Patents

Literature

270results about How to "Big cost advantage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

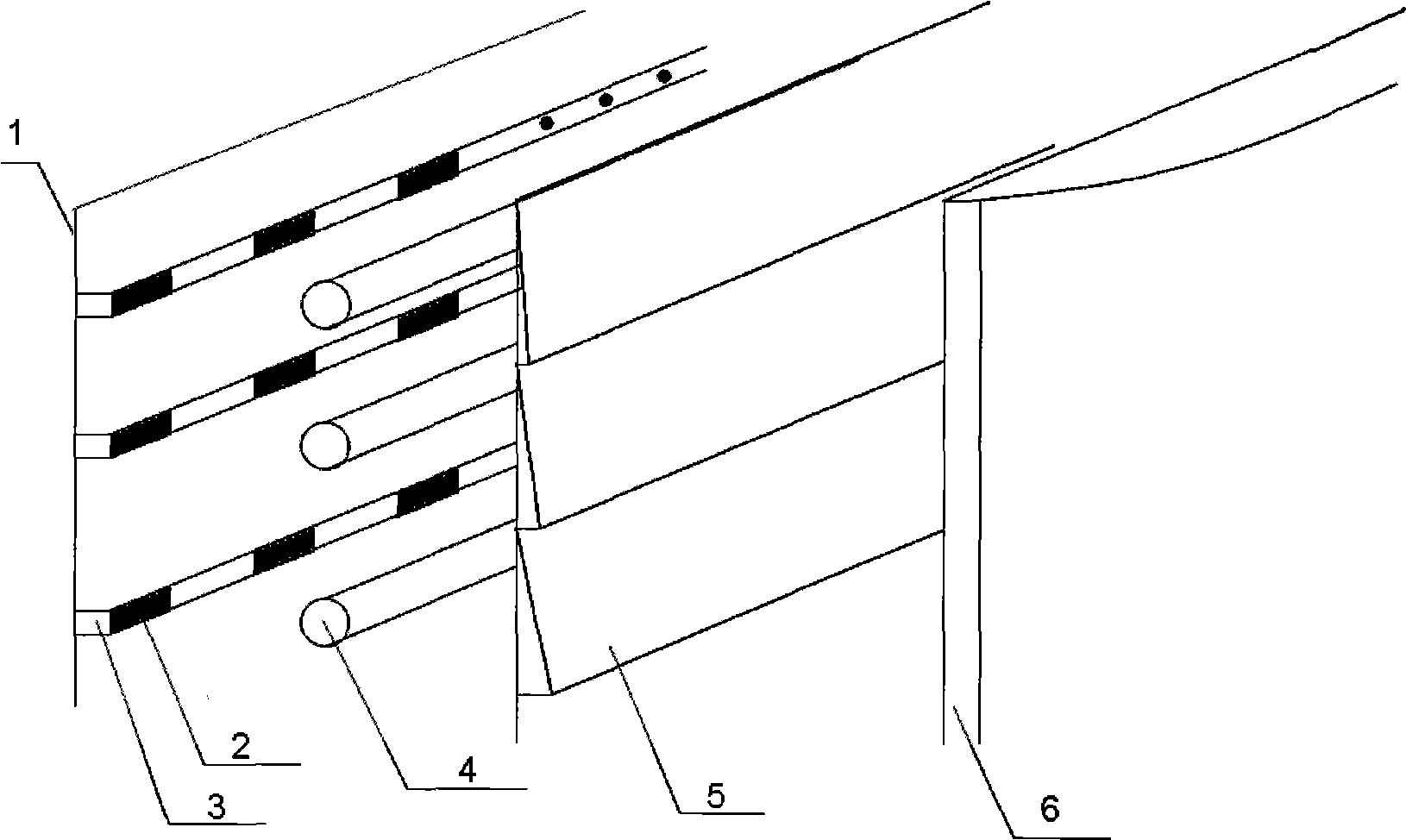

Wet crepe throughdry process for making absorbent sheet and novel fibrous products

InactiveUS20020148584A1Big cost advantageReduce air permeabilityNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

An improved process for making sheet from a fibrous furnish includes: depositing the furnish on a foraminous support; compactively dewatering the furnish to form a nascent web; drying the web on a heated cylinder; creping the web therefrom and throughdrying the web to a finished product. The microstructure of the web is controlled so as to facilitate throughdrying. The product exhibits a characteristic throughdrying coefficient of from 4 to 10 when the airflow through the sheet is characterized by a Reynolds Number of less than about 1. The novel products of the invention are characterized by wet springback ratio, hydraulic diameter and an internal bond strength parameter.

Owner:GPCP IP HLDG LLC

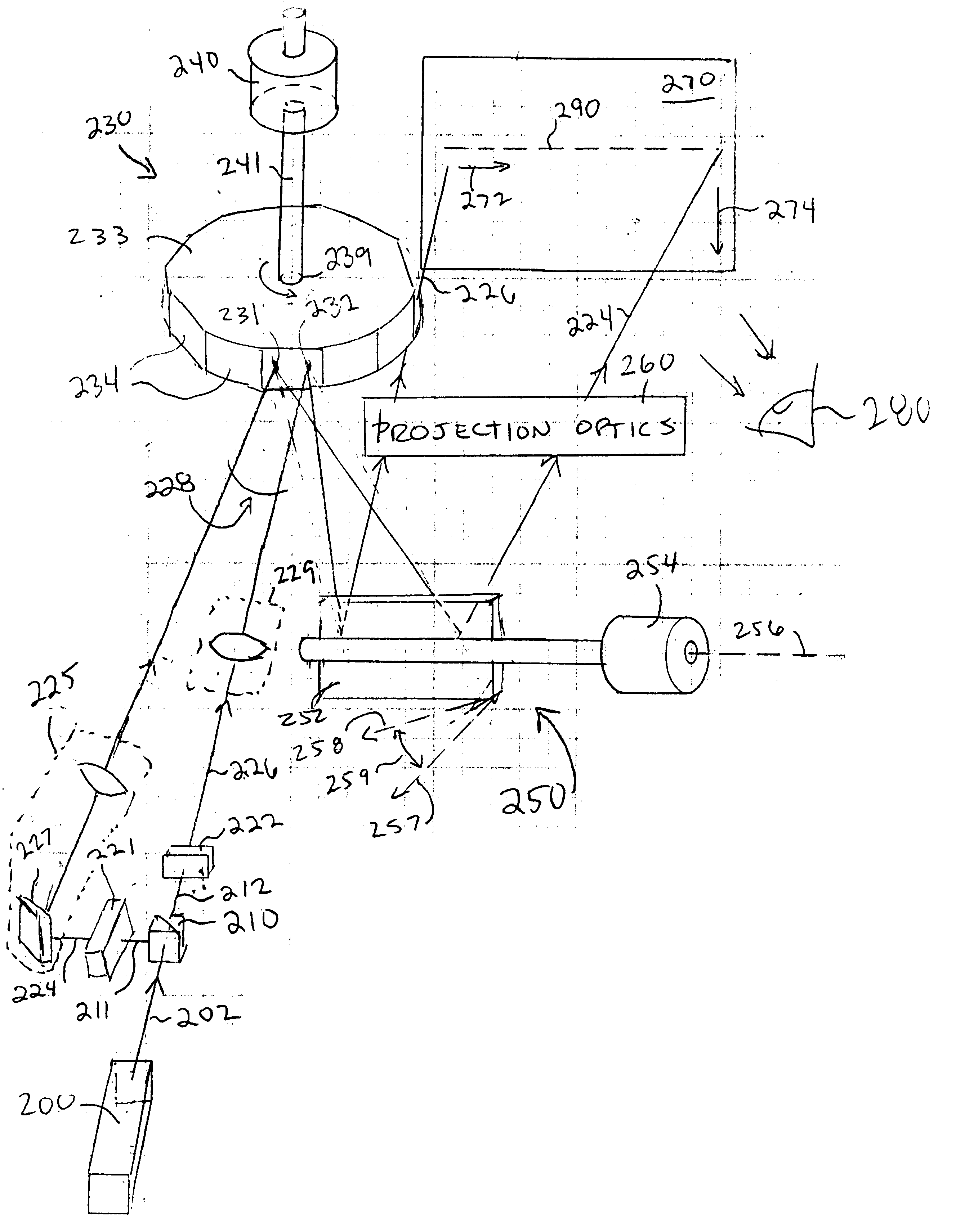

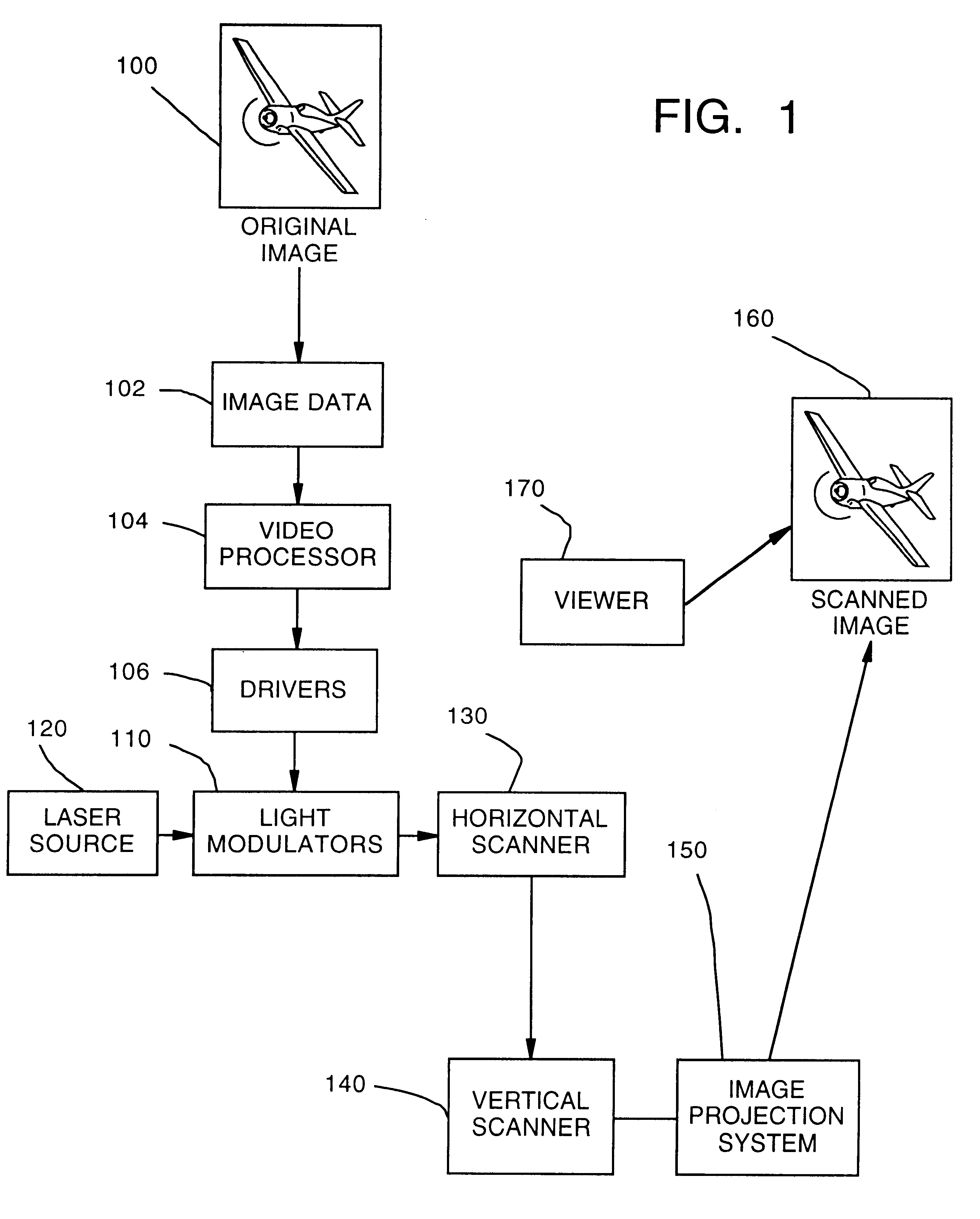

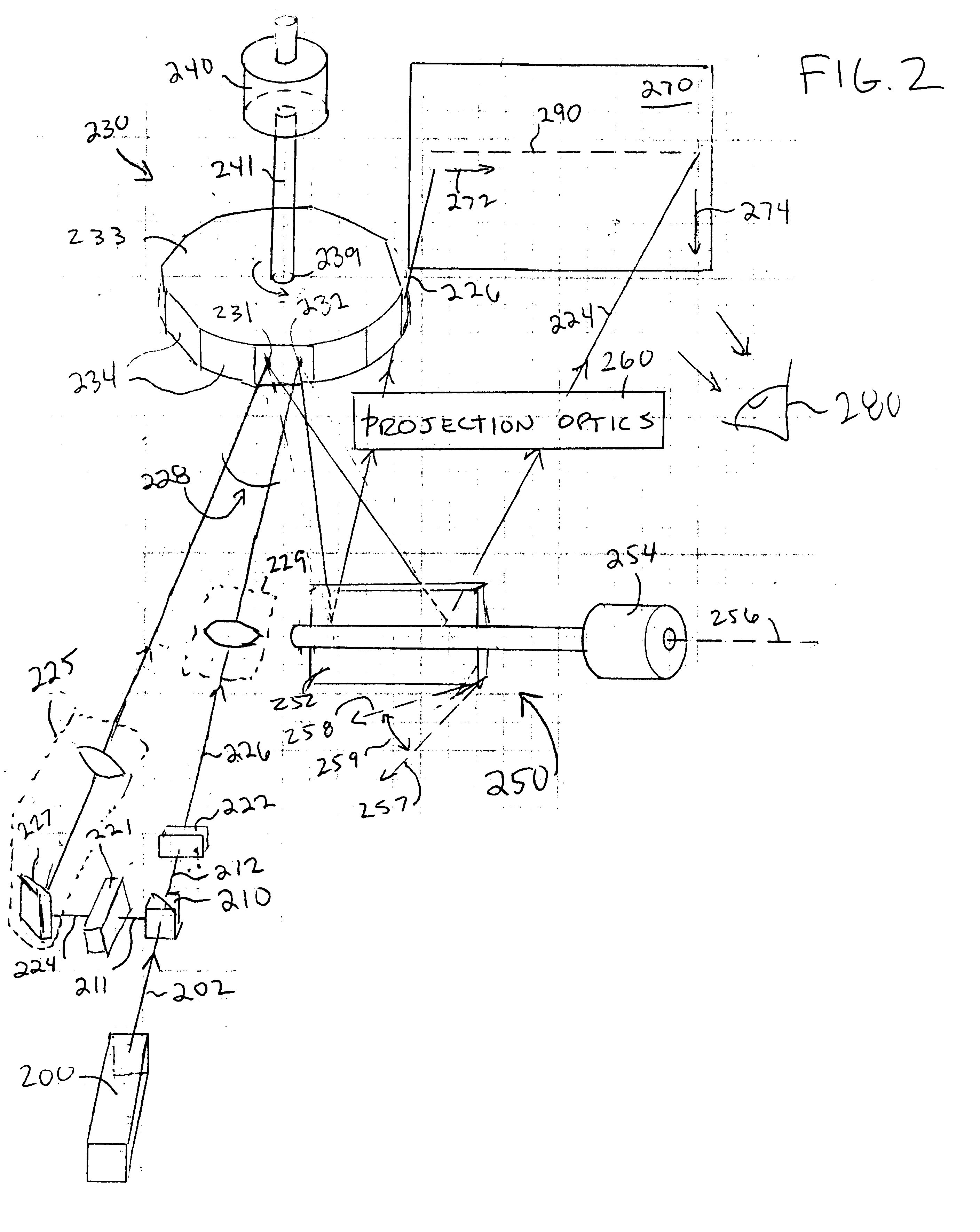

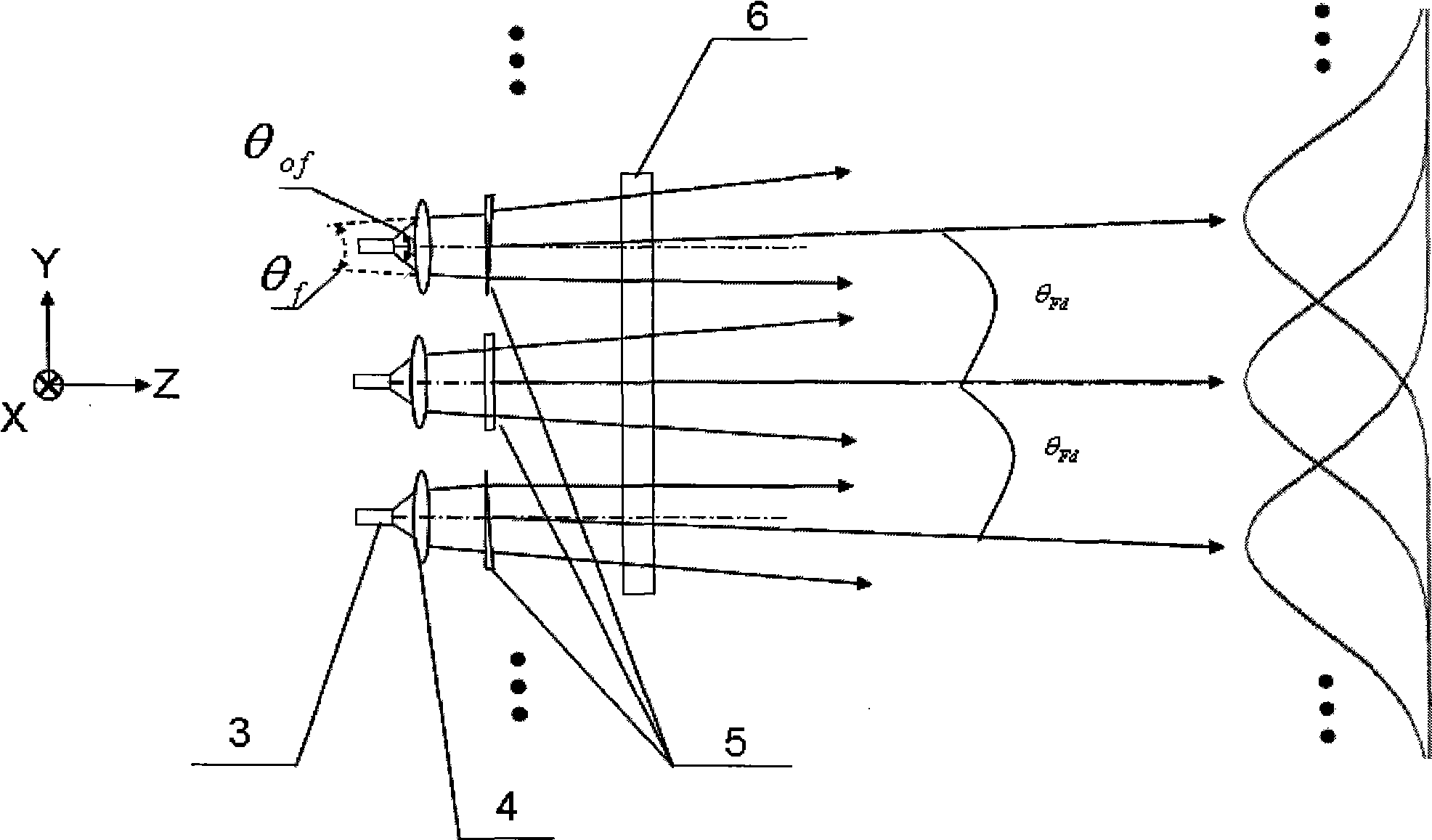

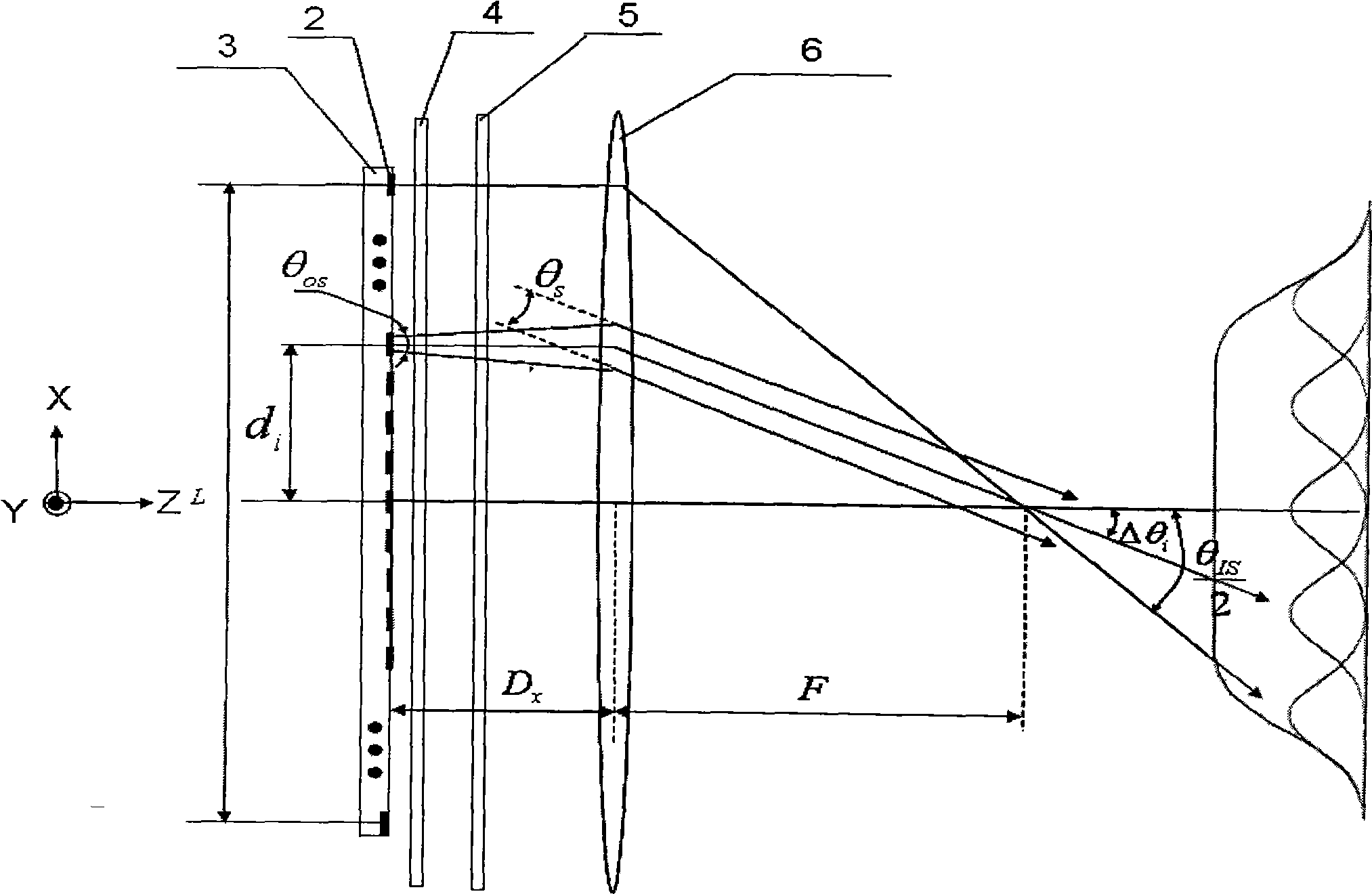

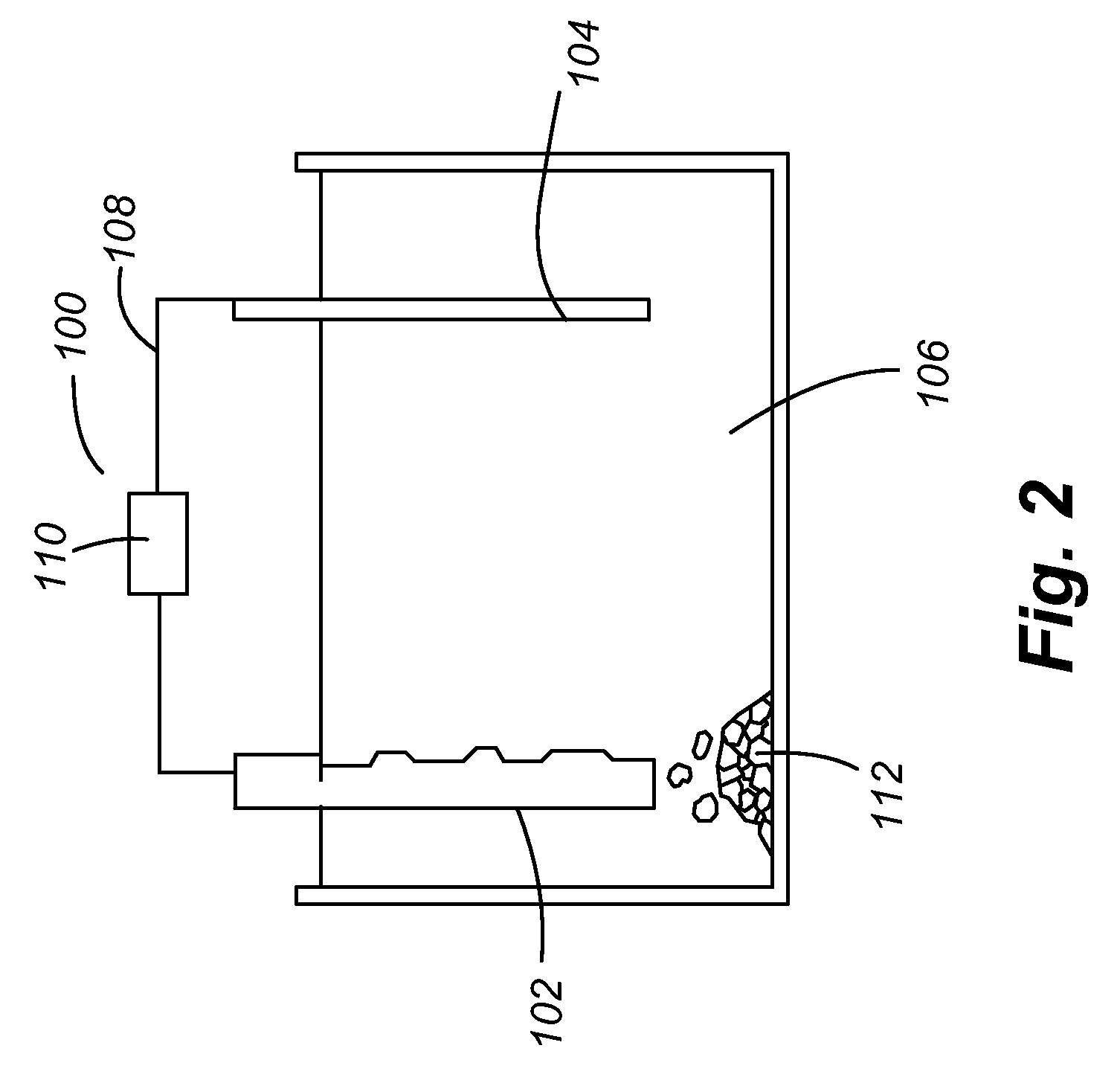

Laser imaging system with progressive multi-beam scan architecture

InactiveUS6351324B1Big cost advantageImprove system efficiencyPicture reproducers using projection devicesPicture signal generatorsColor imageBeam scanning

A progressive scan architecture for displaying a two-dimensional image by alternately scanning two or more laser beams, one after the other with a time delay between adjacent beams. The beams are arranged to become incident upon a polygon scanner in a row with an approximately uniform spatial separation and an approximately equal angle between adjacent beams. The polygon scanner scans horizontally and a galvanometer-driven mirror scans vertically. Adjacent lines are progressively scanned in sequence from top to bottom, which advantageously reduces or eliminates psycho-visual effects and is tolerant of non-linearities in the vertical scanner, allowing use of a low-cost galvo mirror. Typically, the beams in the row are arranged in pairs, and only one beam from each pair will be scanning at any one time. Embodiments are described in which the duty cycle is slightly less than 50% and the laser illumination is switched between two interleaved beam scans thereby allowing a single modulator to be used for both beams which provides significant cost advantages and improves system efficiency. For full-color images, each of the beams described can incorporate separate red, green and blue (RGB) components which are individually modulated by separate red, green, and blue modulators. The system can be scaled up with one or more additional pairs of beams to improve resolution and / or increase pixel count without requiring a high-speed polygon scanner or a highly-linear galvo scanner. Furthermore, the height of each facet in the polygon mirror need be only one beam diameter and its length need only be two beam diameters, which allows the system to approach the minimum pixel size attainable, which is useful to provide high efficiency and high brightness in the image.

