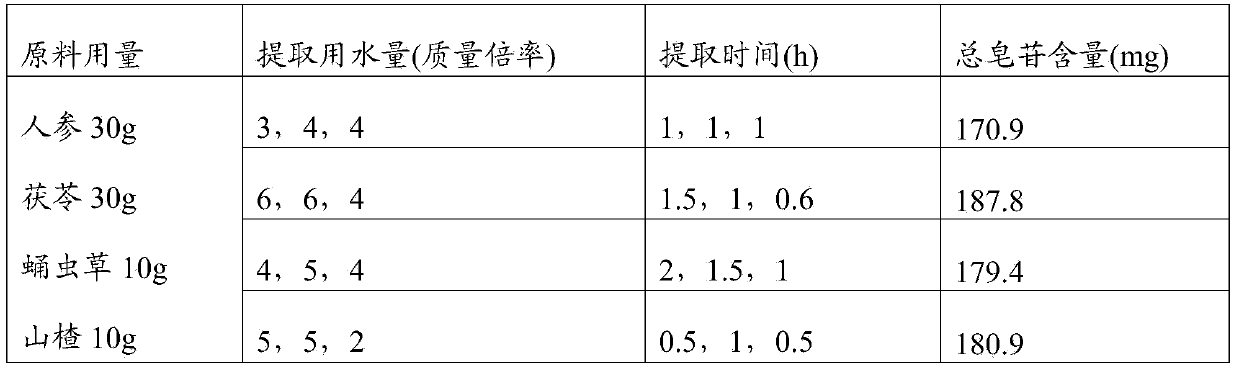

Patents

Literature

80results about How to "Less additives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

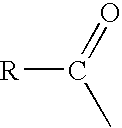

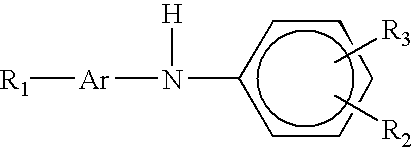

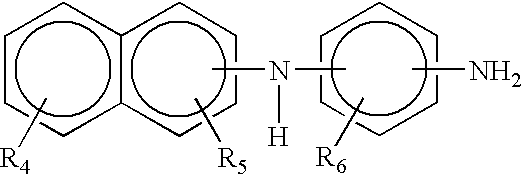

Multiple-Function Dispersant Graft Polymer

ActiveUS20080293600A1Good dispersionLess additivesLiquid carbonaceous fuelsAdditivesPolyesterPolyolefin

A grafted polymer, either polyolefin or polyester, containing monomers associated with sludge and varnish control as well as monomers associated with soot handling to provide a graft polymer exhibiting multiple performance attributes. Also described are methods for manufacturing these novel multiple-function graft polymers via solution and melt processes. Lubricating oil compositions containing these novel multiple-function polymers as an additive that display performance characteristics directed to good soot handling and sludge and varnish control as well as control of viscosity increase are described.

Owner:CASTROL LTD

Composition for the preparation of homemade frozen confections

InactiveUS20150140193A1Pleasant textureCaloric value easilyMilk preparationFrozen sweetsPolysaccharideChemistry

The present invention relates to a shelf-stable composition for the preparation of a frozen confection comprising: (i) a sweetening agent; (ii) a dairy fat; and (iii) one or more polysaccharide having a Dextrose Equivalent (DE) value of maximum 40; with the proviso that the composition does not comprise added emulsifiers or stabilizers. The present invention also relates to a method of preparing a frozen confection by mixing said composition with ice and an edible liquid and blend the mixture.

Owner:NESTEC SA

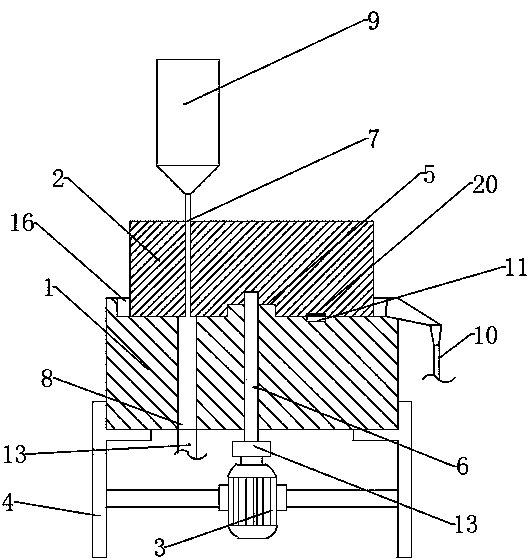

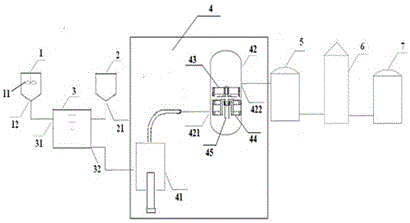

Graphene grinding and stripping device, graphene production system and production method

ActiveCN104401971AKeep the natural plane sizeReduce the chance of crushingCvd grapheneMechanical engineering

The invention discloses a graphene grinding and stripping device which comprises an upper grinding disc, a lower grinding disc, a driving mechanism for driving the upper grinding disc to rotate, and a material collection mechanism for collecting a product after grinding, wherein the upper grinding disc and the lower grinding disc are matched with each other; a horizontal contact surface is formed between the upper grinding disc and the lower grinding disc, the upper grinding disc is provided with an upper feed inlet, the lower grinding disc is provided with a lower feed inlet, the upper feed inlet and the lower feed inlet are both connected with the contact surface between the upper grinding disc and the lower grinding disc, and the lower end of the lower feed inlet is in sealed connection with one water inlet tube; moreover, the upper end face of the lower grinding disc is provided with a groove, and an annular region formed by rotary surrounding of the lower end of the upper feed inlet is surrounded in the groove. The graphene grinding and stripping device can realize large-size successful stripping of graphene. The invention also relates to a graphene production system containing the graphene grinding and stripping device and a graphene production method.

Owner:江苏碳谷二维世界科技有限公司

Wet strength and softness enhancement of paper products

InactiveUS7041197B2Improve wet strengthLess additivesNatural cellulose pulp/paperSpecial paperChemistryPolyelectrolyte

A method for making paper to enhance its wet strength includes adding separately to a cellulosic paper pulp furnish the following additives to form a treated pulp: a cationic wet strength resin whose cationic sites bond to anionic sites of cellulose fibers contained in the paper pulp furnish, and a hydrophobically modified anionic polyelectrolyte whose anionic sites bond with cationic sites of the cationic wet strength resin.

