Patents

Literature

52results about How to "Stripped thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wire stripper for coaxial wire metallic shielding layer

InactiveCN101409435AStripped thoroughlyPeel fitLine/current collector detailsApparatus for removing/armouring cablesBeam expanderGalvanometer

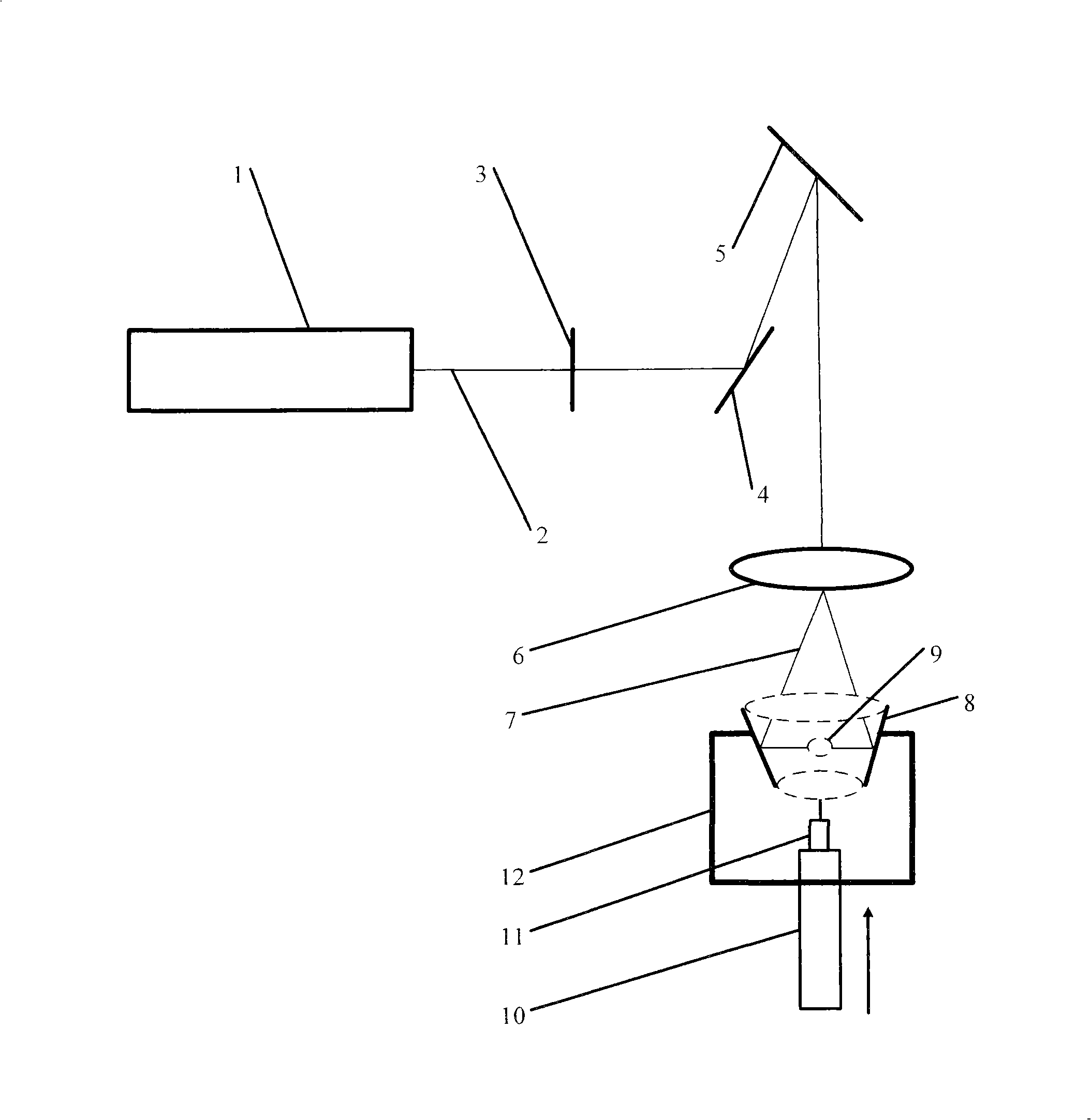

The invention relates to a coaxial metal shielding layer wire stripping machine which comprises a laser source, a galvanometer scanning system, an annular optical reflector and a mechanical device. The machine is characterized in that laser transmitted by the laser source is expanded and collimated by a beam expander, and then passes through a X-direction galvanometer, a Y-direction galvanometer and an F-THETA lens to spatially form a tapered optical path which passes through the annular optical reflector and focuses on a focus to form a focus circle with a certain diameter. The focus circle performs annular stripping on the coaxial metal shielding layer with the same diameter. The machine has novel idea, reasonable design and normative process, can realize effective stripping of the coaxial metal shielding layers of different sizes, and is characterized by fast processing speed, thorough stripping, high yield and high production efficiency. The machine can be widely applied to processing various large-sized coaxial metal shielding layers.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

Stripable paint for laser impact treatment

This invention discloses a strippable coating for laser shock processing, which is composed of carbon powders 5-15 wt.%, bonding agent 50-70 wt.%, self-drying thinner 15-35 wt.% and additive 2-5 wt.%. The thickness of the coating layer is generally 60-150 mums. The strippable coating is manufactured by: (1) placing carbon powders in a reactor, and adding bonding agent, self-drying thinner and additive; and (2) stirring uniformly, and adjusting the pH value to 7.5 with 25% ammonia solution. The strippable coating can intimately adhere to the surface of metals, and cannot be stripped during continuous laser shock process, thus having a good shock effect.

Owner:JIANGSU UNIV

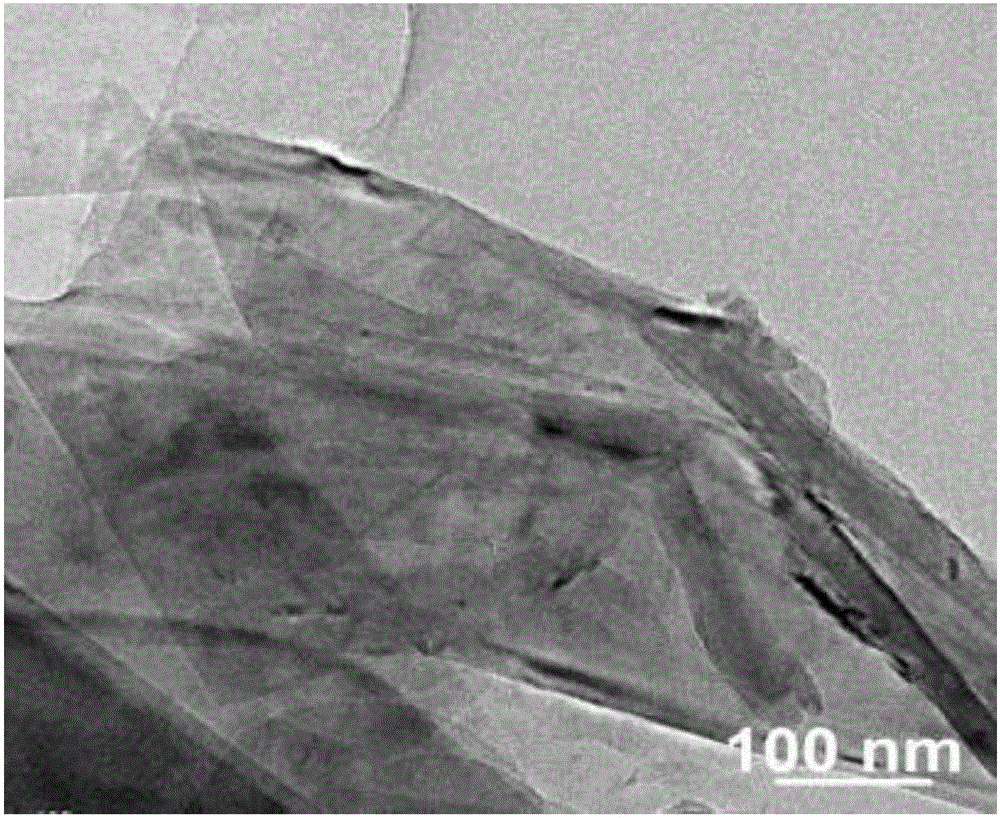

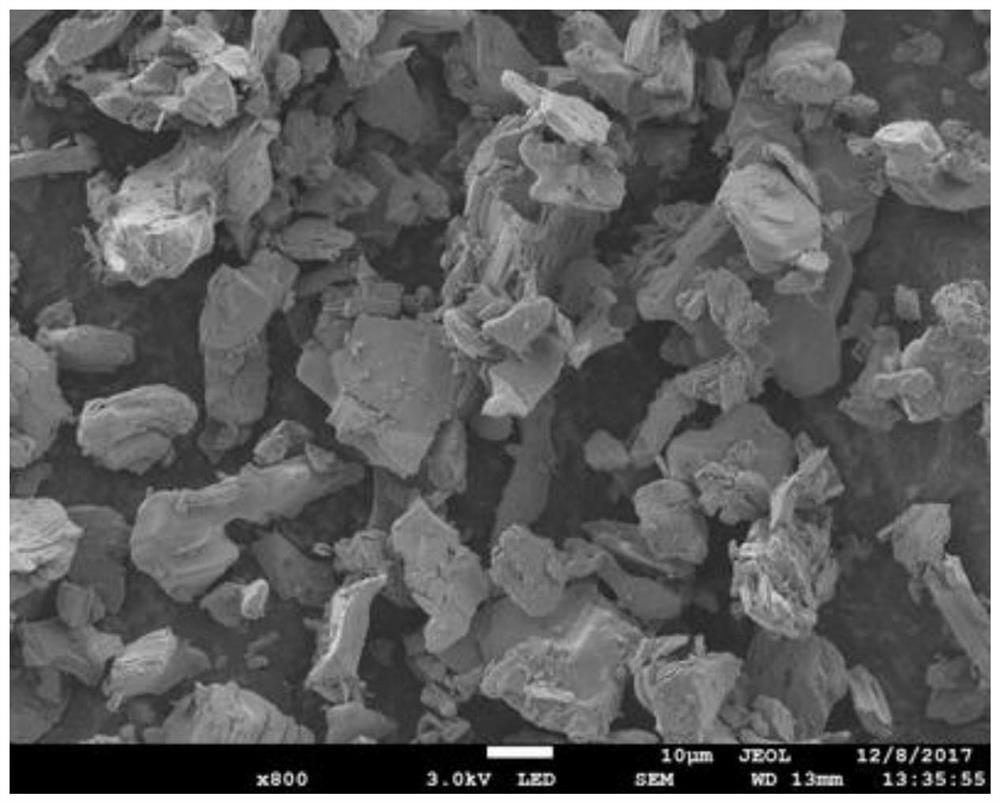

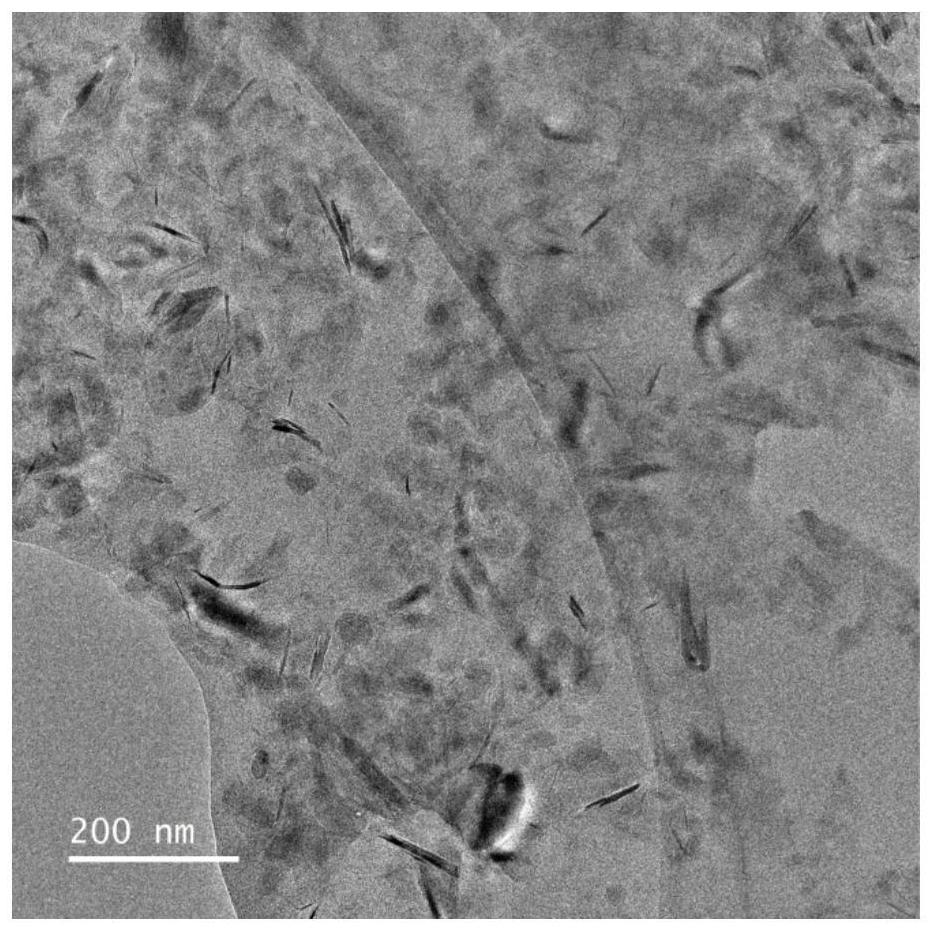

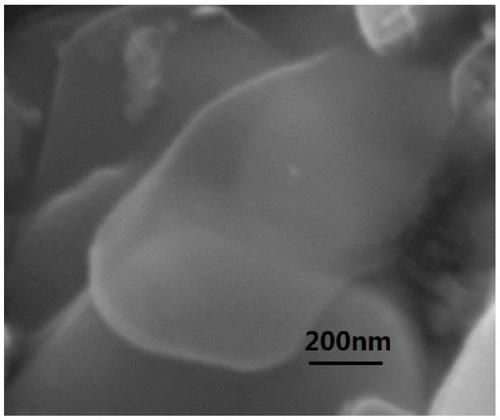

Stable method for preparing boron nitride nanoflake through liquid-phase chemical stripping

ActiveCN106082147AFacilitate strippingAvoid reunionNitrogen compoundsHexagonal boron nitrideFiltration

The invention discloses a stable method for preparing a boron nitride nanoflake through liquid-phase chemical stripping. The method comprises the following steps: (1) subjecting hexagonal boron nitride and strong acid to mixing and infiltration, adding ferrate, carrying out uniform mixing and then carrying out a reaction; (2) after the reaction, adding a reaction product into distilled water drop by drop for dilution; (3) subjecting a diluted solution to centrifugation so as to remove large pieces of unstripped boron nitride powder; and (4) subjecting supernatant liquid to pumping filtration so as to obtain a reaction product, cleaning the reaction product with hydrochloric acid at first, then washing the reaction product with deionized water until the reaction product is neutral and drying the product so as to obtain the boron nitride nanoflake. According to the invention, the boron nitride nanoflake is prepared through a reaction between strong acid and ferrate; raw materials are easily available; the method is safe, stable, free of pollution and simple to operate; complex and expensive equipment is not needed; and the boron nitride nanoflake is high in yield and good in quality.