Owner:PHOTERA TECH

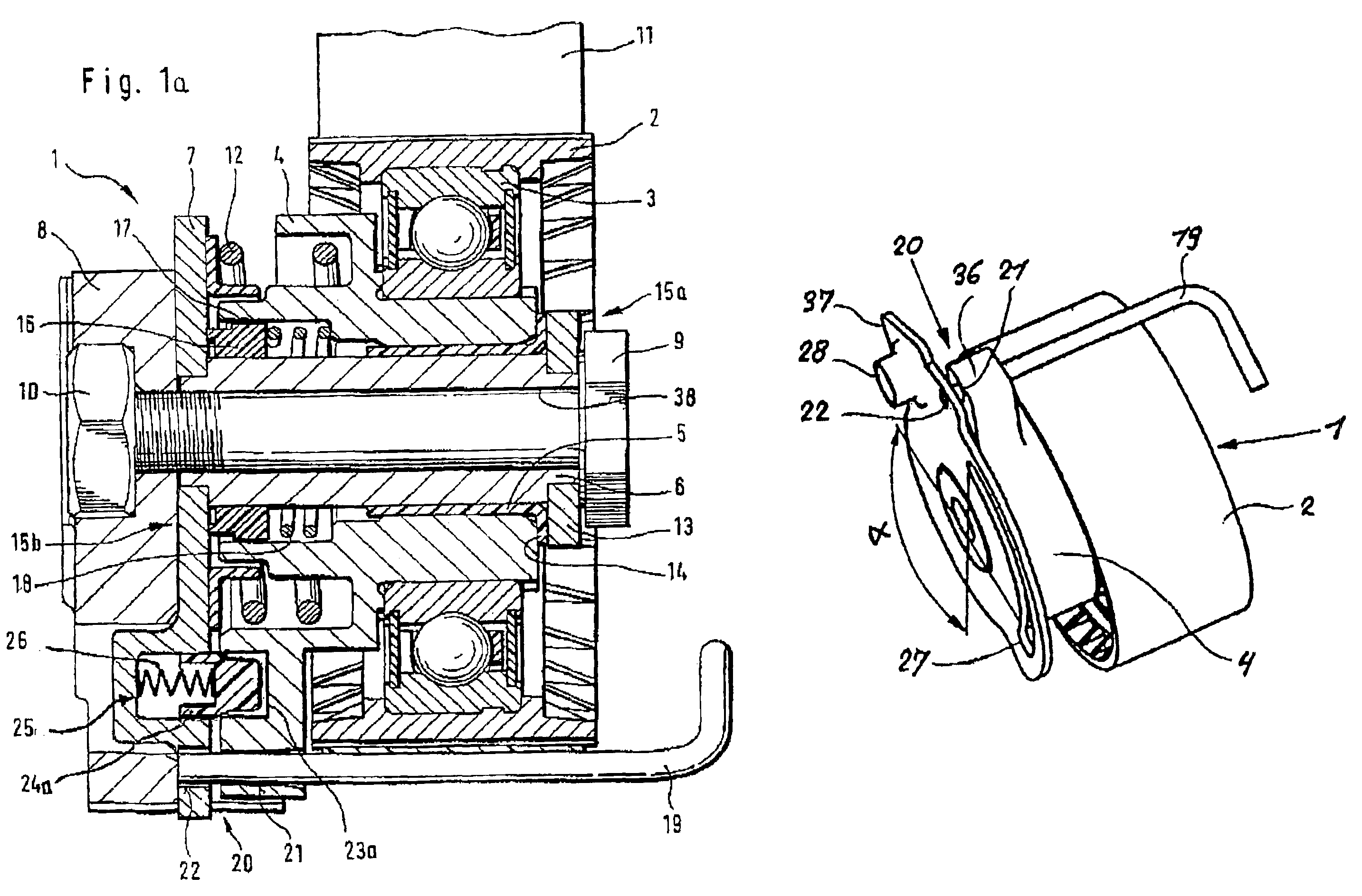

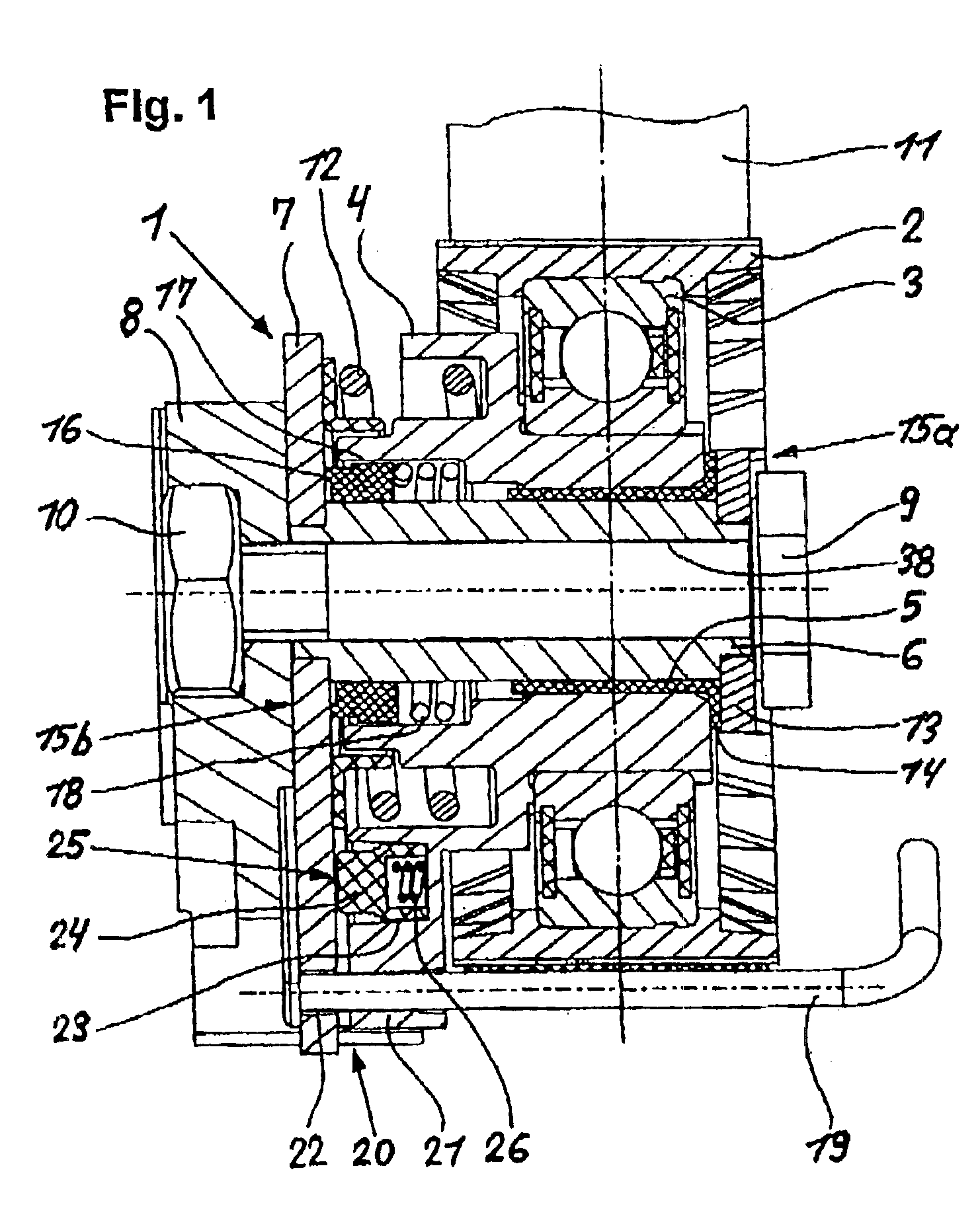

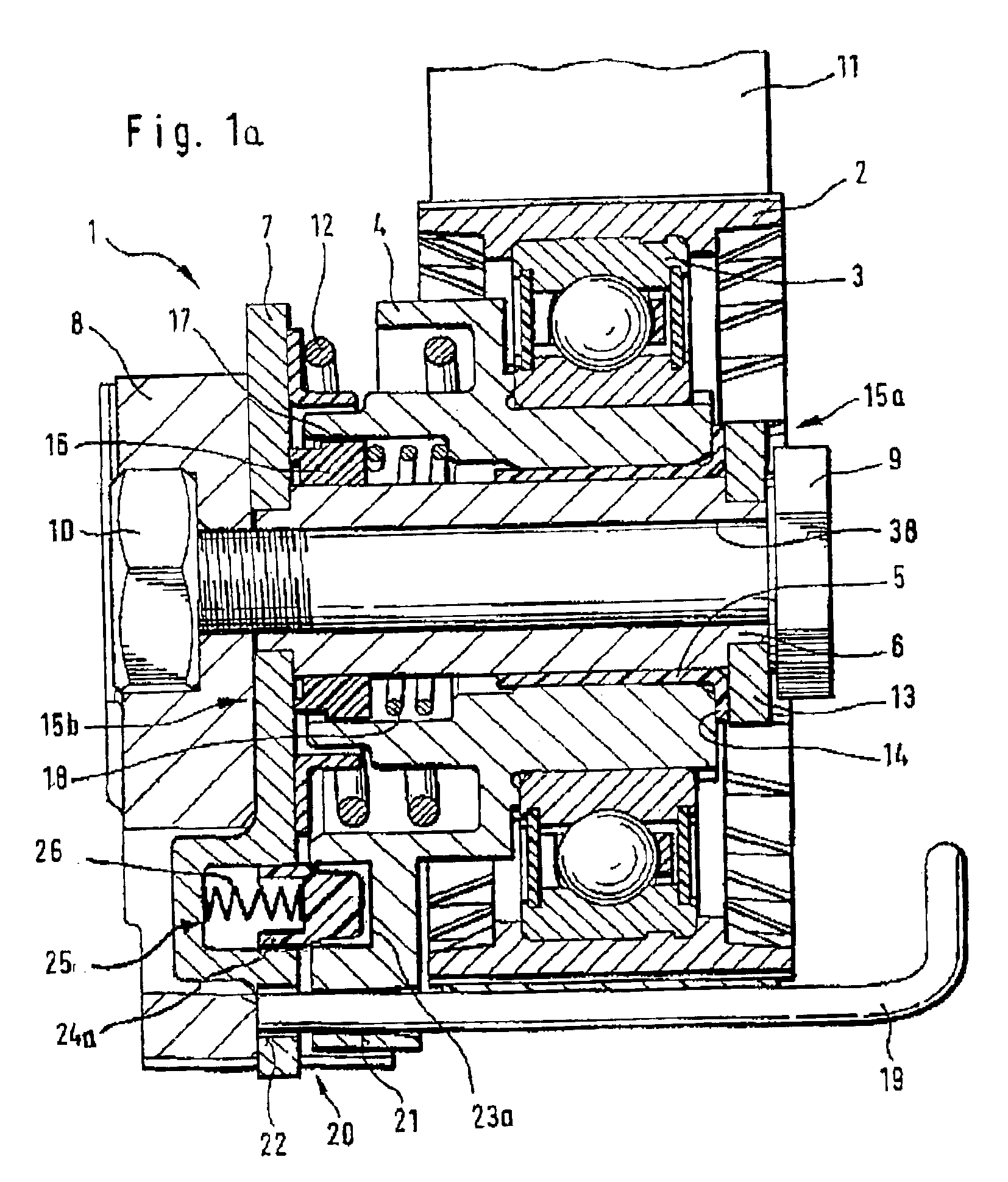

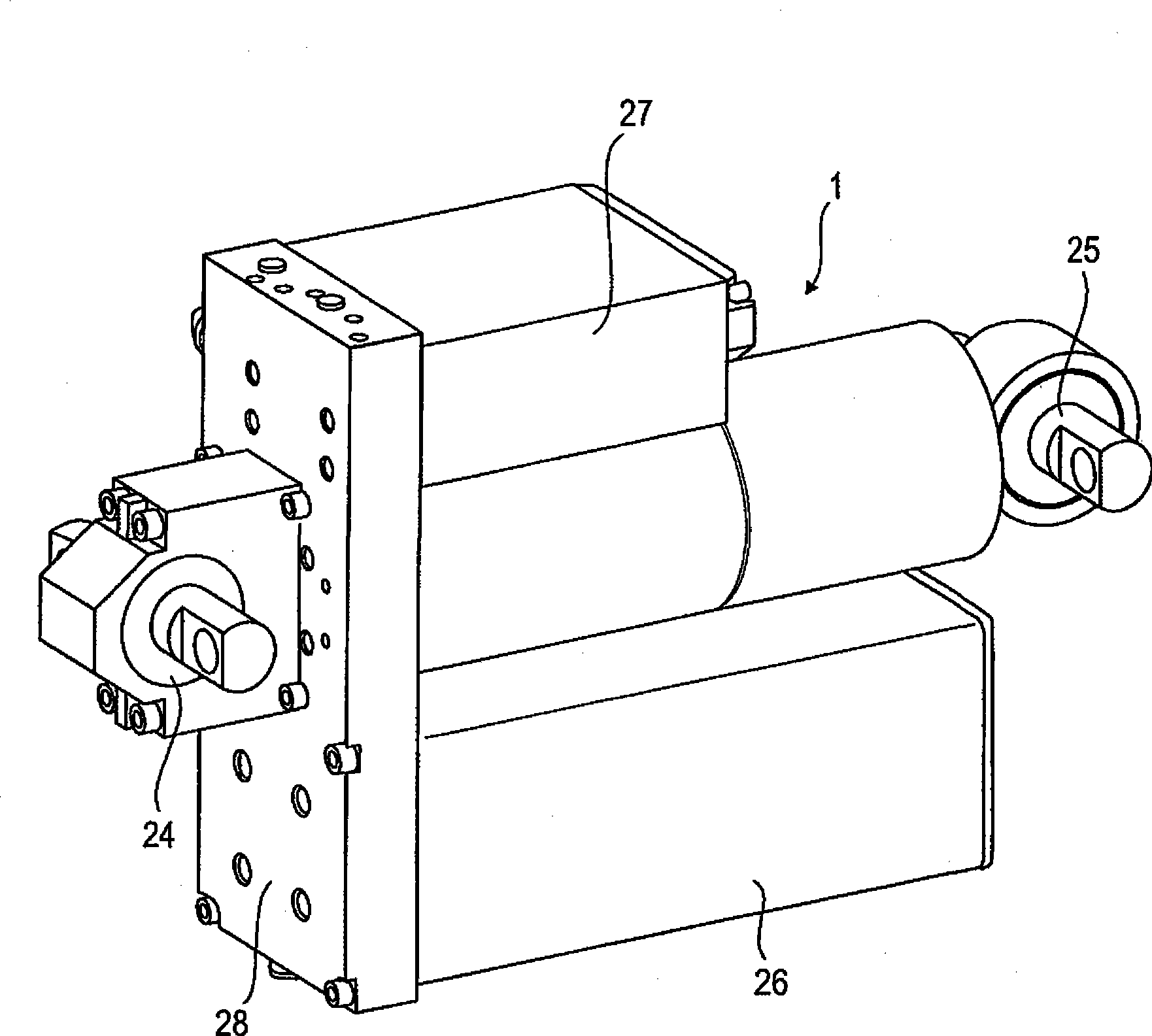

Tensioner

A tensioner for a traction member includes a faceplate that is stationarily secured to a machine part, with a working eccentric member rotatably supported on the faceplate for limited rotation against a spring force. After pre-installation of the tensioner, a locking device fixes the position of the working eccentric member relative to the faceplate. In one installation position, a catch limits the pivot range of the working eccentric member.

Owner:INA SCHAEFFLER KG

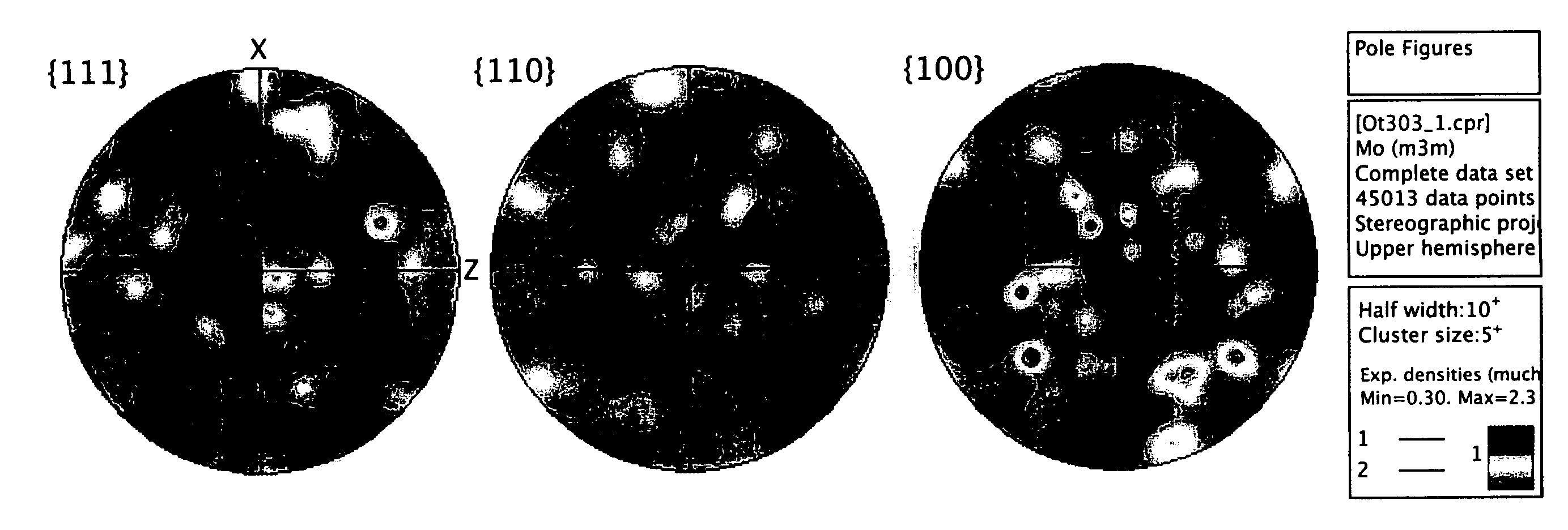

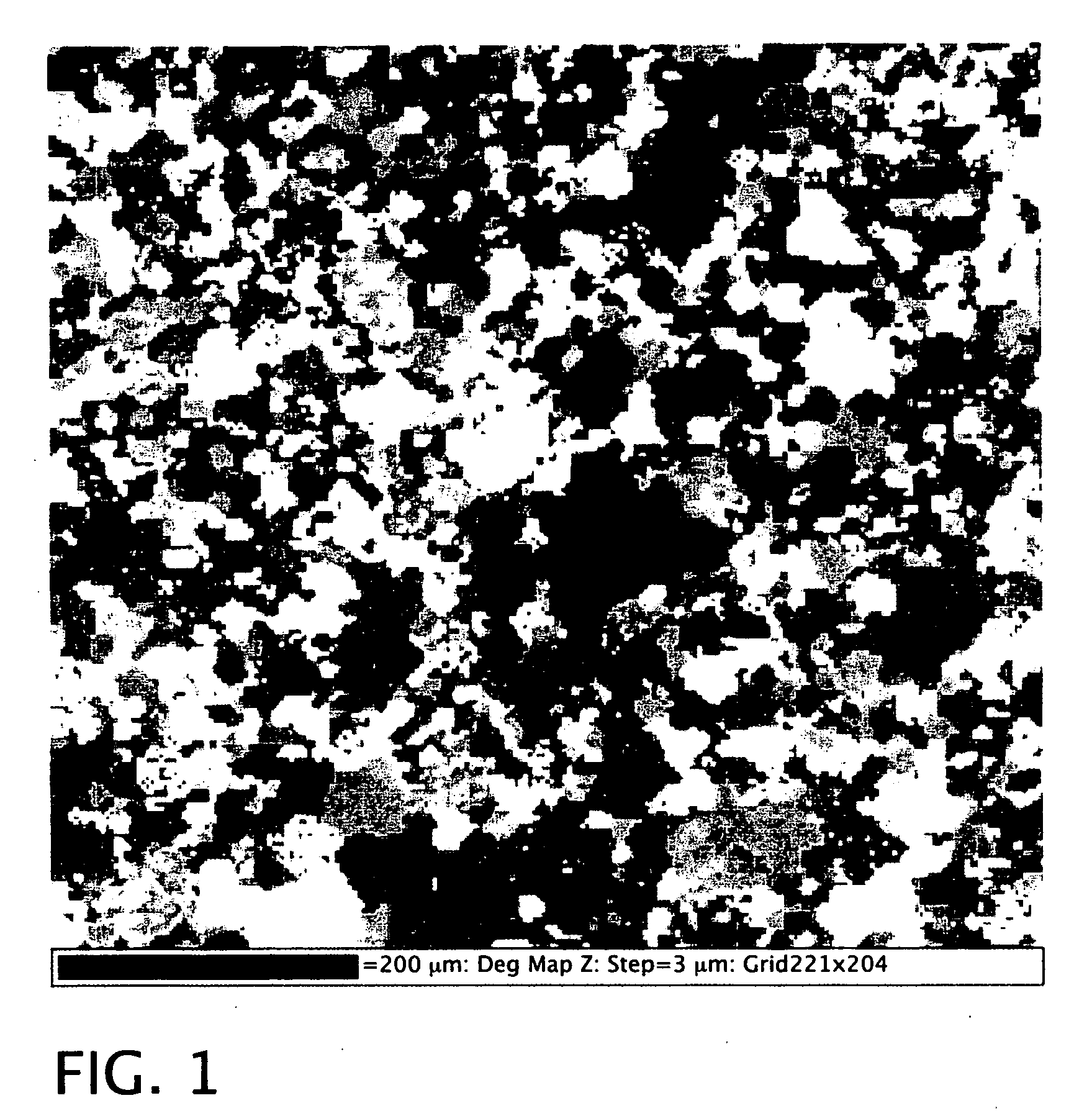

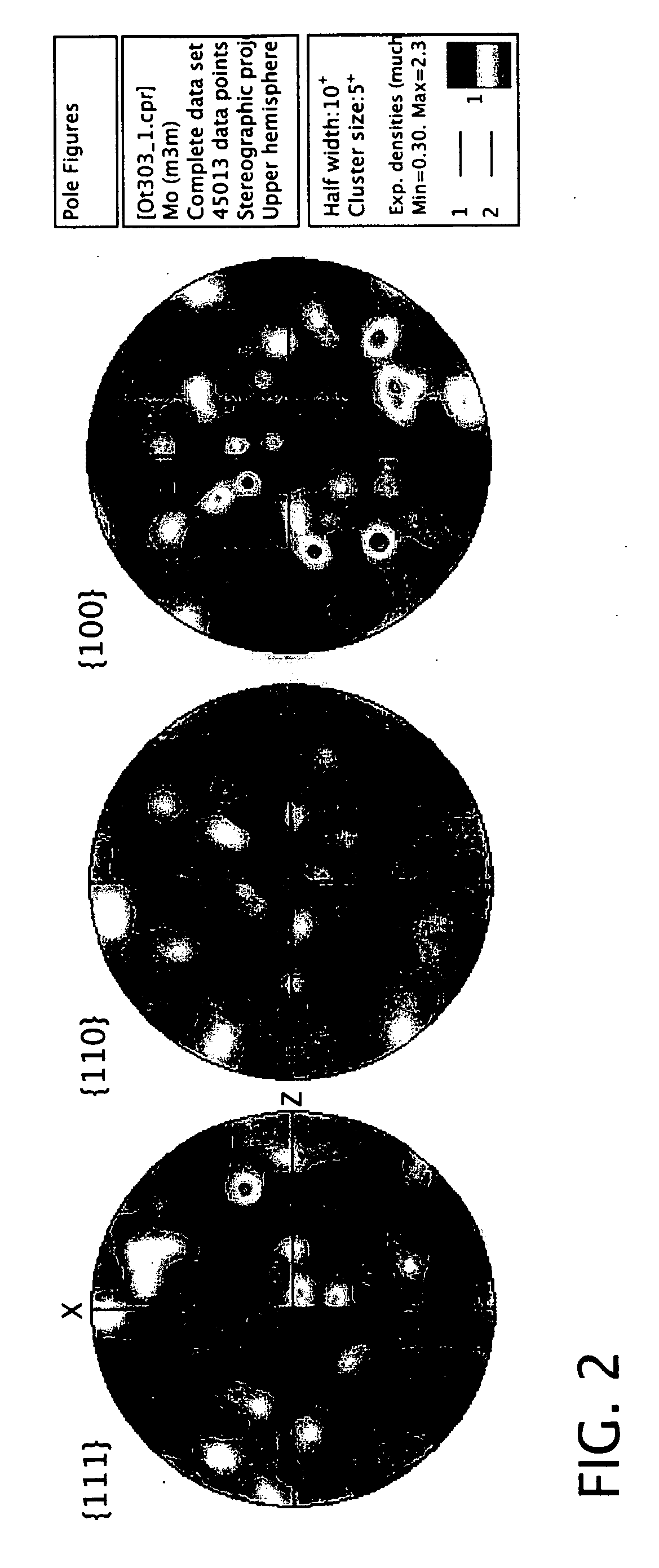

High density refractory metals & alloys sputtering targets

ActiveUS20080171215A1High film forming rateLow resistivityVacuum evaporation coatingSputtering coatingHigh densityAlloy

The present invention is directed to a process for producing high density, refractory metal products via a press / sintering process. The invention is also directed to a process for producing a sputtering target and to the sputtering target so produced.