Owner:GPCP IP HLDG LLC

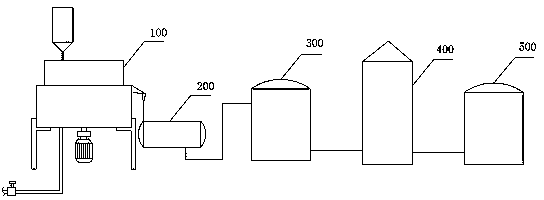

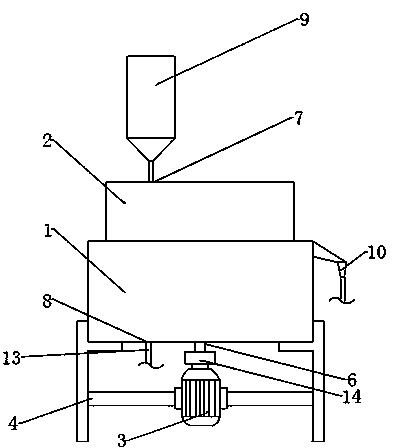

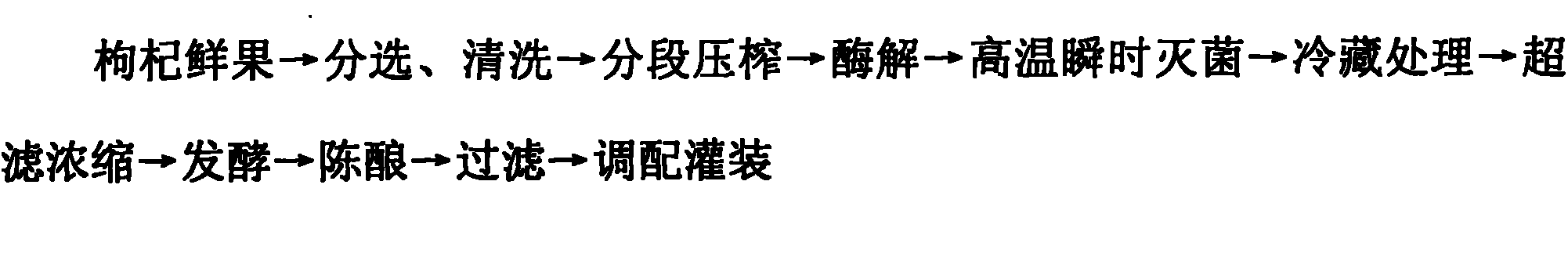

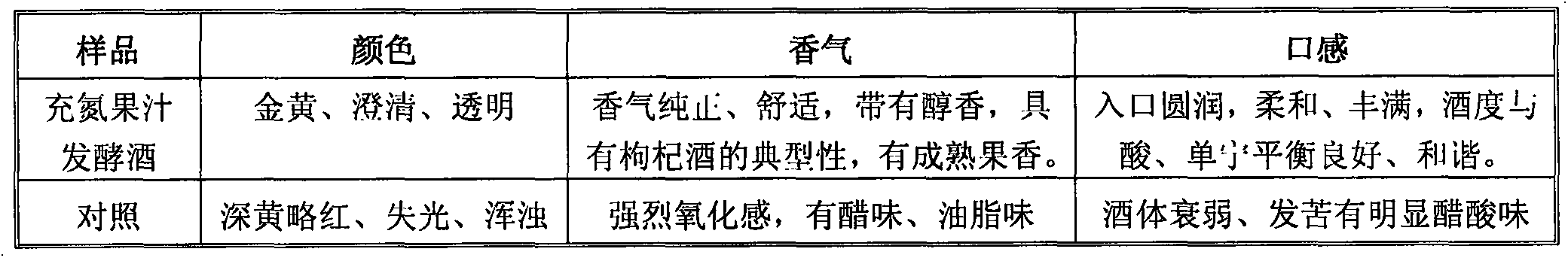

Fresh Chinese wolfberry fruit full juice fermented wine and preparation method thereof

ActiveCN103289858ASimple processLess additivesMicroorganism based processesAlcoholic beverage preparationBiotechnologyFood science

The invention relates to a fresh Chinese wolfberry fruit full juice fermented wine and a preparation method thereof. The fresh Chinese wolfberry fruit full juice fermented wine is prepared by sorting and cleaning fresh Chinese wolfberry fruit, and carrying out stage squeezing, enzymolysis, high-temperature instant sterilization, refrigeration treatment, hyperfiltration concentration, fermenting, aging, filtration and blending encapsulation. The method provided by the invention has the advantages that the process is simple, an addition agent is less, residual is not generated, and the fresh Chinese wolfberry fruit full juice fermented wine prepared by the method is golden yellow in color, clear and transparent, pure and comfortable in fragrance with mellow, has typical mature fruity flavor of Chinese wolfberry wine, is smooth, soft and full in palate, is well balanced among alcoholicity, acidity and tannin with great harmony, and has comprehensive and rich nutrient substances.

Owner:青海柴馥有机枸杞有限公司

Wet strength and softness enhancement of paper products

InactiveUS20060124264A1Wet ratioWet strength strengthNatural cellulose pulp/paperSpecial paperPolyelectrolyteCellulose fiber

A method for making paper to enhance its wet strength includes adding separately to a cellulosic paper pulp furnish the following additives to form a treated pulp: a cationic wet strength resin whose cationic sites bond to anionic sites of cellulose fibers contained in the paper pulp furnish, and a hydrophobically modified anionic polyelectrolyte whose anionic sites bond with cationic sites of the cationic wet strength resin.

Owner:KOKKO BRUCE J +1

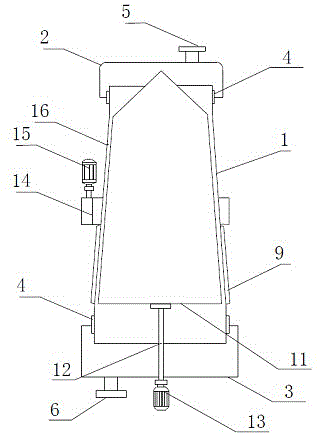

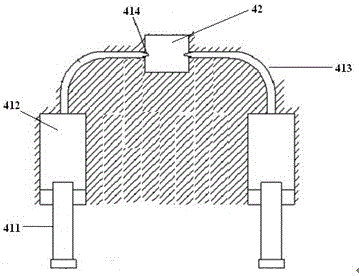

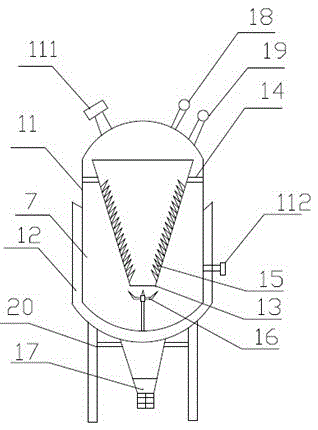

Rotary graphene stripping device, graphene production system and production method

The invention discloses a rotary graphene stripping device including a rotary cylinder body; a top cover is arranged above the rotary cylinder body, a bottom cover is arranged below the rotary cylinder body, the top of the top cover is provided with a feed inlet, the bottom of the bottom cover is provided with a discharge port, and the feed inlet is communicated with the interior of the rotary cylinder body; the outer side of the rotary cylinder body is provided with a first motor, and is used for driving the rotary cylinder body to horizontally rotate; the rotary cylinder body is also internally provided with an inner cylinder, and a second motor used for driving the inner cylinder to horizontally rotate in a direction opposite to the rotating direction of the rotary cylinder body is arranged below the rotary cylinder body; the upper part of the inner cylinder is shrunk in a certain angle, and a material storage space is left between the upper part of the inner cylinder and the upper part of the rotary cylinder body; the lower part of the inner cylinder and the lower part of the rotary cylinder body are in clearance fit to be used for grinding graphite sheets, and a clearance between the lower part of the inner cylinder and the lower part of the rotary cylinder body is successively decreased downward along the axial direction of the rotary cylinder body. The rotary graphene stripping device can achieve successful stripping of graphene. The invention also relates to a graphene production system containing the rotary graphene stripping device and a graphene production method.

Owner:江苏碳谷二维世界科技有限公司

Polycarbonate composition and preparation method thereof

The invention relates to a polycarbonate composition and a preparation method thereof. The composition comprises the following components in portion by weight: 100 portions of polycarbonate, 0.1 to 10 portions of polyhedral oligomeric silsesquioxane, and 0 to 0.1 portion of sulphonate flame retardant. The preparation method comprises the following steps: placing the polycarbonate, the polyhedral oligomeric silsesquioxane and the sulphonate flame retardant into a blending device, and mixing the components; melting and mixing the mixture into a melt blending device, and cooling the mixture to form a modified polycarbonate blank; and drying the modified polycarbonate blank, processing the blank by adopting a plastic molding process, and cooling and molding the processed blank to obtain the polycarbonate composition. The composition can carry out laser marking with high contrast, and has good flame retardant property; the light transmittance of the material is not reduced; and simultaneously, the problems of mechanical property reduction and high price of the material due to excessive added laser assistants are solved.

