Use of a rare earth for the removal of antimony and bismuth

a rare earth and antimony technology, applied in the production of electrolytic organic materials, instruments, electrolysis components, etc., can solve the problems of troublesome materials such as arsenic, antimony and bismuth, interfering with the cathodic deposition of metals, etc., and achieves the effects of easy recovery, low cost and prolonged exposure to water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

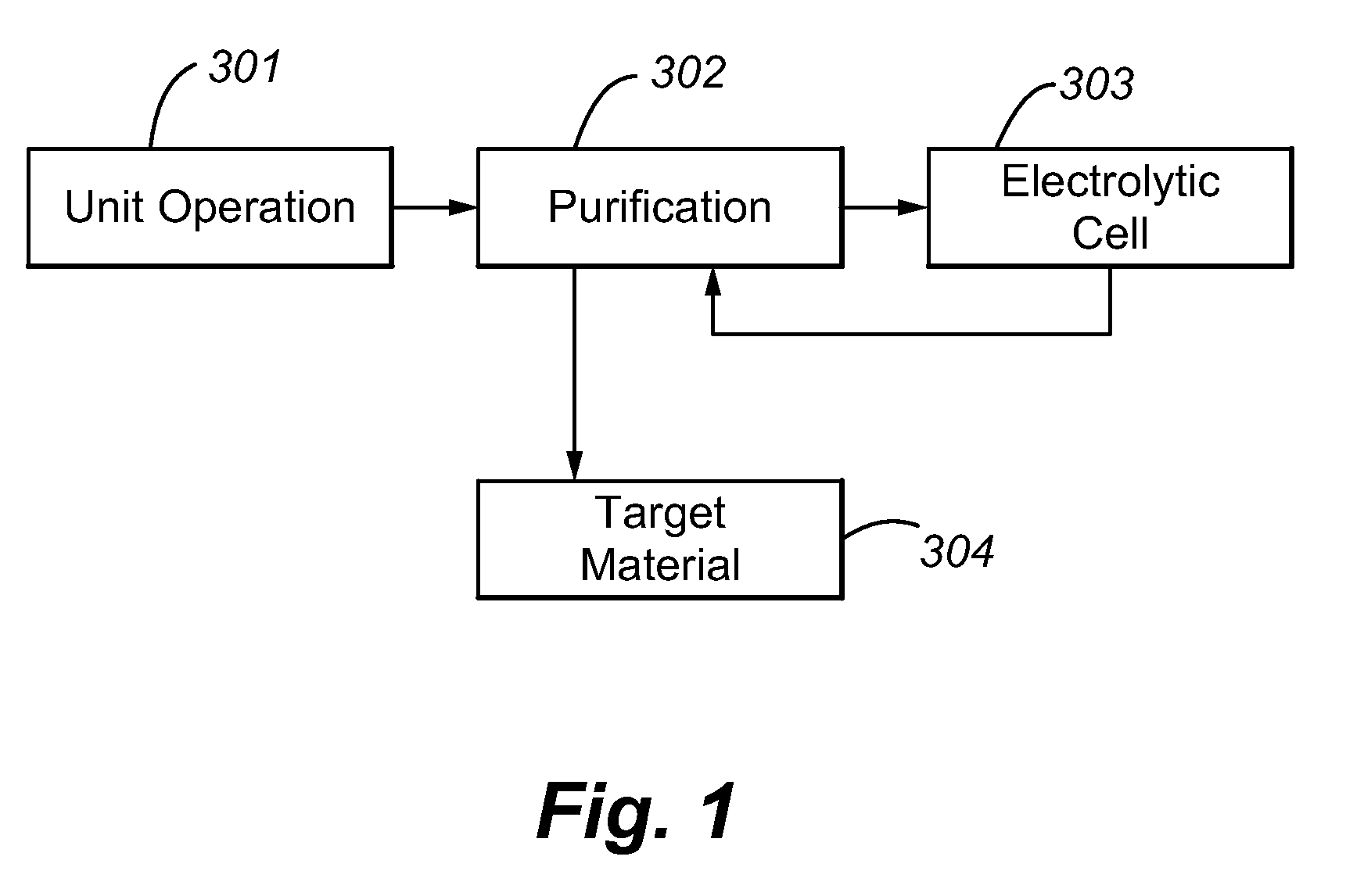

[0087]One aspect of the present invention uses one or both of insoluble and soluble fixing agents to remove selected target materials from an electrolytic solution. Preferably, the electrolytic solution comprises an aqueous solution. The fixing agent, whether soluble or insoluble, preferably includes a rare earth. Specific examples of such materials for removing target materials include lanthanum (III) compounds, soluble lanthanum metal salts, lanthanum oxide, cerium dioxide, and soluble cerium salts, which have been described in U.S. patent application Ser. No. 12 / 616,653 with a filing date of Nov. 11, 2009, the contents of which is incorporated herein in its entirety by this reference.