Owner:GLAS TRUST +1

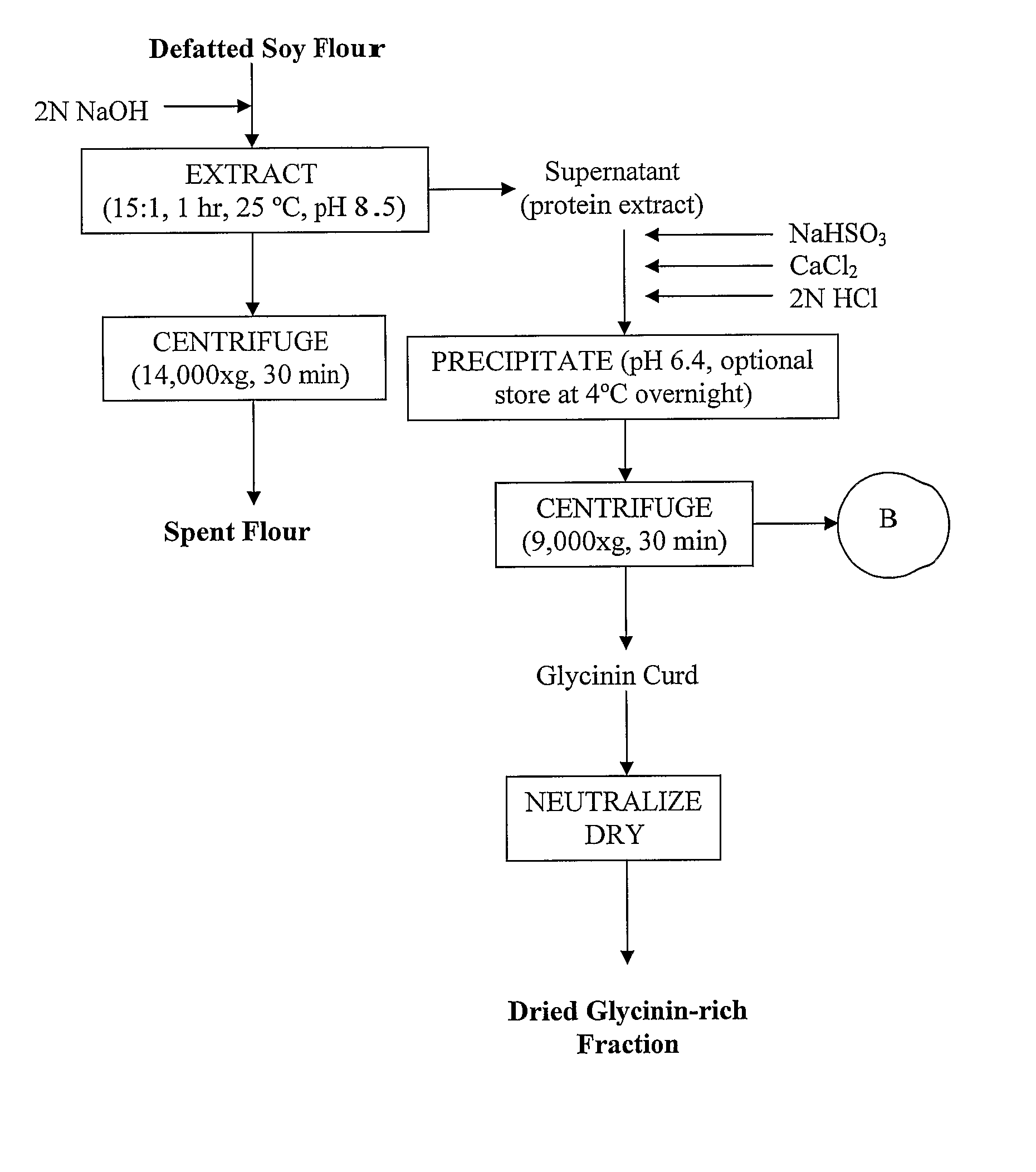

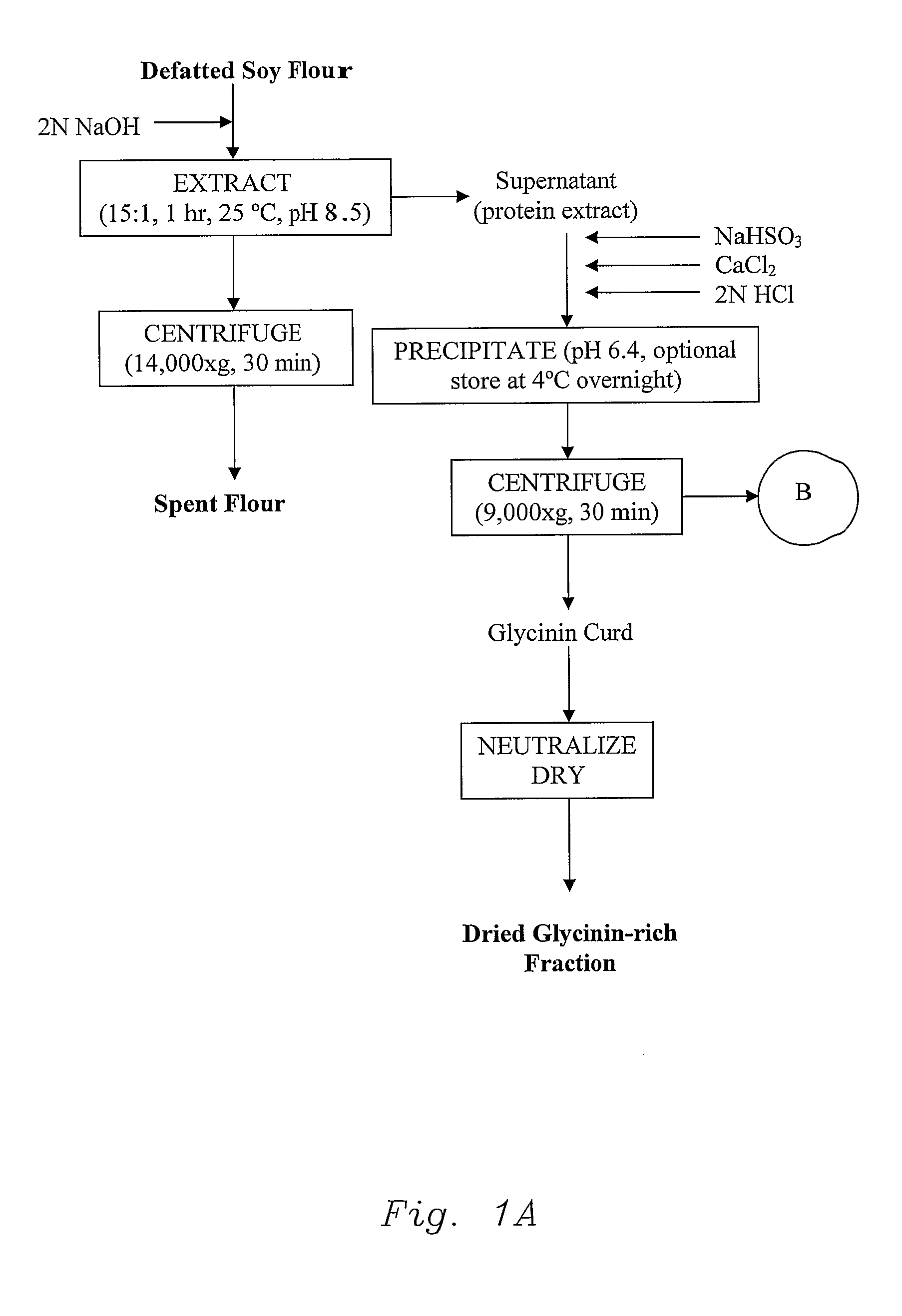

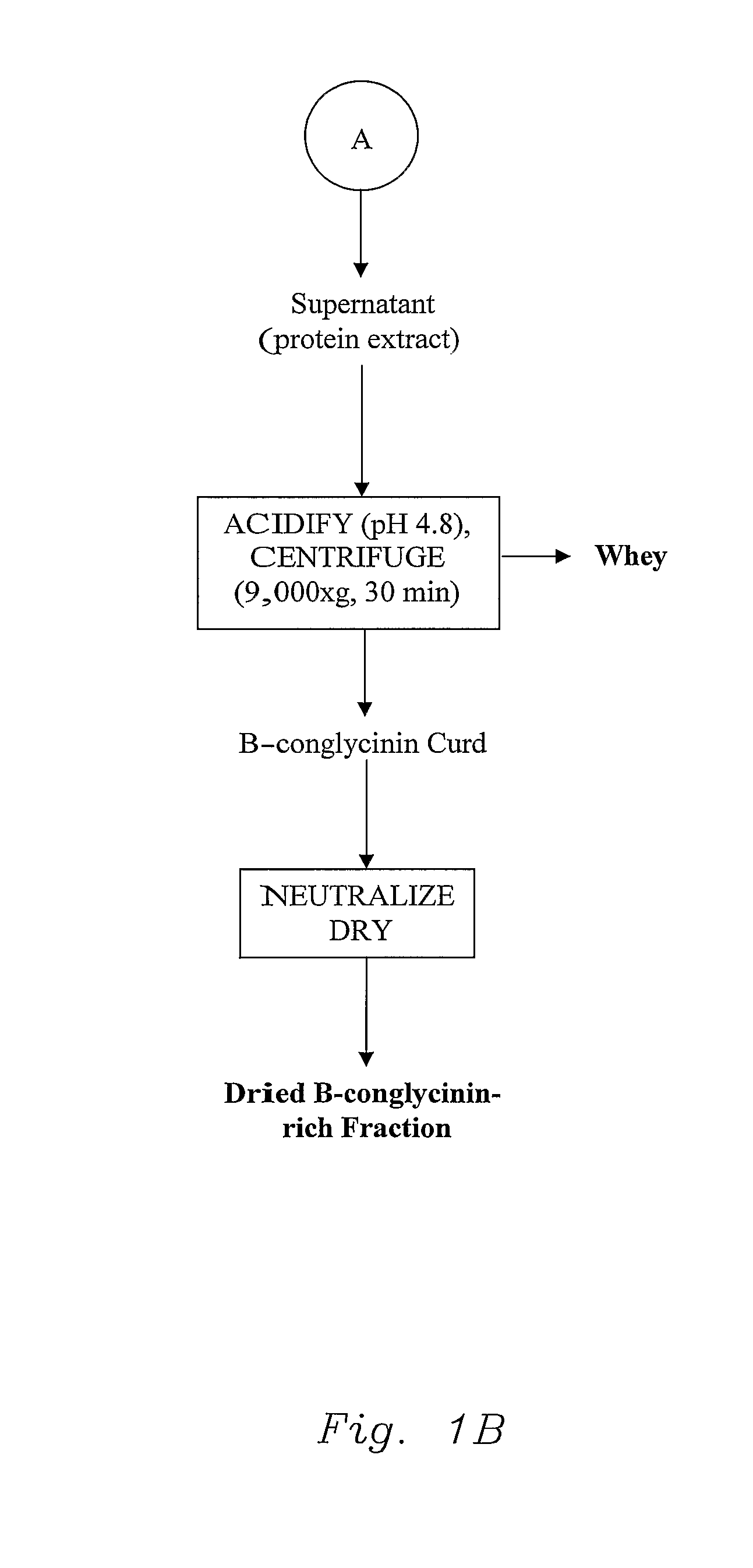

Novel Vegetable Protein Fractionization Process And Compositions

InactiveUS20080095914A1High in isoflavone contentUnique functional and nutritional applicabilityProtein composition from vegetable seedsDepsipeptidesFood industryFractionation

According to the invention a novel vegetable protein fractionation procedure is disclosed which includes a straightforward process to obtain 7S-rich (β-conglycinin-rich) and 11S-rich (glycinin-rich) isolated protein fractions with unique functional and nutritional properties desired by the food industry. The process is much simplified compared to the art and avoids multiple steps in the usual fractionation of soy protein and uses very small amounts of salts avoiding the necessity of excessive washing and desalting steps. The process yields high amounts of protein fractions with high isoflavone contents and improved functional properties.

Owner:IOWA STATE UNIV RES FOUND

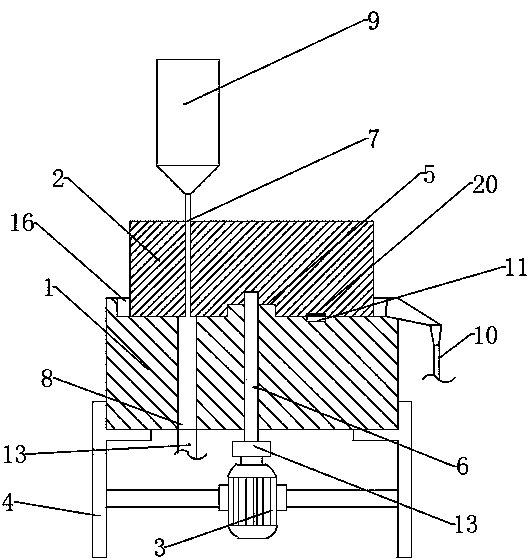

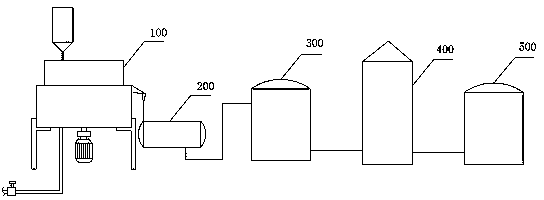

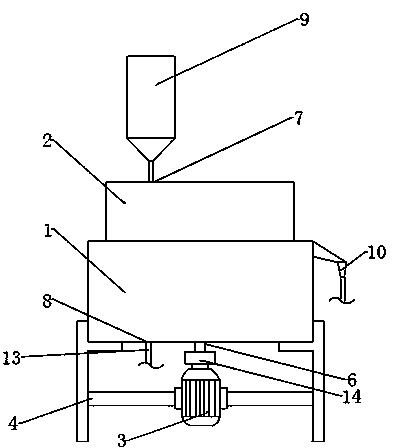

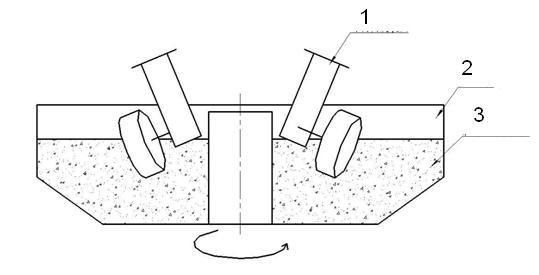

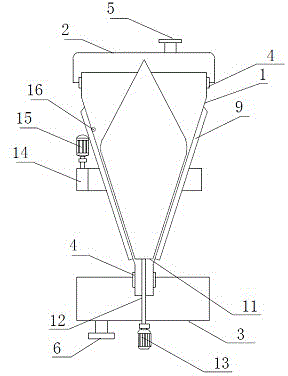

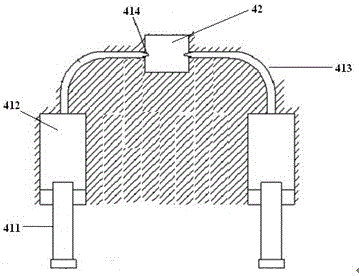

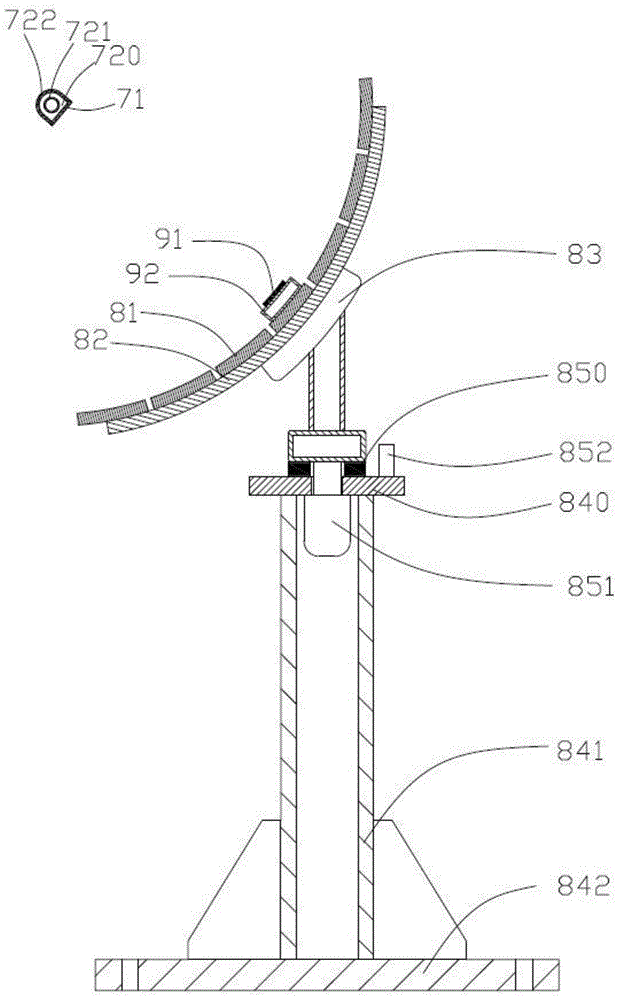

Graphene grinding and stripping device, graphene production system and production method

ActiveCN104401971AKeep the natural plane sizeReduce the chance of crushingCvd grapheneMechanical engineering

The invention discloses a graphene grinding and stripping device which comprises an upper grinding disc, a lower grinding disc, a driving mechanism for driving the upper grinding disc to rotate, and a material collection mechanism for collecting a product after grinding, wherein the upper grinding disc and the lower grinding disc are matched with each other; a horizontal contact surface is formed between the upper grinding disc and the lower grinding disc, the upper grinding disc is provided with an upper feed inlet, the lower grinding disc is provided with a lower feed inlet, the upper feed inlet and the lower feed inlet are both connected with the contact surface between the upper grinding disc and the lower grinding disc, and the lower end of the lower feed inlet is in sealed connection with one water inlet tube; moreover, the upper end face of the lower grinding disc is provided with a groove, and an annular region formed by rotary surrounding of the lower end of the upper feed inlet is surrounded in the groove. The graphene grinding and stripping device can realize large-size successful stripping of graphene. The invention also relates to a graphene production system containing the graphene grinding and stripping device and a graphene production method.

Owner:江苏碳谷二维世界科技有限公司

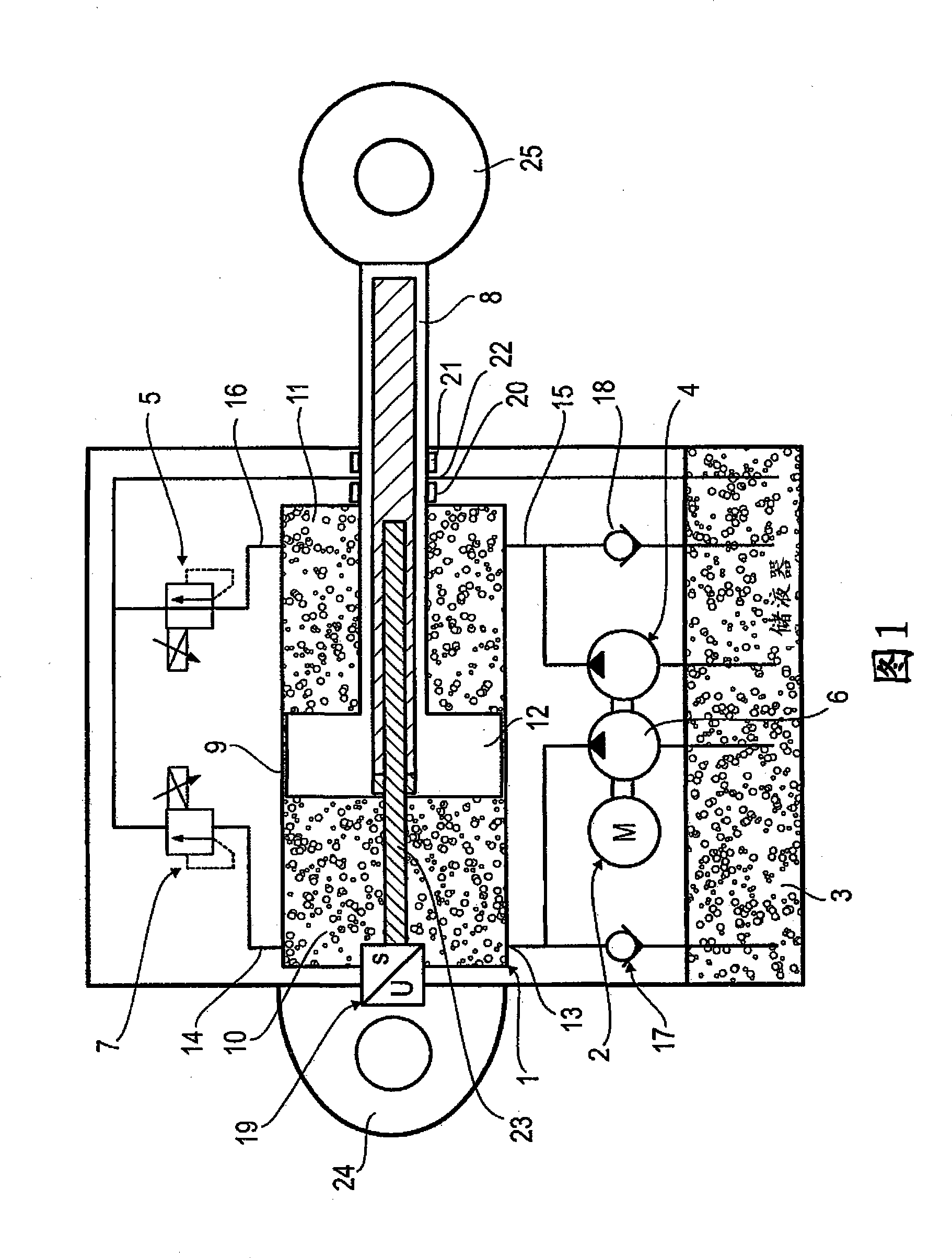

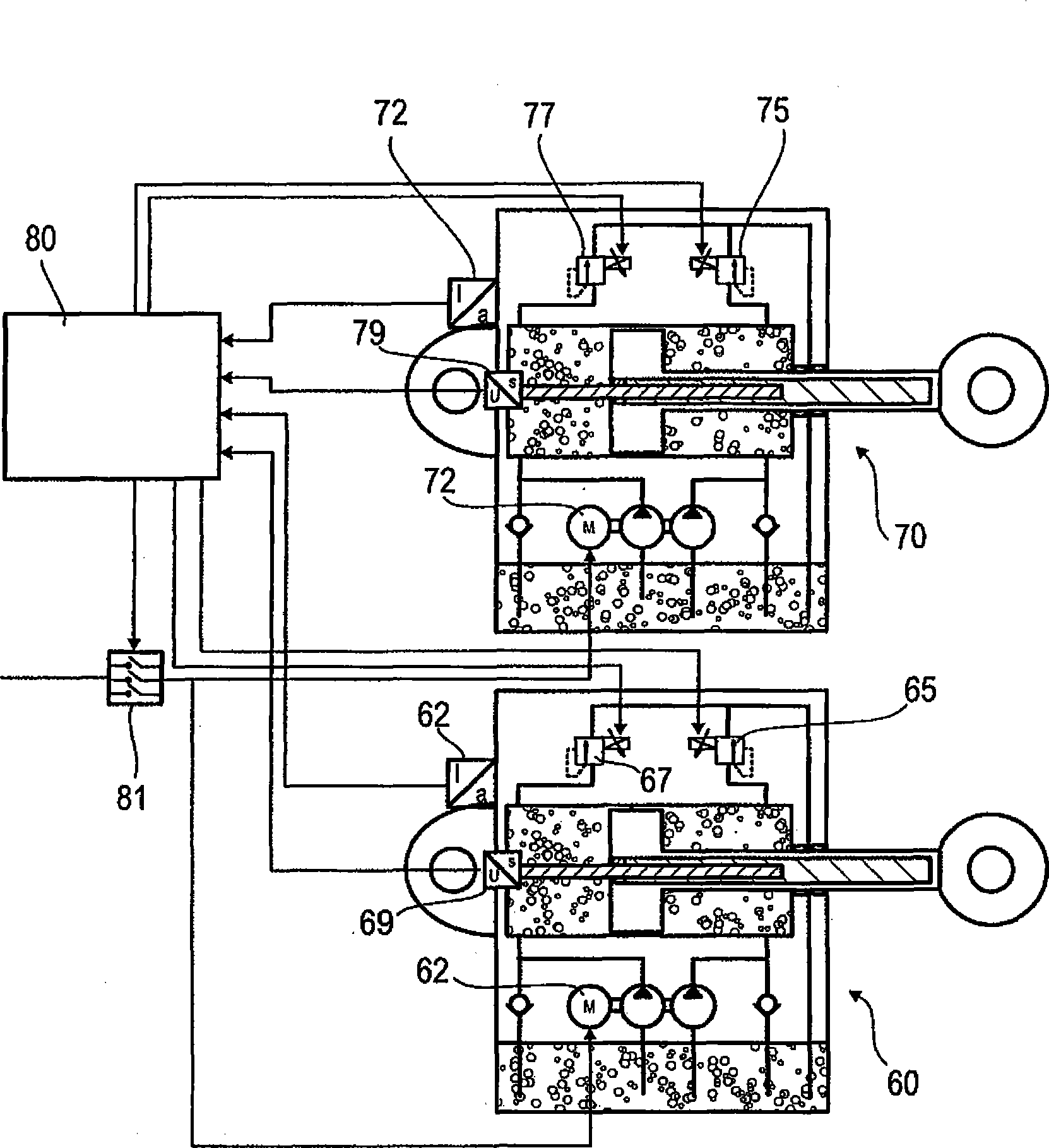

Active hydraulic damper and hydraulic actuator

ActiveCN101392809ASave packing spaceReduce weightSpringsLiquid based dampersHydraulic cylinderActuator

The invention relates to an active hydraulic damper specially for railway vehicles, comprising a hydraulic cylinder, an electric motor, a hydraulic accumulator, at least a pump and at least a control valve. According to the invention, all components of the active hydraulic damper are arranged at the hydraulic cylinder.