Owner:SHANGHAI JIAO TONG UNIV

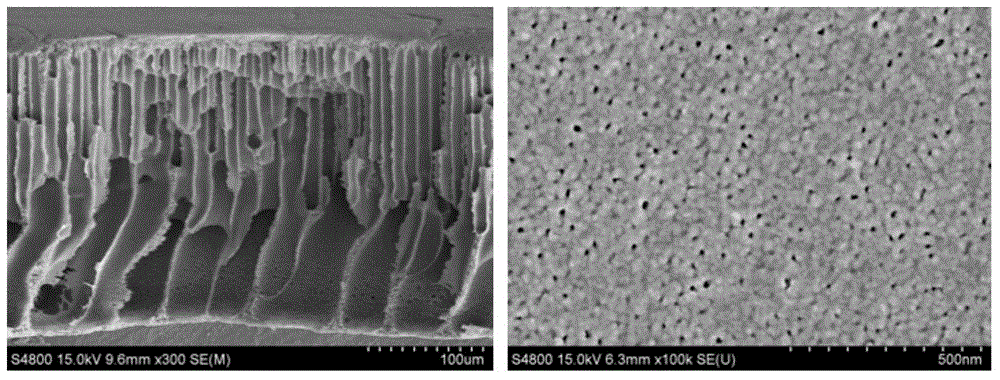

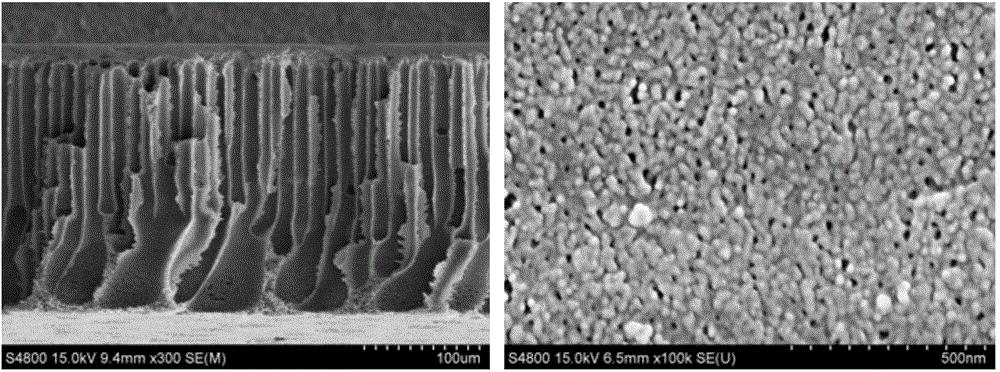

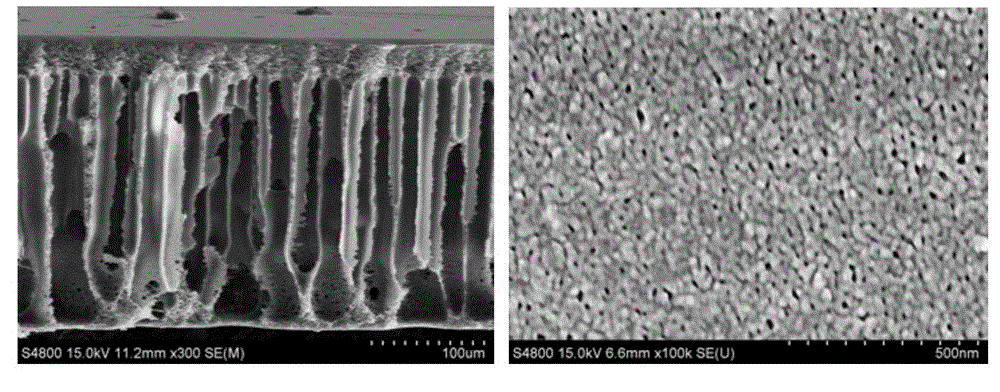

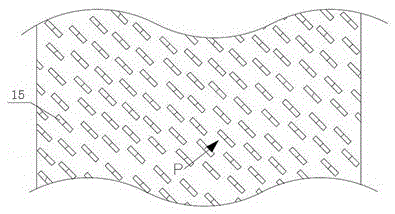

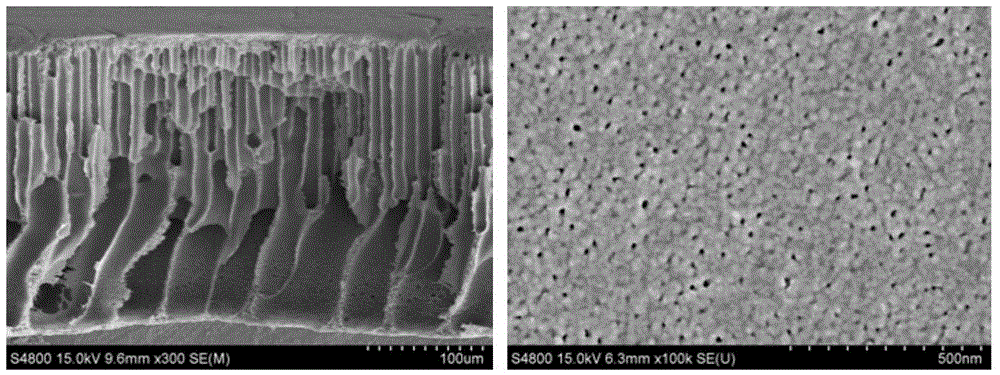

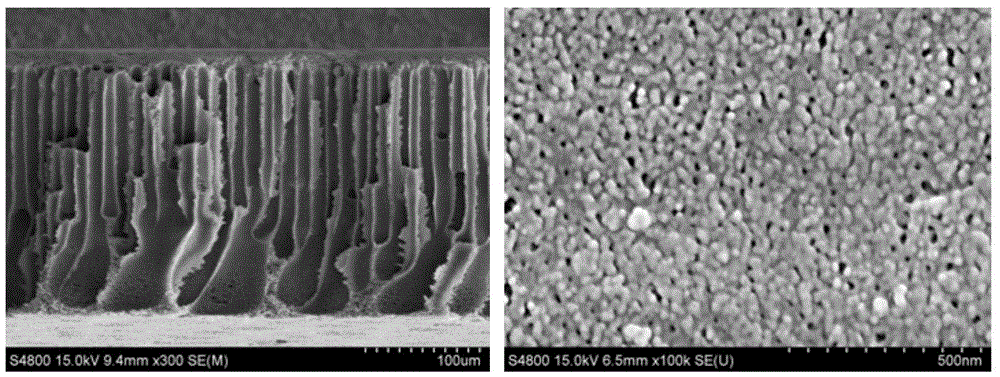

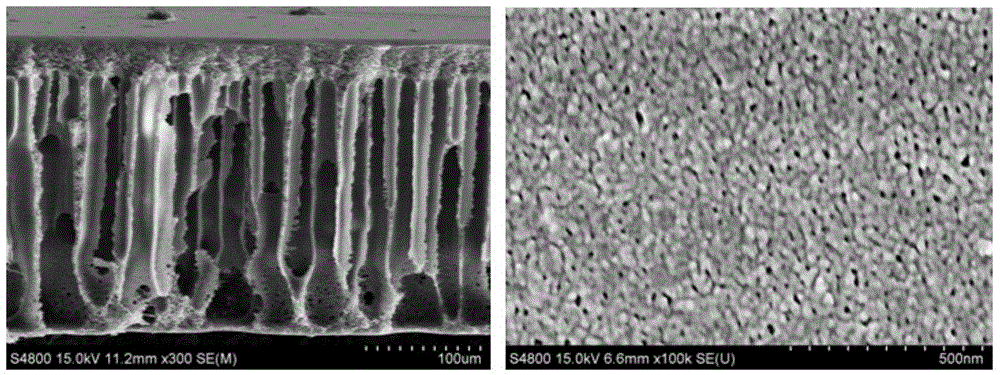

Polyether sulfone ultrafiltration membrane preparation method capable of improving permeability and selectivity simultaneously

ActiveCN104056557AHigh porosityIncreasing the thicknessSemi-permeable membranesPolyetherimideUltrafiltration

The invention discloses a polyether sulfone ultrafiltration membrane preparation method capable of improving permeability and selectivity simultaneously. An ultrafiltration membrane is prepared by adopting a phase inversion method, and PEI (polyetherimide) is used as an additive, and is added to change the phase inversion process and regulate the structure of the PES ultrafiltration membrane to achieve high permeability and high selectivity. The preparation method comprises the following steps of (1) dissolving the PEI in a solvent (DMF) (dimethyl formamide), adding polyether sulfone and PVP (polyvinylpyrrolidone), and performing heating to dissolve the polyether sulfone and the PVP to form a homogeneous membrane coating solution; and (2) controlling membrane forming conditions, and preparing the flat membrane. According to the method, the structure of the PES ultrafiltration membrane is effectively regulated, and the aperture ratio of the PES ultrafiltration membrane and the thickness of a selective layer are increased to greatly improve the permeability and the selectivity; the preparation method is simple and suitable for being used in the industrial production and the preparation of a basic membrane of a nanofiltration membrane.

Owner:NANJING UNIV OF SCI & TECH

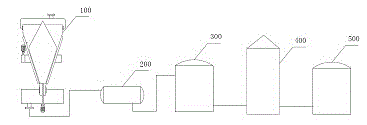

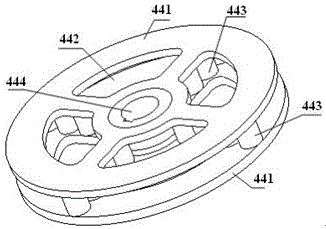

Device for continuously preparing graphene and method for producing graphene

The invention belongs to the technical field of graphene and particularly relates to a device for continuously preparing graphene and a method for producing graphene. The device comprises a raw material grinding tank, a grinding medium storage bin, a stirring tank, a continuous grinding mechanism, a material storage tank, a centrifugal filtering device and a drying device. A blade type stirring mill is arranged in the raw material grinding tank. The continuous grinding mechanism comprises a high-pressure pump, the grinding bin, a flow guide ring, a dispersion impeller and a transmission shaft. The flow guide ring is located in the middle of the grinding bin and fixedly connected with the transmission shaft, the dispersion impeller is located between the flow guide ring and the bottom of the grinding bin, and the transmission shaft passes through the center of the dispersion impeller. The probability that graphene is smashed is reduced through continuous stripping step by step, structural defects of graphene are reduced, and meanwhile the situation that structural defects are caused again to stripped graphene due to re-grinding is avoided. The invention further discloses the method for producing graphene by means of the device for continuously preparing graphene from the slurry.

