A preparation method of polyethersulfone ultrafiltration membrane with improved permeability and selectivity at the same time

A polyethersulfone ultrafiltration membrane and selective technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology and other directions, can solve the problems of low permeability of polyethersulfone ultrafiltration membrane, and achieve high industrial applications Value, porosity increase, effect of separation layer thickness increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing a polyethersulfone ultrafiltration membrane with improved permeability and selectivity simultaneously, the method comprising:

[0026] (1) Preparation of casting solution: Mix four components of polyethersulfone, polyethyleneimine, polyvinylpyrrolidone and solvent to make a casting solution, heat and stir to dissolve, and after forming a homogeneous solution, let it stand for defoaming for later use ;

[0027] The ratio of polyethersulfone, polyvinylpyrrolidone, polyethyleneimine, and N-N dimethylformamide is as follows, and its component content is:

[0028]

[0029] All percentages are by weight;

[0030] (2) Use a scraper to form a uniform solution layer on a glass plate with the above-mentioned degassed solution, pre-evaporate, the pre-evaporation medium is air, and then immerse in a coagulation bath to form a film; after the film is formed, fully wash it with ultrapure water , remove solvent, and save.

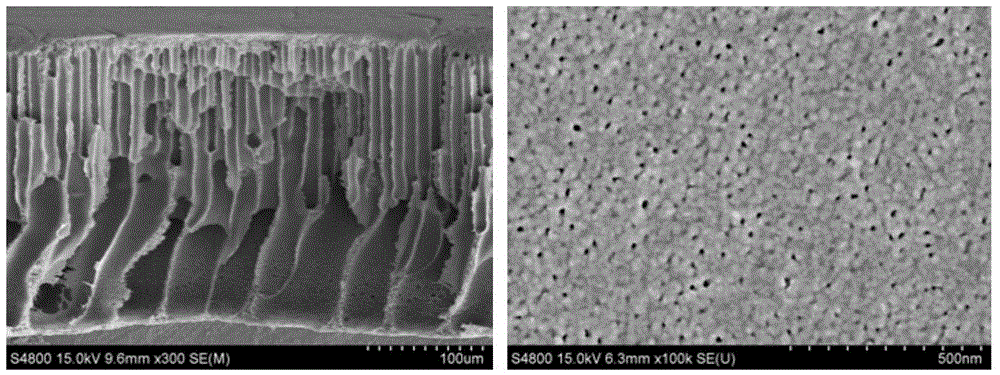

Embodiment 1

[0033] Dissolve 0.1 g of polyethyleneimine in 78.9 g of N-N dimethylformamide, add 16 g of polyethersulfone (PES) and 5 g of polyvinylpyrrolidone (PVP) after it is completely dissolved, and place it in a 60°C oil bath Continue to stir for 6-8 hours to form a homogeneous casting solution. The casting solution is left to stand for more than 12 hours for defoaming.

[0034] The defoamed casting solution was scraped on a clean glass plate at 25°C and 60% relative humidity, and stayed in the air for 30 seconds, then soaked in a coagulation bath for half an hour, taken out and soaked in deionized water, and Store in deionized water until use. Its pure water flux is 239L / m 2 ·h·bar, bovine serum albumin (67000MW) rejection rate is 95.5%.

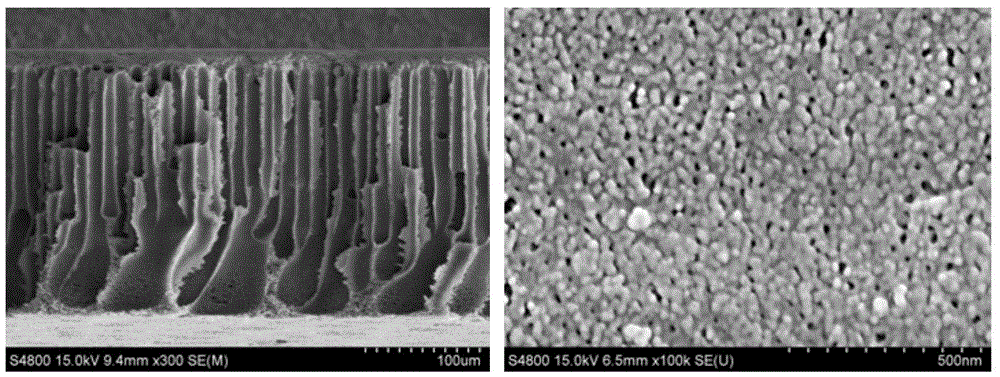

Embodiment 2

[0036] Dissolve 0.3 grams of polyethyleneimine in 78.7 grams of N-N dimethylformamide, add 16 grams of polyethersulfone (PES) and 5 grams of polyvinylpyrrolidone (PVP) after it is completely dissolved, and place it in an oil bath at 60 ° C Continue to stir for 6-8 hours to form a homogeneous casting solution. The casting solution is left to stand for more than 12 hours for defoaming.

[0037] The defoamed casting solution was scraped on a clean glass plate at 25°C and 60% relative humidity, and stayed in the air for 30 seconds, then soaked in a coagulation bath for half an hour, taken out and soaked in deionized water, and Store in deionized water until use. Its pure water flux is 359L / m 2 ·h·bar, bovine serum albumin (67000MW) rejection rate is 96.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com