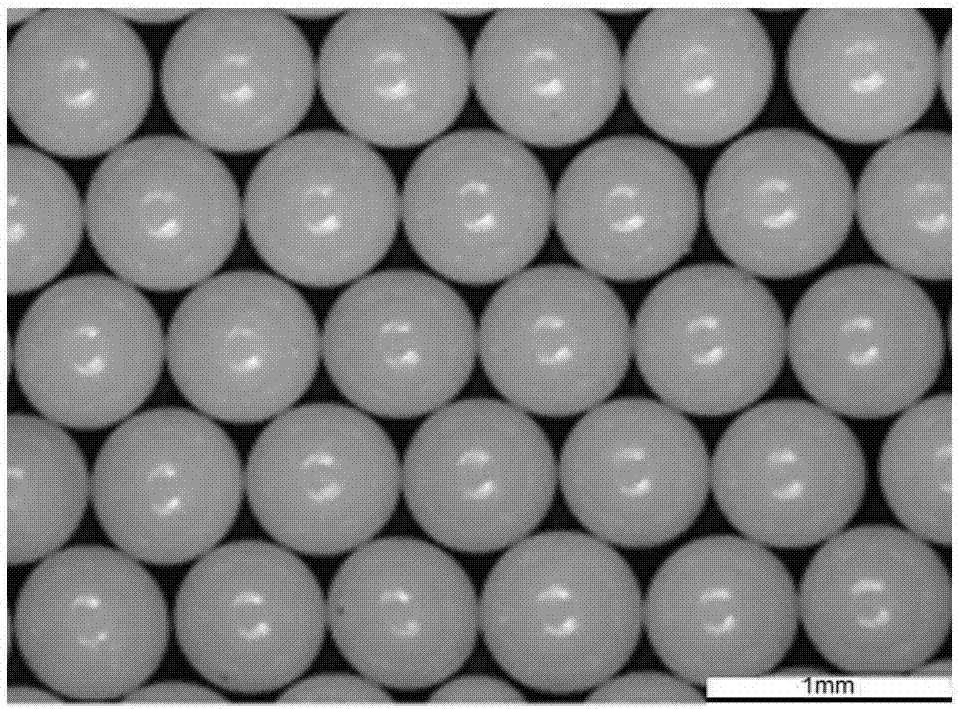

Method for preparing ceramic micro-spheres of thorium oxide

A technology of ceramic microspheres and thorium oxide, applied in the field of preparation of ceramic microspheres, can solve the problems of complex thorium oxide process, etc., and achieve the effects of avoiding the use of ammonia water or organic matter, reducing the rupture rate, and avoiding a large amount of release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

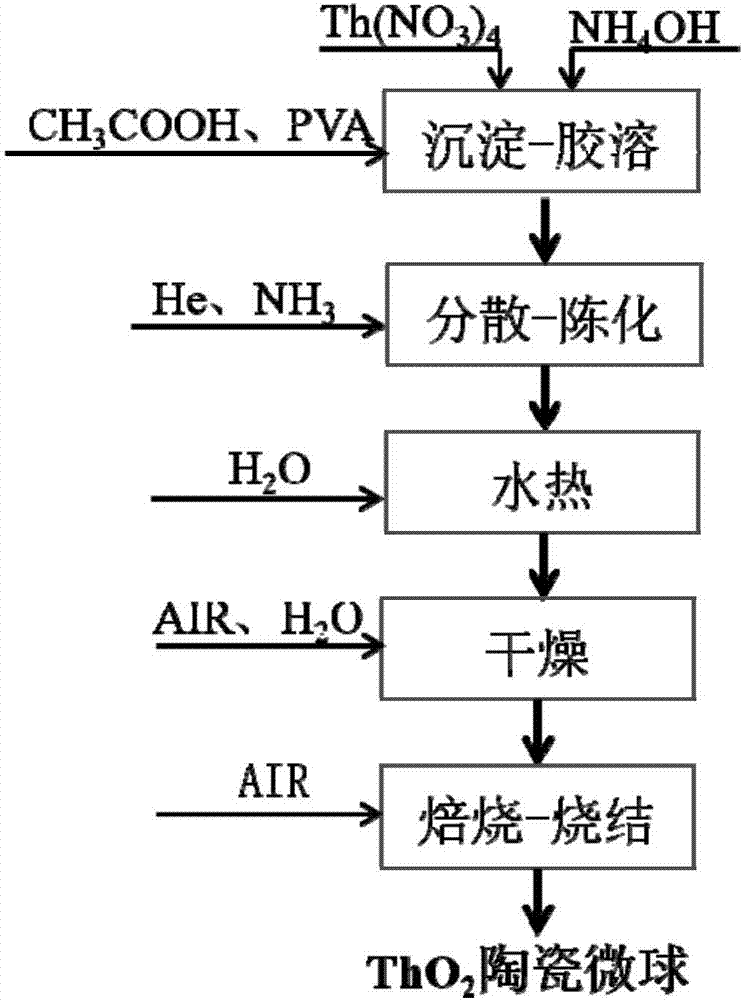

Method used

Image

Examples

Embodiment 1

[0025] S1, preparation of thorium oxide colloid: weighing 105.75g Th(NO 3 ) 4 ·6H 2 O was prepared into 150 mL of 1.2 mol / L thorium nitrate solution, heated up to 60°C, and 15 mol / L ammonia water was added dropwise at a rate of 2 mL / min until the pH of the solution was 3.0, then changed to a rate of 0.5 mL / min and concentrated ammonia water was added dropwise When the pH of the solution is 3.9, there are tiny precipitates that are not dissolved, add 0.1Ml glacial acetic acid dropwise, stir and react at 60°C to obtain a transparent colloid, forming a hydrolysis solution. After cooling, add 25 mL of 120 g / L PVA with stirring. After fully stirring evenly, let stand to eliminate air bubbles and form thorium oxide colloid.

[0026] S2, Dispersed Aging: The thorium oxide colloid was transported into a needle valve with a diameter of 21 g by pressure transport to disperse into liquid droplets, and then passed through the helium gas zone, ammonia gas zone, and ammonia water zone in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com