Owner:利勃海尔运输系统股份有限公司

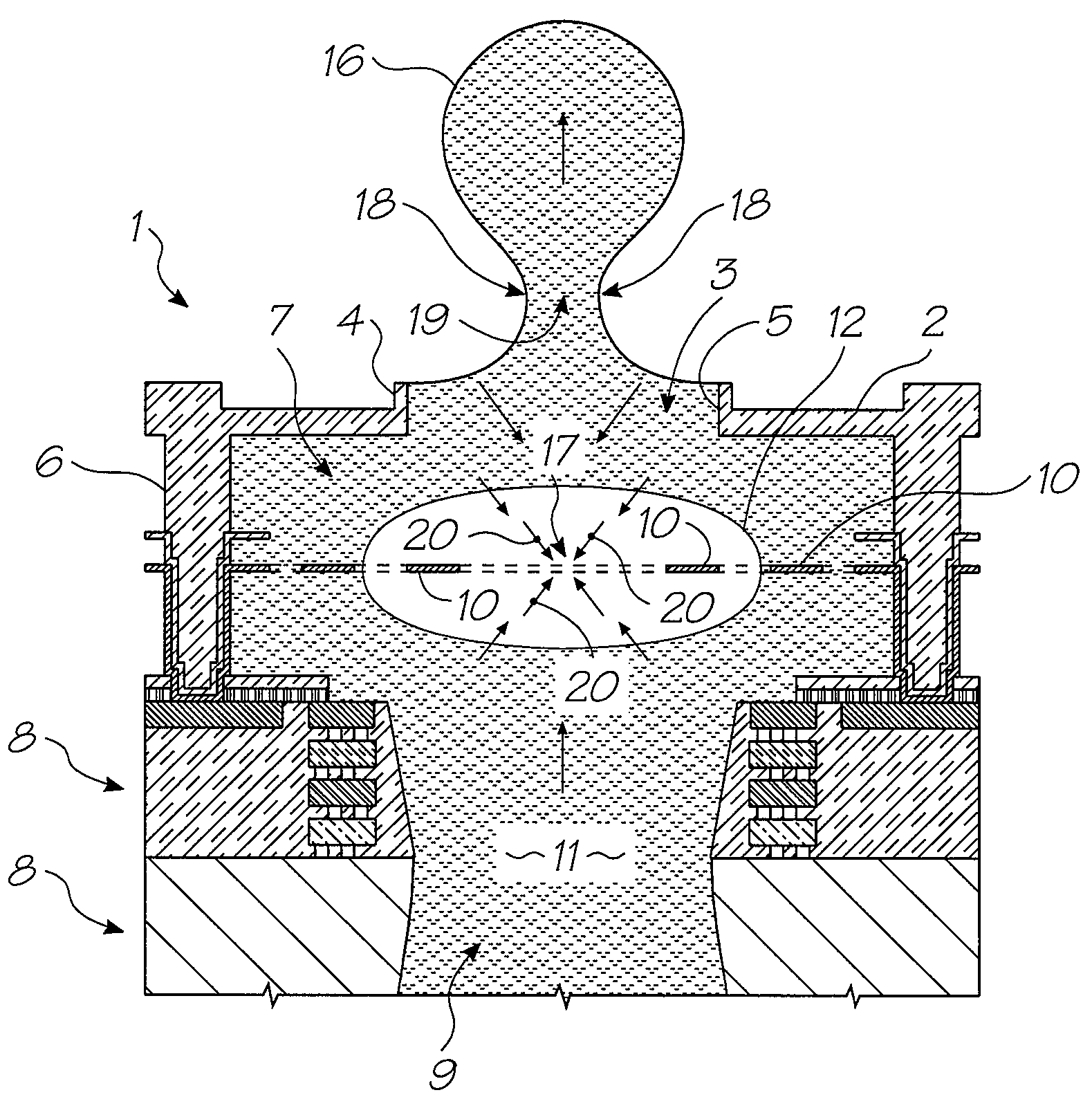

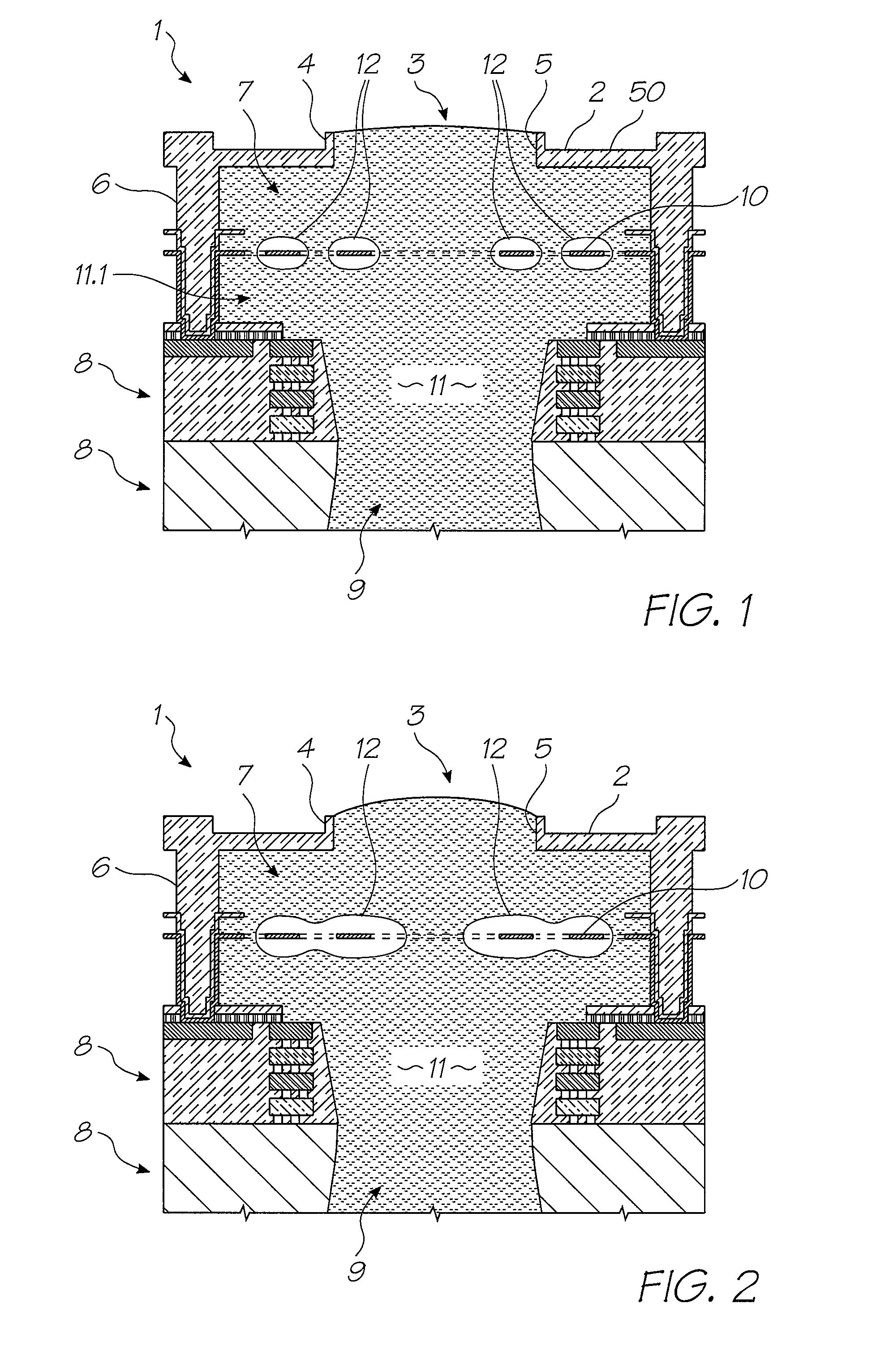

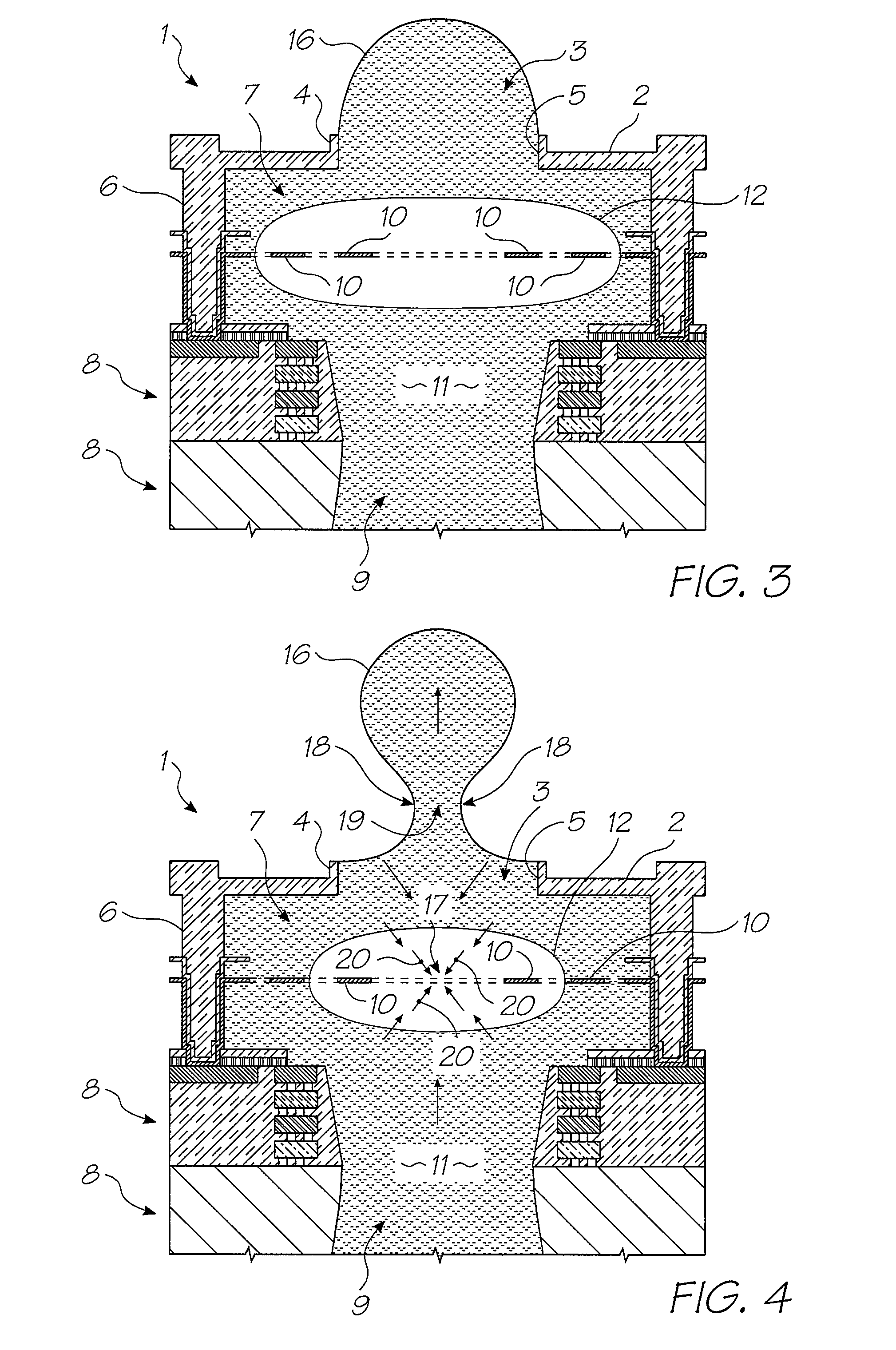

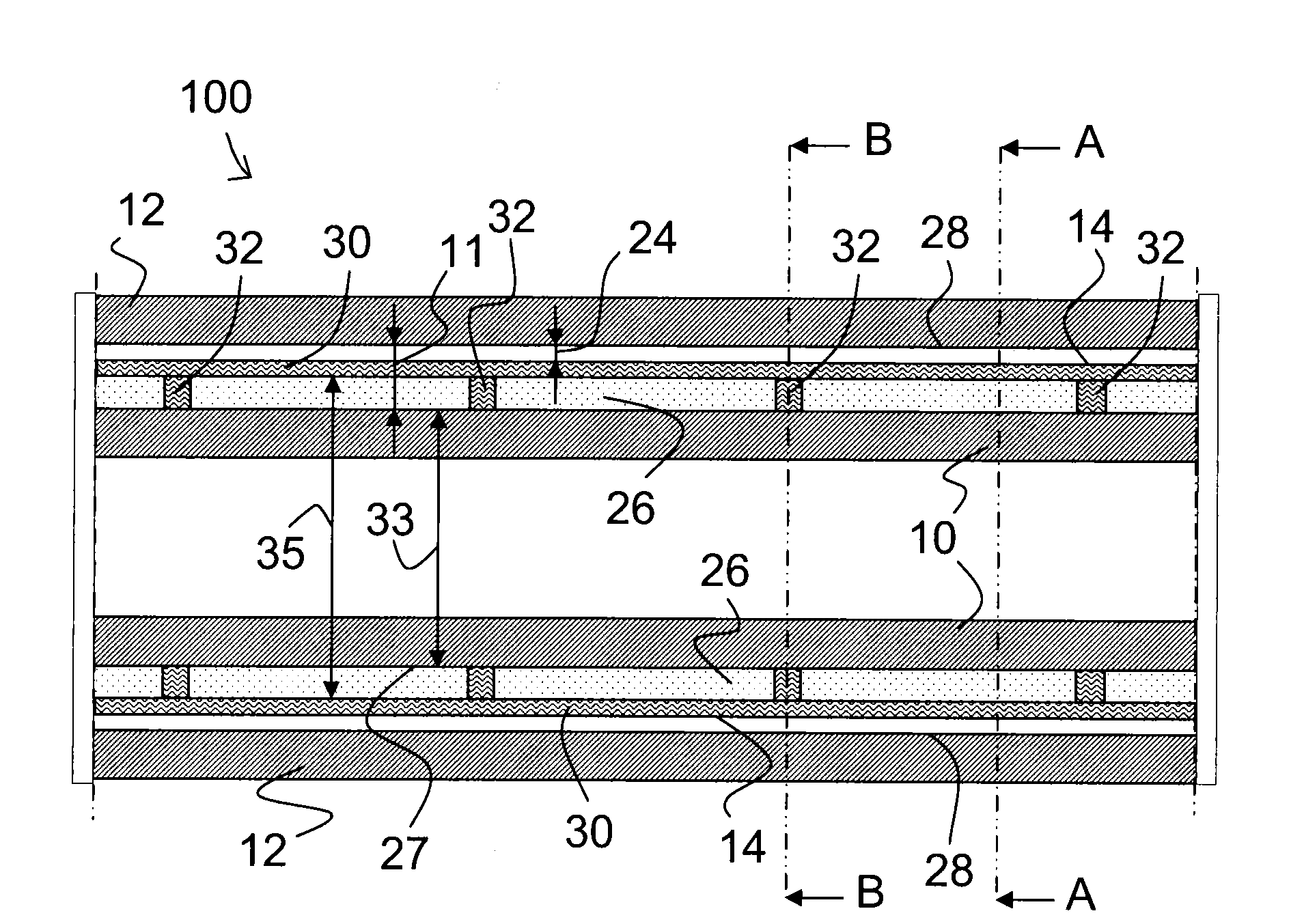

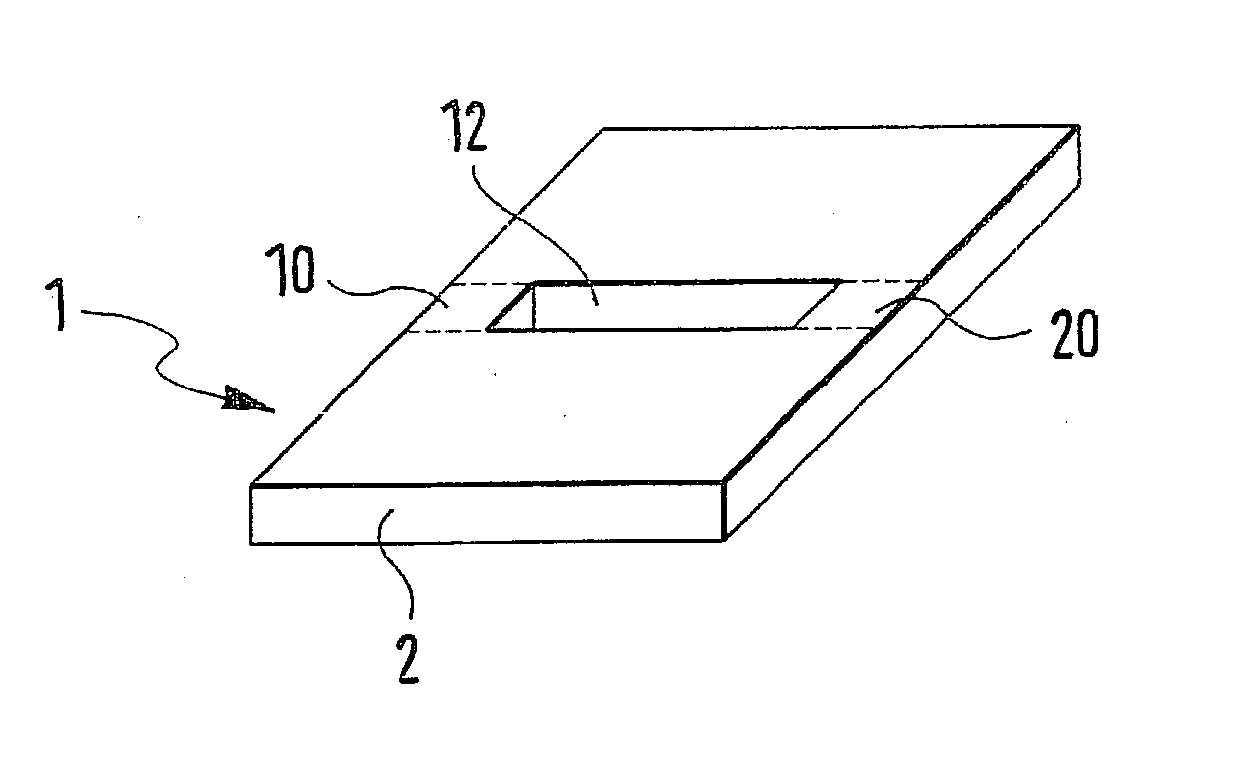

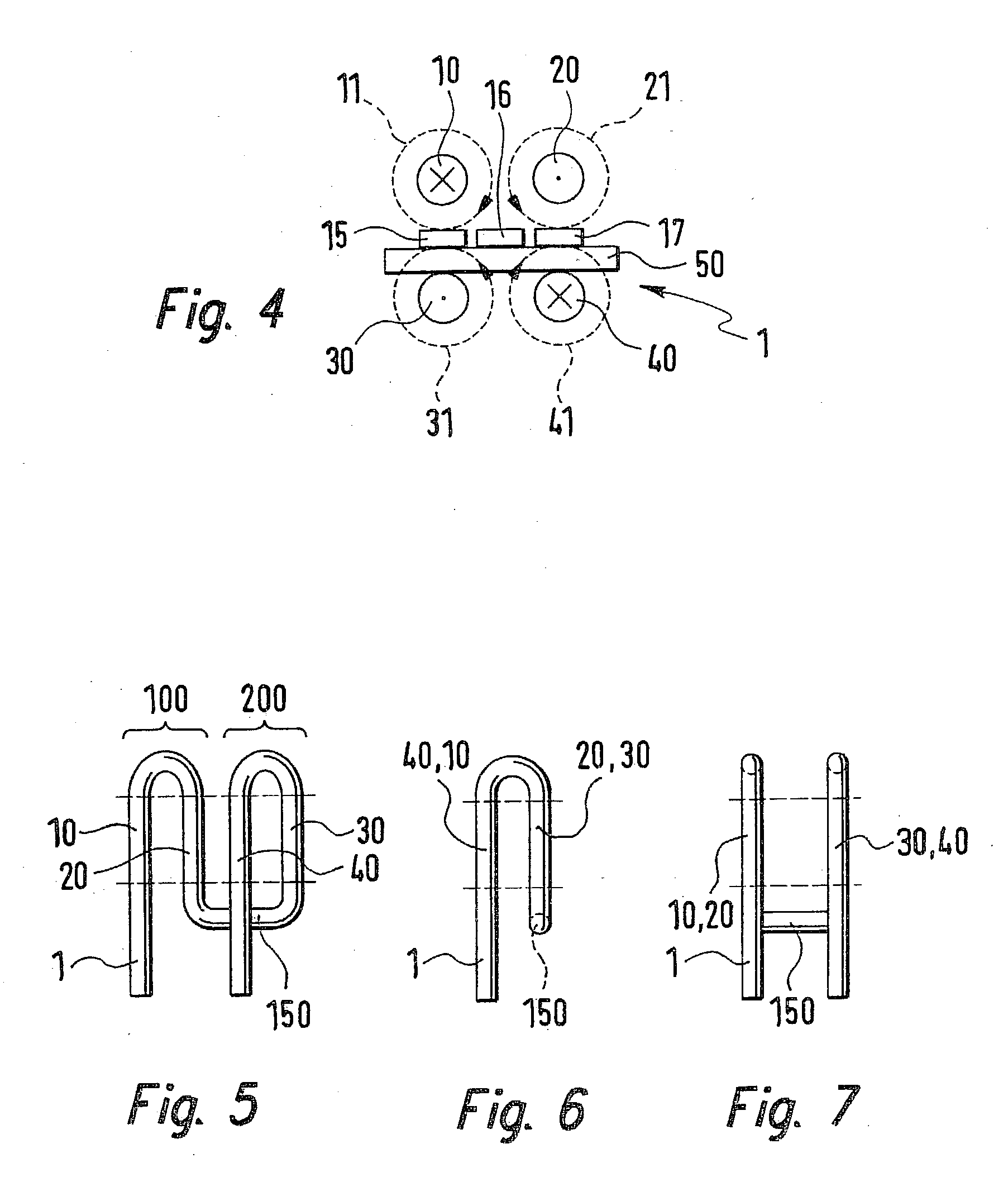

Inkjet printhead with low voltage ink vaporizing heaters

InactiveUS7581822B2Improve efficiencySimple power supplyInking apparatusOther printing apparatusVapor bubbleLow voltage

There is disclosed an ink jet printhead which comprises a plurality of nozzles and one or more heater elements 10 corresponding to each nozzle. Each heater element 10 is configured to heat a bubble forming liquid 11 in the printhead to a temperature above its boiling point to form a gas bubble 12 therein. The generation of the bubble 12 causes the ejection of a drop of an ejectable liquid (such as ink) through an ejection aperture 5 in each nozzle, to effect printing. In each nozzle, the heater element 10 requires an electrical pulse with a voltage less than 8 volts and a duration less than 1.5 microseconds, to form the vapor bubble that causes the ejection of the drop. With the realization that drive pulse voltages above, say, 12 volts are not a fixed parameter of printhead design, the benefits of low voltage printhead operation can be incorporated into a design that yields efficiencies that negate the circumstances that created the initial demand for high voltage operation.

Owner:MEMJET TECH LTD +1

Beam shaping illumination system of semiconductor laser array

InactiveCN101545582AImprove utilization efficiencyReduce the numberSemiconductor laser arrangementsLaser arrangementsBeam transmissionLight source

The invention discloses a beam shaping illumination system of a semiconductor laser array, which comprises the semiconductor laser array, an optical system for transforming beam divergence angles of a fast axis, a device for deflecting angles of beams in the fast axis direction, and an optical system for transforming divergence angles of a slow axis and deflecting the beams in the slow axis direction. The system has a key point that the superposition effect of Gaussian beam parts of a plurality of laser units is formed in a distant field by controlling the deflection degree of beam transmission axes of each laser unit in the fast axis and slow axis directions respectively so as to construct illumination beams according with field coverage requirements. The system has the characteristics of high efficiency, simple structure, low cost, integration and practicability, and is particularly applicable as an illumination light source of area array imaging laser radar and active laser illumination detecting systems.

Owner:ZHEJIANG UNIV

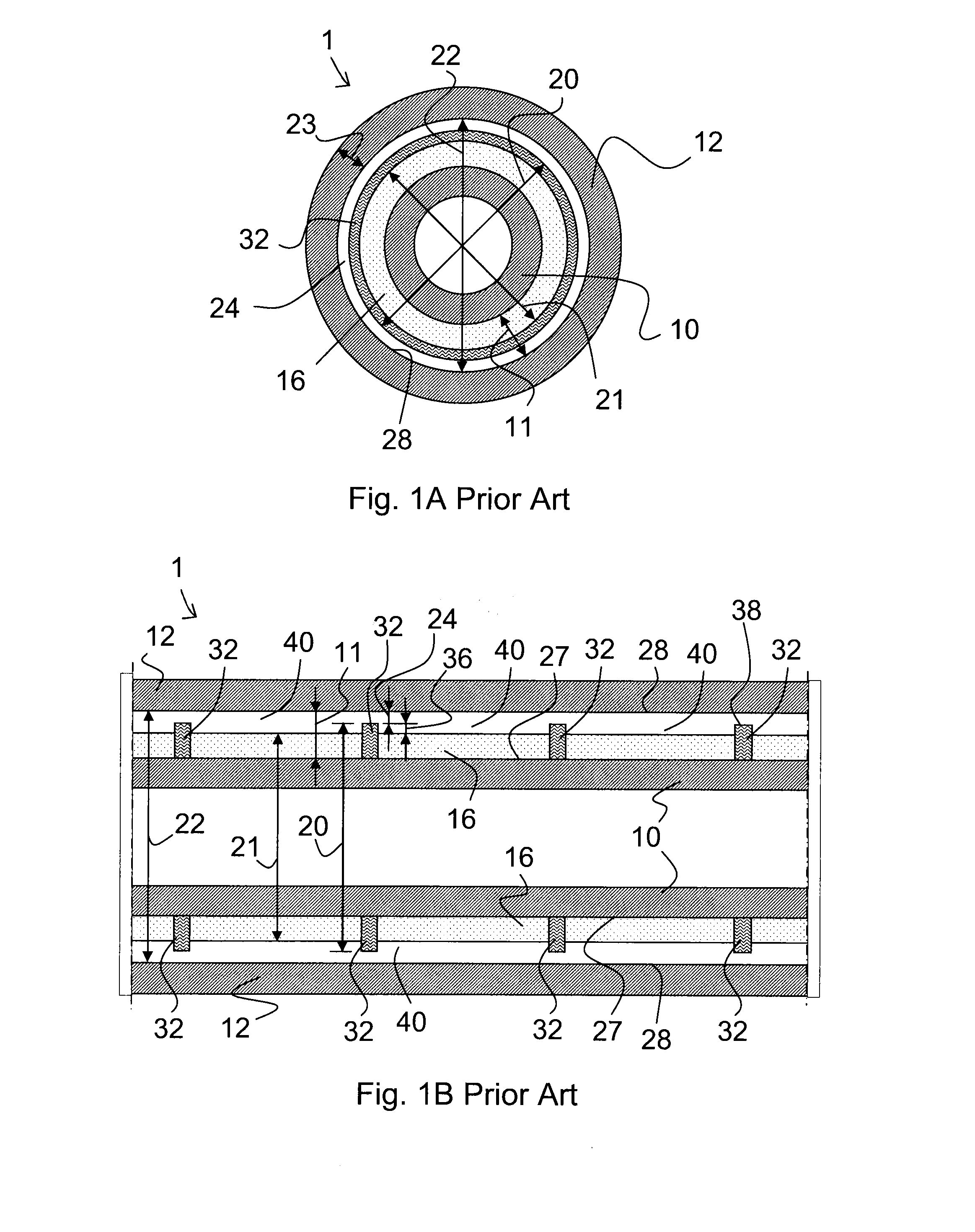

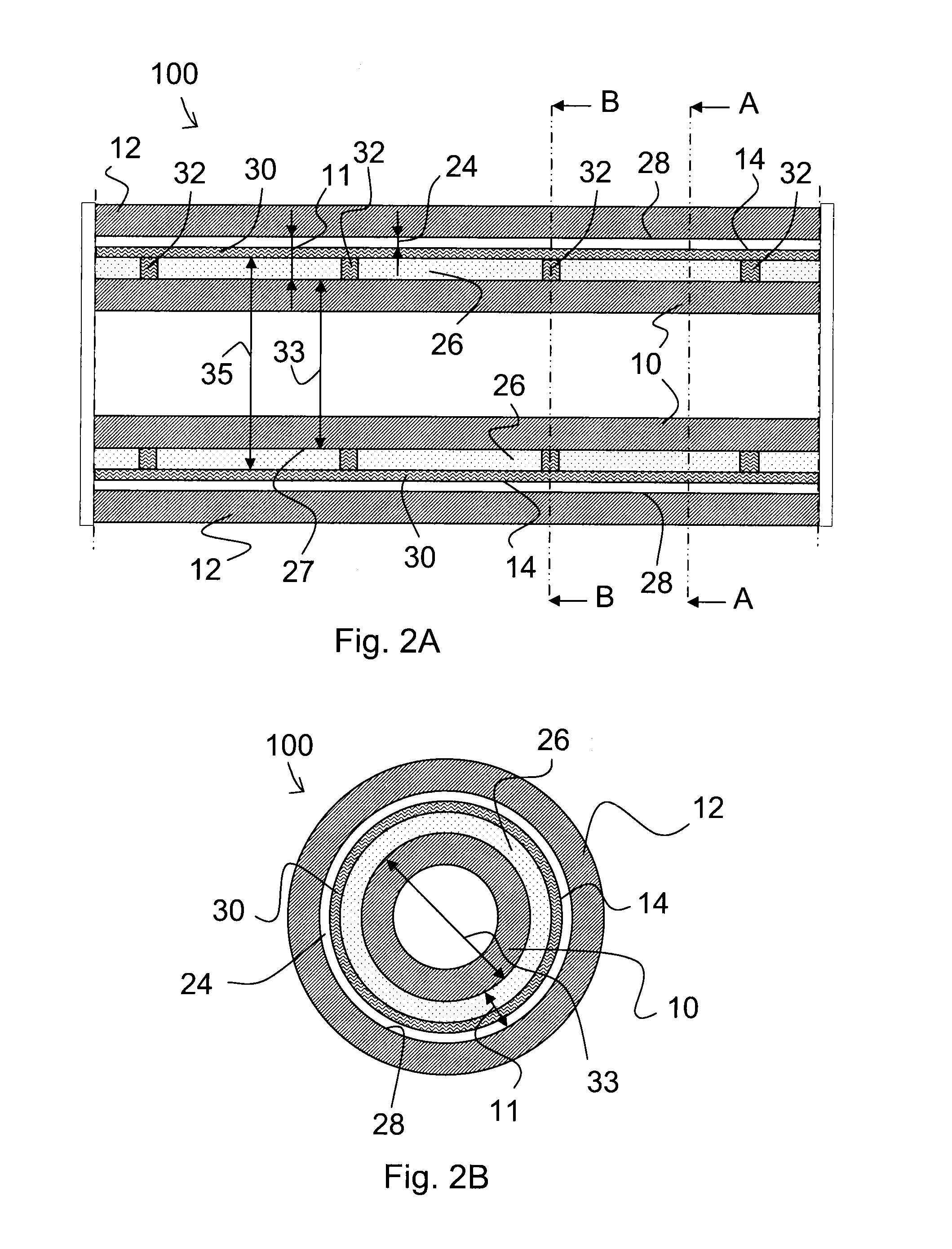

Insulation for pipe-in-pipe systems

InactiveUS20090301596A1Big cost advantageQuick assemblyThermal insulationFlexible pipesThermal insulationThick wall

A method of providing an insulated pipe-in-pipe assembly includes providing an inner pipe; providing a thermal insulation layer of a highly porous solid formed from a gel, the highly porous solid having pores smaller than 100 nanometre, the thermal insulation layer being provided around the inner pipe for thermal insulation of the inner pipe; providing a protective layer on the outer surface of the thermal insulation layer for protecting the thermal insulation layer, and providing a thick walled outer pipe around the protective layer. A Pipe-in-pipe assembly and a pipe-in-pipe section made by the method are also provided.