Owner:淮安双洋新材料有限公司

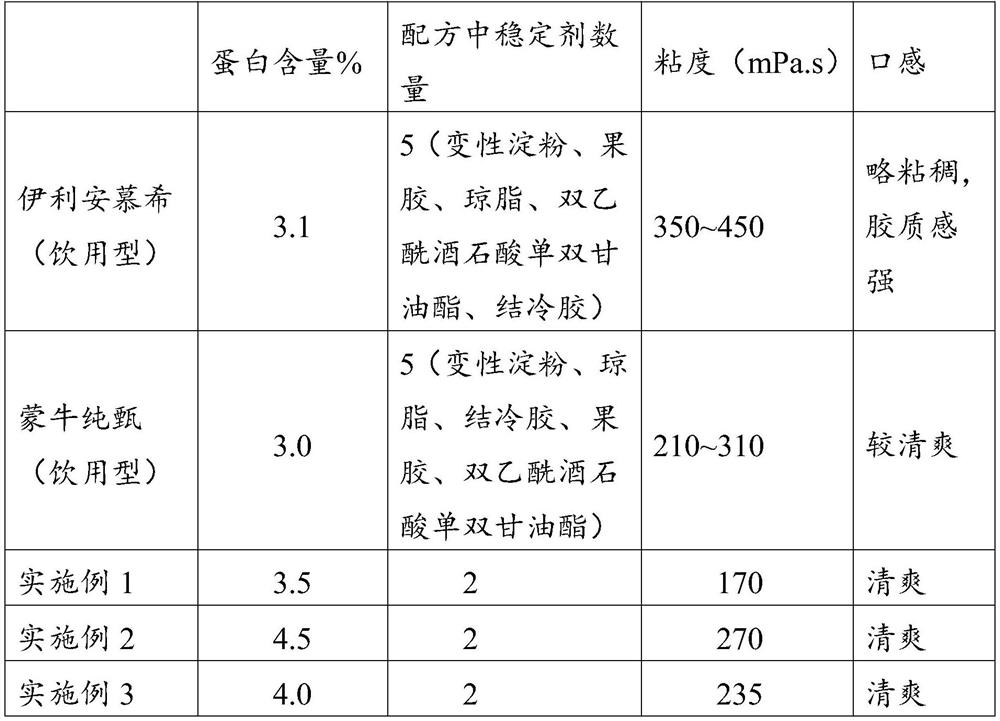

Drinking type normal-temperature yoghourt and preparation method thereof

InactiveCN112616921AOvercoming problems with using multiple stabilizersAdd lessMilk preparationBiotechnologySucrose

The invention discloses drinking type normal-temperature yoghourt and a preparation method thereof. The drinking type normal-temperature yoghourt comprises the following raw materials: concentrated milk, cane sugar, milk protein powder, pectin, a thickening agent, a leavening agent and water. The preparation method comprises the following steps of: concentrating raw milk through a Reverse Osmosis (RO) membrane to obtain the concentrated milk; sterilizing and cooling the concentrated milk, and adding the milk protein powder and part of cane sugar to obtain a mixed base material; homogenizing and sterilizing the mixed base material, and cooling to a fermentation temperature to obtain a fermentation substrate; adding the leavening agent into the fermentation substrate for fermentation to obtain a yoghourt base material; heating water obtained by intercepting the Reverse Osmosis (RO) membrane, and adding the pectin, the thickening agent and the rest of cane sugar to obtain a mixed solution; performing high-speed shearing and stirring treatment, sterilizing and cooling to obtain a pectin solution; and mixing and stirring the obtained yoghourt base material and the obtained pectin solution in proportion to obtain a drinking type normal-temperature yoghourt base material, and homogenizing, sterilizing, cooling and filling the drinking type normal-temperature yoghourt base material to obtain the drinking type normal-temperature yoghourt. The drinking type normal-temperature yoghourt has the advantages that the protein content of the normal-temperature drinking type yoghourt is increased, the quantity of a stabilizer is reduced, and the drinking type normal-temperature yoghourt tastes fresh and cool.

Owner:BRIGHT DAIRY & FOOD

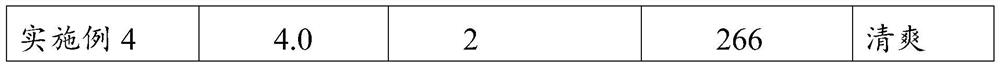

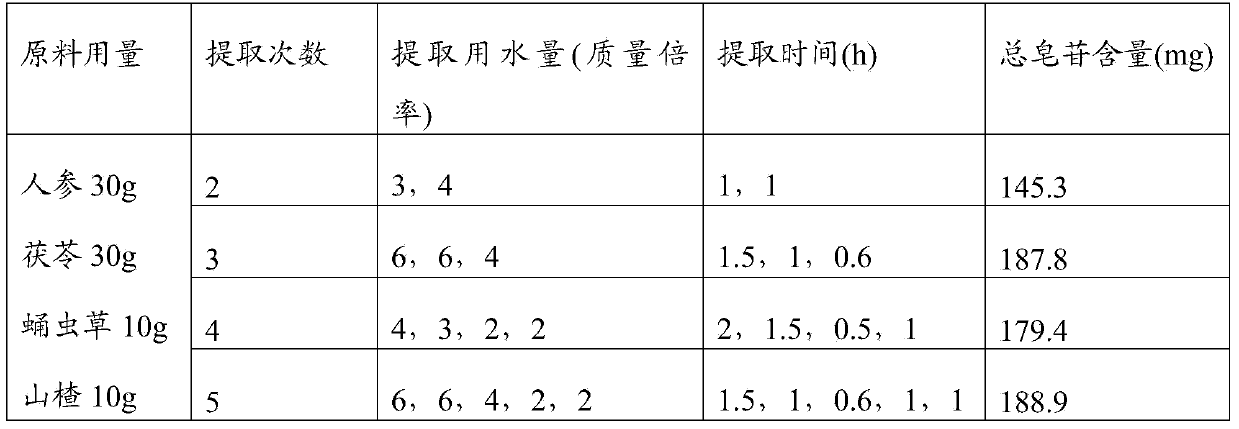

Pharmaceutical composition of ginseng and donkey-hide gelatin as well as preparation method and use thereof

The invention relates to a pharmaceutical composition of ginseng and donkey-hide gelatin with effects of enhancing immunity and resisting fatigue, and a preparation method of the pharmaceutical composition. The pharmaceutical composition is prepared from the following crude drugs in parts by weight: 2-6 parts of ginseng, 2-6 parts of poria cocos, 1-3 parts of donkey-hide gelatin, 1-3 parts of cordyceps militaris and 1-3 parts of hawthorn. The pharmaceutical composition disclosed by the invention is a pure traditional Chinese medicine preparation, and the drug components have the action, and also have synergistic effects, so as to achieve the targets of improving the immunity, resisting fatigue and relieving sub-health in common. Meanwhile, a plurality of screening tests can be carried out on the preparation technology. The optimal extracting technology and drying method are determined by test and comparison, and the effective ingredients of each drug component can be stored to the maximal extent, so as to improve the drug effect. In design of a dosage form, granules which are convenient to take and good in taste are adopted, and the pharmaceutical composition is simple in preparation technology, fewer in additive and healthier.

Owner:SHAN DONG DONG E E JIAO +1

Application of maltodextrin in preparing low-fat cakes, yoghourt and yoghourt cakes

InactiveCN105076294ASimple manufacturing methodLow fat contentMilk preparationDough treatmentFlavorAdditive ingredient

The invention discloses application of maltodextrin in preparing low-fat cakes, yoghourt and yoghourt cakes. The invention further discloses a formula and process of making the low-fat cakes, the yoghourt and the yoghourt cakes. The taste of food is improved by adding the maltodextrin. The made cakes, the yoghourt and yoghourt cakes have the advantages of being low in fat, low in sugar, appropriate in egg flavor, light and sweet in taste, reasonable in nutritional structure and the like. According to the application of maltodextrin in preparing low-fat cakes, yoghourt and yoghourt cakes, no chemical additive harmful to the human body or containing potential harmful components such as baking powder and emulsifying agents is added, the required raw materials are easy to obtain, the cost is low, the processing process is easy and controllable, and large-scale production is facilitated.