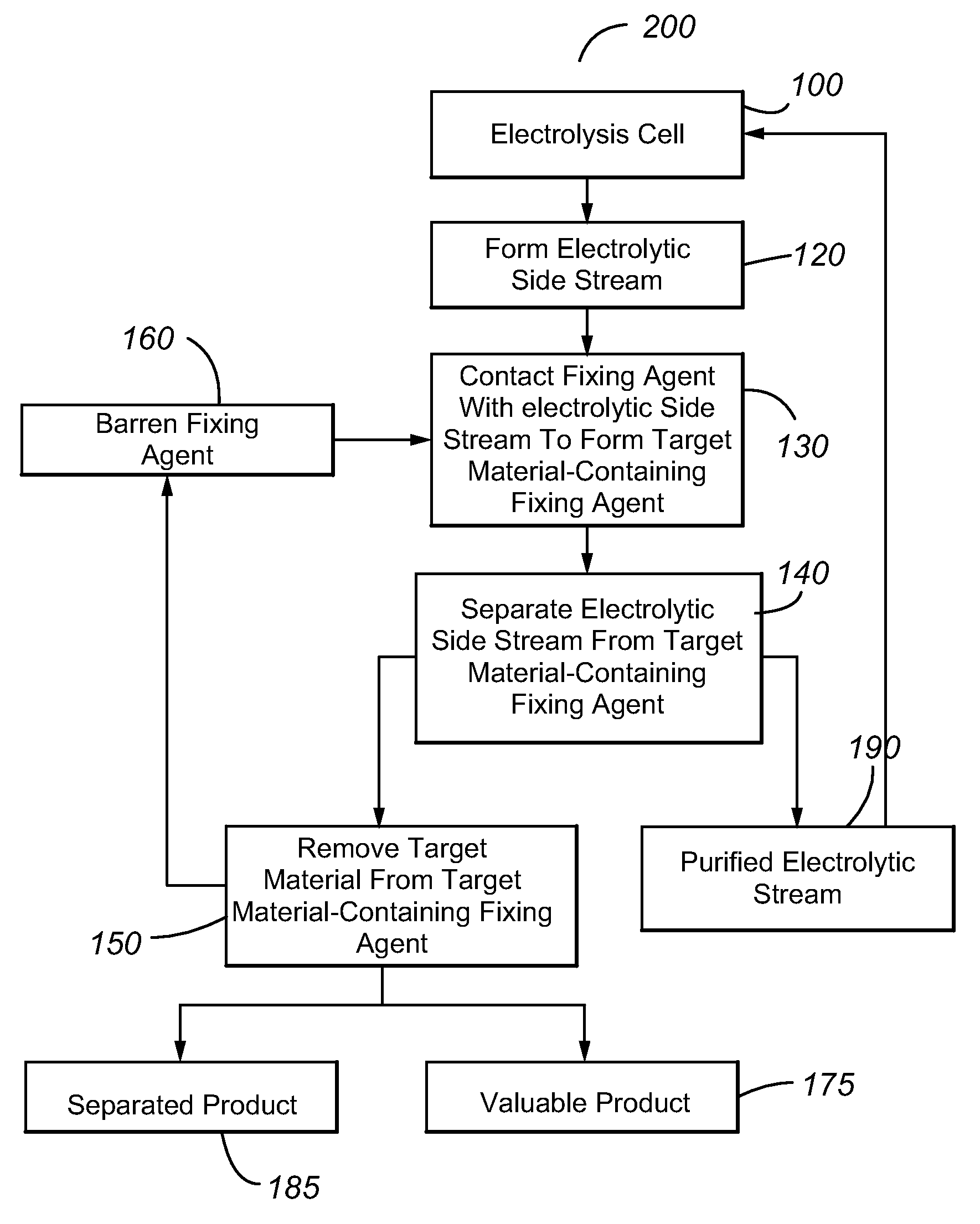

[0088]The electrolytic solution can be a rich electrolytic solution formed in unit operation 301 (FIG. 1) and / or an electrolyzed-electrolytic solution formed in an electrolysis cell 303. The rich electrolytic solution is substantially pregnant with a valuable metal to be electrodeposited on an electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Solubility (mass) | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com