Owner:HEEREMA MARINE CONTRACTORS NEDERLAND

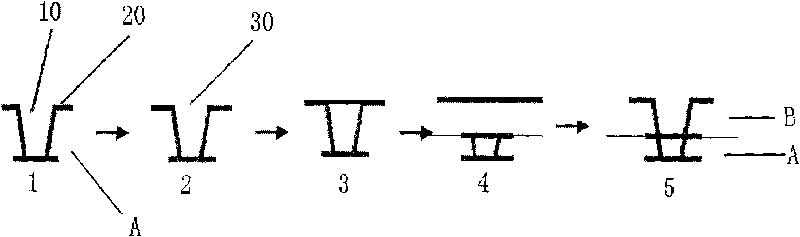

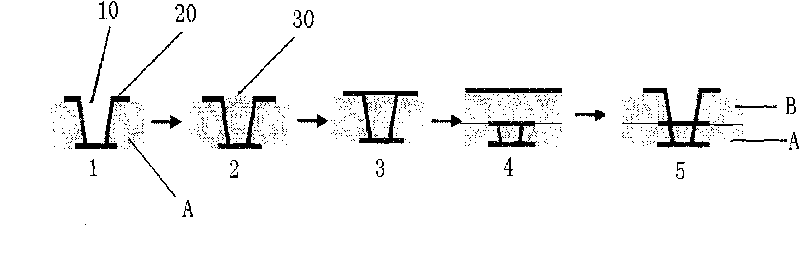

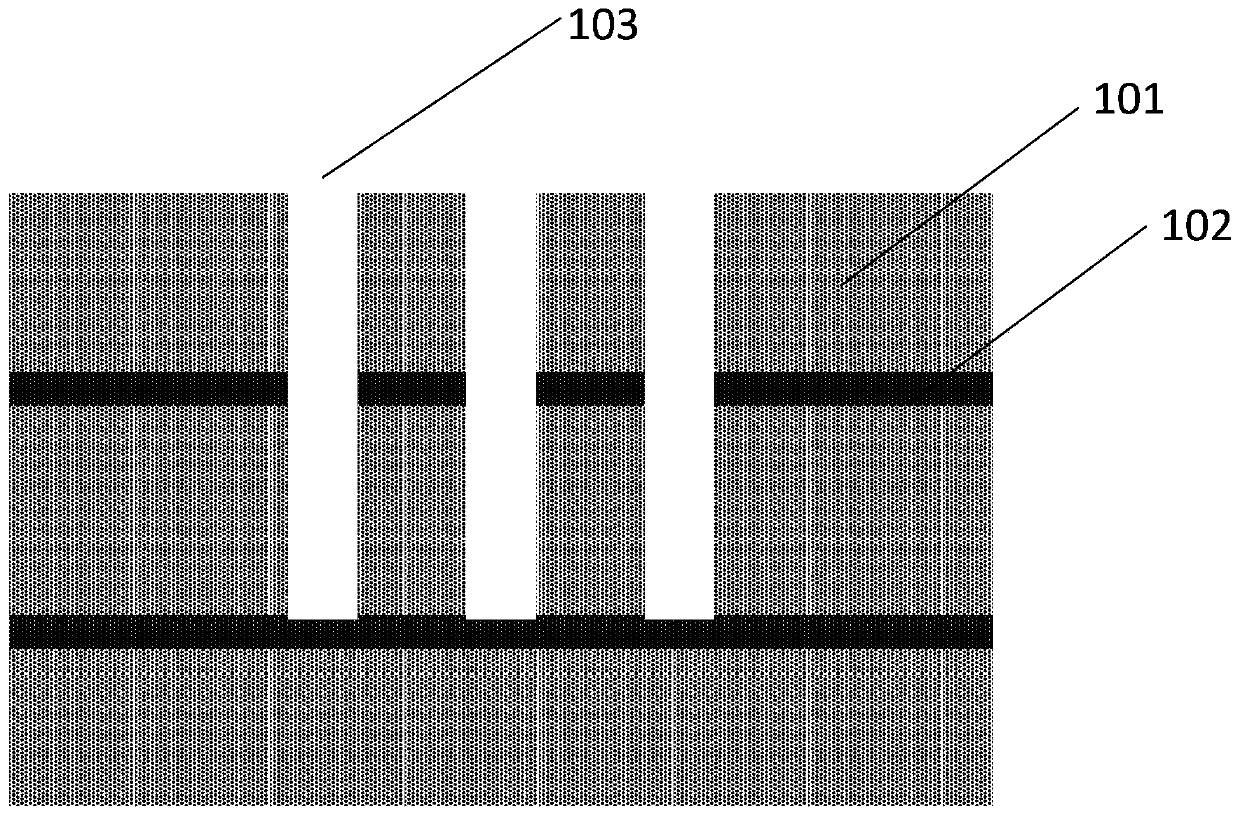

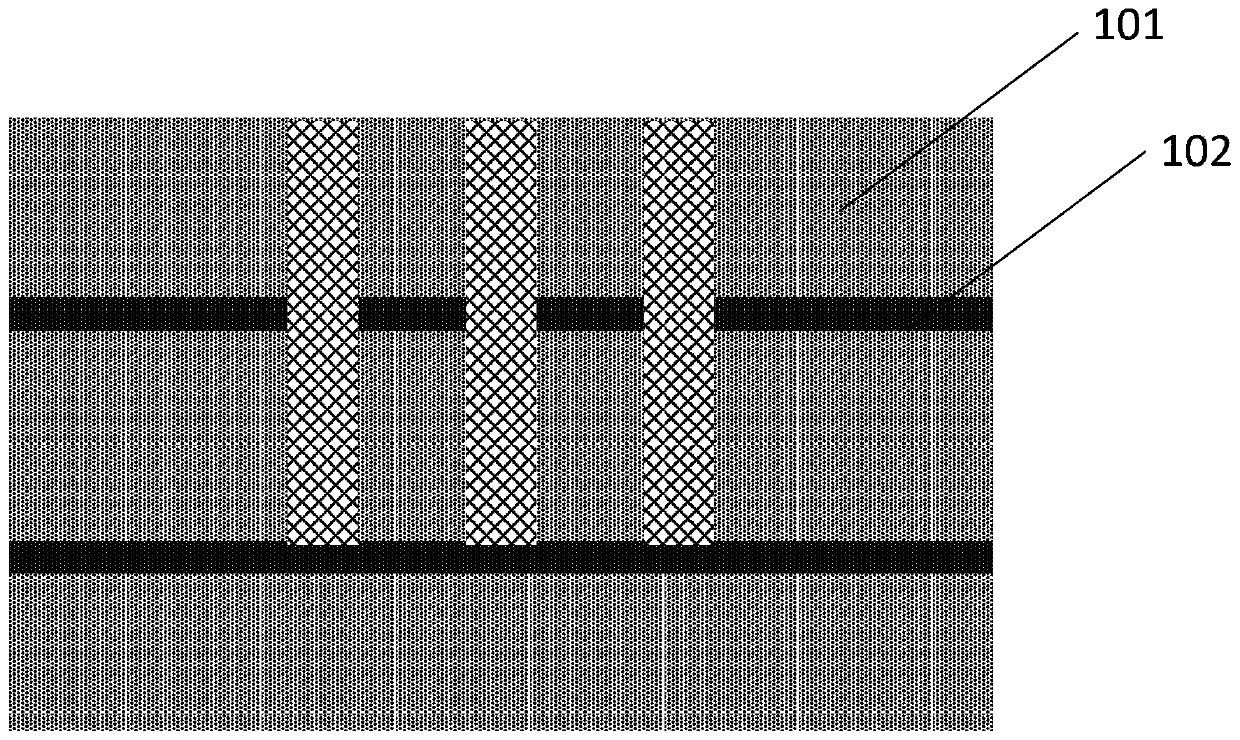

Micro hole manufacturing process of multilayer HDI circuit board

InactiveCN101711096AEasy to achieve stacked via interconnection between layersImprove routing densityPrinted element electric connection formationMiniaturizationInterconnection

The invention discloses a micro hole manufacturing process of a multilayer HDI circuit board. The process comprises the following steps of: (1) carrying out inner-layer laser hole drilling and electroplating; (2) stuffing the electroplated micro holes or micro through holes by resin; (3) grinding orifice resin; (4) carrying out copper deposition and electroplating on the ground orifice resin after stuffing the holes so as to ensure that the surface of the orifice resin is metallized; (5) carrying out inner-layer circuit board etching and outer-layer lamination; (6) carrying out outer-layer laser hole drilling; and (7) electroplating outer-layer patterns to realize interlaminar electrical interconnection. The process breaks a conventional processing mode of micro hole filling and electroplating at present and adopts the method of electroplating after laser hole drilling, stuffing the holes and then electroplating to realize the interlaminar electrical interconnection of PCB boards. The process can realize micro hole overlapping and interconnection and the resetting of welding points on the surfaces of the through holes, can further improve the wiring density of inner-layer and outer-layer circuit boards and is beneficial to developing the PCB boards to miniaturization, densification and high reliability.

Owner:惠州中京电子科技股份有限公司

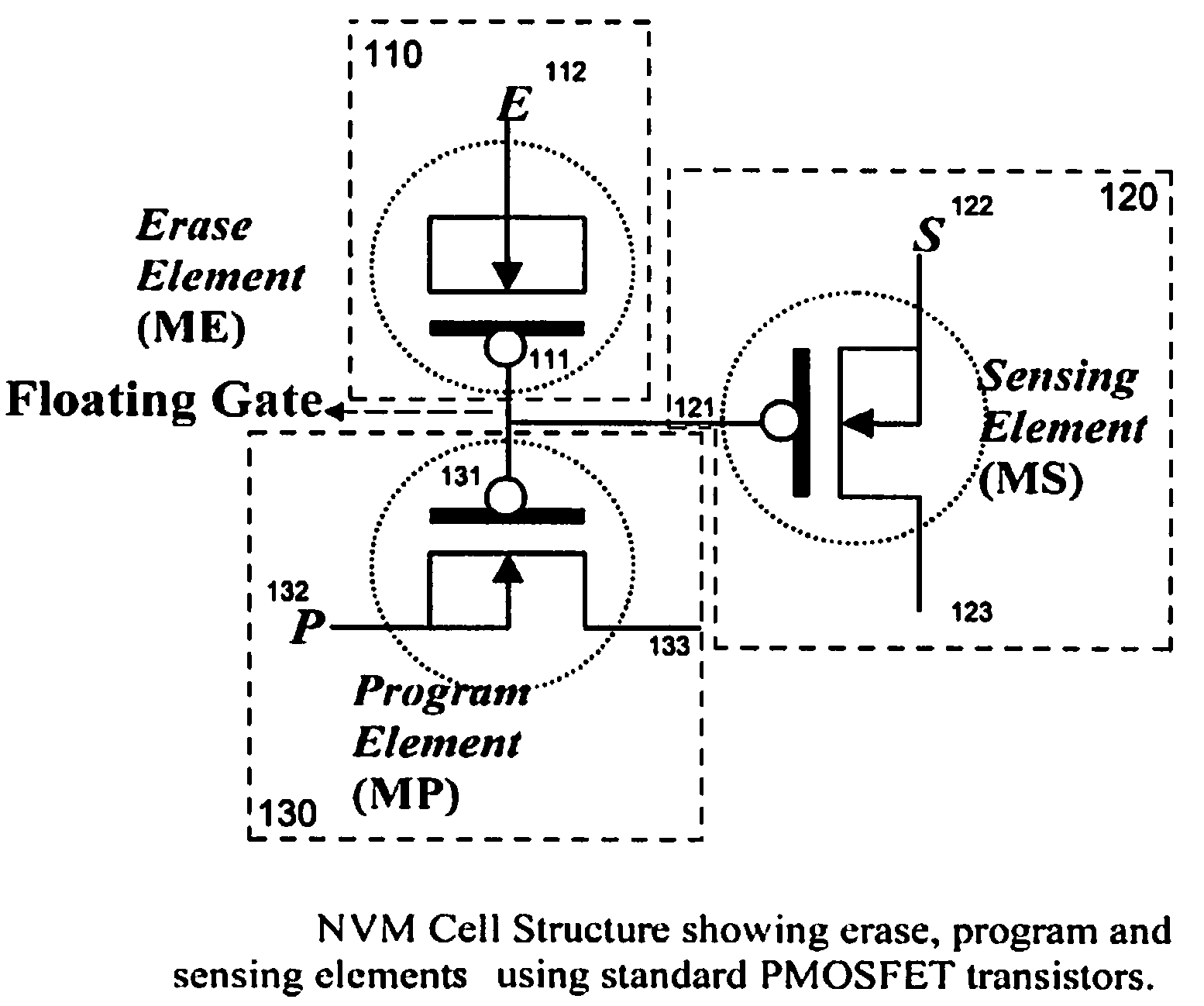

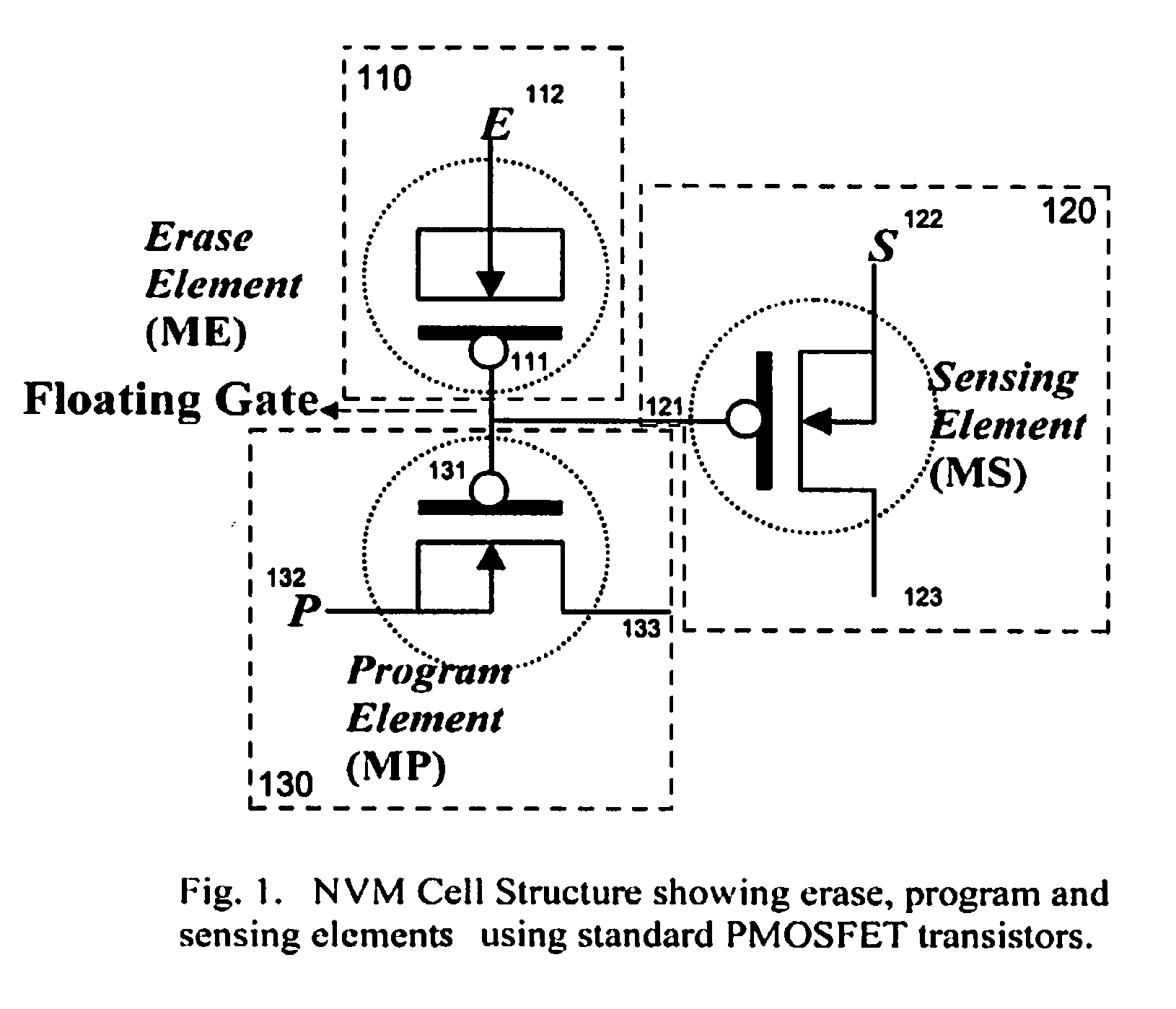

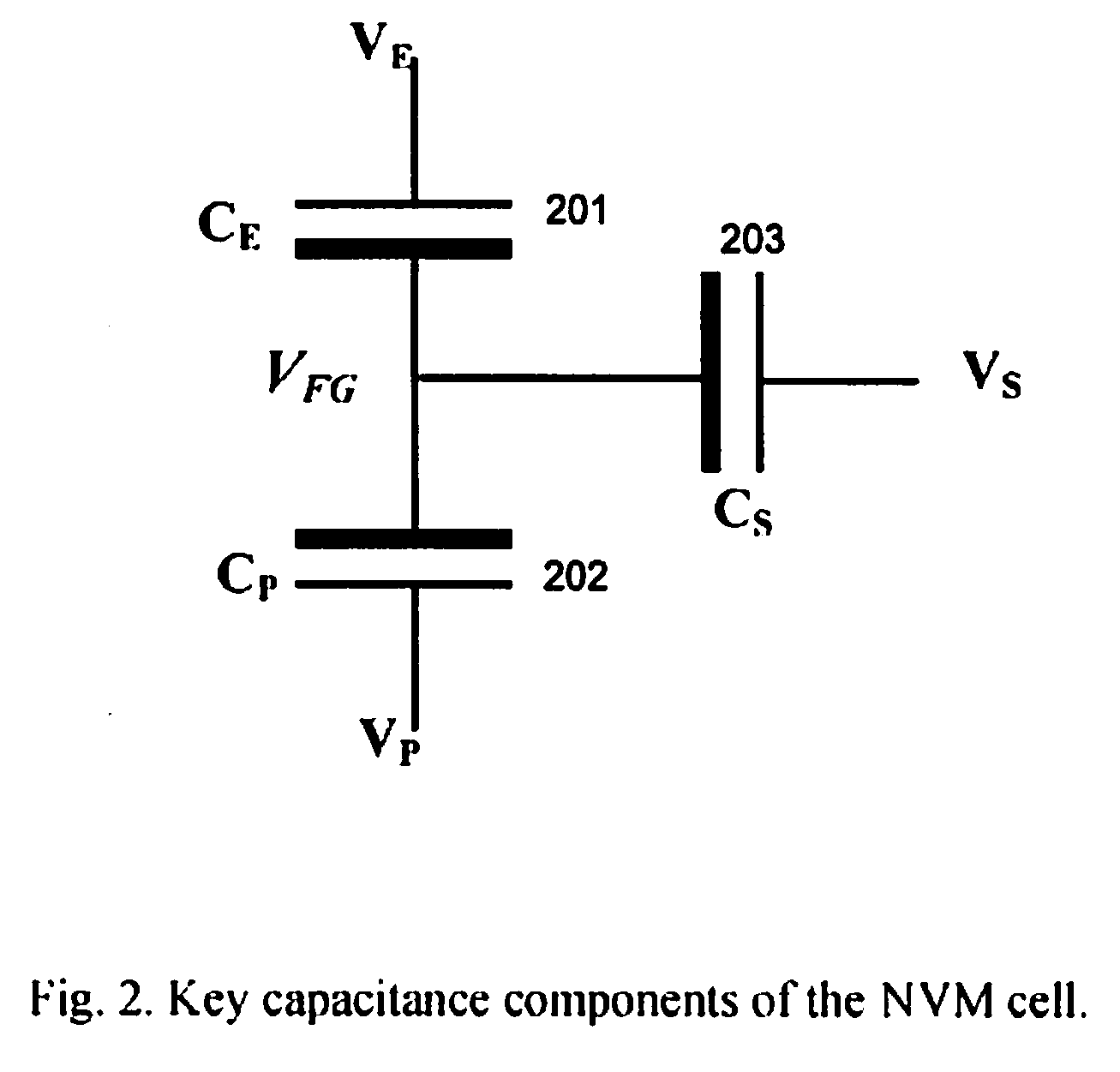

CMOS Compatible Single-Poly Non-Volatile Memory

InactiveUS20080310237A1Little and no extra cost addedImpact transistor performanceSolid-state devicesRead-only memoriesLow voltageComputer terminal

The present invention teaches a single-poly non-volatile memory cell which is compatible with the CMOS process, uses lower voltages for operating, and is more reliable in program, read, or erase operation. The single-poly non-volatile memory cell in accordance with the present invention comprises a program transistor with a program terminal; a sensing transistor with a sensing terminal; and an erase transistor with an erase terminal, wherein the sensing transistor shares a floating gate with the program transistor and the erase transistor. By employing the present invention, significant cost advantages in feature-rich semiconductor products, such as System-on-Chip (SoC) design, compared to conventional dual-poly floating gate embedded Flash memory are provided.

Owner:CYPRESS SEMICON CORP

Method for embedding chips into cavities in front and back sides of adapter plate

ActiveCN111293078ABig cost advantageSolid-state devicesSemiconductor/solid-state device manufacturingBi layerEngineering

The invention discloses a method for embedding chips into cavities in the front and back sides of an adapter plate. The method comprises the steps that the adapter plate adopts a silicon wafer with double SOI (silicon on insulator) layers to manufacture a silicon through hole, the silicon through hole penetrates through a first SOI layer and stops on a second SOI layer to obtain the silicon waferwith the silicon through hole, and then the silicon through hole is filled with electroplated metal to obtain the silicon wafer filled with metal; a groove is etched on the opening surface of the silicon through hole, a metal column in the groove is corroded, and cavities are formed on the front side and the back side to obtain the adapter plate with grooves on the two sides; and the chips with soldering tin are embedded, then an RDL interconnection layer is manufactured on the surface, a second SOI layer is continuously etched to expose one end of the metal column filled in the silicon through hole, the chips with soldering tin balls are embedded, the filling colloid is solidified, and the surface colloid is removed. According to the invention, the adapter plate is manufactured, and the grooves are formed in the front side and the back side of the adapter plate; chips are embedded into the grooves; and the purpose that the chips are embedded into the front side and the back side of the adapter plate is achieved.