Owner:EAST CHINA NORMAL UNIVERSITY

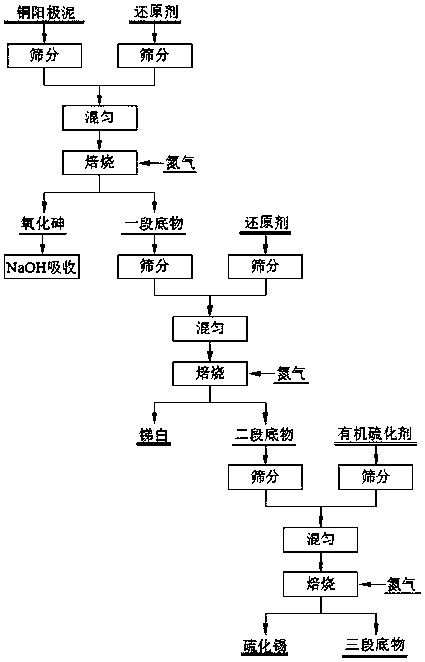

Method for separating arsenic and further recycling antimony and tin with copper anode slime reduction-organic vulcanization method

The invention relates to a method for separating arsenic and further recycling antimony and tin with a copper anode slime reduction-organic vulcanization method, and belongs to the technical field ofresource comprehensive recovery, utilization and environmental protection. The method includes the steps that copper anode slime and a reducing agent are evenly mixed after being ground at first, andreduction roasting volatilization arsenic removing is conducted under the inert gas shielding condition to obtain arsenic-containing soot and a first section of substrate; the obtained first section of the substrate and the reducing agent are evenly mixed after being ground, and reduction roasting is performed under the inert gas shielding condition to obtain the volatile product of antimony oxideand a second section of substrate; and the obtained second section of the substrate and an organic vulcanizing agent are evenly mixed after being ground, and reduction roasting is conducted under theinert gas shielding condition to obtain tin sulfide and a third section of substrate. The main phases of arsenic, antimony and tin in anode slime include As2O5, Cu3(AsO4)2, Sb2O4 and SnO2. By adoption of the method, the characteristics that high-value arsenic and antimony can be reduced easily and the oxide of the arsenic and antimony has different volatilities are fully utilized, and the arsenicand antimony separation problem of the copper anode slime is solved; and meanwhile the characteristics that the tin can be vulcanized easily and tin sulfide can volatilize easily are used for volatile recycling of the tin in the substrate.

Owner:ZHAOQING FEINAN METAL

Dyeing pretreatment process for cotton and cheese or warp beam containing cotton fiber

InactiveCN101381960AImprove dye uptakeReduce energy consumptionBiochemical fibre treatmentBleaching apparatusCotton fibreEnzyme

The invention provides a dyeing pretreatment process for cotton and cheese or warp beams containing cotton fiber, which is characterized by adopting the following steps: (1) treating the cheese or warp beams in a main cylinder by use of biological enzyme for 30 to 50 minutes at the temperature of between 40 and 55 DEG C, and bleaching the cheese or warp beams with oxygen for 30 to 50 minutes at the temperature of between 70 and 95 DEG C; (2) discharging water; (3) washing, discharging water again; and (4) performing enzyme treatment for removing hydrogen peroxide. As the process changes the prior pretreatment for the cotton and cheese or warp beams containing cotton fiber into biological enzyme treatment and oxygen bleaching and reduces the amount of caustic soda and hydrogen peroxide as auxiliaries, the process has the advantages that the maximum temperature of the process is 15 to 40 DEG C lower than of the temperature of the normal oxygen bleaching, the process reduces energy consumption, improves dye-uptake rate, reduces pollution on environment, allows pretreatment to be more friendly to environment, ensures that the whiteness and capillary effect after treatment are equivalent to that of the normal high-temperature pretreatment, improves the dye-uptake rate of cotton fiber, does not limit or affect dyeing process, does not need to replace equipment, has low energy consumption, and is simple to realize.

Owner:LUTAI TEXTILE

Method for preparing enzyme from kudzuvine roots and mulberry fruits

ActiveCN105919099AQuality improvementFully retain active ingredientsFood hydrolysisFood ingredient functionsBiotechnologyNutrition

The invention discloses a method for preparing an enzyme from kudzuvine roots and mulberry fruits. The method comprises the following steps that the kuzuvine roots and the mulberry fruits are smashed by a pulping machine and mixed to be uniform; a mixture is poured into a fermentation container, a precooled disodium hydrogen phosphate-citric acid buffer solution is added, a complex enzyme and ferrous carbonate are added, and enzymatic low-temperature extraction is conducted; filtrate is extracted to prepare first-time fermentation liquor, the first-time fermentation liquor is inoculated with lactobacillus plantarum to prepare second-time fermentation liquor, and the second-time fermentation liquor is subjected to solid-liquid separation to obtain the enzyme. According to the method, through enzymatic low-temperature extraction, the nutritional ingredients in the kudzuvine roots and the mulberry fruits can be fully extracted, the product effect and edible safety are greatly improved, the technology is simple, and the prepared enzyme fully retains the effective ingredients of the kudzuvine roots and leaves and the mulberry fruits, is stable in quality, has multiple effects of reducing blood vessel resistance, improving cardio-cerebral blood circulation, reducing the myocardial oxygen consumption and the like and can achieve the nutrition and health care effects.

Owner:JIANSU MAOBAO GEYE CO LTD

Beef fat hot pot condiment

PendingCN112042913AFatty fragranceGood lubricity and stabilityFood ingredient as thickening agentYeast food ingredientsChemistryAllium

The invention discloses a beef fat hot pot condiment, and belongs to the field of food. The beef fat hotpot condiment comprises 450-500 parts of edible beef fat, 80-100 parts of shortening, 70-90 parts of glutinous rice cake capsicum annuum L., 10-20 parts of dry capsicum annuum L., 10-20 parts of piperis Dahongpao, 10-20 parts of thick broad-bean sauces, 1-10 parts of fermented soya beans, 10-20parts of rhizoma zingiberis, 5-10 parts of allium cepa L., 5-10 parts of Allium. fistulosum L. var. gigantum Makino, 1-10 parts of foeniculi fructus, 1-5 parts of rock candies, 10-15 parts of chickenpowders, 1-5 parts of yeast extracts, 0.5-3 parts of ethyl maltol and 1-10 parts of liquor and spirits. The beef fat hot pot condiment is clear and bright, is free from impurities and has a thick fatfragrance and good oil wettability and stability, the taste of the beef fat hot pot condiment is natural and is emitted for a long time, the beef fat hot pot condiment is smooth to eat, has a good taste, is not greasy, is free from soup turbidity, is health to eat and is environmentally-friendly, and in addition, the beef fat hot pot condiment has few additives and small ingredients and has a lowcost.

Owner:糜富林

Under-forest ecological sanhuang chicken breeding method

InactiveCN107637580AReduce the cost of farmingEasy to operateAnimal feeding stuffAccessory food factorsNutritive valuesAnimal Foraging

The invention provides an under-forest ecological sanhuang chicken breeding method. The under-forest ecological sanhuang chicken breeding method comprises the four steps of farm selection, farm erection, forage grass and fodder selection and feeding and management. The under-forest ecological sanhuang chicken breeding method has the advantages of being low in production cost and convenient to operate, making chicken delicious, making the nutritive value of eggs high and the like.