Owner:山东晶亿新材料有限公司

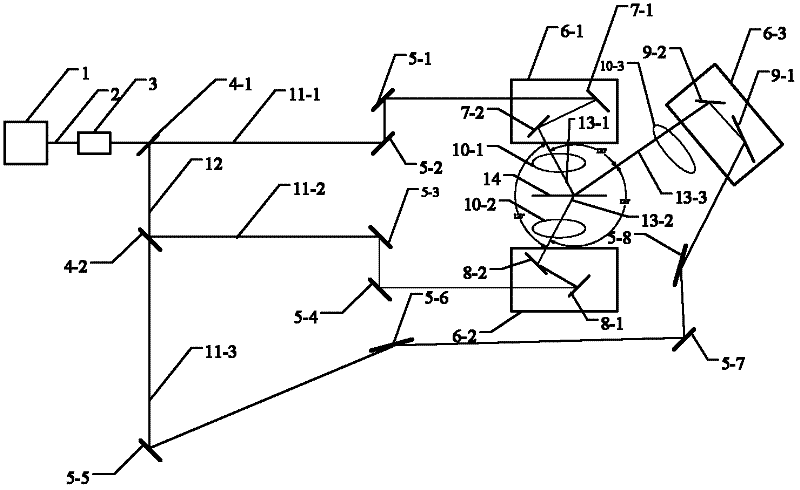

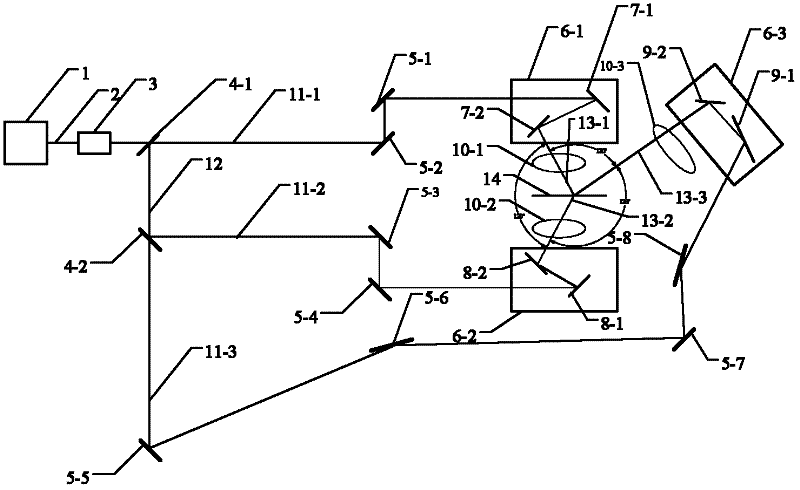

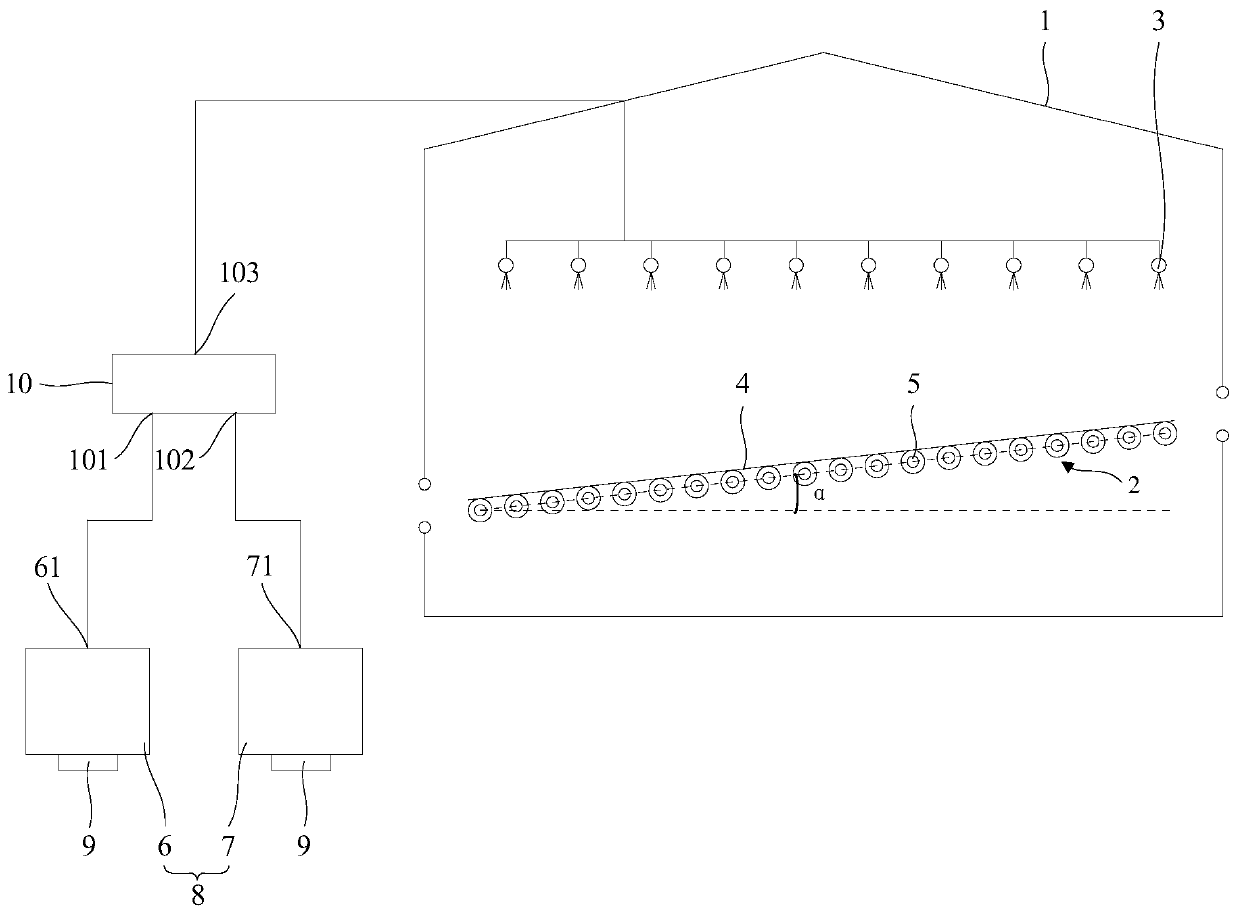

Laser paint stripping machine

InactiveCN102386547ARealize online stripping paintStripped thoroughlyLine/current collector detailsLacquerGalvanometer

The invention relates to a laser paint stripping machine. The machine comprises: a solid laser light source (1); a beam expanding lens (3); two spectroscopes; eight holophotes; three galvanometer scanning systems. The each galvanometer scanning system comprises: one X-direction galvanometer, one Y-direction galvanometer and one field lens. Focal lengths of the three field lenses are the same. Laser passes through the beam expanding lens so as to be aligned and amplified, and passes through the two spectroscopes and then the eight holophotes. The laser is reflected and formed scanning beams which have mutual 120 DEG angles between each other. Three scanning beams scan simultaneously so as to form circle paint stripping around an enameled wire in space. In the invention, a speed is fast andan efficiency is high. A paint layer can be peeled thoroughly. The machine can be widely applied in a magnetic-head enameled wire, an inductance coil and surface paint stripping of a surface-varnished object whose cross section is heterotypical, such as a circle, a square, a triangle and the like.

Owner:ZHENGZHOU CHUSHANG LASER SCI & TECH

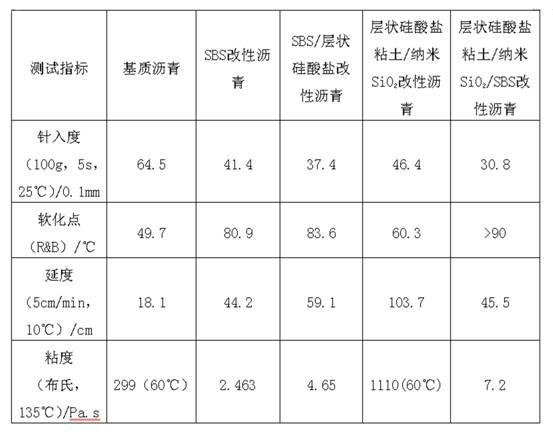

Nanoparticle modified asphalt and preparation method thereof

The invention discloses nanometer sheet material modified asphalt and a preparation method thereof. The modified asphalt consists of phyllosilicate clay, nanometer SiO2 particles, styrene-butadiene-styrene (SBS) and matrix asphalt, wherein a weight ratio of the phyllosilicate clay to the SBS to the nanometer SiO2 particles is 1:0.5-1:0.05-2.0, the phyllosilicate clay accounts for 1 to 10 weight percent of the modified asphalt and the matrix asphalt accounts for 90 to 99 weight percent of the modified asphalt. The preparation method of the modified asphalt comprises the following steps of: adding a proper amount of nanometer SiO2 particles and SBS into melt matrix asphalt and performing primary shear stirring; and adding the phyllosilicate clay, maintaining the temperature of between 100 and 200 DEG C, and continuously performing shear stirring at the speed of between 500 and 10,000 rpm for 0.5 to 4 hours to ensure that various modifiers are dispersed and uniformly mixed in the matrix asphalt so as to prepare the modified asphalt. Compared with the matrix asphalt, the modified asphalt prepared by the method has remarkably improved high-temperature property, enhanced rutting resistance and improved temperature sensitivity.