Owner:ZHEJIANG UNIV

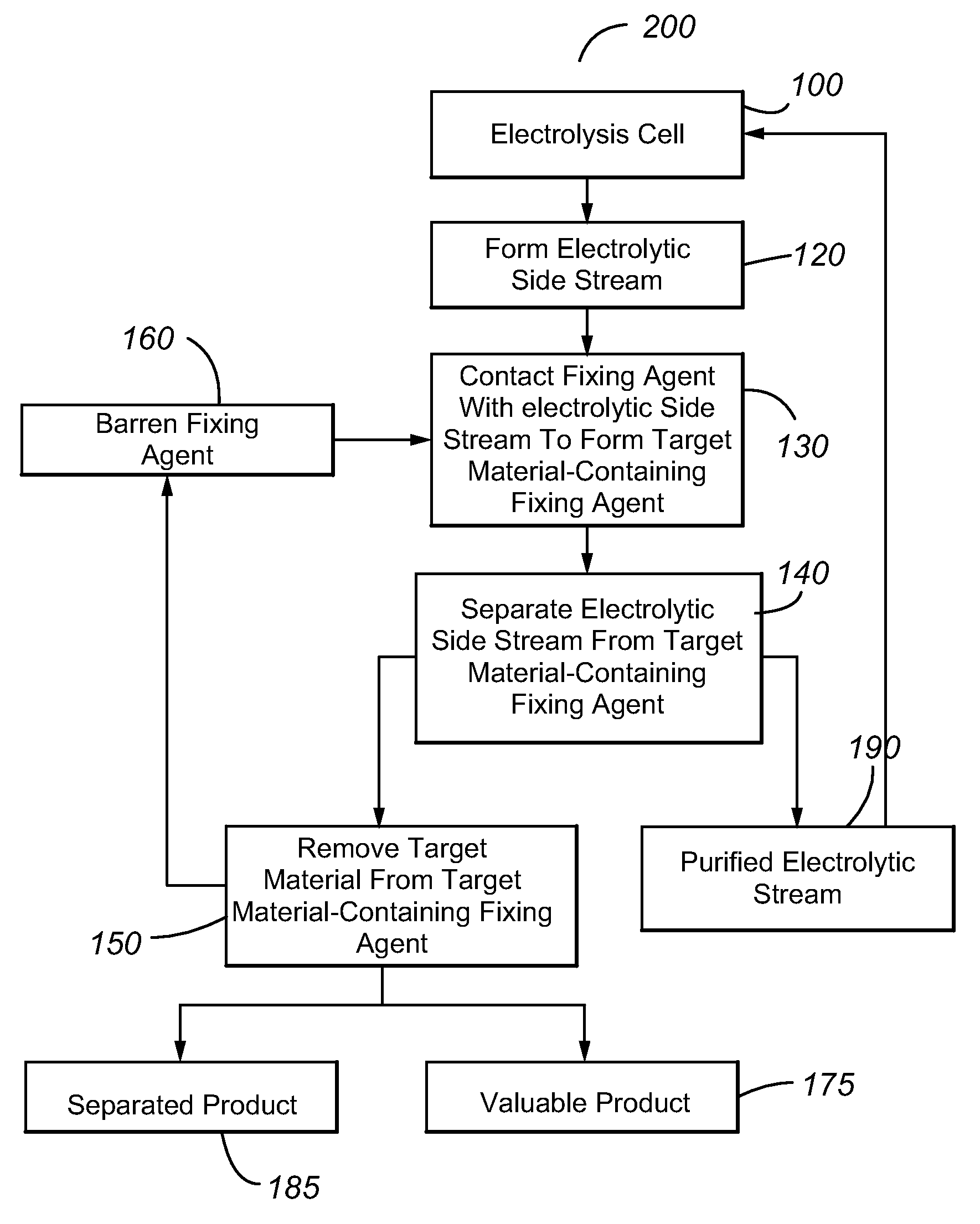

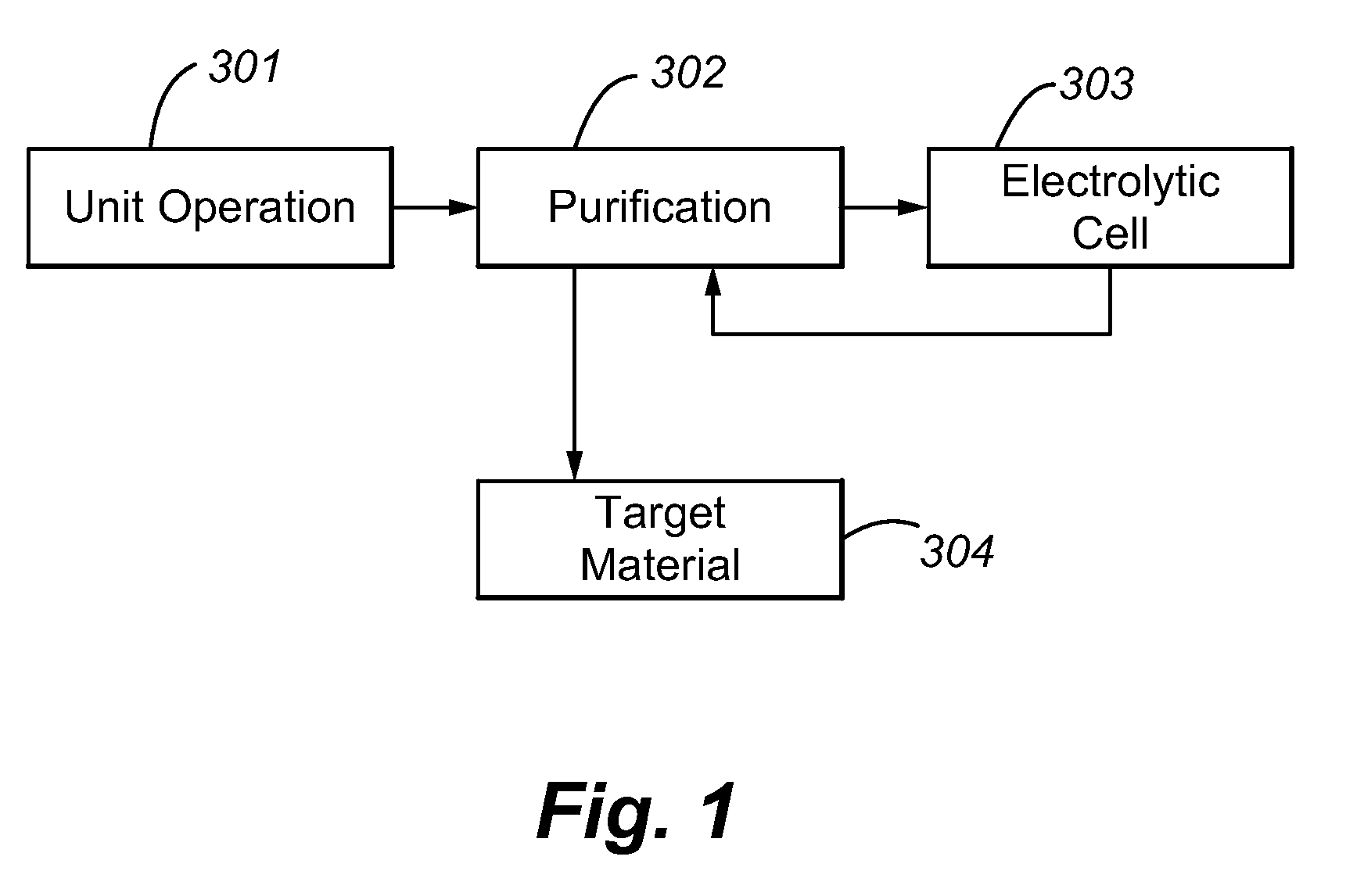

Use of a rare earth for the removal of antimony and bismuth

InactiveUS20100258448A1Promote recoveryIncrease exposureElectrolysis componentsPhotography auxillary processesMischmetalMulti pollutant

The invention relates generally to a process for removing one or more contaminants from an electrolytic solution and more particularly to a process for removing the one or more contaminants contained in an electrorefining solution using rare earth metals.

Owner:MOLYCORP MINERALS

Aluminum wheel finishing process

InactiveCN102430974AOvercoming qualityOvercome efficiencyEdge grinding machinesPolishing machinesAlloy wheelAluminium alloy

The invention discloses an aluminum alloy wheel finishing process, which comprises the steps of: aslant pouring and immersing aluminum alloy blank subjected to thermal processing in a rotating container filled with a grinding material and a grinding agent, forming a medium flow in the front of the wheel through the rotation of the wheel and the relative movement of the container, and carrying out regular and efficient grinding and polishing processing on the front of the wheel and window parts by the medium flow, and finally realizing a mirror polishing effect with extremely excellent surface consistency. By adopting the process, the problems of poor appearance quality in tradition mechanical polishing and low efficiency of a vibration finishing process are overcome, the labor intensity of workers is greatly reduced, the labor environment of the workers is improved, the efficiency is 5-6 times that of the tradition polishing process and vibration finishing, and great cost advantage is achieved.

Owner:CITIC DICASTAL +1

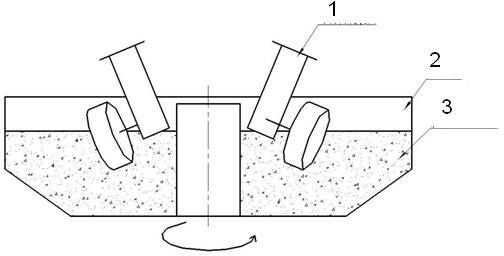

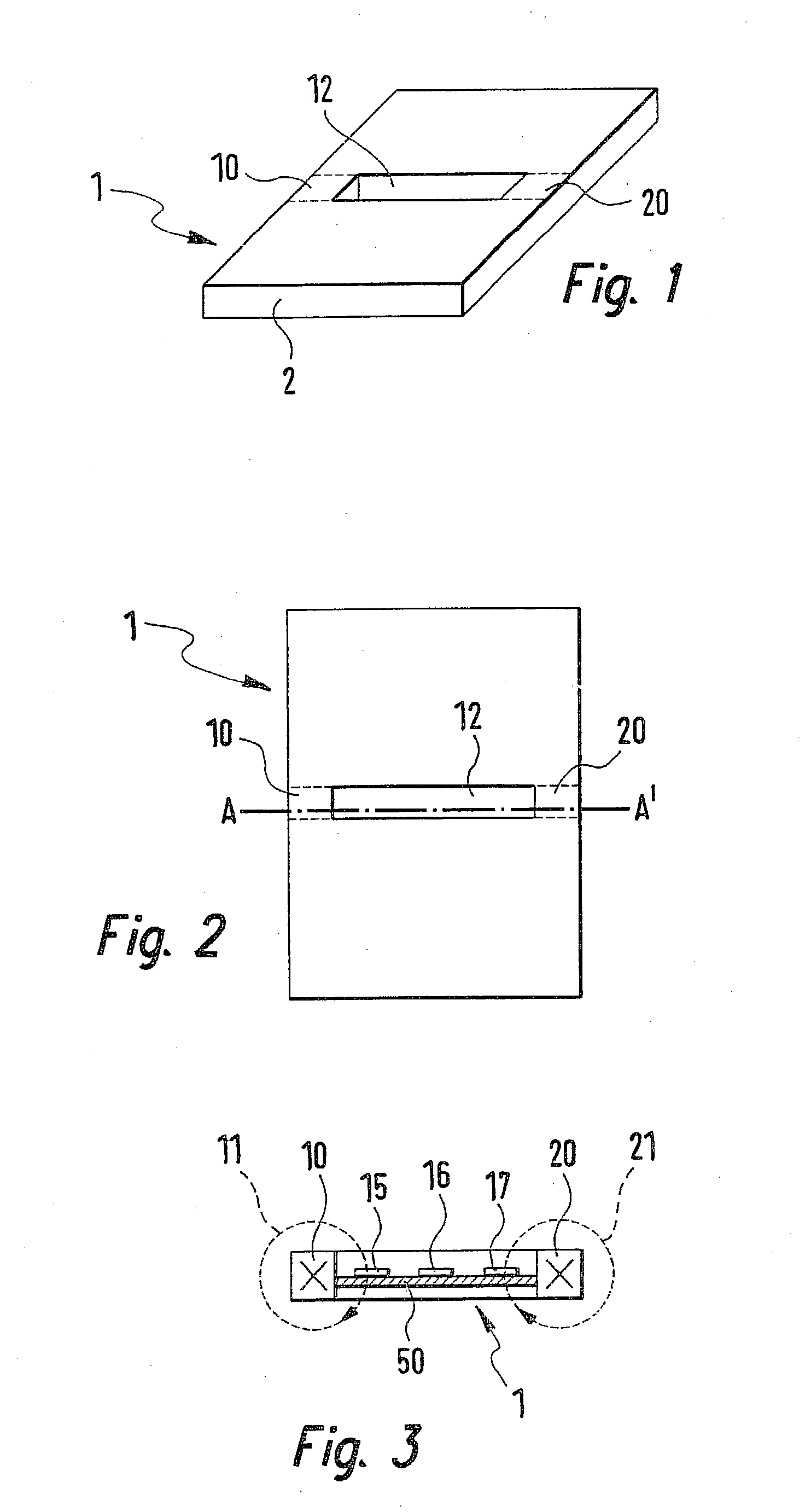

Device, ammeter and motor vehicle

InactiveUS20030146744A1Reduce dependenceEasy to detect and compensateMeasurement using dc-ac conversionMagnetic measurementsElectricityMobile vehicle

A device, an ammeter and a motor vehicle, having a first section (10) and a second section (20) of a conductor (1) for the purpose of measuring the electrical amperage in the conductor (1) are described; a first sensor means (15) and a second sensor means (16) being provided; the current flowing in the first section (10) and in the second section (20) generating a useful magnetic field; the first sensor means (15) being provided to measure the useful magnetic field; the second sensor means (16) being provided in a location where the useful magnetic field disappears; the second sensor means (16) being provided to measure a magnetic interference field; and the measurement of the useful magnetic field being correctable by the measurement of the magnetic interference field.

Owner:ROBERT BOSCH GMBH

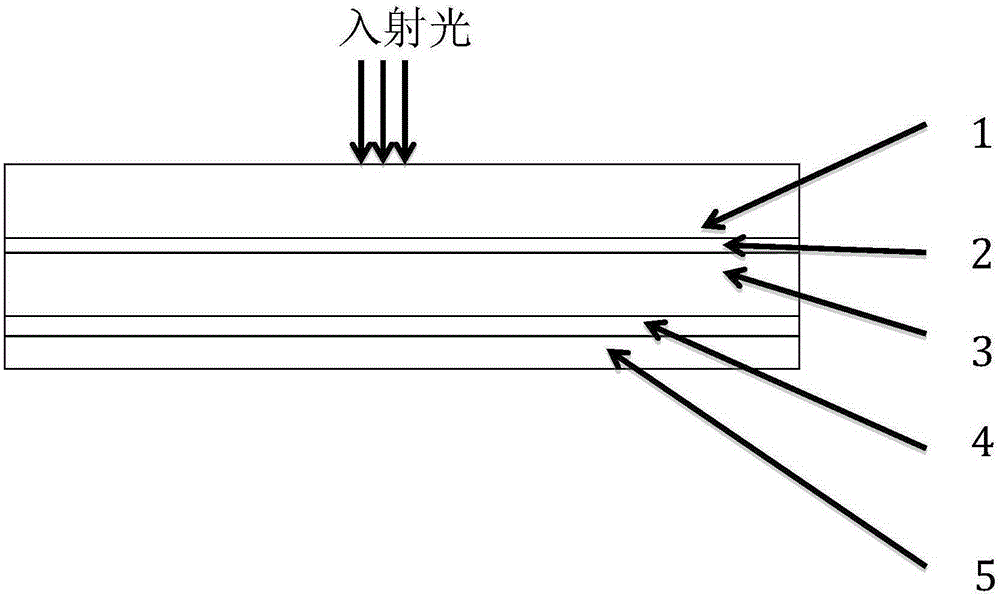

Thin film crystalline silicon perovskite heterojunction solar battery and preparation method thereof

ActiveCN105226187AOvercome the disadvantage of low light absorption coefficientReduce compoundingSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionHole transport layer

The invention relates to a thin film crystalline silicon perovskite heterojunction solar battery and a preparation method thereof, and relates to a semiconductor device for converting luminous energy into electric energy. The thin film crystalline silicon perovskite heterojunction solar battery includes a transparent conductive substrate, a P-type thin film crystalline silicon hole transport layer, a perovskite light absorption layer, an electron transport layer formed by compact titanium dioxide, and a back electrode, wherein the perovskite light absorption layer and the P-type thin film crystalline silicon hole transport layer have matched energy levels. The configuration pattern: the P-type thin film crystalline silicon hole transport layer is arranged on the transparent conductive substrate; the perovskite light absorption layer is arranged on the P-type thin film crystalline silicon hole transport layer; the perovskite light absorption layer and the P-type thin film crystalline silicon hole transport layer form a thin film crystalline silicon perovskite heterojunction; the electron transport layer formed by the compact titanium dioxide is arranged on the perovskite light absorption layer; the back electrode is arranged on the electron transport layer formed by the compact titanium dioxide. According to the invention, the defects that the existing perovskite solar battery is low in stability and high in preparation cost, and a mass of silicon materials are used can be overcame.

Owner:HEBEI UNIV OF TECH

Method for processing wood grain on aluminium section bar

InactiveCN101486289ASolve the technical problem that the surface cannot have wood grainExquisite appearanceDecorative surface effectsPretreated surfacesLacquerSpray coating

The invention relates to a method for processing wood grains on an aluminum section, which comprises a step of preprocessing, a step of spray coating and a step of wood grain transfer printing sequentially, wherein in the step of preprocessing, the aluminum section is mounted to perform chemical degreasing and roll scale removal, then the aluminum section is washed in water and chromized by chromate, and is washed in the water again and dried; in the step of spray coating: the aluminum section is hung up to perform dust blowing, wiping, spraying a fluorocarbon prime lacquer and a fluorocarbon top coat, drying and solidification; and in the step of wood grain transfer printing, a transfer printing water tank and a soaking water tank is added with water and heated up first, a wood grain membrane is tiled on the water surface of the transfer printing water tank, and the surface of the aluminum section is contacted with the wood grain membrane so as to transfer the paint on wood grains to the surface of the aluminum section; then the aluminum section is transferred to the soaking water tank; after that the aluminum section is cleaned and wiped clean and dried, and is baked and solidified. The method coats the wood grains on the surface of an aluminum veneer or the aluminum section by a transfer printing method, and solves the technical problem that in the prior art, and the surface of the aluminum veneer or the aluminum section cannot be provided with the wood grains.

Owner:SHANGHAI HUAHUI CURTAIN WALL MFG

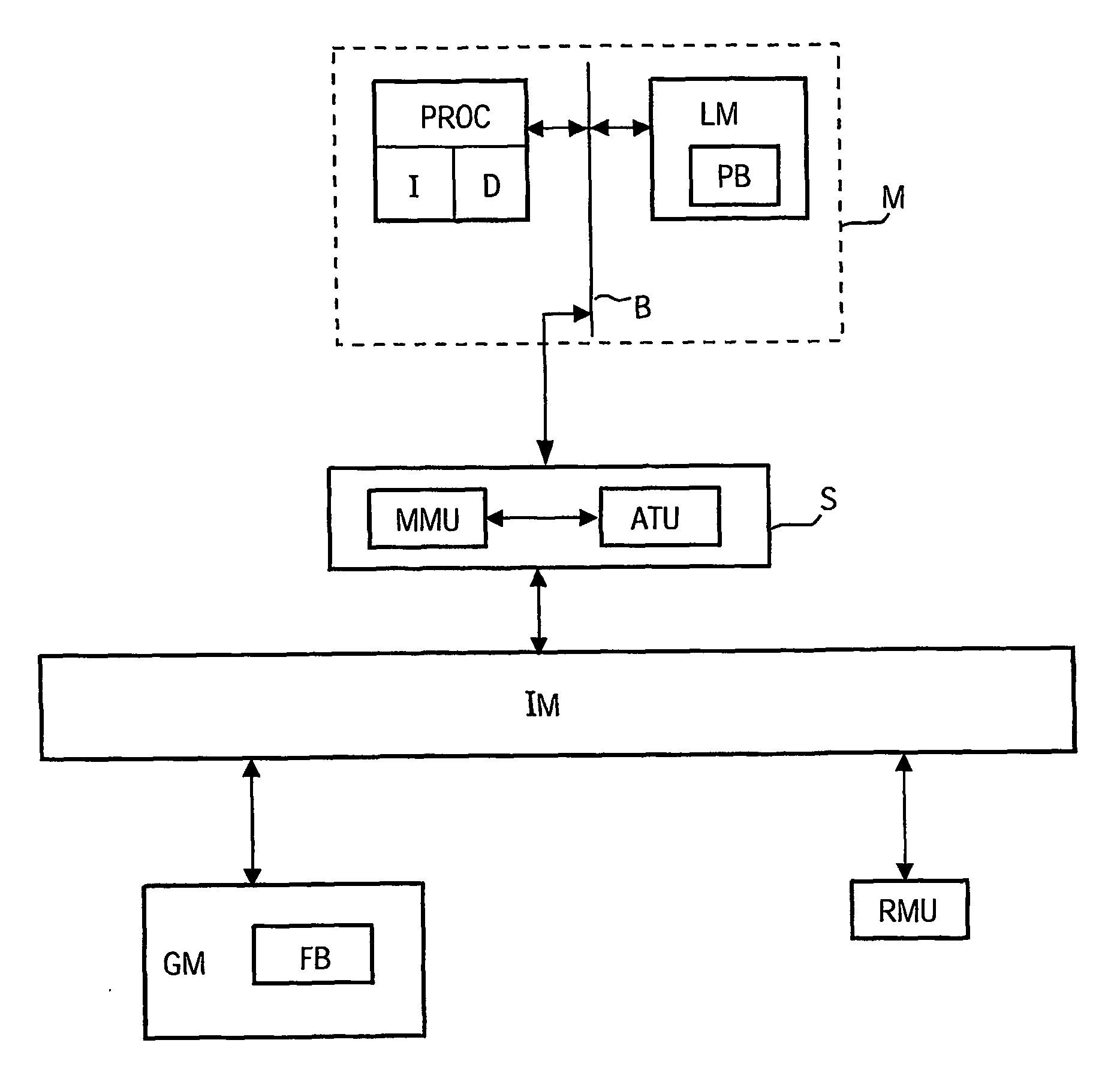

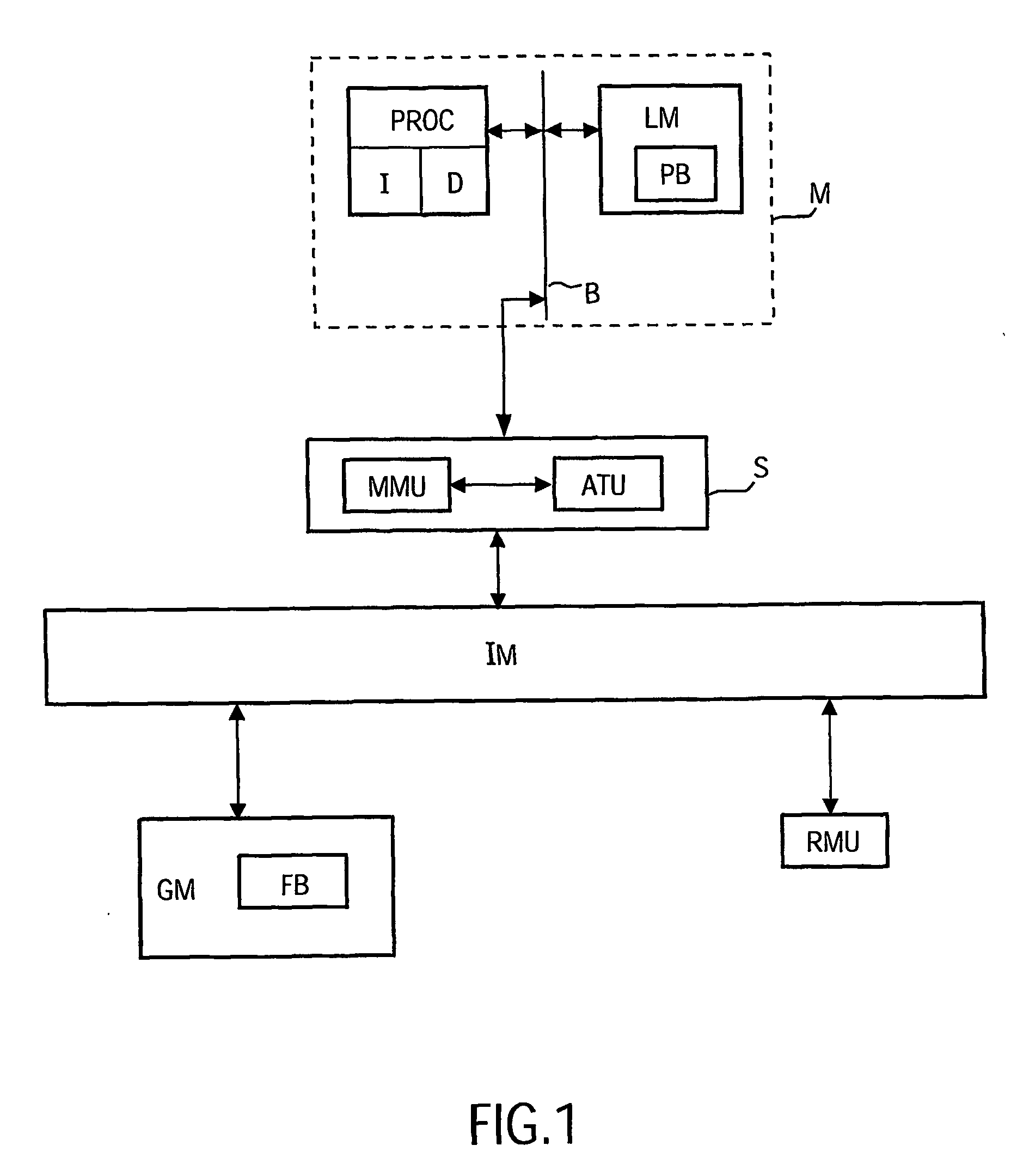

Integrated circuit with dynamic memory allocation

ActiveUS20070064500A1Significant cost advantageSufficient flexibilityEnergy efficient ICTMemory adressing/allocation/relocationEmbedded systemLocal memories

An integrated circuit comprising a plurality of modules (M) for processing applications is provided, wherein each of said modules comprise a local memory (LM). The integrated circuit further comprises a global memory (GM), which can be shared between the plurality of modules (M), and an interconnect means (IM) for interconnecting said modules (M) and said global memory (GM). A memory managing unit (MMU) is associated to each of said modules (M) and determines whether the local memory (LM) provides sufficient memory space for the currently processed application. If this is not the case, the memory managing unit (MMU) requests a global buffer (FB) in said global memory (GM) to be exclusively reserved for the processing data of its associated module (M). Accordingly, by using the local memory (LM), whenever possible, before data is outsourced to the global memory (GM), power as well as bandwidth of the interconnect means can be saved. Furthermore, sufficient flexibility is introduced to the system on-chip to enable running applications that demand more local resources e.g. local memory, than are available in the subsystems or modules (M), without having the need to design the subsystems or modules for worst case scenarios. Especially, when the worst-case demands are much higher than the average case, the cost advantage can be significant.

