Method for separating arsenic and further recycling antimony and tin with copper anode slime reduction-organic vulcanization method

A copper anode slime and organic technology, which is applied in the field of comprehensive resource recycling and environmental protection, can solve the problems of poor separation effect and long process flow of antimony separation, and achieve the effect of easy control, less additive dosage and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

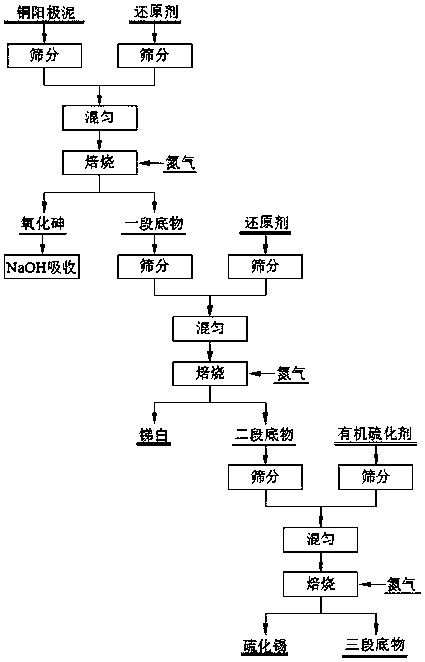

[0040] Such as figure 1 Shown, this copper anode slime reduction-organic vulcanization method separates arsenic and reclaims the method for antimony, tin, and its specific steps are as follows:

[0041] Step 1, first copper anode slime (wherein As mass percentage content is 9.91%, Sb mass percentage content is 6.34%, Sn mass percentage content is 13.34%, also comprises the metal element of following mass percentage: also comprises the following mass percentage of metal Elements: Cu 11.62%, Ni 5.8%, Pb 1.54%), reducing agent (the reducing agent is carbon powder, and the amount of reducing agent added is 5% of the mass of the copper anode slime) respectively ground to a particle size of 74 μm and mixed evenly, and passed The inflow gas flow rate is 0.4L / min under the protection of nitrogen inert gas, reduction roasting at 600°C for 90 minutes to volatilize and remove arsenic to obtain arsenic-containing fumes and a substrate, and the arsenic-containing fumes are absorbed by NaOH...

Embodiment 2

[0046] Such as figure 1 Shown, this copper anode slime reduction-organic vulcanization method separates arsenic and reclaims the method for antimony, tin, and its specific steps are as follows:

[0047] Step 1, first copper anode slime (wherein As mass percentage content is 9.91%, Sb mass percentage content is 6.34%, Sn mass percentage content is 13.34%, also comprises the metal element of following mass percentage: also comprises the following mass percentage of metal Elements: Cu 11.62%, Ni 5.8%, Pb 1.54%), reducing agent (the reducing agent is coke, and the amount of reducing agent added is 10% of the mass of copper anode slime) respectively ground to a particle size of 74 μm and mixed evenly, The gas flow rate is 0.4L / min, under the protection of nitrogen inert gas, reduction roasting at 700°C for 60 minutes to volatilize and remove arsenic to obtain arsenic-containing fumes and a substrate, and the arsenic-containing fumes are absorbed by NaOH with a concentration of 20g / ...

Embodiment 3

[0052] Such as figure 1 Shown, this copper anode slime reduction-organic vulcanization method separates arsenic and reclaims the method for antimony, tin, and its specific steps are as follows:

[0053] Step 1, first copper anode slime (wherein As mass percentage content is 9.91%, Sb mass percentage content is 6.34%, Sn mass percentage content is 13.34%, also comprises the metal element of following mass percentage: also comprises the following mass percentage of metal Elements: Cu 11.62%, Ni 5.8%, Pb 1.54%), reducing agent (the reducing agent is anthracite, and the amount of reducing agent added is 8% of the mass of the copper anode slime) were respectively ground to a particle size of 74 μm, mixed evenly, and passed through Under the protection of nitrogen inert gas flow rate of 0.4 L / min, reduction roasting at 800 °C for 90 min to remove arsenic by volatilization to obtain arsenic-containing fumes and a substrate, arsenic-containing fumes were treated with NaOH with a conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com