Owner:丁爱军

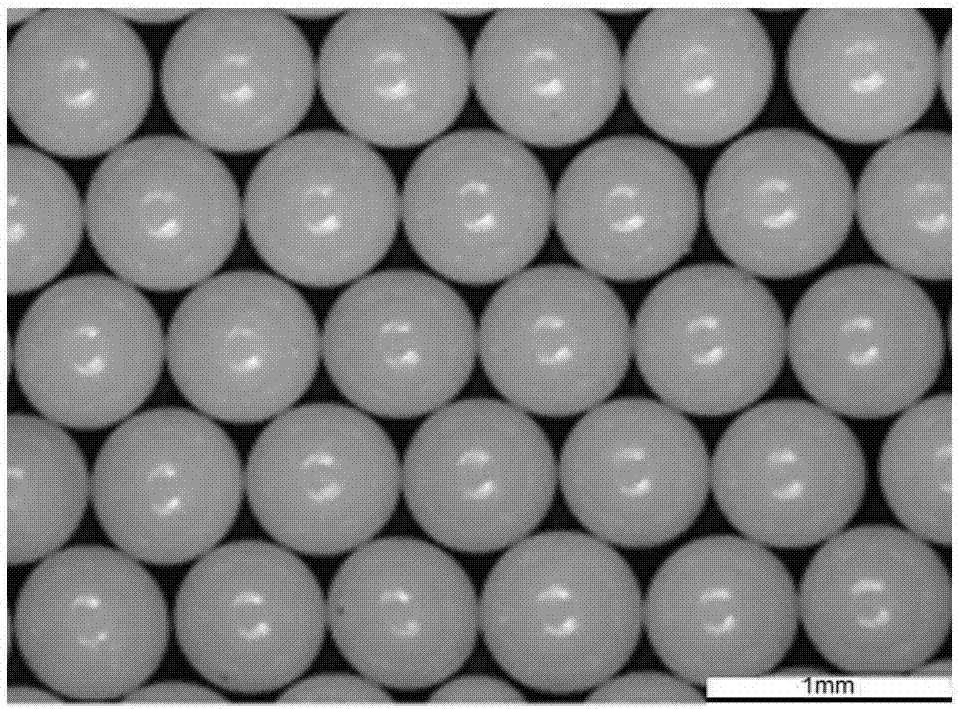

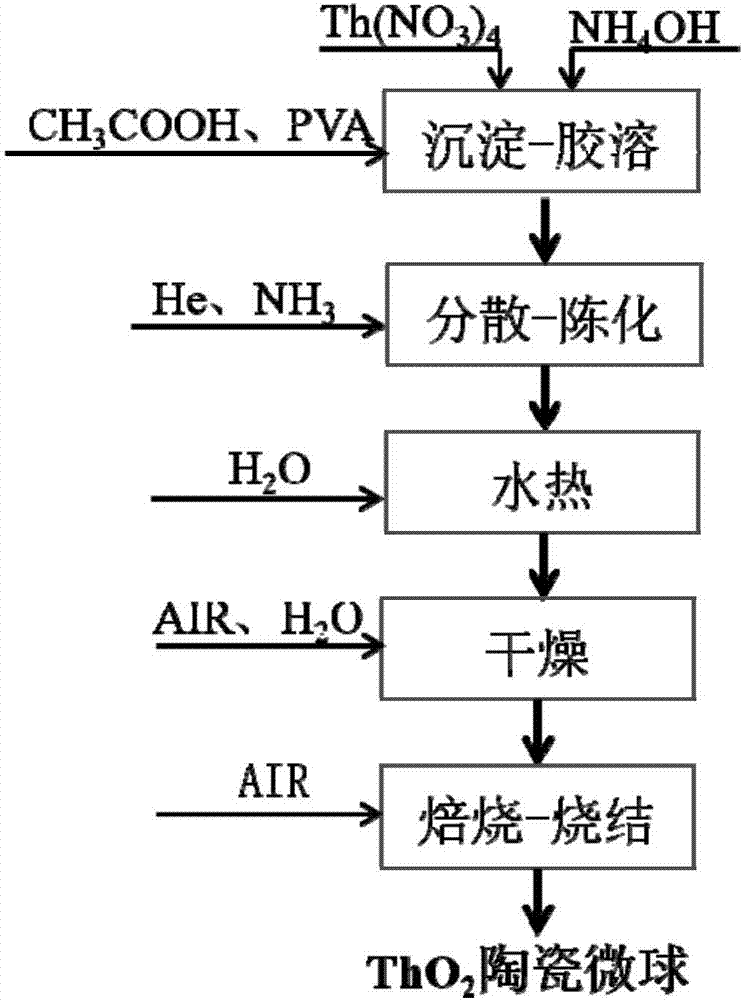

Method for preparing ceramic micro-spheres of thorium oxide

ActiveCN107010955AReduce the probability of ruptureAvoid breakingNuclear energy generationReactors manufacturePolyvinyl alcoholThorium oxide

The invention relates to a method for preparing ceramic micro-spheres of thorium oxide. The method includes dropwise adding ammonia water into thorium nitrate solution to form hydrolysis solution, dropwise adding glacial acetic acid into the hydrolysis solution to regulate the pH (potential of hydrogen) of the hydrolysis solution, and adding polyvinyl alcohol into the hydrolysis solution under stirring conditions to form thorium oxide colloidal solution; dispersing the thorium oxide colloidal solution to obtain liquid drop and allowing the liquid drop to sequentially flow through helium zones, ammonia gas zones and ammonia water zones; arranging dispersed gel particles in strong ammonia water and aging the dispersed gel particles; adding the aged gel particles and deionized water into a hydrothermal reaction kettle and carrying out temperature reaction; placing gel particles into a drying furnace after hydrothermal reaction is carried out on the gel particles, and heating and drying the gel particles under humidity control to form dried gel particles; placing the dried gel particles in a calcination furnace, filling the calcination furnace with air and heating and calcining the gel particles to obtain calcined gel particles; placing the calcined gel particles in a sintering furnace, filling the sintering furnace with air and heating and sintering the calcined gel particles to obtain the ceramic micro-spheres. The method has the advantage that the ceramic micro-spheres of the thorium oxide can be prepared by the aid of simple technologies.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Edible fungi table vegetable and making method thereof

The invention provides an edible fungi table vegetable and a making method thereof. The table vegetable is made from, by weight, 145-160 parts of vegetable oil, 28-35 parts of pickled red pepper, 13-17 parts of pickled vegetables, 15-18 parts of pickled ginger, 7-10 parts of pickled rice chili, 58-65 parts of fried dry shiitake mushrooms, 85-90 parts of salted pleurotus eryngii, 3-5 parts of preserved pickle, 2.5-3.5 parts of onions, 11-15 parts of pickled garlic, 2-2.3 parts of chili powder and 2.5-3 parts of salt. The edible fungi table vegetable is rich in nutrition, has strong flavor and few additives, is green, healthy and excellent in gastronomic performance, and the raw materials are low in cost.

Owner:SICHUAN GAOFUJI FOOD

Feed sweetener for livestock and poultry and preparation method thereof

InactiveCN102028101AImprove palatabilityIncreased Digestive PotentialAnimal feeding stuffAccessory food factorsSolventFodder

The invention discloses a feed sweetener for livestock and poultry and a preparation method thereof. A production method for the feed sweetener product comprises the following steps of: a, dissolving neotame in a cosolvent to form neotame solution, wherein a ratio of the neotame to the cosolvent is about 2:1 to about 1:2; b, dissolving an active aid in water to form active aid solution, wherein a ratio of the active aid to the water is about 2:1 to about 1:1; c, mixing the neotame solution and the active aid solution to form mixed solution, wherein a ratio of the neotame solution to the active aid solution is about 1:3 to about 1:100, and the neotame and the active aid are completely dissolved in the mixed solution; and d, performing spray drying on the mixed solution to obtain the feed additive containing less than 7 percent of water and less than 20 percent of neotame. The feed sweetener has good uniformity, flowing property, stability and sweet taste, can improve the palatability of a feed, promotes the ingestion of animals and improves production efficiency.

Owner:湖南现代资源生物科技有限公司

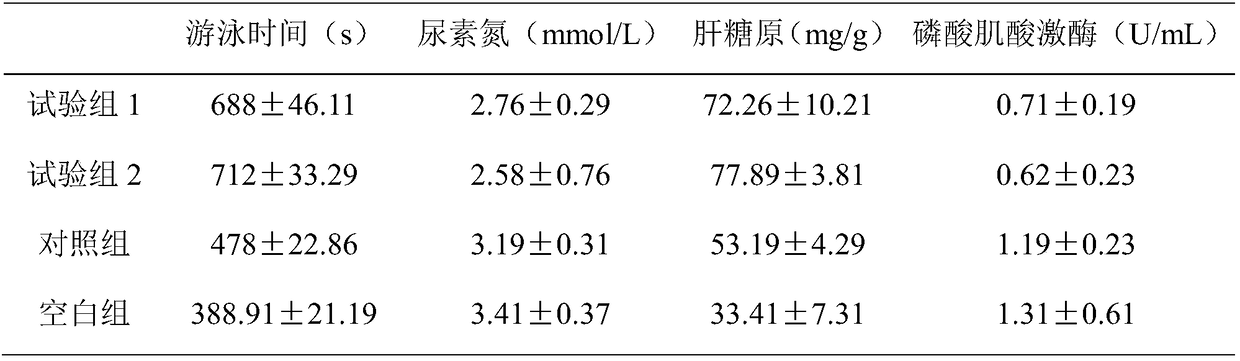

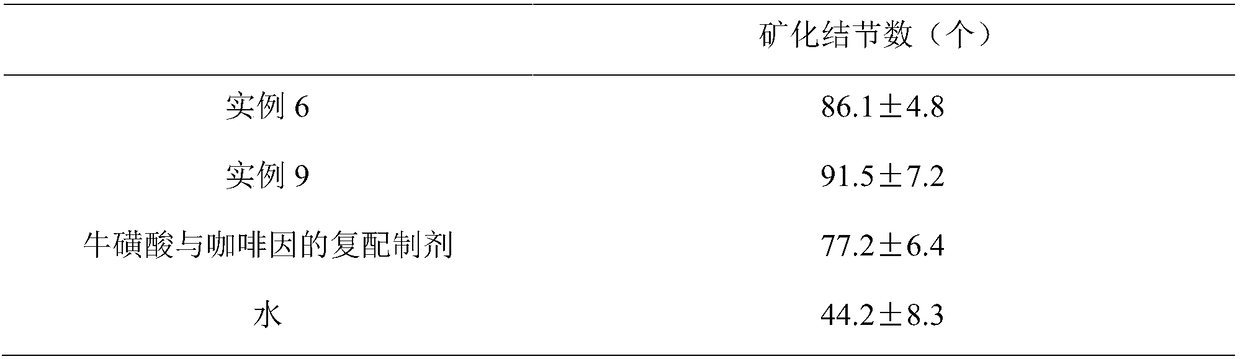

Tablet for relieving physical fatigue and preparation technology thereof

PendingCN108851089AImprove solubilityPromote absorptionHydroxy compound active ingredientsAntinoxious agentsMedicineNatural substance