Owner:III HLDG 6

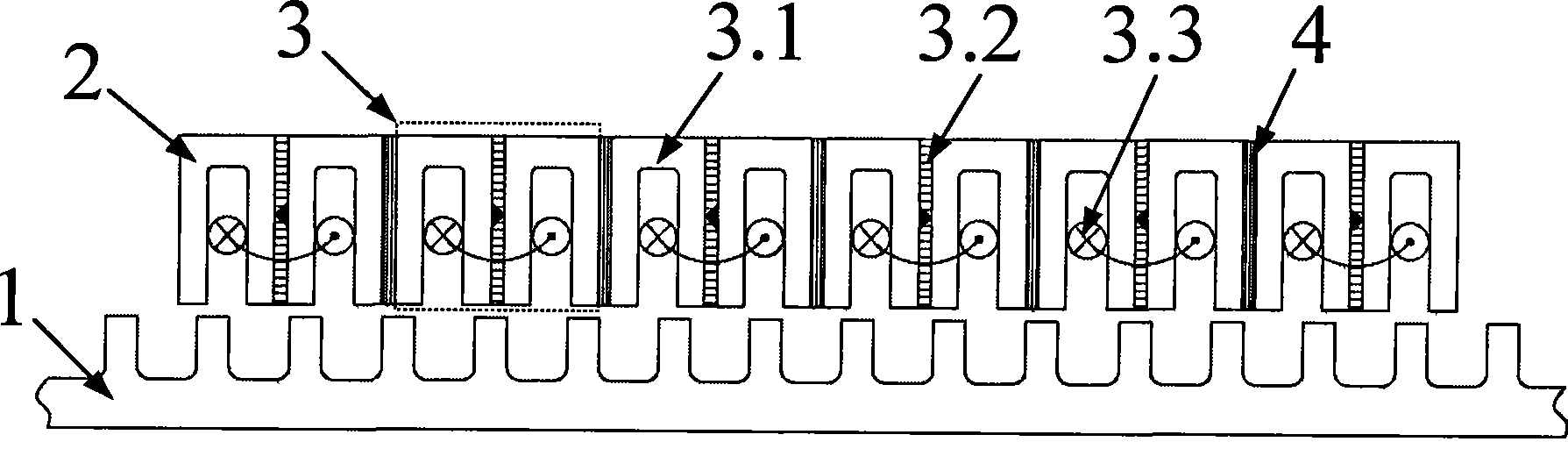

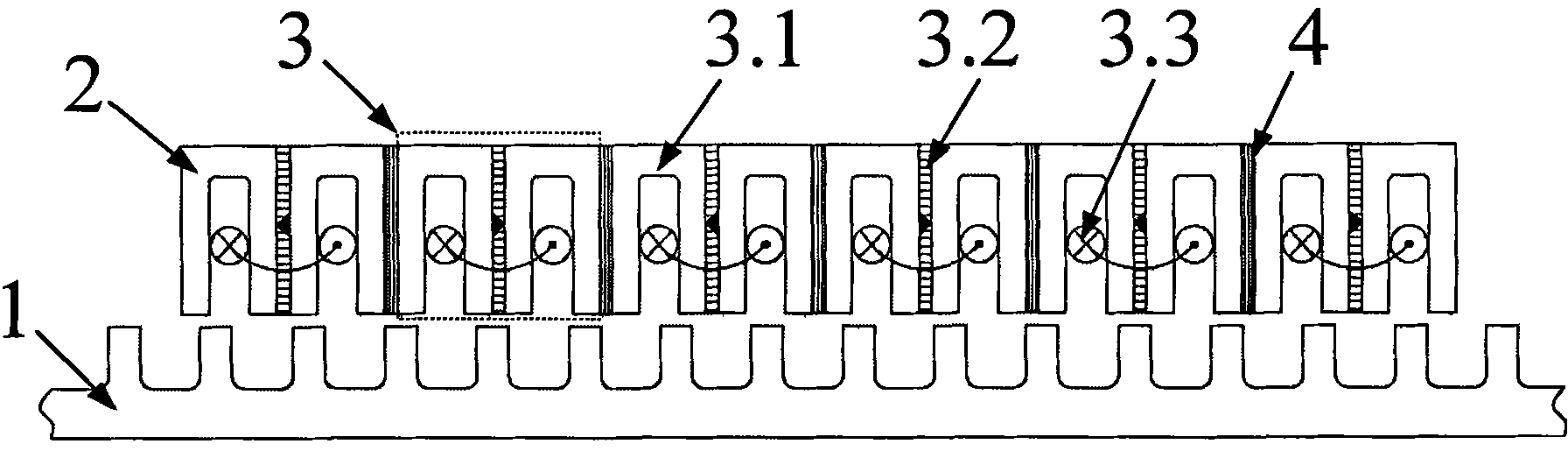

Modularization error-tolerance type permanent magnet switch magnetic linkage straight line motor

The invention discloses a modularized fault-tolerance type permanent-magnet switched magnetic linkage linear motor, comprising a stator and a mover, wherein the stator is a flat plate or a cylinder formed by a toothed groove type iron core, the mover is a flat plate or a cylinder formed by a plurality of modules and reluctance pieces which are arranged at intervals, each module comprises two reversed U-shaped iron cores, a permanent magnet clamped between the two U-shaped iron cores, and a three-phase armature winding, armature teeth are formed on the sides of the two U-shaped iron core for clamping the permanent magnet, auxiliary teeth are formed on the sides of the two U-shaped iron core sides for clamping the reluctance piece, the three-phase armature winding is wound on the armature teeth, the auxiliary teeth are not wound with a winding, and N poles and S poles of adjacent modules are arranged at intervals. In the linear motor, the coil and the permanent magnet are arranged on the mover part, the stator part only consists of an iron core lamination at low cost and is particularly suitable for a long-distance linear motion drive system; in addition, the modularized design brings convenience to the assembly and is easy to implement the large-scale production.

Owner:ZHEJIANG UNIV

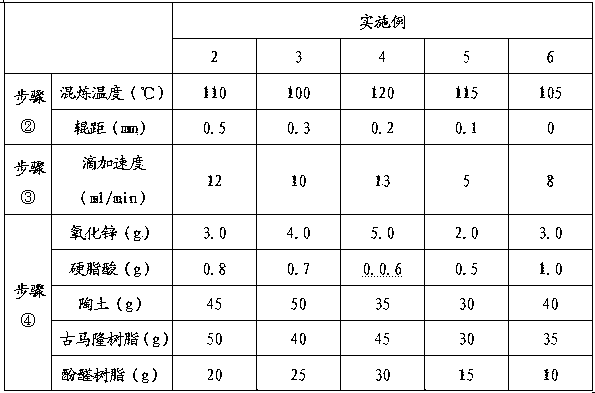

Low-hardness high-damping rubber composition and preparation method thereof

ActiveCN103724908AIncrease the scope of applicationImprove material heat resistance and ozone resistanceComposite materialPolymer chemistry

The invention discloses a low-hardness high-damping rubber composition and a preparation method thereof. According to the composition, butyl rubber and polynorbornene rubber are used together, so that the damping application range of the material is widened, the application temperature is from 40 DEG C below zero to 80 DEG C, and the heat resistance and ozone resistance of the material are improved to a certain degree. A wide-temperature range, low-hardness and high-damping material is prepared through blending, the application range of the damping material is improved, especially a high-damping effect at room temperature is achieved, the rebound rate of vulcanized rubber at room temperature is less than 1 percent, and 90 percent of kinetic energy is converted into heat energy, so that an effect of maximizing the damped oscillation is achieved. The rubber composition disclosed by the invention can be widely applied to the fields of buildings, automobiles and high-precision instruments so as to achieve the damping aim.

Owner:GREAT WALL MOTOR CO LTD

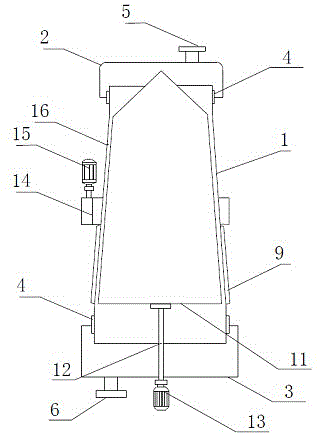

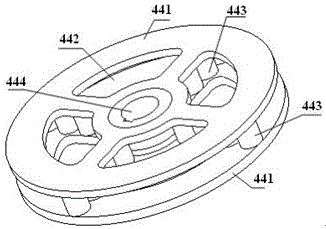

Rotary graphene stripping device, graphene production system and production method

The invention discloses a rotary graphene stripping device including a rotary cylinder body; a top cover is arranged above the rotary cylinder body, a bottom cover is arranged below the rotary cylinder body, the top of the top cover is provided with a feed inlet, the bottom of the bottom cover is provided with a discharge port, and the feed inlet is communicated with the interior of the rotary cylinder body; the outer side of the rotary cylinder body is provided with a first motor, and is used for driving the rotary cylinder body to horizontally rotate; the rotary cylinder body is also internally provided with an inner cylinder, and a second motor used for driving the inner cylinder to horizontally rotate in a direction opposite to the rotating direction of the rotary cylinder body is arranged below the rotary cylinder body; the upper part of the inner cylinder is shrunk in a certain angle, and a material storage space is left between the upper part of the inner cylinder and the upper part of the rotary cylinder body; the lower part of the inner cylinder and the lower part of the rotary cylinder body are in clearance fit to be used for grinding graphite sheets, and a clearance between the lower part of the inner cylinder and the lower part of the rotary cylinder body is successively decreased downward along the axial direction of the rotary cylinder body. The rotary graphene stripping device can achieve successful stripping of graphene. The invention also relates to a graphene production system containing the rotary graphene stripping device and a graphene production method.

Owner:江苏碳谷二维世界科技有限公司

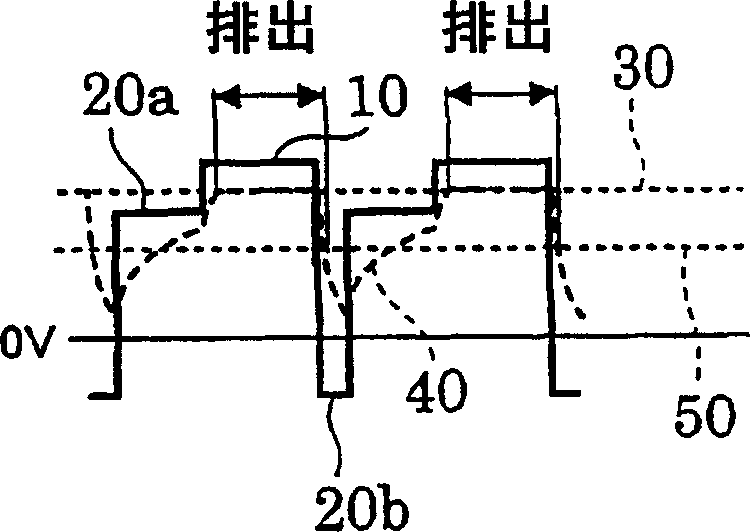

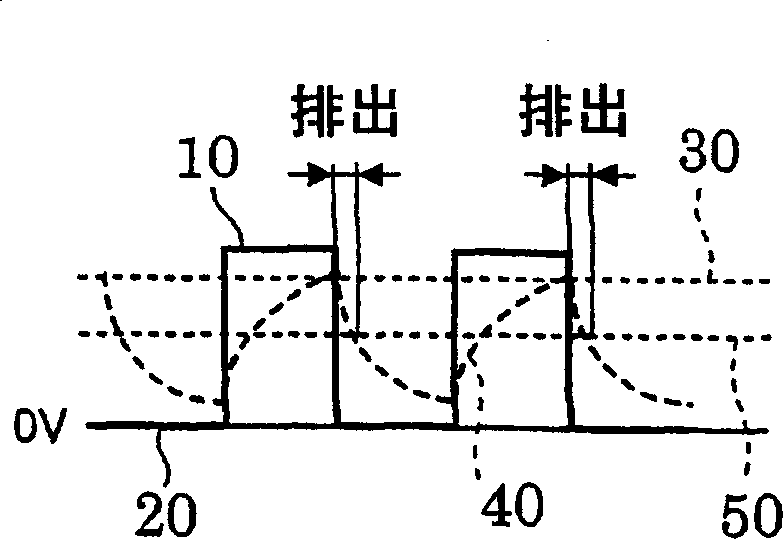

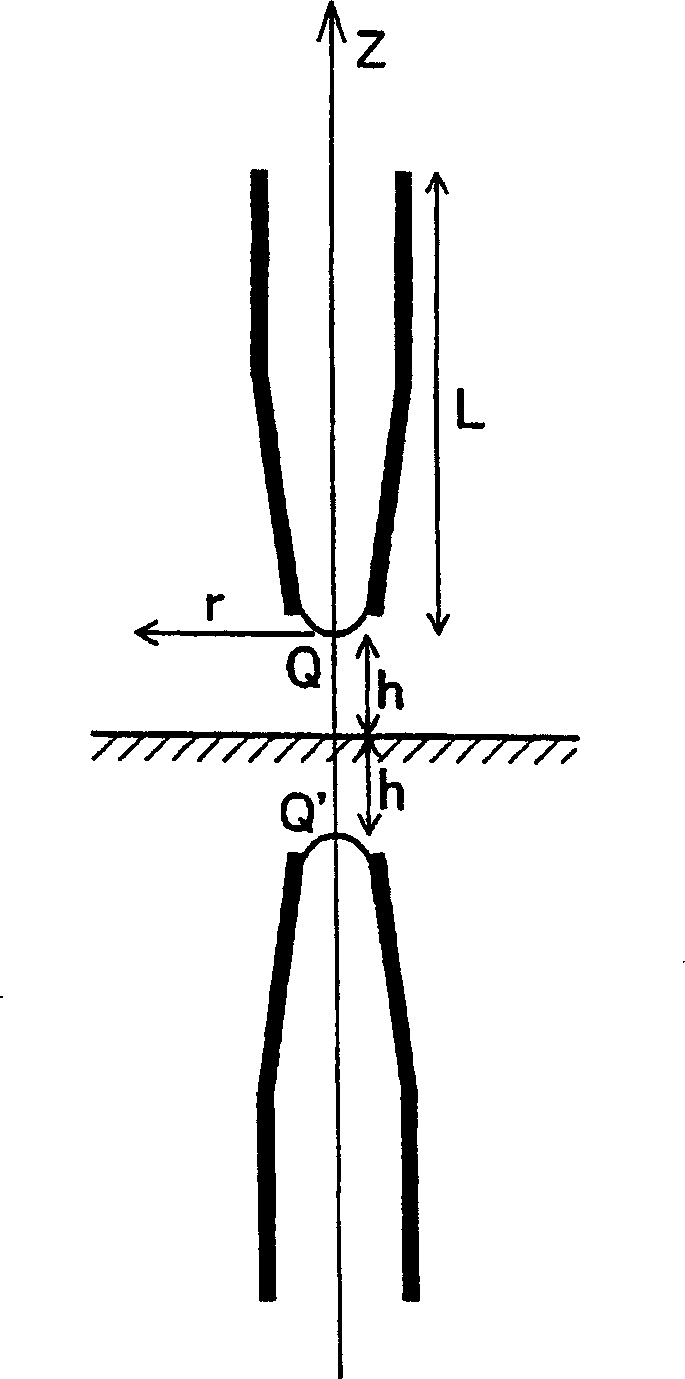

Electrostatic suction-type fluid discharging method and device

InactiveCN1849178AImprove reliabilityHigh cost advantageLiquid surface applicatorsCoatingsLower limitStart stop

The discharge hole diameter of the nozzle is 0.01 to 25 μm, and the upper limit voltage (10) set to be greater than or equal to the minimum dischargeable voltage (30) as a voltage condition for starting fluid discharge is applied between the nozzle and the substrate by a voltage applying unit the pulse voltage. Before the rising edge of the pulse voltage, set the first lower limit voltage (20a) whose polarity is the same as the upper limit voltage (10) and whose absolute value is smaller than the lowest dischargeable voltage (30), and immediately after the rising edge of the pulse voltage, set A second lower limit voltage (20b) having a polarity opposite to the upper limit voltage (10). Therefore, it is possible to provide an electrostatic attraction type fluid discharge method and device, which can achieve miniaturization of nozzles, discharge of tiny fluids, high accuracy of impact position, and low voltage of driving voltage, while improving discharge start-stop characteristics and driving frequency. And it can control the pulse time of the discharge volume.

Owner:NAT INST OF ADVANCED IND SCI & TECH

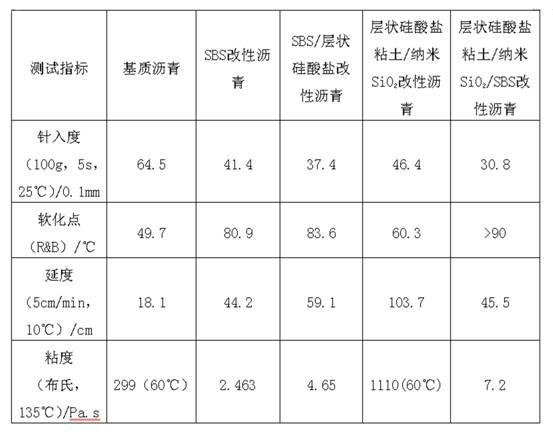

Nanoparticle modified asphalt and preparation method thereof

The invention discloses nanometer sheet material modified asphalt and a preparation method thereof. The modified asphalt consists of phyllosilicate clay, nanometer SiO2 particles, styrene-butadiene-styrene (SBS) and matrix asphalt, wherein a weight ratio of the phyllosilicate clay to the SBS to the nanometer SiO2 particles is 1:0.5-1:0.05-2.0, the phyllosilicate clay accounts for 1 to 10 weight percent of the modified asphalt and the matrix asphalt accounts for 90 to 99 weight percent of the modified asphalt. The preparation method of the modified asphalt comprises the following steps of: adding a proper amount of nanometer SiO2 particles and SBS into melt matrix asphalt and performing primary shear stirring; and adding the phyllosilicate clay, maintaining the temperature of between 100 and 200 DEG C, and continuously performing shear stirring at the speed of between 500 and 10,000 rpm for 0.5 to 4 hours to ensure that various modifiers are dispersed and uniformly mixed in the matrix asphalt so as to prepare the modified asphalt. Compared with the matrix asphalt, the modified asphalt prepared by the method has remarkably improved high-temperature property, enhanced rutting resistance and improved temperature sensitivity.

Owner:SOUTHEAST UNIV

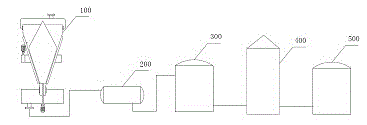

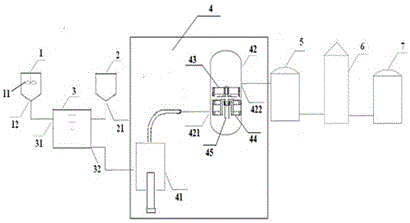

Device for continuously preparing graphene and method for producing graphene

The invention belongs to the technical field of graphene and particularly relates to a device for continuously preparing graphene and a method for producing graphene. The device comprises a raw material grinding tank, a grinding medium storage bin, a stirring tank, a continuous grinding mechanism, a material storage tank, a centrifugal filtering device and a drying device. A blade type stirring mill is arranged in the raw material grinding tank. The continuous grinding mechanism comprises a high-pressure pump, the grinding bin, a flow guide ring, a dispersion impeller and a transmission shaft. The flow guide ring is located in the middle of the grinding bin and fixedly connected with the transmission shaft, the dispersion impeller is located between the flow guide ring and the bottom of the grinding bin, and the transmission shaft passes through the center of the dispersion impeller. The probability that graphene is smashed is reduced through continuous stripping step by step, structural defects of graphene are reduced, and meanwhile the situation that structural defects are caused again to stripped graphene due to re-grinding is avoided. The invention further discloses the method for producing graphene by means of the device for continuously preparing graphene from the slurry.

Owner:淮安双洋新材料有限公司

Preparation method of briquetted active carbon

The invention relates to a preparation method of briquetted active carbon, which sequentially comprises the following technical processes: (1) oxidizing and drying a coal material; (2) mixing; (3) pulverizing; (4) molding; (5) charring; (6) drying the charred material; (7) activating; (8) screening the activated material; (9) performing acid pickling; and (10) drying the acid-pickled material. The method has the advantages of low investment, high yield, favorable environmental protection effect, low cost and low comprehensive energy consumption. The product has the characteristics of light bulk specific gravity, well-developed macropores, mesopores and minipores, and high adsorption speed.