Owner:SOUTHEAST UNIV

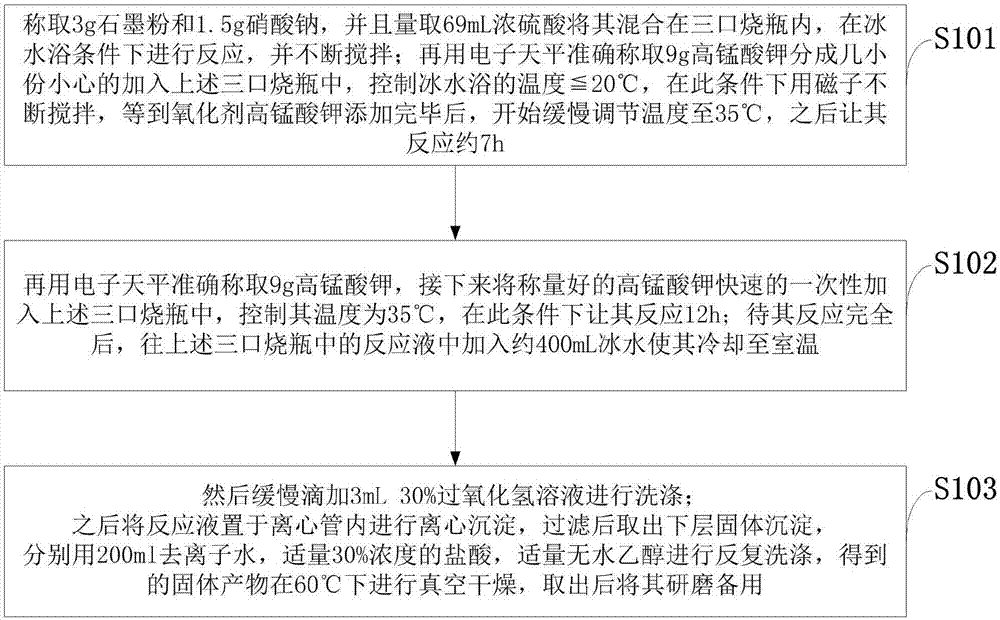

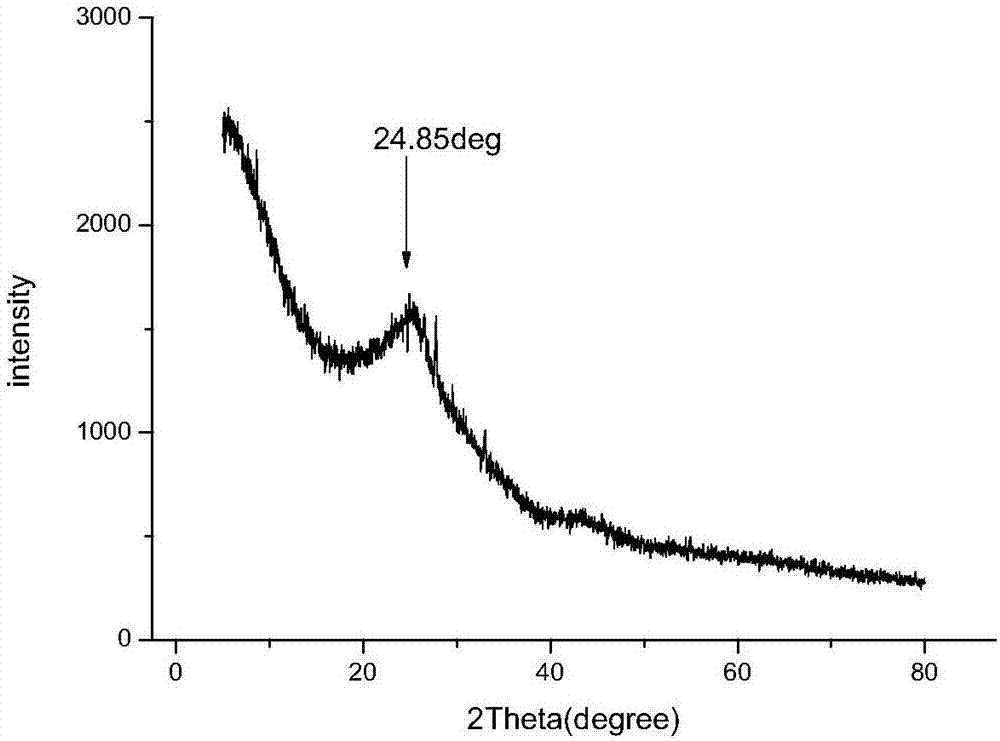

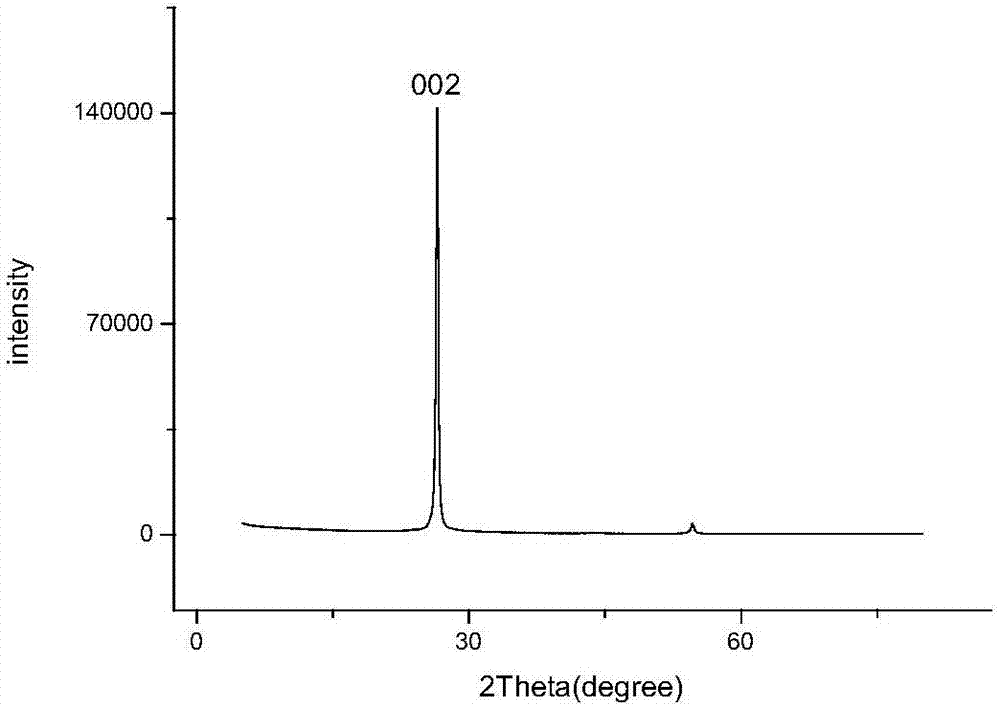

Preparation method and electrochemical performance test method of anode material graphene

InactiveCN106853965AFully oxidizedIncrease layer spacingCarbon compoundsCell electrodesWater bathsIce water

The invention discloses a preparation method and an electrochemical performance test method of an anode material graphene. The preparation method comprises the following steps: weighing a graphite powder and sodium nitrate; measuring out concentrated sulfuric acid, mixing the concentrated sulfuric acid in a three-mouth flask and reacting under the condition of a water bath; then weighing potassium permanganate, adding into the three-mouth flask and starting to adjust the temperature; adding the potassium permanganate into the three-mouth flask by two times and controlling the temperature; adding ice water and cooling a mixed solution to a room temperature; then dropwise adding 30 percent of hydrogen peroxide solution for washing; carrying out centrifugal precipitation, taking out lower-layer solid precipitation and repeatedly washing to obtain a solid product, carrying out vacuum drying, taking out the dried product, and grinding the product for later use. Graphene oxide disclosed by the invention is used as an anode material of a lithium battery, and discharged specific capacity of the graphene oxide at the temperature of 0.1DEG C is 403.4mAh / g. Furthermore, the graphene prepared by using a hydrothermal-solvent thermal reduction method is more stable in performance, the discharged specific capacity of the graphene at the temperature of 0.1DEG C is 782.8 mAh / g, and the capacity retention ratio is higher.

Owner:SHAOXING UNIVERSITY

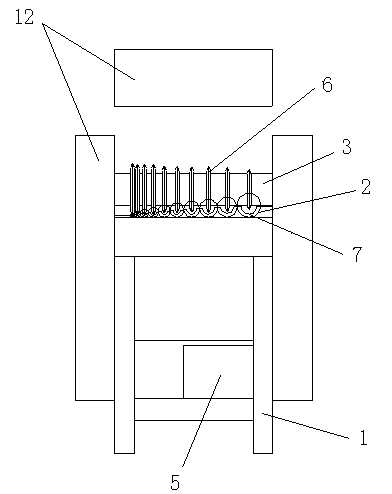

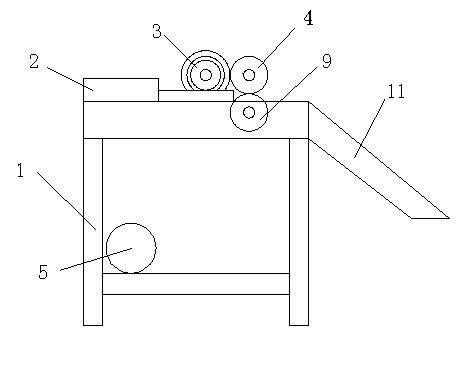

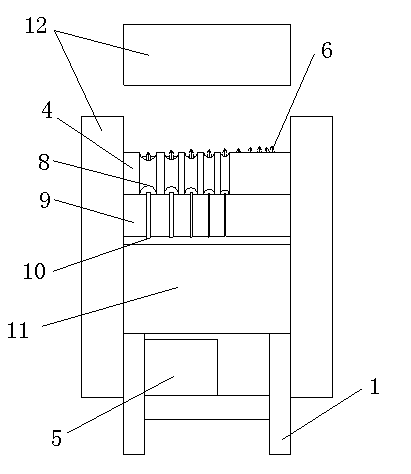

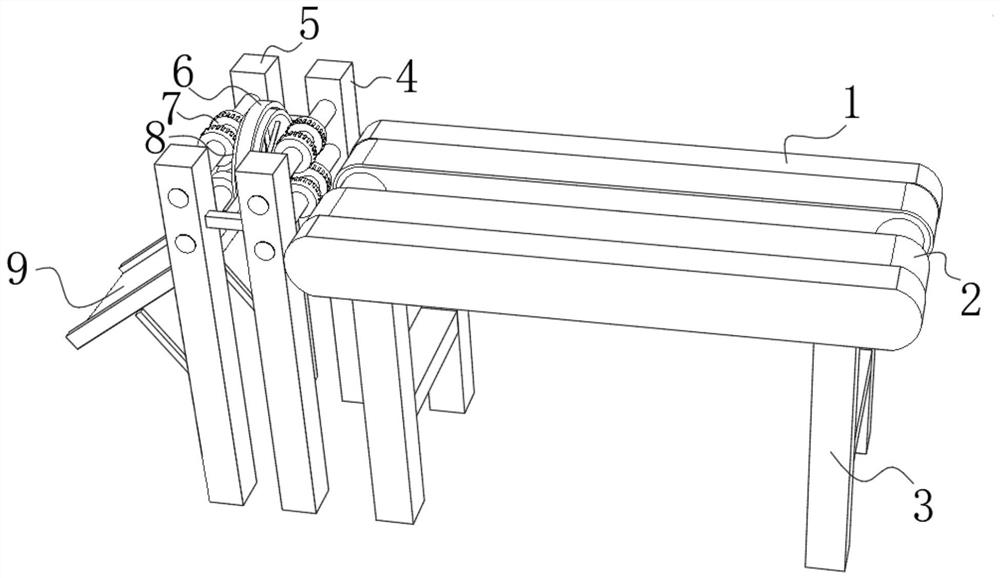

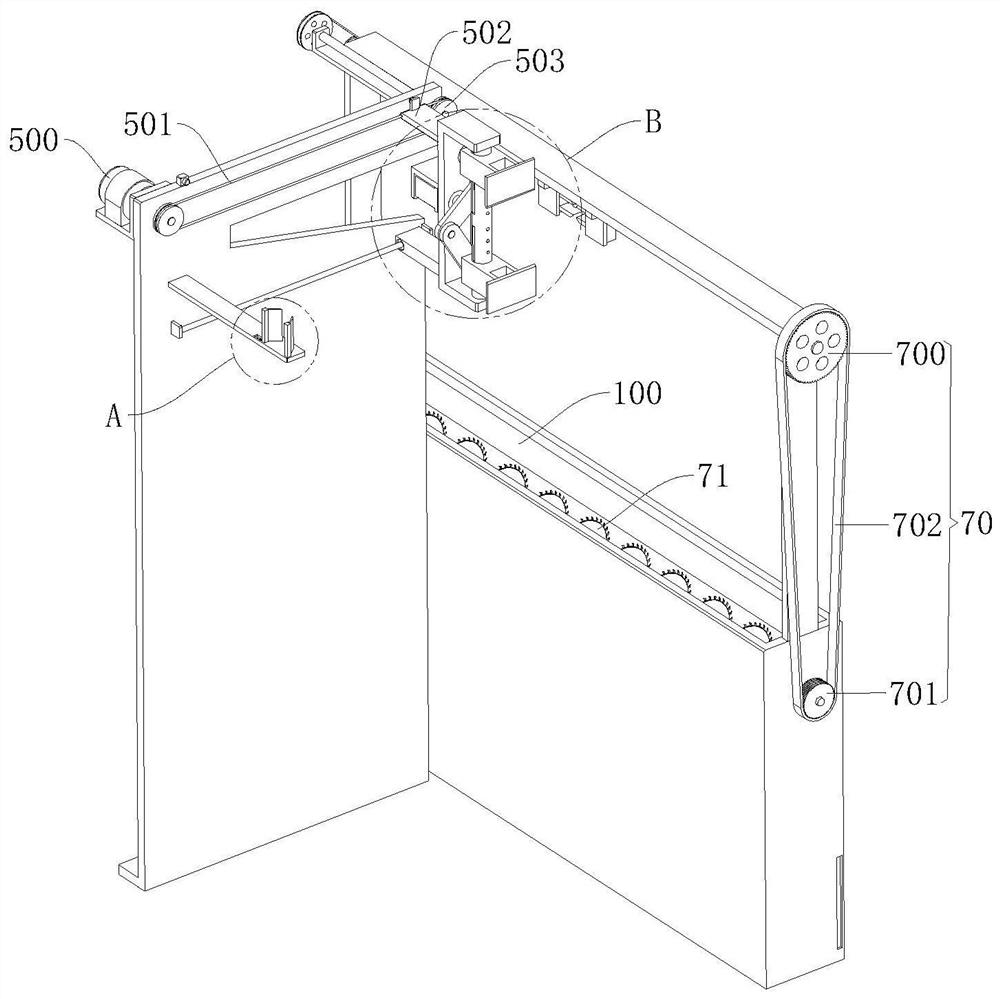

Stripping machine

InactiveCN103683121ASimple structureStripped thoroughlyApparatus for removing/armouring cablesPulp and paper industryEngineering

The invention discloses a stripping machine. The stripping machine includes a bracket, feeding guide pipes, a stripping roll shaft, a rolling compaction roll shaft and a motor, wherein the motor is fixed below the bracket, the stripping roll shaft and the rolling compaction roll shaft are both driven by the motor, the two ends of the stripping roll shaft and the two ends of the rolling compaction roll shaft are all fixed on the bracket, the feeding guide pipes are fixed on the upper front side of the bracket and arranged in a diameter decreasing manner, the stripping roll shaft is arranged behind the feeding guide pipes, and the rolling compaction roll shaft is arranged behind the stripping roll shaft. The stripping machine provided by the invention is applicable for the recovery of various waste wires longer than 30cm and with different diameters. The stripping machine has a simple structure, is applicable for different wire diameters, and achieves complete stripping, thereby avoiding a great number of shortcomings of manual stripping.

