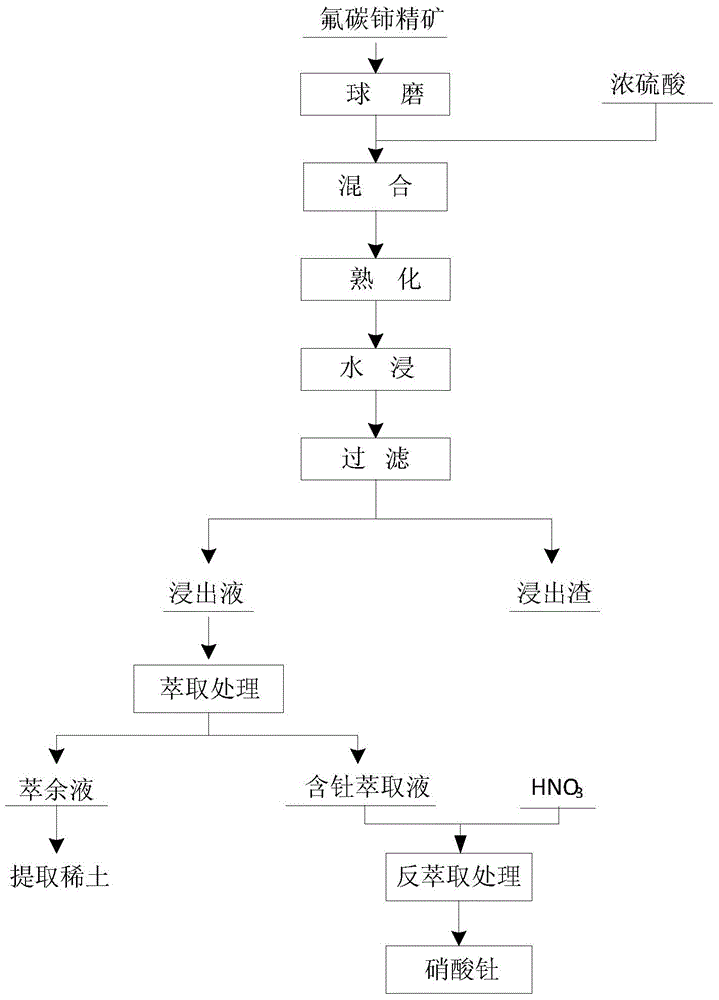

Method used

Image

Examples

Embodiment 1

[0035] Get 500g of bastnaesite concentrate particles processed through ball milling, the average particle diameter of the bastnaesite concentrate particles after the ball milling is 200 orders, and the REO content is 68.29%. Adding 650g of concentration in the concentrate particles is 98% concentrated Sulfuric acid, mixed evenly, matured at 200°C for 5 hours, took the matured mature ore and immersed it in water at room temperature for 2 hours according to the solid-to-liquid ratio of 1:10, filtered and washed to obtain the leached slag after the leaching reaction was completed, dried and tested the slag Residual REO content, ThO 2 content. The measured slag rate is 5.86%, the REO leaching rate is 96.12% based on slag, the thorium content in the slag is 290ppm, and the thorium leaching rate is above 98%.

[0036] The above method has simple process, high REO leaching rate, low energy consumption, less consumption of auxiliary materials, thorium radioactivity content in the sla...

Embodiment 2

[0038] Get 500g of bastnaesite concentrate particles processed through ball milling, the average particle diameter of the bastnaesite concentrate particles after the ball milling is 280 mesh, REO content 58.37%, add 500g massfraction 98% concentrated H in this concentrate 2 SO 4 , mixed evenly, and matured at a temperature of 210°C for 4 hours. Take the matured mature ore and soak it in water at room temperature for 1 hour according to the solid-to-liquid ratio of 1:8. After the leaching reaction is completed, filter and wash to obtain the leached slag. Residual REO content, ThO 2 content. The measured slag rate is 6.13%, the REO leaching rate is 95.47% based on slag, the thorium content in the slag is 207ppm, and the thorium leaching rate is 98.6%.

[0039] The above method has simple process, high REO leaching rate, low energy consumption, less consumption of auxiliary materials, thorium radioactivity content in the slag is within the range required by the discharge standa...

Embodiment 3

[0041] Get 500g of bastnaesite concentrate particles processed through ball milling, the average particle diameter of the bastnaesite concentrate particles after the ball milling is 240 mesh, REO content 67.25%, add 650g mass fraction 98% concentrated H in this concentrate 2 SO 4 , mixed evenly, and matured at a temperature of 180°C for 5 hours. Take the matured mature ore and soak it in water at room temperature for 1 hour according to the solid-to-liquid ratio of 1:10. Residual REO content, ThO 2 content. The measured slag rate is 6.08%, the REO leaching rate is 96.15% based on slag, the thorium content in the slag is 285ppm, and the thorium leaching rate is 98.02%.

[0042] The above method has simple process, high REO leaching rate, low energy consumption, less consumption of auxiliary materials, thorium radioactivity content in the slag is within the range required by the discharge standard, and no fluorine and radioactive thorium wastes are discharged in the whole proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com