Owner:PINGLUO XIANGTAI COAL CHEM

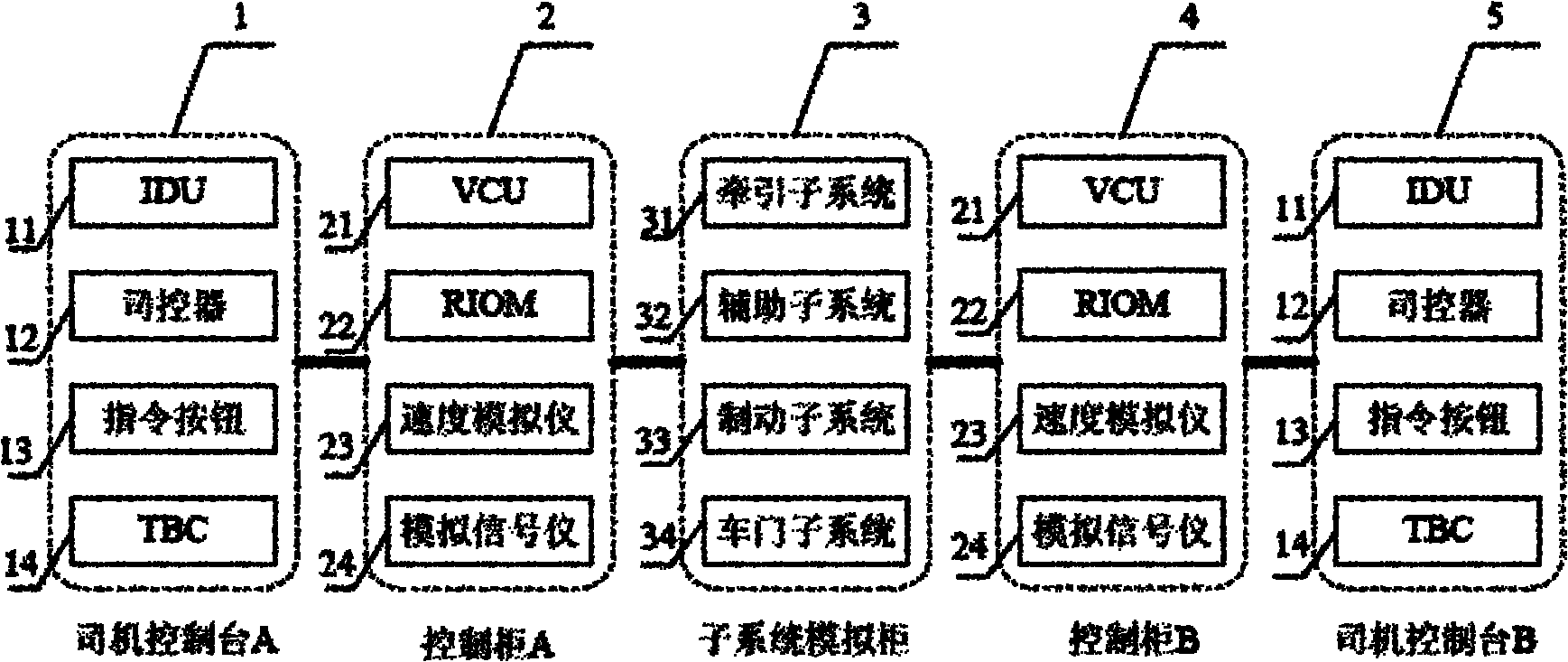

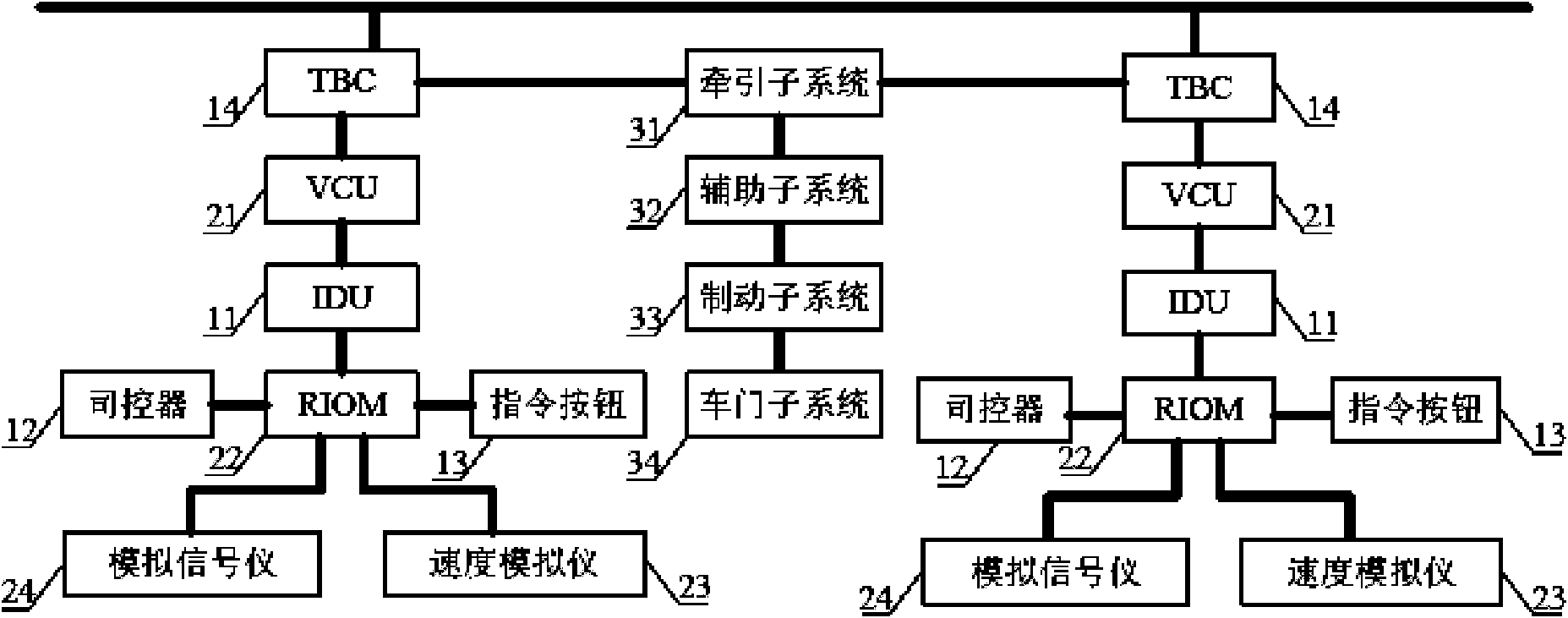

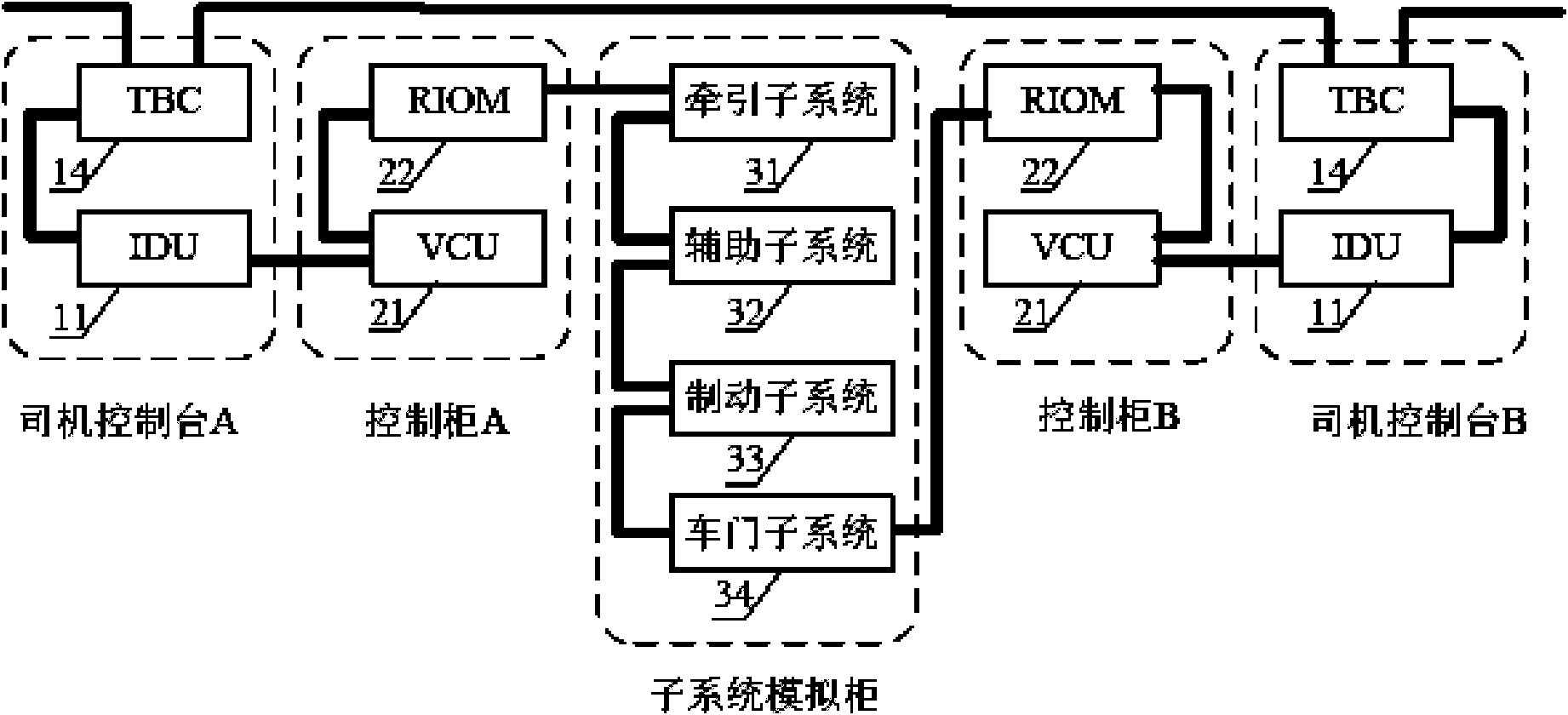

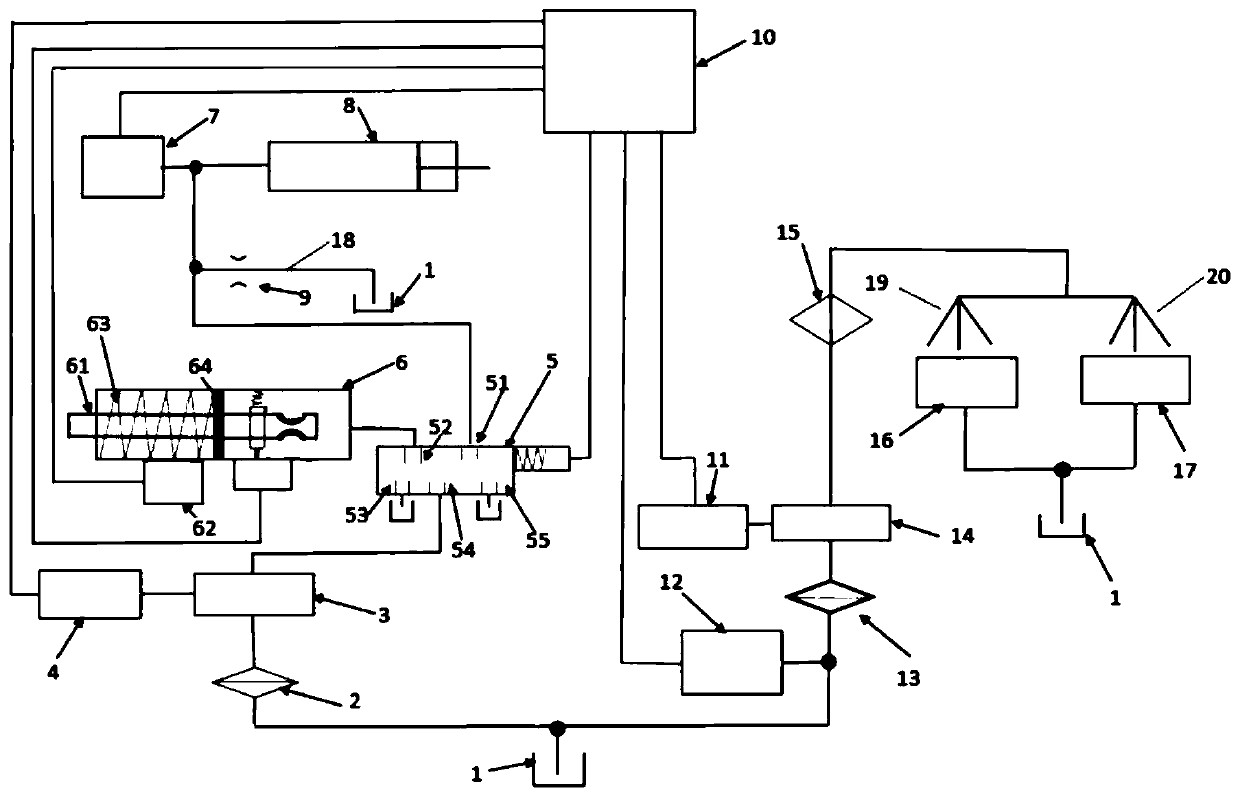

Test platform of controller area network (CAN)-based light rail vehicle network control system

InactiveCN102023637AGuaranteed normal operationDebug impactElectric testing/monitoringArea networkControl system

The invention discloses a test platform of a controller area network (CAN)-based light rail vehicle network control system, which comprises a driver console A, a driver console B, a control cabinet A, a control cabinet B and a subsystem simulation cabinet, wherein the driver consoles A and B have the same structure; the control cabinets A and B have the same structure; and the driver console A, the control cabinet A, the subsystem simulation cabinet, the control cabinet B and the driver console B are connected by a CAN. The test platform can greatly shorten the debugging time of the vehicle network control system so as to shorten the time of delivering vehicles to users by original equipment manufacturers and finally realize the advanced delivery or operation of the vehicles. The test platform and a research platform are provided for the CAN technology-based control system, are favorable for the popularization and application of a CAN system in China and further promote the diversified development of the light rail vehicle network control system in China.

Owner:CHINA CNR CORPORATION

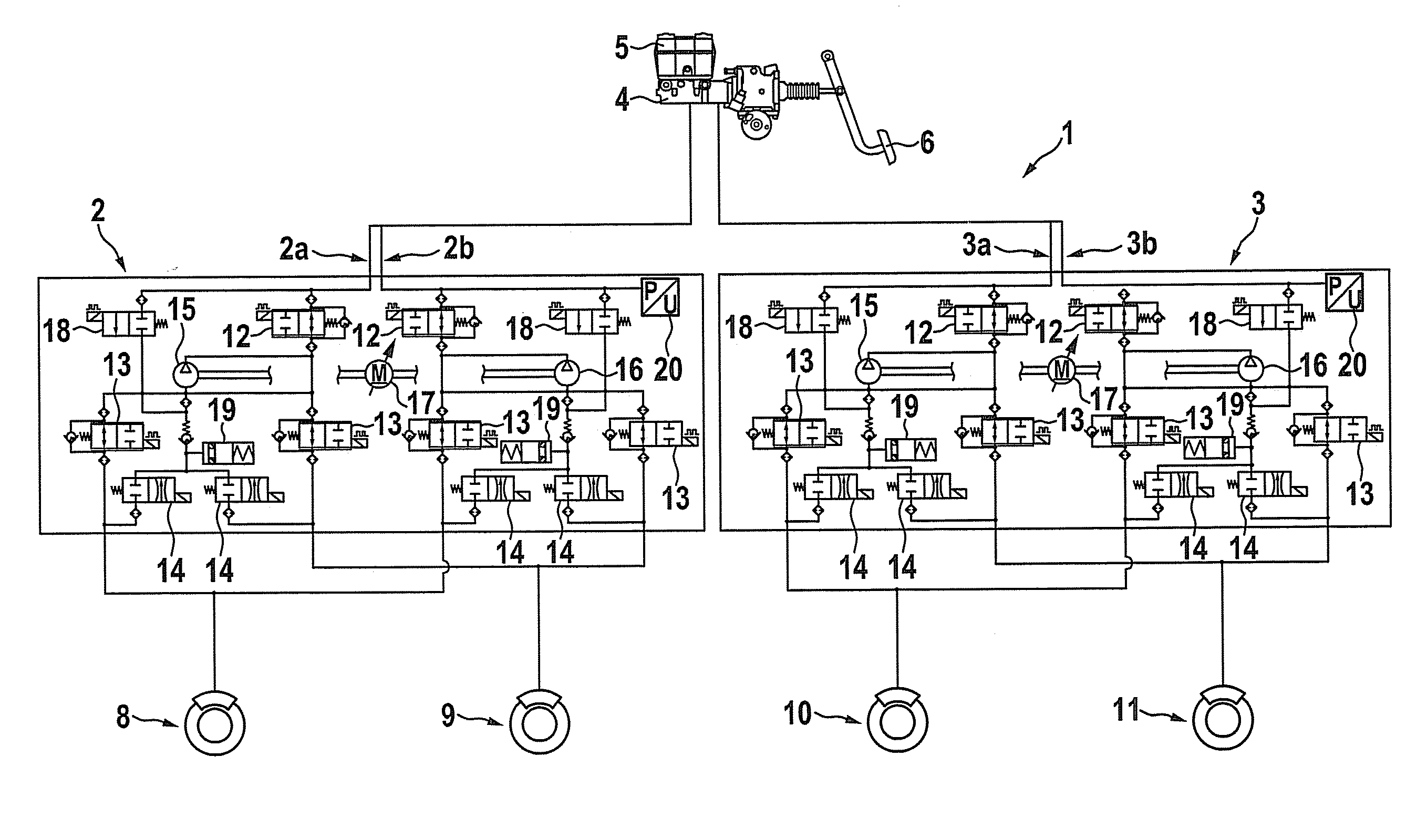

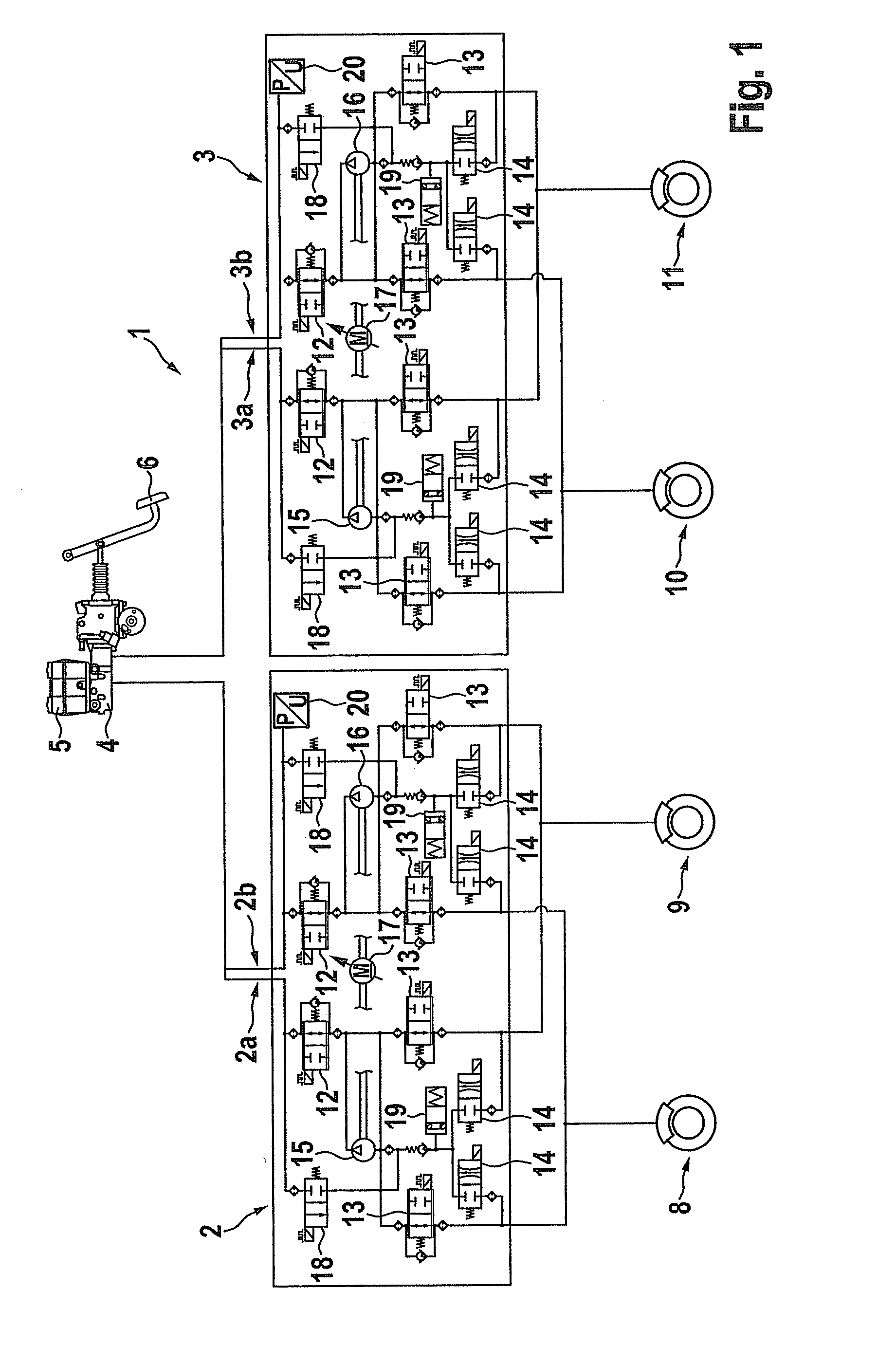

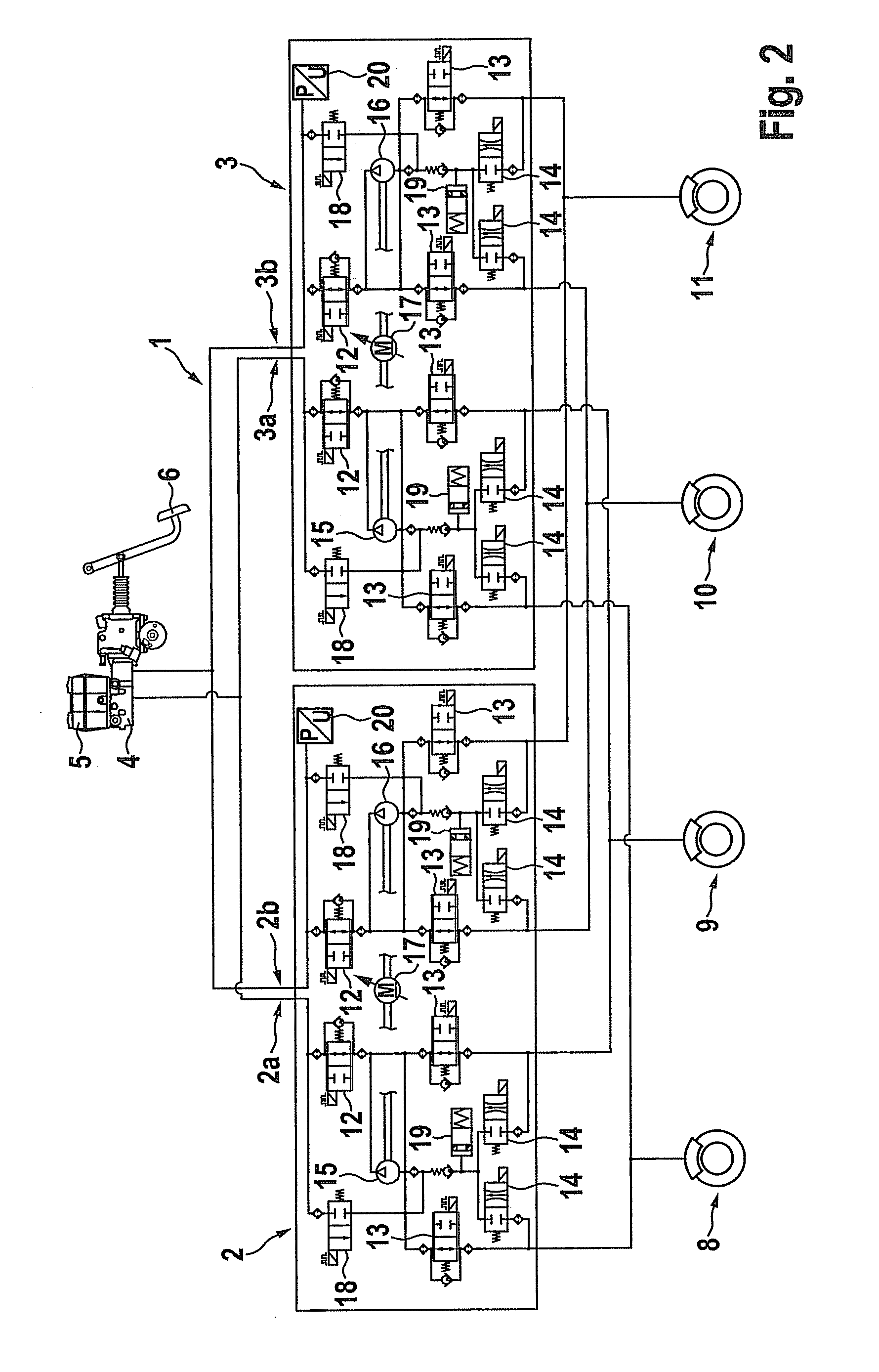

Vehicle brake system

InactiveUS20110233011A1High gradientBig cost advantageFluid braking transmissionBrake actuating mechanismsHydraulic brakeVehicle brake

A vehicle brake system has a plurality of hydraulic brake circuits via which wheel brake units are supplied with brake pressure. At least one wheel brake unit is connected to at least two brake circuits and supplied with brake pressure via these two brake circuits.

Owner:ROBERT BOSCH GMBH

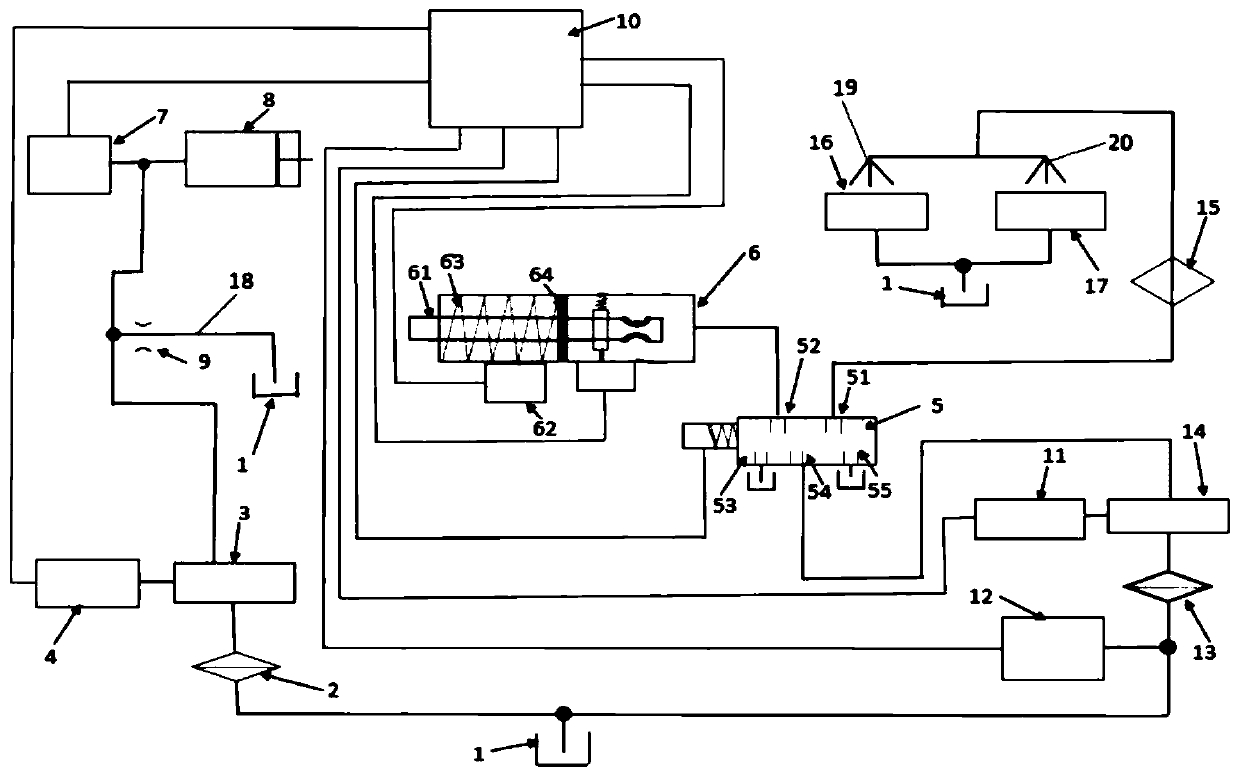

Hydraulic control method and system of hybrid power gearbox

InactiveCN109764132AReduce typesReduce settingsClutchesGear lubrication/coolingEngineeringOil pressure

The invention discloses a hydraulic control method and system of a hybrid power gearbox. The hydraulic control system of the hybrid power gearbox comprises a first hydraulic actuating mechanism, at least one second hydraulic actuating mechanism, oil pumps and driving systems thereof and a reversing valve, wherein the first hydraulic actuating mechanism is used for performing parking unlocking andparking actions; the oil pumps input hydraulic oil into the reversing valve; the reversing valve selectively transfers the hydraulic oil to the first hydraulic actuating mechanism to perform the parking unlocking action or the parking action, or selectively transfers the hydraulic oil to the second hydraulic actuating mechanisms. According to the hydraulic control method and system of the hybrid power gearbox, a parking actuating mechanism is integrated into a clutch actuating mechanism or a cooling actuating mechanism, and the oil pressure control unlocking of the parking actuating mechanismis carried out through the oil pump of the clutch actuating mechanism or the cooling actuating mechanism; and the structure is compact and high in integrated level, the required assembly space is small, the number of varieties of parts of the system is small, the hydraulic control method is simple, and the integrated level of the system is greatly improved.

Owner:DONGFENG MOTOR CORP HUBEI

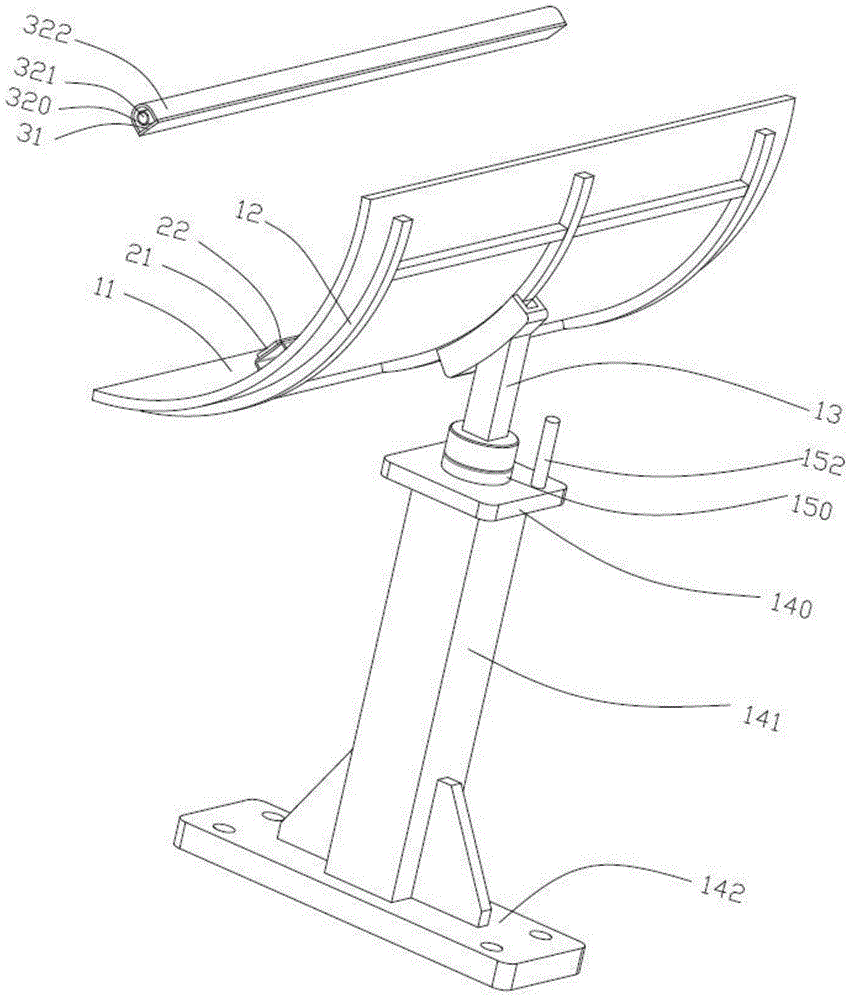

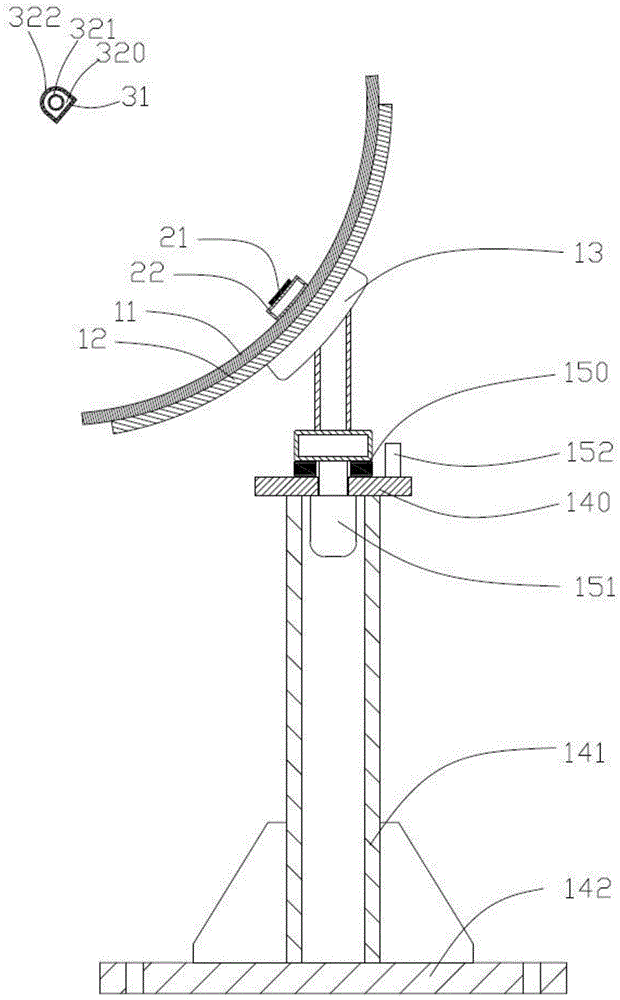

Photovoltaic and photo-thermal combined system for full-spectrum solar energy frequency-division, regulation and control

ActiveCN104901625AIncrease temperatureReduce areaPhotovoltaic supportsSolar heating energyUltraviolet lightsEngineering

The invention discloses a photovoltaic and photo-thermal combined system for full-spectrum solar energy frequency-division, regulation and control. The photovoltaic and photo-thermal combined system comprises an optical-focusing apparatus, a photovoltaic battery assembly and a frequency-division and heat-collecting apparatus, wherein the frequency-division and heat-collecting apparatus is arranged above the optical focus of the optical-focusing apparatus, the photovoltaic battery assembly is positioned on the optical-focusing apparatus and right below the frequency-division and heat-collecting apparatus, and the frequency-division and heat-collecting apparatus comprises a frequency division apparatus and a heat-collecting tube. Incident sunlight on the optical-focusing apparatus is reflected to and focused on the frequency-division and heat-collecting apparatus, the frequency division apparatus decomposes the sunlight into near infrared and ultraviolet light and visible light through frequency and division. The near infrared and ultraviolet light is directly transmitted to and absorbed by the heat-collecting tube from the frequency division apparatus, and converted into heat energy. The frequency division apparatus reflects the visible light to the photovoltaic battery assembly, which converts the visible light into electric energy. The photovoltaic and photo-thermal combined system makes full use of the full spectrum energy of sun light, and the energy conversion efficiency of the entire system is improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com