Owner:WUHU SHUNCHENG ELECTRONICS

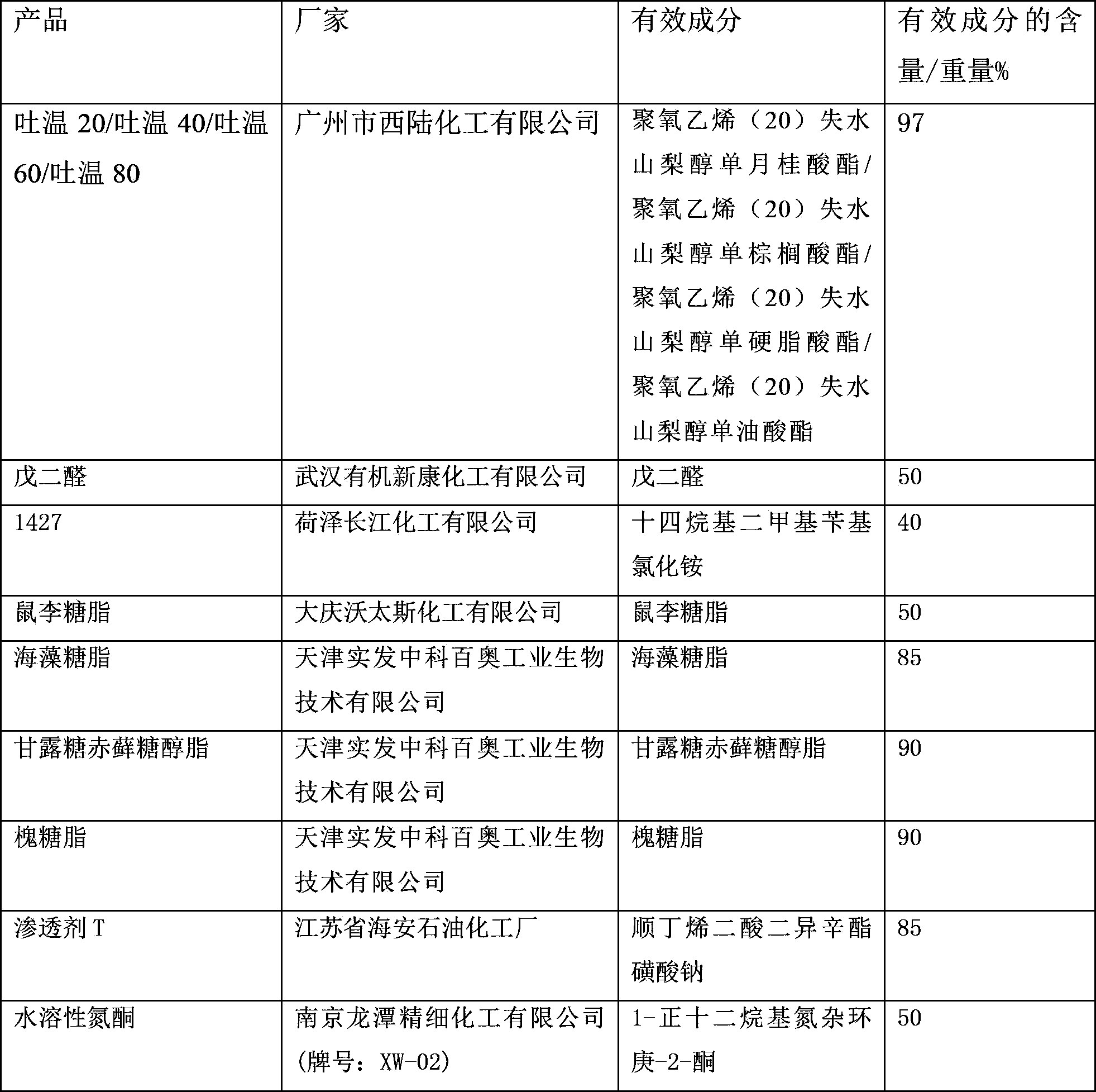

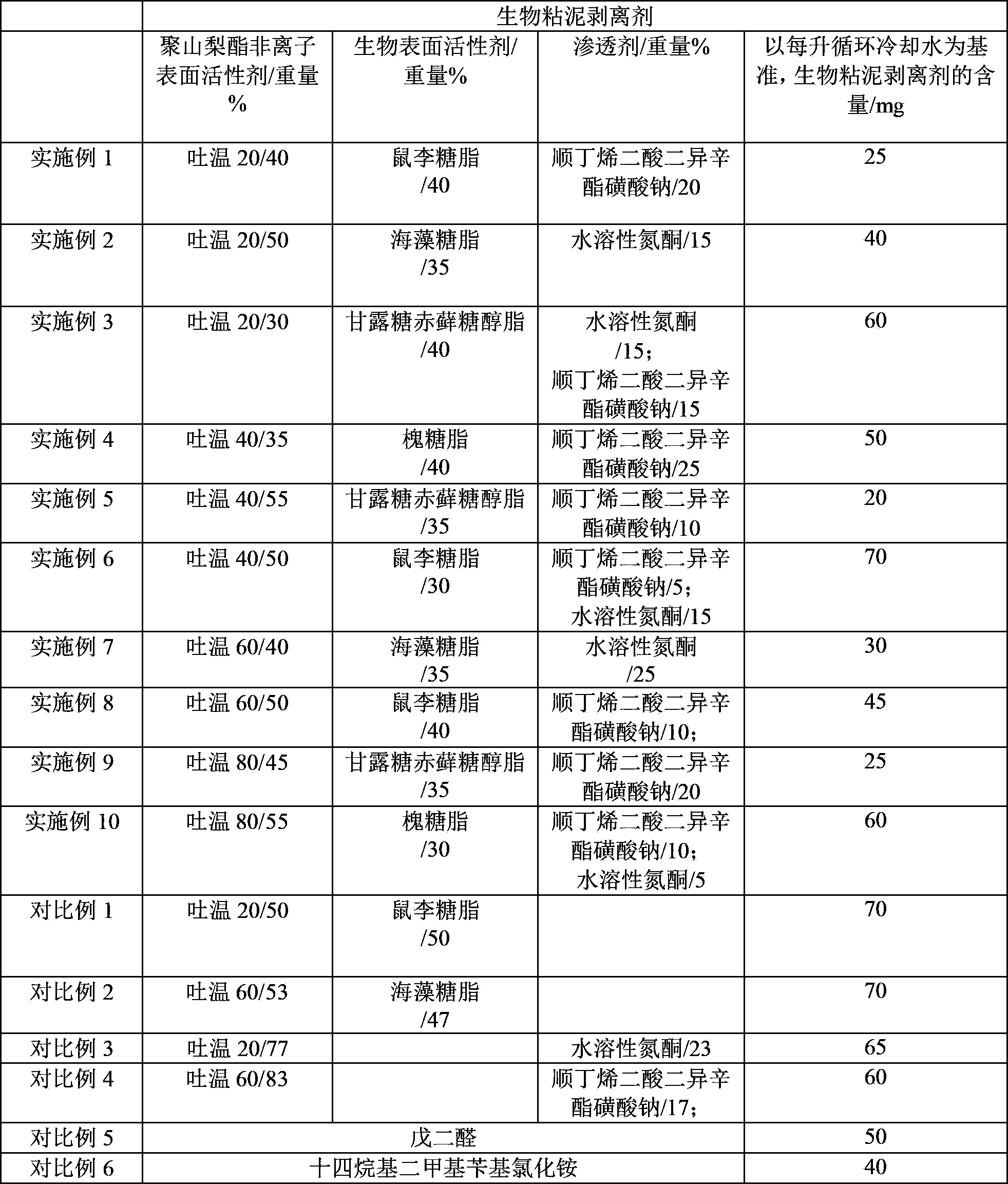

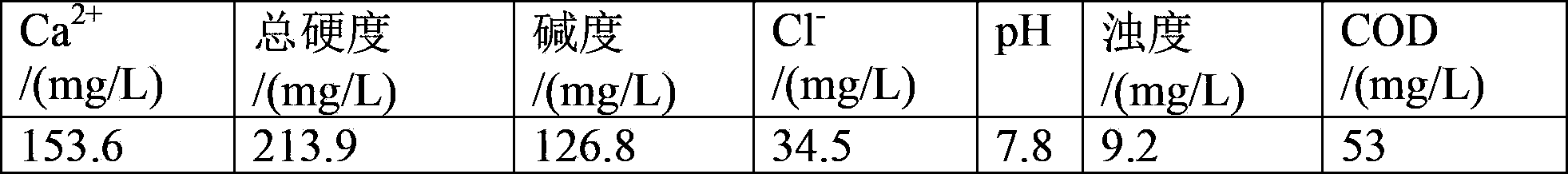

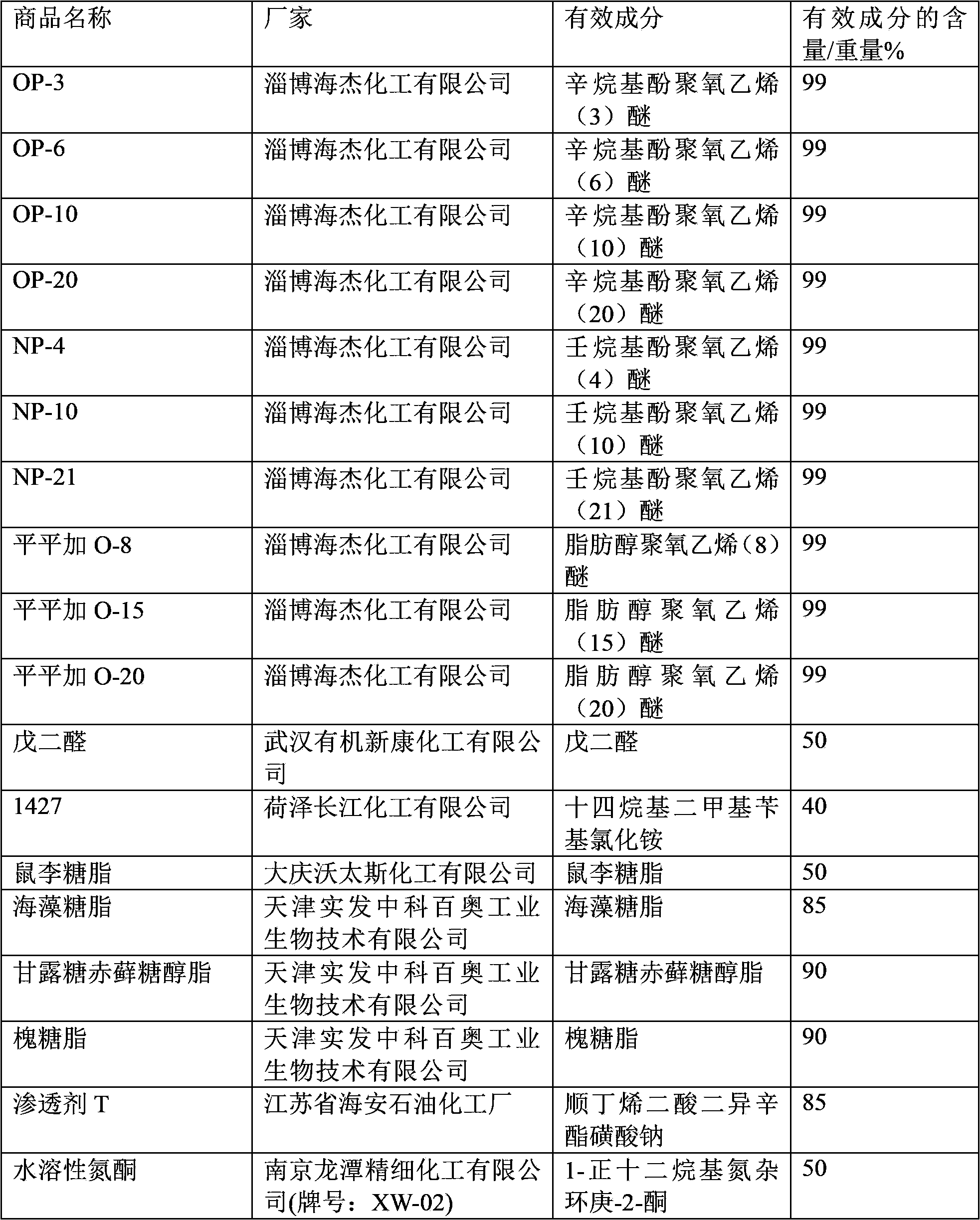

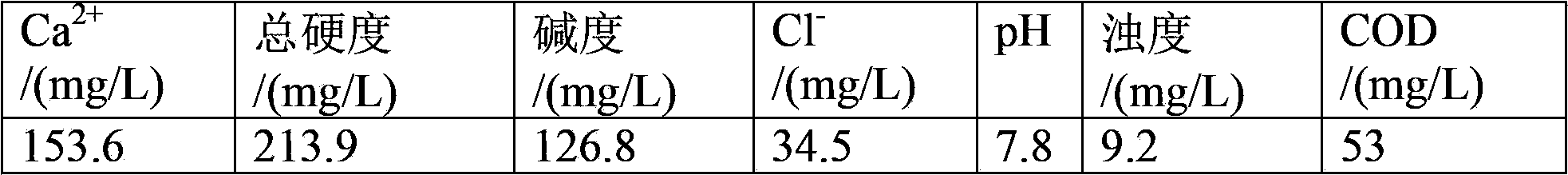

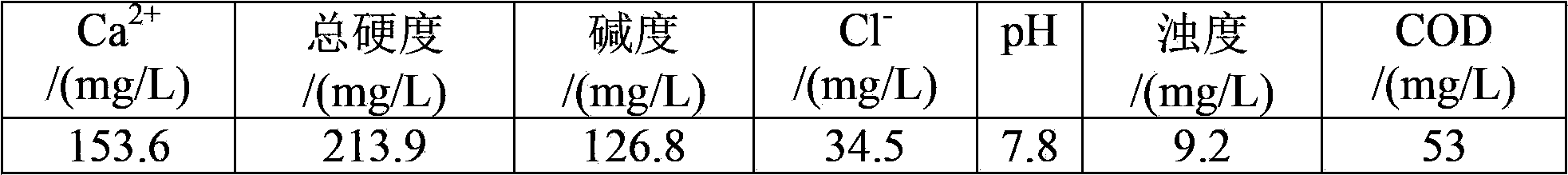

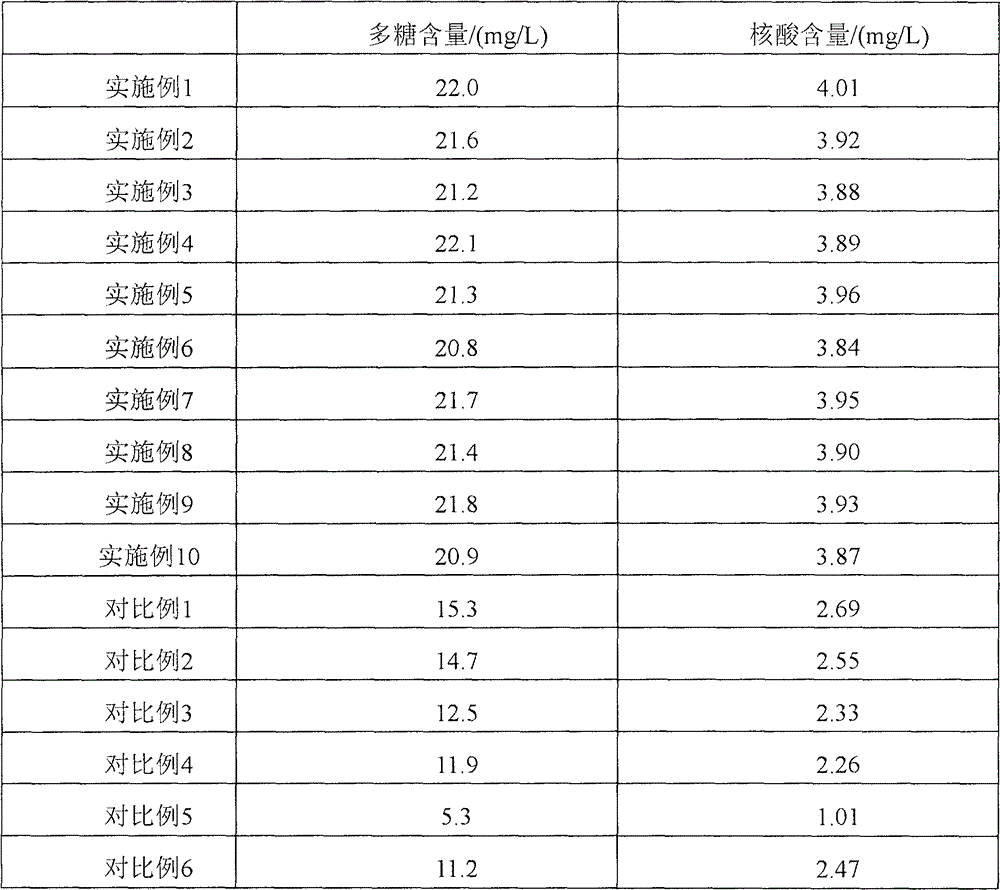

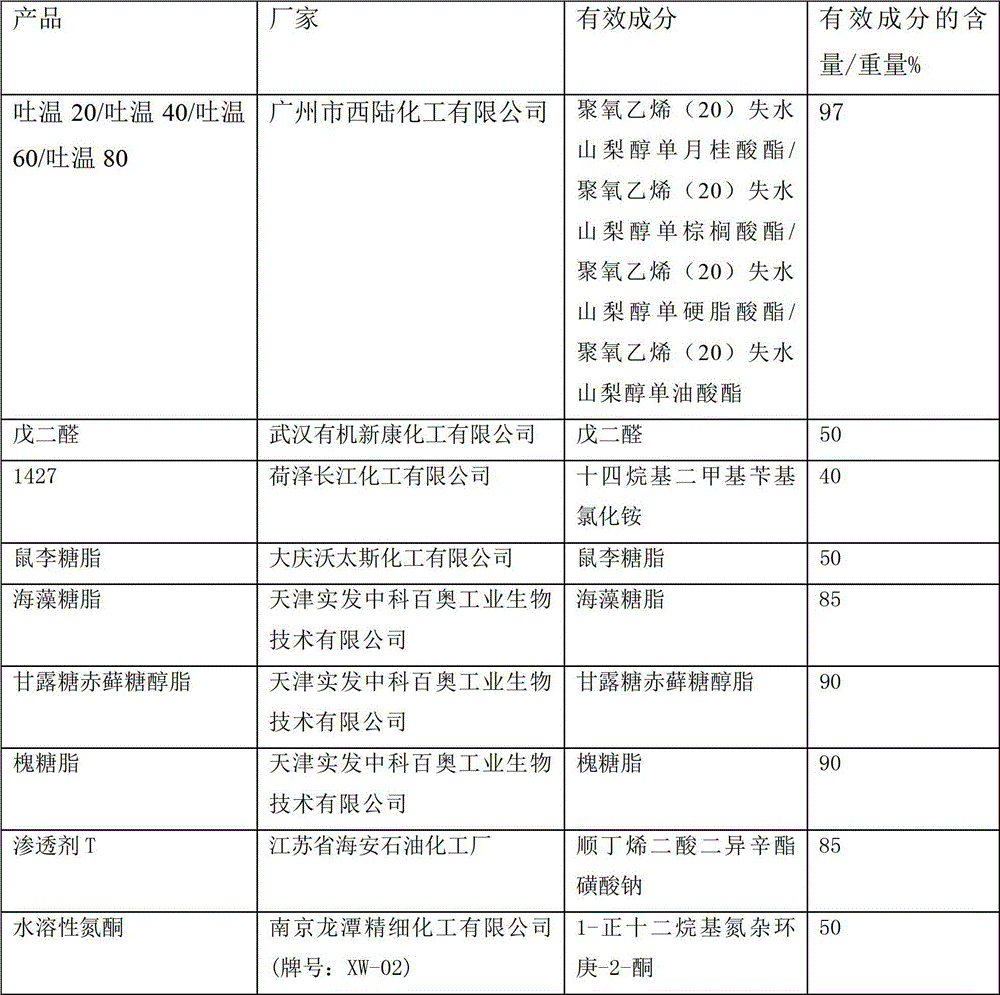

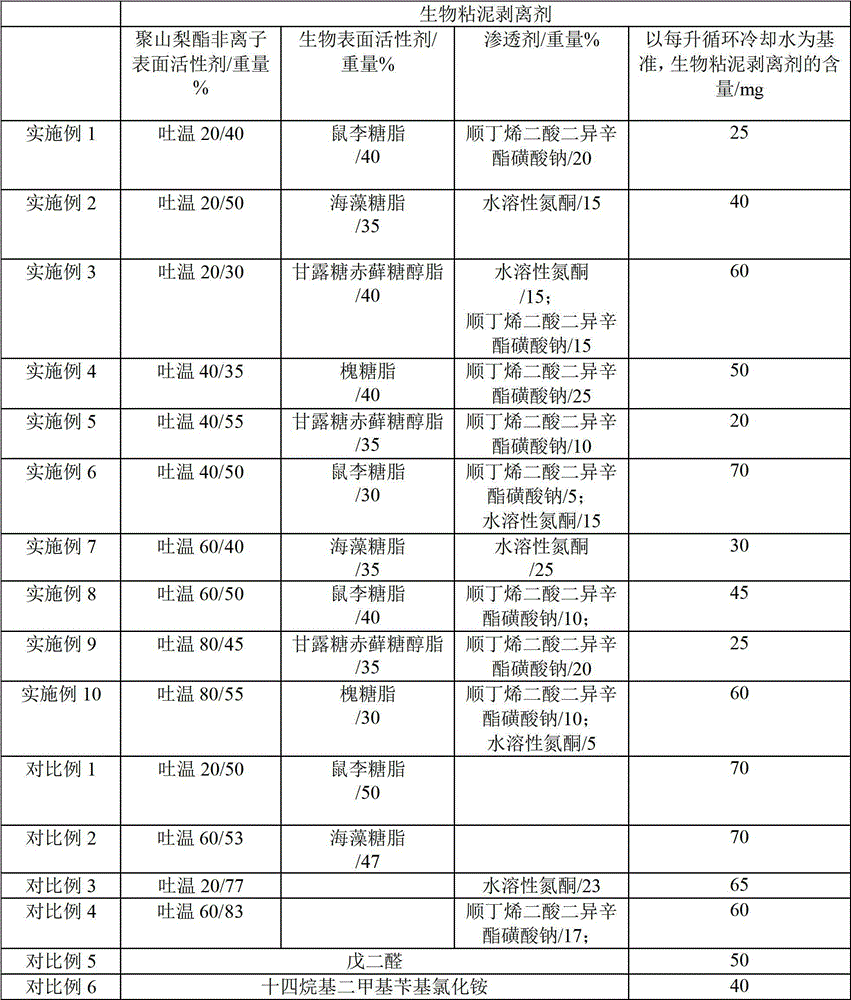

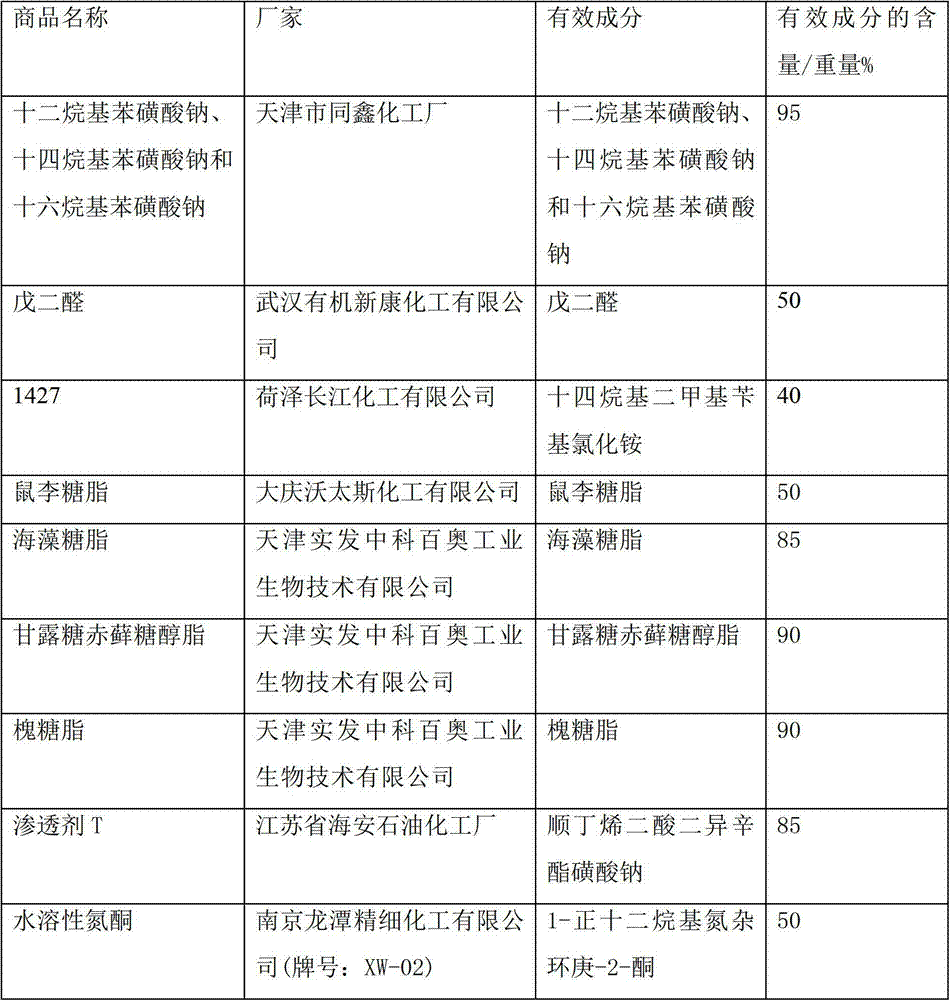

Remover for removing biological slime in recirculated cooling water and method for removing biological slime in recirculated cooling water system

ActiveCN103773614AStripped thoroughlyReduce depositionOrganic detergent compounding agentsSurface-active detergent compositionsChemical synthesisSynthetic surfactant

The invention discloses a remover for removing biological slime in recirculated cooling water. The remover contains a polysorbate nonionic surfactant, a biosurfactant and an osmotic agent. The biosurfactant is a glycolipid-type biosurfactant. The invention also provides a method for removing biological slime in a recirculated cooling water system by the remover. The method comprises putting the remover into the recirculated cooling water. The remover effectively removes biological slime deposited on the equipment and pipes of the recirculated cooling water system, effectively improves effects of removing biological slime of the recirculated cooling water system, reduces a synthetic surfactant use amount, and reduces draining environment pollution caused by use of the synthetic surfactant.