The invention discloses a tablet for relieving physical fatigue. The tablet is prepared from the following raw materials in parts by weight: 400 to 500 parts of taurine, 90 to 110 parts of caffeine, 140 to 160 parts of L-lysine hydrochloride, 45 to 55 parts of inositol, 30 to 40 parts of nicotinamide and 4 to 6 parts of vitamin B6. The invention also discloses a preparation technology of the tablet for relieving the physical fatigue. The preparation technology disclosed by the invention creatively prepares health-care products into tablets and extracts the taurine and the caffeine from naturalsubstances; the safety of the tablet is higher than the safety of artificially synthesized products; the prepared product can significantly relieve the physical fatigue.

Owner:沈方雄

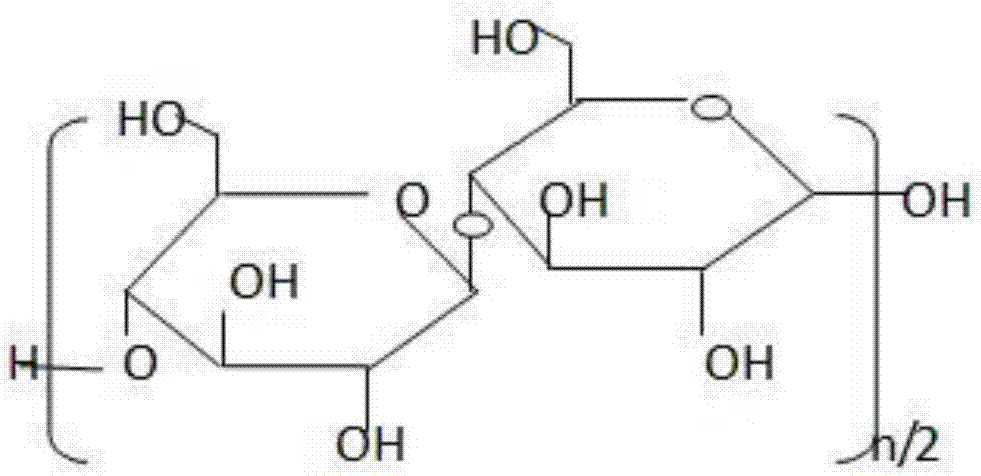

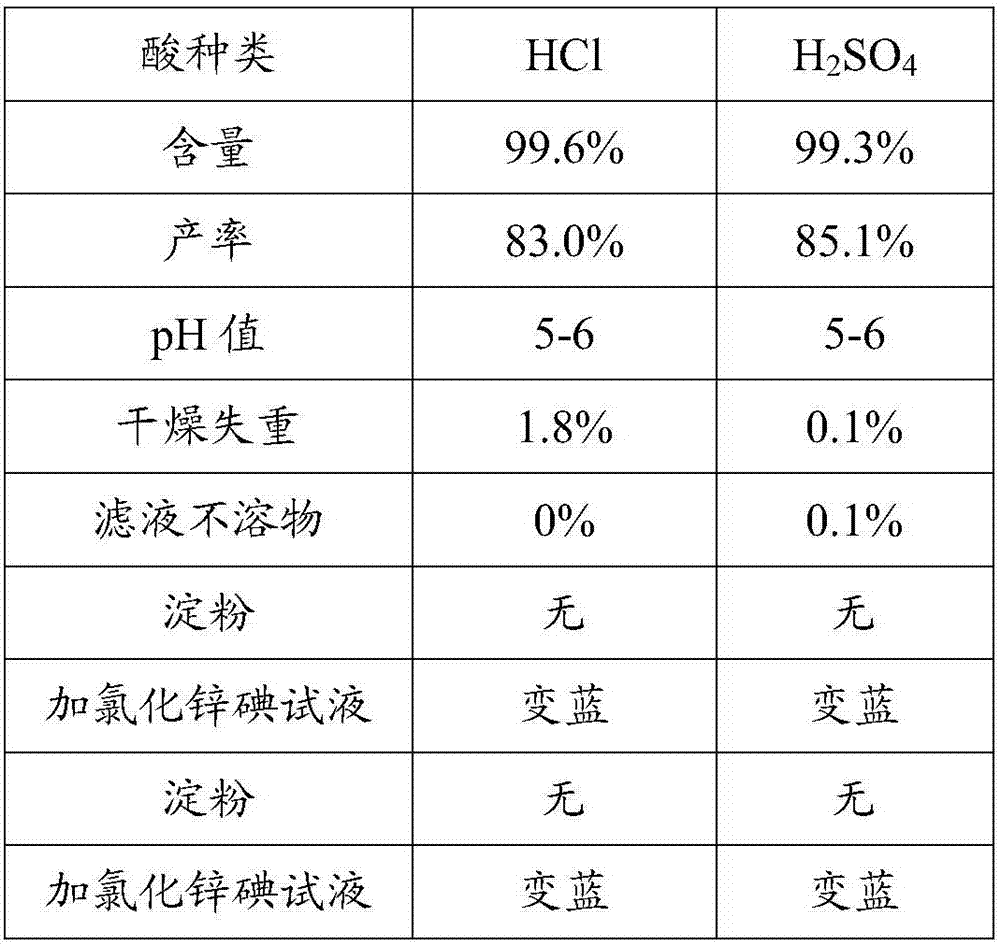

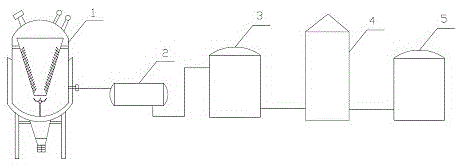

Process for preparing microcrystalline cellulose by cotton noils

The invention discloses a process for preparing microcrystalline cellulose by cotton noils. The cotton noils are used for preparing the microcrystalline cellulose, and pretreatment mainly adopts low-dosage scouring-oxygen bleaching-soaping-washing processes. The dosage of additives used for cotton treatment is greatly reduced, a hydrolysis process of 6%-8% hydrochloric acid or sulfuric acid within the range of 60-80 DEG C is used for preparing the microcrystalline cellulose, and the high-purity microcrystalline cellulose is obtained while the industrial waste cotton noils are sufficiently used.

Owner:HUAFANG +1

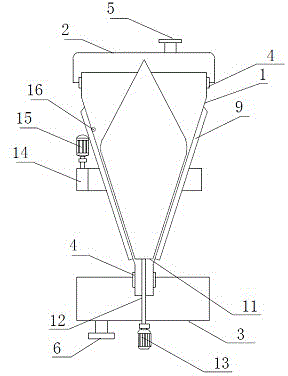

A kind of vortex type graphene stripping device, graphene production system and production method

A vortex graphene stripping device is disclosed. The vortex graphene stripping device comprises an outer cylinder provided with a heating jacket. The outer cylinder is provided with a pressure gage for detecting the pressure in the outer cylinder and a temperature measuring device for measuring the temperature in the outer cylinder. The top of the outer cylinder is provided with a feed port. The middle and lower part of the outer cylinder is provided with a discharging port. An inner sleeve of the outer cylinder is provided with a truncated cone-shaped inner cylinder with a downward taper angle. The upper and lower ends of the inner cylinder are open. The inner cylinder is fixed in the outer cylinder in a suspension manner through a hollowed-out support. Shear blades used for stripping graphene flakes are tightly arranged on the inner wall of the inner cylinder. A groove is formed between each adjacent shear blades. A turbine is disposed between the lower end of the inner cylinder and the lower end of the outer cylinder, and is driven to rotate by a driving mechanism disposed outside the outer cylinder. Turbine blades are perpendicular to and towards the opening at the lower end of the inner cylinder. The vortex graphene stripping device can achieve successful stripping of graphene. The invention also relates to a graphene producing system comprising the vortex graphene stripping device and a graphene producing method.

