Nanoparticle modified asphalt and preparation method thereof

A modified bitumen and nanotechnology, which is applied in building components, building insulation materials, buildings, etc., can solve the problem that the improvement effect is not obvious, and achieve the effect of simple and easy preparation method, large cost advantage and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

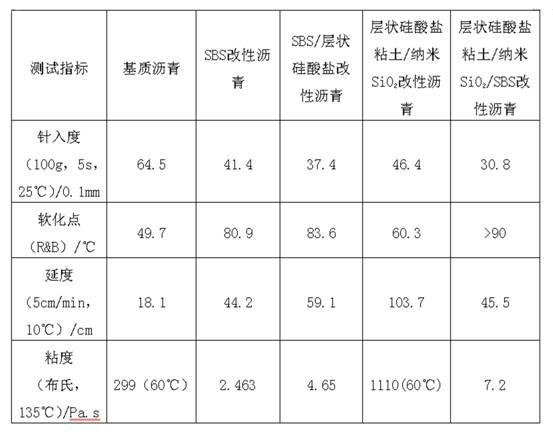

[0026] (1) Weigh an appropriate mass of layered silicate clay, SBS, nano-SiO 2 Particle and matrix bitumen, among which layered silicate clay, nano-SiO 2 The weight ratio of particles is: 1:0.05~0.2, the weight ratio of layered silicate clay and SBS is: 1:0~1, and the weight percentage of layered silicate clay and base asphalt is 0.01~0.09:1 respectively .

[0027] (2) Combine SBS and nano-SiO 2 Add the particles into the molten base asphalt, maintain the temperature at 100-200°C, and use a high-speed shear emulsifier at a speed of 1000-10000rpm to continuously shear and stir for 0.5-4

[0028] Hour.

[0029] (3) Finally, layered silicate clay was added to the shear-stirred SBS / nano-SiO 2 In the modified asphalt, the temperature is maintained at 100-200° C., and the shearing and stirring is continued at a speed of 1000-10000 rpm for 0.5-4 hours to obtain the composite modified asphalt to be prepared.

[0030] The nano material of the present invention is gas phase nano S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com