Owner:CHINA PETROLEUM & CHEM CORP +1

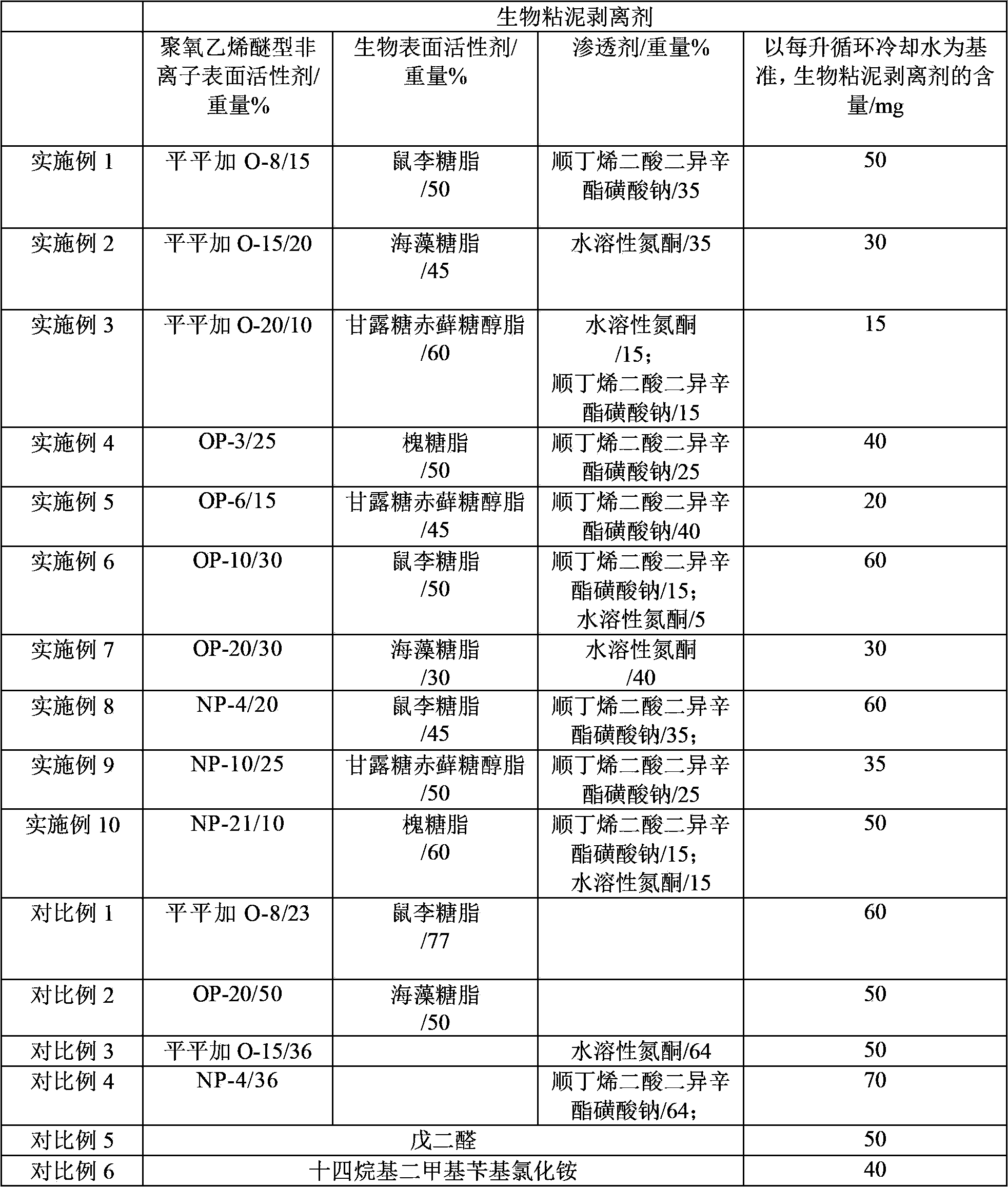

Remover for removing biological slime in recirculated cooling water and method for removing biological slime in recirculated cooling water system

ActiveCN103771593AStripped thoroughlyReduce depositionOrganic detergent compounding agentsNon-ionic surface-active compoundsSynthetic surfactantPollution

The invention discloses a remover for removing biological slime in recirculated cooling water. The remover contains a polyoxyethylene ether-type nonionic surfactant, a biosurfactant and an osmotic agent. The invention also provides a method for removing biological slime in a recirculated cooling water system by the remover. The method comprises putting the remover into the recirculated cooling water. The remover effectively removes biological slime deposited on the equipment and pipes of the recirculated cooling water system, utilizes the biodegradable environmentally-friendly biosurfactant to replace a part of synthetic surfactants, reduces a synthetic surfactant use amount, has good biological slime removal effects and reduces secondary pollution on the environment.