Owner:江苏碳谷二维世界科技有限公司

Lipid-lowering tomato sauce and preparation method thereof

InactiveCN107319497AHas lipid-lowering effectHas the same effect of medicine and foodFood ingredient functionsMonosodium glutamateChinese hawthorn

The invention belongs to the technical field of food, and particularly relates to lipid-lowering tomato sauce and a preparation method thereof. The invention aims at enabling the tomato sauce to have a healthcare and lipid-lowering efficacy while maintaining the delicious taste, no pollution and no additive by virtue of novel raw material configuration and production method so as to achieve a medicinal and edible effect. The lipid-lowering tomato sauce is prepared from the following components in parts by weight: 5 to 10 parts of tomato, 0.5 to 1 part of soybeans, 0.5 to 1 part of peanut kernels, 0.5 to 1 part of Chinese hawthorn, 0.25 to 0.5 part of fructus lycii, 0.25 to 0.5 part of ginger, 0.05 to 0.1 part of aniseed, 0.05 to 0.1 part of Sichuan pepper, 0.1 to 0.5 part of table salt, and 0.05 to 0.1 part of aginomoto.

Owner:赵欣丽

Antifoaming agent for delaying coking

InactiveCN104707366ALower the altitudeGood anti-foaming effectThermal non-catalytic crackingFoam dispersion/preventionDefoamerProcess engineering

The invention relates to an antifoaming agent for delaying coking. The antifoaming agent comprises 10-35% of modified polysiloxane, 30-60% of long chain fatty alcohol and 20-50% of a solvent. The antifoaming agent is prepared through the following steps: mixing above components in proportion, stirring the above obtained system at 60-90DEG C for 1h, and cooling. The antifoaming agent has a low content of silicon of below 3%, is used for a coking delaying technology, can effectively inhibit and eliminate foams in a coke tower, and has the advantages of good antifoaming effect, small addition amount of 30-50ppm, wide sources of raw materials, and low cost.

Owner:营口风光新材料股份有限公司

A preparation method of polyethersulfone ultrafiltration membrane with improved permeability and selectivity at the same time

ActiveCN104056557BHigh porosityIncreasing the thicknessSemi-permeable membranesUltrafiltrationSolvent

The invention discloses a preparation method of a polyethersulfone ultrafiltration membrane which improves both permeability and selectivity. The ultrafiltration membrane is prepared by a phase inversion method, and PEI is used as an additive. The addition of PEI changes the phase inversion process and regulates the structure of the PES ultrafiltration membrane to achieve high flux and high selectivity. The preparation includes: (1) dissolving PEI in a solvent (DMF), then adding polyethersulfone and polyvinylpyrrolidone (PVP) to heat and dissolve to form a homogeneous casting solution; (2) then controlling the film-forming conditions to prepare a flat film. The invention effectively regulates the structure of the PES ultrafiltration membrane, increases the opening ratio and the thickness of the selective layer, and greatly improves the permeability and selectivity. The preparation method is simple, and is suitable for industrial production and the preparation of nanofiltration membrane base membranes.

Owner:NANJING UNIV OF SCI & TECH

Preparation method for environment-friendly sticky rice glue

InactiveCN108219708ALess additivesHigh viscosityNon-macromolecular adhesive additivesStarch adhesivesSodium stearateAcetic acid solution

The invention discloses a preparation method for environment-friendly sticky rice glue. The preparation method comprises the following steps: (1) weighing raw materials; (2) cleaning sticky rice, soaking the sticky rice with deionized water, and adding into an acetic acid solution to soak; (3) preparing modified starch; (4) uniformly mixing the product obtained in step (2) with modified starch obtained in step (3), and adding urea and an emulsifying stabilizer to uniformly stir; (5) adding sodium tripolyphosphate, sodium stearate and anhydrous aluminum sulfate into a product obtained in step (4), stirring and uniformly mixing, and heating up to perform high-temperature pasting reaction; and (6) sequentially adding a bactericide, modified bamboo charcoal powder and a plant extracting solution into a pasting reaction product obtained in step (5), stirring and uniformly mixing, reacting and processing, cooling, sterilizing and packaging to obtain the environment-friendly sticky rice glue.The environment-friendly sticky rice glue takes sticky rice, starch and the like as raw materials, is less in additive, is high in viscosity, is long in storage time, and is excellent in freezing resistance.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

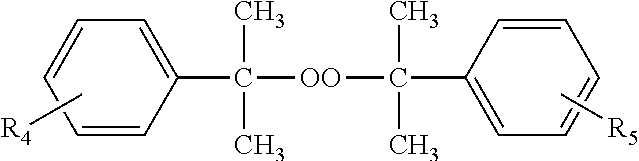

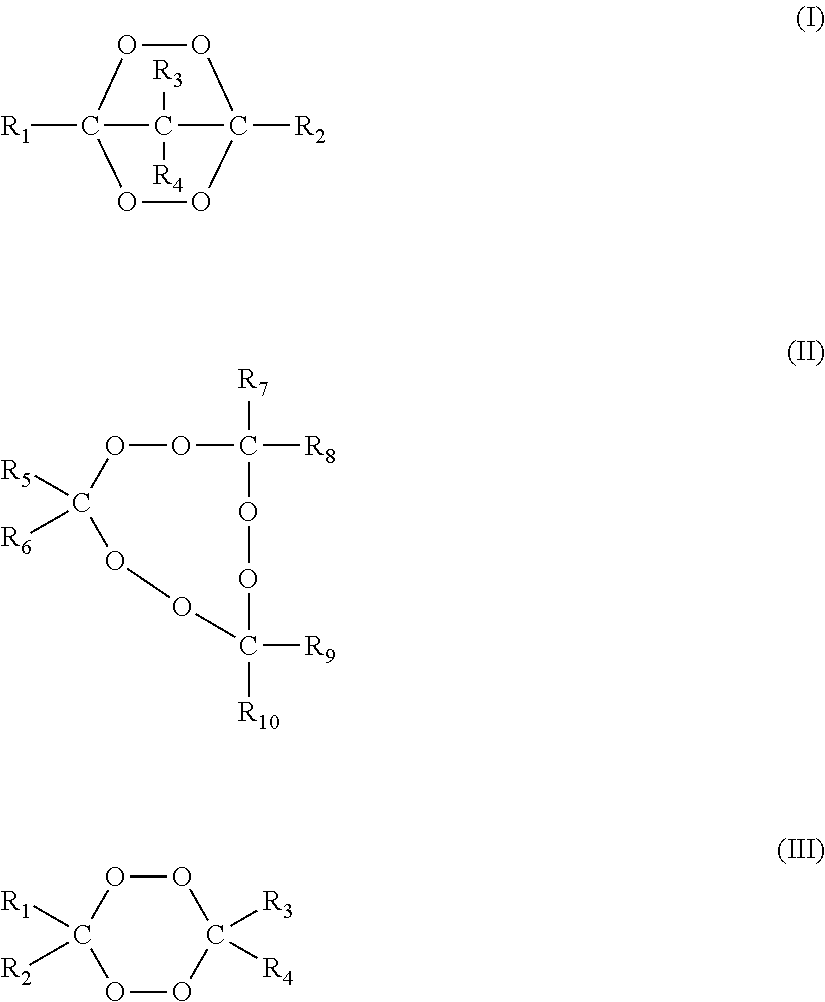

Liquid and meltable solid grades of scorch protected peroxides

Embodiments of organic peroxide formulations provide longer scorch time protection and require fewer additives. The peroxide formulations may include, for example, at least one organic peroxide, at least one nitroxide-containing compound (e.g., 4-hydroxy-TEMPO), and at least one quinone-containing compound (e.g., mono-tert-butylhydroquinone). Embodiments of the present invention relate to organic peroxide compositions comprising scorch retarders. Embodiments of the invention also relate to crosslinkable elastomer compositions, processes for curing the elastomers, and products made by such processes.

Owner:ARKEMA INC

Meat rabbit breeding method under robinia pseudoacacia forest

InactiveCN109329206ARaw materials are pure and naturalPure Natural NutritionFood processingAnimal feeding stuffDiseaseAnimal science

The invention discloses a meat rabbit breeding method under a robinia pseudoacacia forest. The method comprises the steps of field construction, feed feeding, disinfection management and disease immunization. Accordingly, by means of the space under the robinia pseudoacacia forest, timing free range is implemented on meat rabbits, not only is the space under the robinia pseudoacacia forest fully utilized and the land cost reduced, but also the meat rabbits move freely for a certain period of time under the forest every day, the immunity of the meat rabbits is enhanced, diseases are reduced, and rabbit meat is tenderer, the nutritional value is high, and the palatability is good. The feed is prepared according to the meat rabbits in different growth periods, the fecundity can be effectivelyimproved, the growth speed is increased, and the economic benefit is improved.

Owner:泓森林业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com