Device for continuously preparing graphene and method for producing graphene

A graphene and graphite technology, which is applied in the field of continuous graphene preparation devices, can solve the problems of many defects, small graphene size, and low peeling efficiency, and achieve the effects of less structural defects, high production efficiency, and reduced structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a device for continuously grinding slurry to prepare graphene.

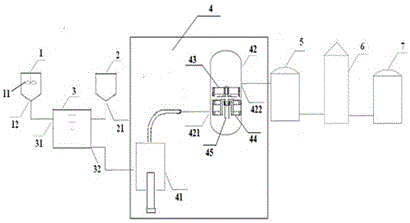

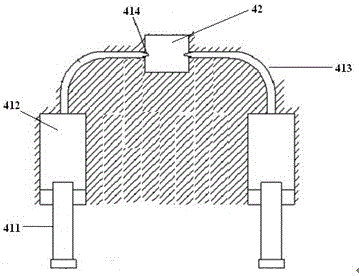

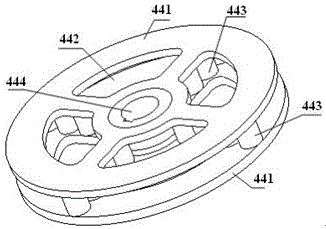

[0034] A device for continuously preparing graphene, such as figure 1 As shown, it includes raw material grinding tank (1), grinding medium storage bin (2), stirring tank (3), continuous grinding mechanism (4), storage tank (5), centrifugal filter device (6) and drying device ( 7). The raw material grinding tank (1) is equipped with a blade-type agitating mill (11) for coarse grinding of graphite raw materials; the grinding medium storage bin (2) is used to store grinding media; the bottom of the raw material grinding tank and the grinding media storage bin are both set The outlets (12), (21); the stirring tank (3) is used to prepare graphite slurry, the stirring tank (3) is provided with an upper feeding port (31) and a lower feeding port (32), and the outlet of the raw material grinding tank The feed port (12) and the discharge port (21) of the grinding medium storage bin are r...

Embodiment 2

[0039] The present embodiment provides a kind of production method of graphene, and it is the method that adopts the preparation device of the graphene of embodiment 1 to carry out production, and this method comprises the following steps:

[0040] (1) Put the graphite raw material into the raw material grinding tank, add quartz sand and ceramic beads with a diameter of 2mm, and use media grinding to roughly grind the graphite raw material;

[0041] (2) Put the coarsely ground graphite raw material in the raw material grinding tank into the stirring tank through the upper feeding port of the stirring tank, then add the grinding medium in the grinding medium storage bin, inject water from the lower feeding port, and set the stirring tank The stirring speed is 500rpm to obtain a graphite dispersion slurry; wherein the grinding medium is composed of the following components by weight percentage: 40% amphiphilic polymer, 30% nano-modified hydrotalcite, 10% micro-expansion agent, an...

Embodiment 3

[0048] The present embodiment provides a kind of production method of graphene, and it is the method that adopts the preparation device of the graphene of embodiment 1 to carry out production, and this method comprises the following steps:

[0049] (1) Put the graphite raw material into the raw material grinding tank, add ceramic beads and zirconium beads with a diameter of 5mm, and use media grinding to roughly grind the graphite raw material;

[0050] (2) Put the coarsely ground graphite raw material in the raw material grinding tank into the stirring tank through the upper feeding port of the stirring tank, then add the grinding medium in the grinding medium storage bin, inject water from the lower feeding port, and set the stirring tank The stirring speed is 800rpm to obtain a graphite dispersion slurry; wherein the grinding medium is composed of the following components by weight percentage: 30% amphiphilic polymer, 30% nano-modified hydrotalcite, 10% micro-expansion agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com