Owner:CHINA PETROLEUM & CHEM CORP +1

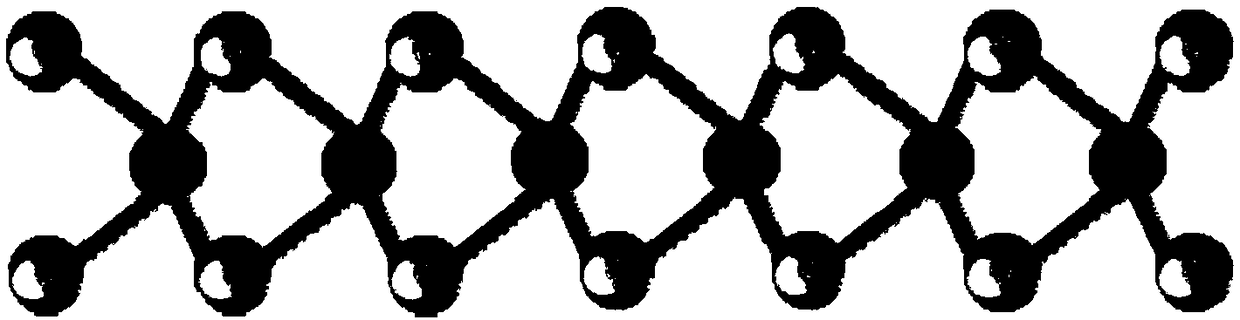

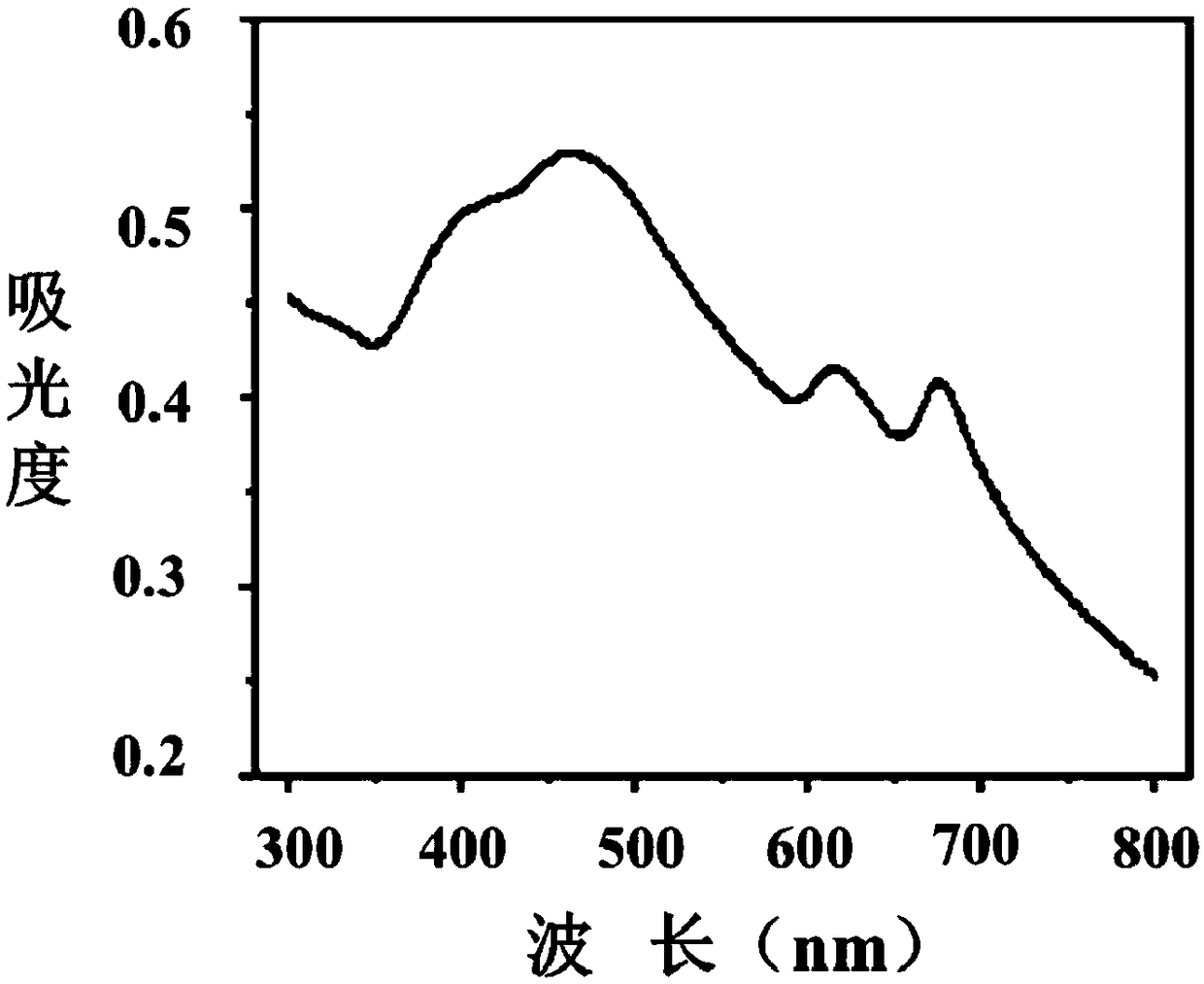

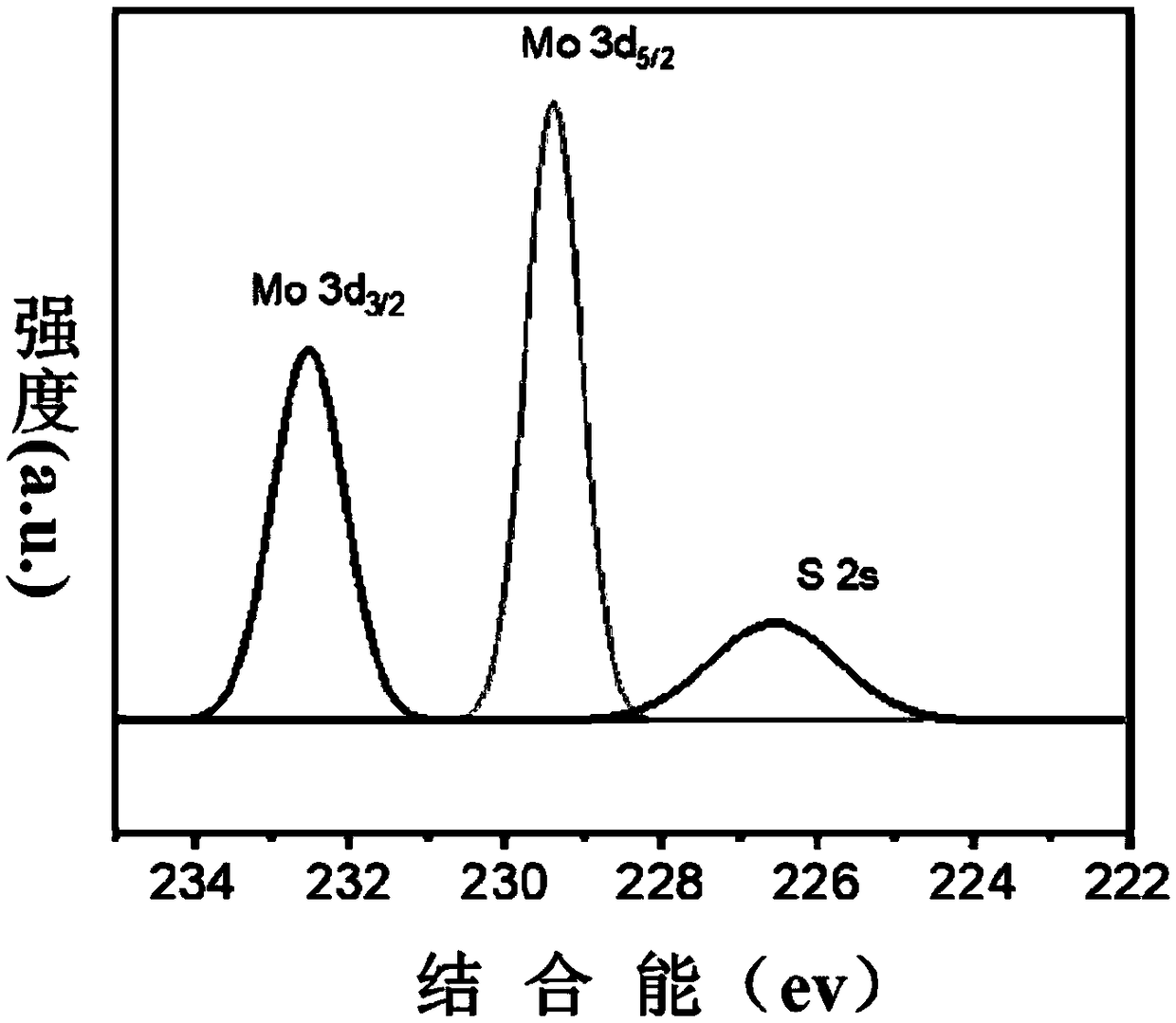

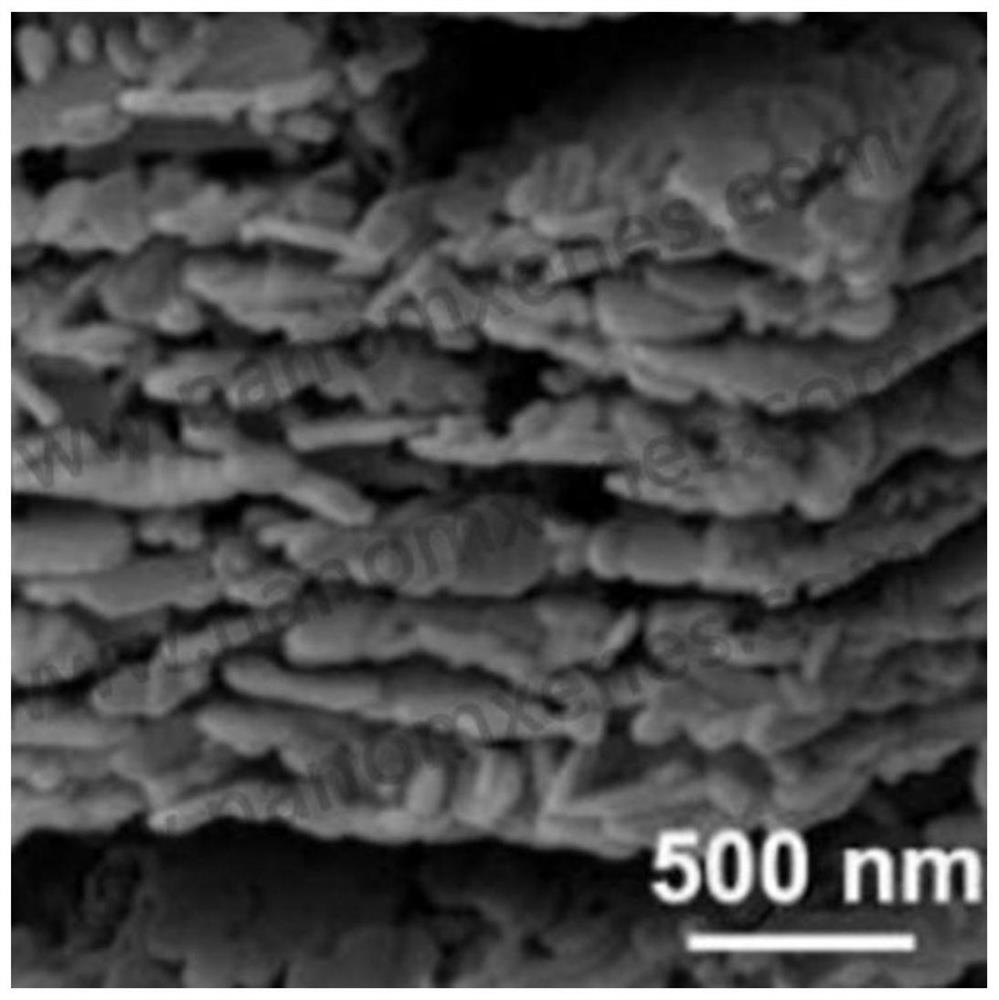

Molybdenum disulfide peeling method as well as molybdenum disulfide prepared by molybdenum disulfide peeling method and application thereof

InactiveCN109231272AImprove dispersionStripped thoroughlyMolybdenum sulfidesSurface-active agentsAqueous solution

The invention relates to a molybdenum disulfide peeling method. The method comprises the following steps: (1) mixing molybdenum disulfide powder, water and a surface active agent to obtain a mixed solution; (2) performing ultrasonic peeling treatment on the mixed solution to obtain molybdenum disulfide. The surface active agent utilized by the molybdenum disulfide peeling method disclosed by the invention contains hydrophilic groups and hydrophobic groups, the hydrophobic groups can be stably combined with molybdenum disulfide, and the hydrophilic groups can make molybdenum disulfide be stablydispersed into water; under the action of the hydrophilic groups and the hydrophobic groups, the molybdenum disulfide powder can be emulsified into colloid, dispersity of the molybdenum disulfide powder in a water solution can be improved, the molybdenum disulfide powder can be peeled more completely, and the peeled molybdenum disulfide can be stably dispersed into the water solution; furthermore, molybdenum disulfide has good antibacterial activity, the mass concentrate of molybdenum disulfide in suspension liquid is larger than or equal to 0.089 mg / mL; when the mass concentration of molybdenum disulfide is 10 mg / L, the antibacterial rate is larger than or equal to 12%; when the mass concentration of molybdenum disulfide is 20 mg / L, the antibacterial rate is larger than or equal to 26%;when the mass concentration of molybdenum disulfide is 50 mg / L, the antibacterial rate is larger than or equal to 70%.

Owner:TSINGHUA BERKELEY SHENZHEN INST +1

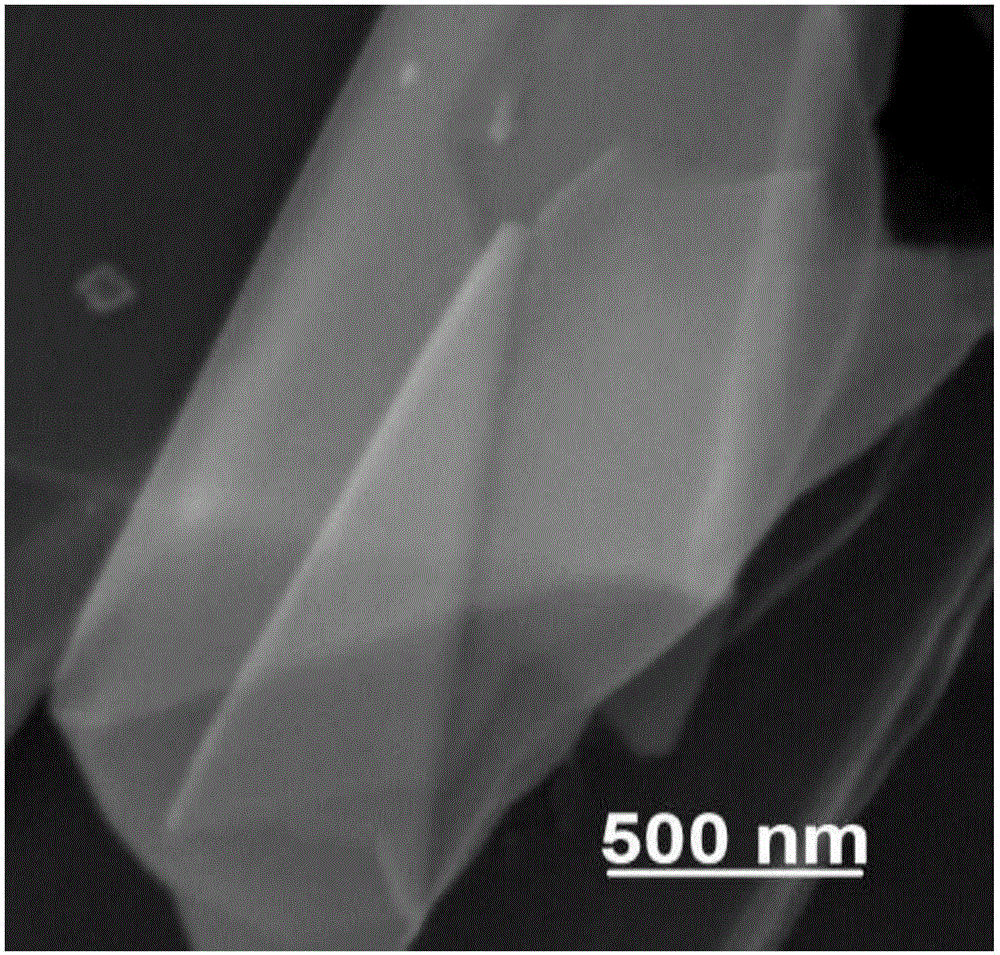

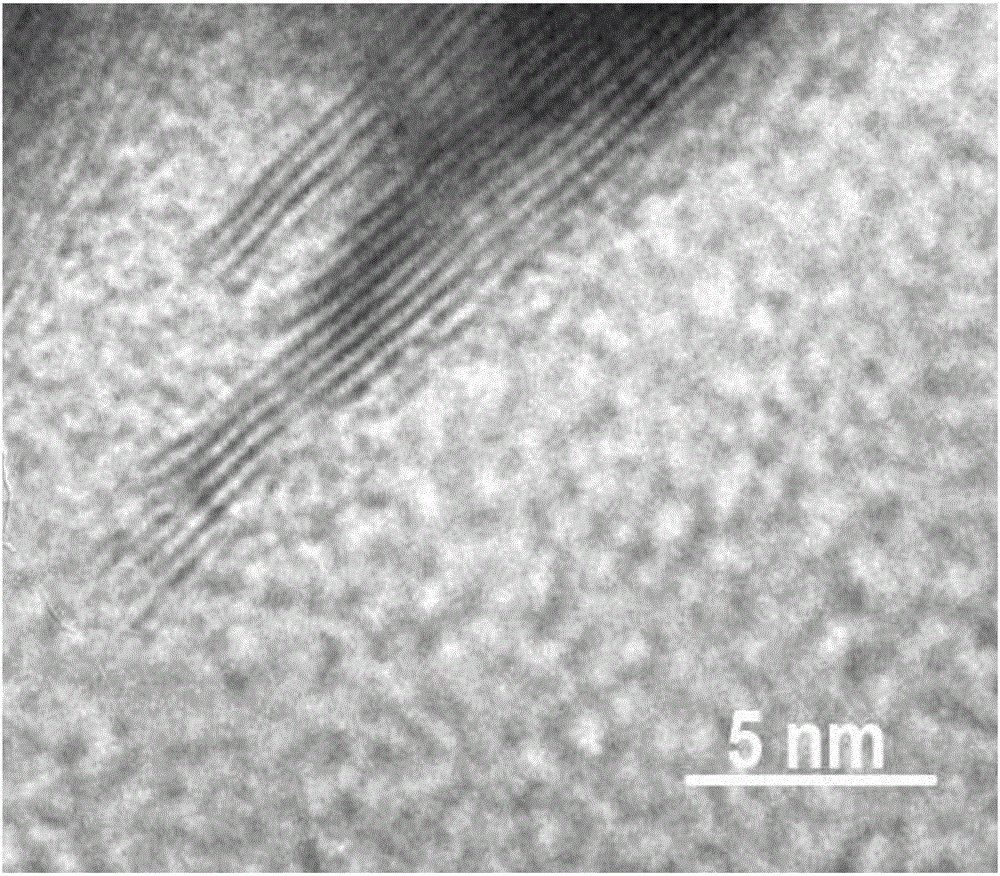

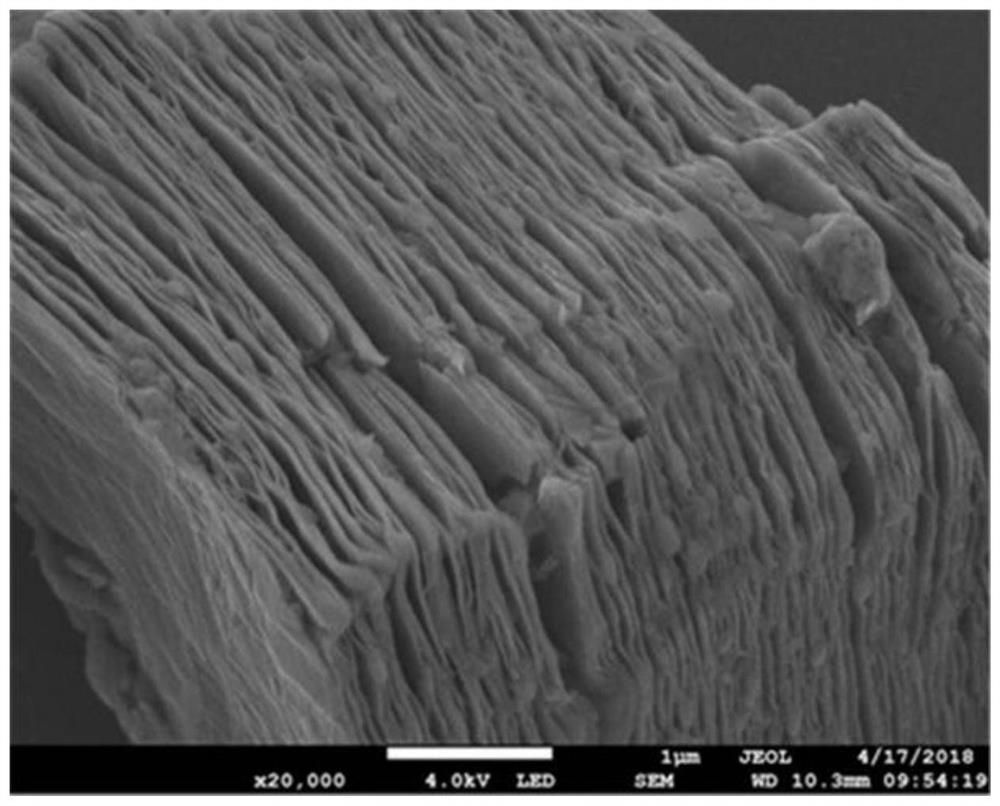

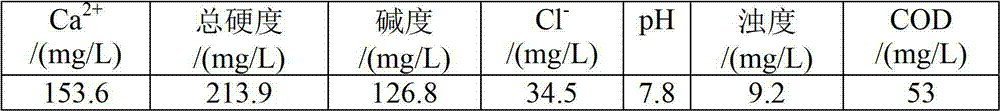

Preparation method of tungsten disulfide nano sheet

ActiveCN108285173AOptimizing Process ParametersGood structural integrityMaterial nanotechnologyPhysical/chemical process catalystsIonStrong acids

The invention provides a preparation method of a tungsten disulfide nano sheet. The preparation method comprises the following steps: (1) mixing tungsten disulfide with a strong acid, carrying out full infiltration, and adding a ferrate or a metal peroxide for carrying out a reaction; (2) slowly and dropwise adding the reactant obtained after the reaction into deionized water for dilution; (3) carrying out ultrasonic treatment on the diluted liquid in an ultrasonic dispersion device; (4) carrying out standing on the dispersed liquid, and removing tungsten disulfide which is not stripped or hasa low stripping degree in the obtained precipitate; (5) carrying out suction filtration treatment on the supernatant liquid obtained after standing, washing the obtained material with hydrochloric acid, and then carrying out washing to neutrality by using deionized water; and (6) finally drying the obtained product to obtain the tungsten disulfide nano sheet. According to the method provided by the invention, the tungsten disulfide nano sheet is prepared by stripping through the reaction of the strong acid with the ferrate or the metal peroxide and through the ultrasonic action; the method issafe and stable, is free of pollution, and has easily available raw materials; the operation is easy; the equipment is simple; the yield is high; and the product quality is good.

Owner:SHANDONG UNIV

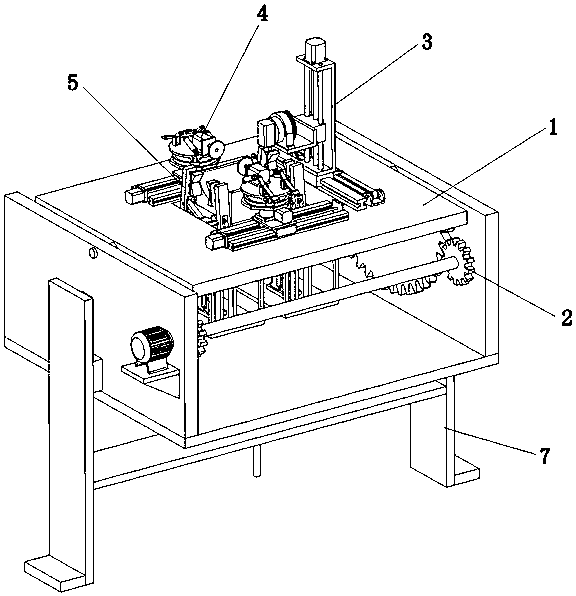

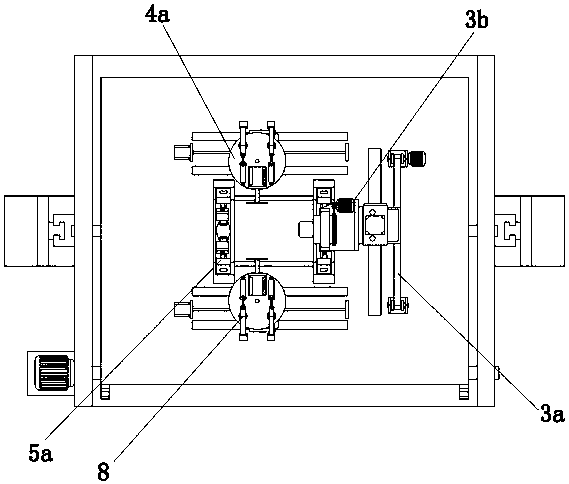

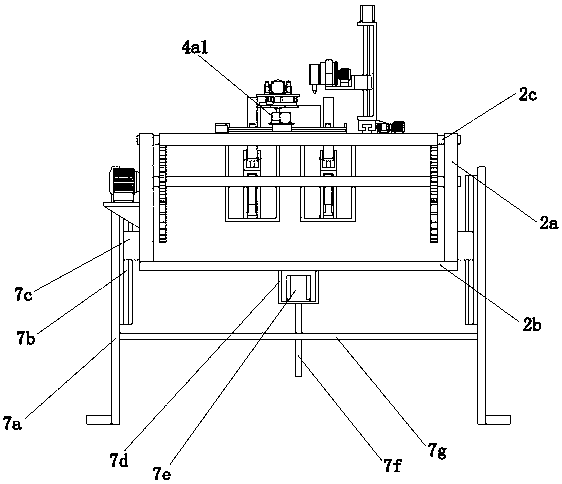

Work method of work table

InactiveCN109567223AAffects peeling efficiencyThorough peelingHuskingHullingEngineeringMechanical engineering

The invention discloses a work method of a work table. The work table comprises a bearing plate, an angle regulating mechanism, a cocoanut husk hole drilling mechanism, a cutting and prying mechanismand a cocoanut position limiting mechanism, wherein the top of the bearing plate is provided with a bearing and carrying block; the top of the bearing and carrying block is provided with an arc-shapedgroove; the bottom of the angle regulating mechanism is provided with a height regulating mechanism; the cutting and prying mechanism comprises two cocoanut husk peeling assemblies; each of the two cocoanut husk peeling assemblies comprises a cutting and prying component, an ascending and descending component and a first lead screw sliding table arranged at the bottom of the ascending and descending component; the cutting and prying component is arranged at the top of the ascending and descending component. The clamping position limiting operation can be performed on cocoanuts with differentsizes through the cocoanut position limiting mechanism; husks at two sides of the cocoanut can be subjected to cutting and prying operation through the cutting and prying mechanism, so that the cocoanut peeling is more thorough.

Owner:郭雅文

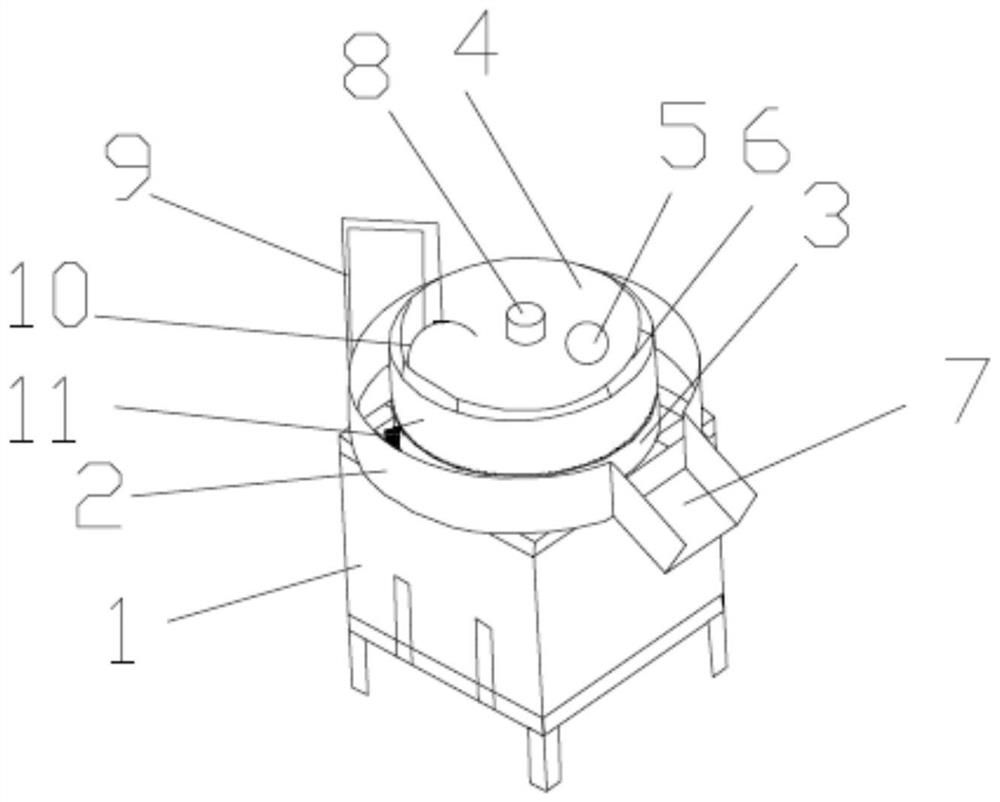

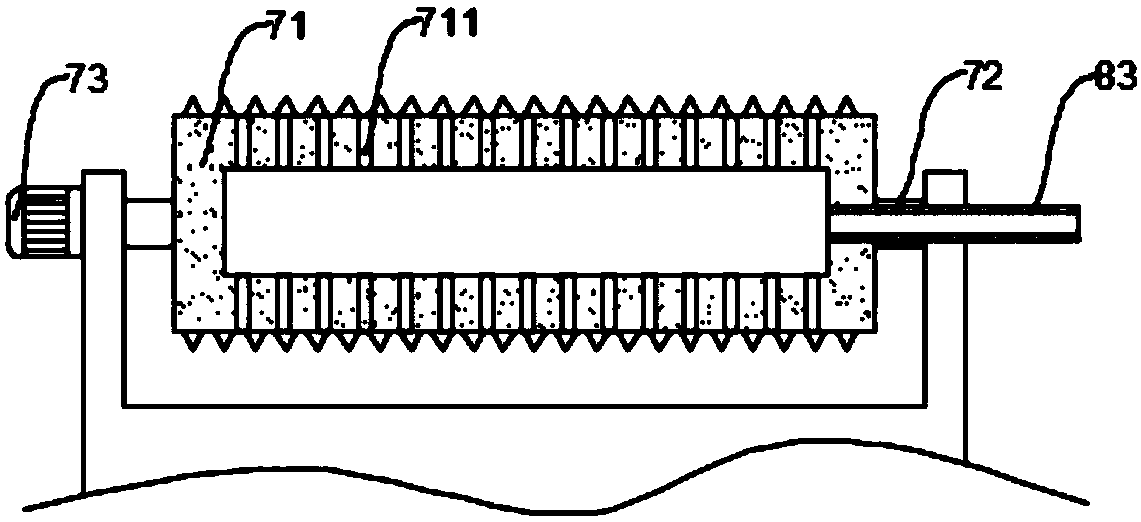

Grinding device for producing moxa

PendingCN112657610ARetain physical and chemical propertiesStripped thoroughlyCocoaGrain treatmentsFiberCold treatment

The invention discloses a grinding device for producing moxa. The comprises a base for supporting, a controller, a driving device, a grinding mechanism and an adjusting device, wherein the controller is used for controlling the driving device and the adjusting device to work; the driving device is used for driving the grinding mechanism to rotate, is mounted in the base and is connected with the controller; the grinding mechanism is used for grinding folium artemisiae argyi, is arranged on the base and is connected with the driving device; the adjusting device is used for adjusting the size of the gap of the grinding mechanism, is arranged in the base and is connected with the controller. Stone millstones are adopted to grind the folium artemisiae argyi, metal is not contacted in the whole process, a cold treatment process is adopted, a high-temperature process is avoided, and meanwhile, physicochemical properties of moxa fibers and moxa are reserved to the maximum extent; and a gap is formed between an upper millstone and a lower millstone, the size of the gap is adjustable according to the quality of the folium artemisiae argyi, and the action of rubbing braids by hands is completely simulated in the production process, so that long fibers cannot be damaged, and mesophyll stripping is more thorough.

Owner:HANGZHOU XINHAN PHOTOELECTRIC SCI & TECH

MXene-ACF composite material for catalyzing hydrochlorination reaction of acetylene as well as preparation method and application of MXene-ACF composite material

PendingCN114160176AStripped thoroughlyPlay a cleaning rolePreparation by halogen halide additionCatalyst activation/preparationFiberActivated carbon

The invention discloses an MXene-ACF composite material for catalyzing an acetylene hydrochlorination reaction as well as a preparation method and application of the MXene-ACF composite material. The preparation method comprises the following steps: 1, adding LiF powder into an HCl solution, sufficiently dissolving, slowly adding MAX powder, stirring and etching in an ultrasonic-assisted oil bath, and centrifugally washing with deionized water to obtain a plurality of layers of MXene precipitates; 2, re-dispersing the multi-layer MXene precipitate obtained in the step 1 into deionized water to form an MXene suspension, immersing the cut activated carbon fiber into the MXene suspension, and forming MXene / ACF through electrostatic self-assembly; and 3, taking out the MXene / ACF obtained in the step 2, and carrying out vacuum drying under ultraviolet irradiation to obtain the MXene / ACF composite material. The prepared MXene / ACF composite material is used for catalyzing acetylene hydrochlorination to synthesize vinyl chloride, the good catalytic performance is shown, the acetylene conversion rate and the vinyl chloride selectivity are high, and the stability is good.

Owner:ZHEJIANG UNIV OF TECH

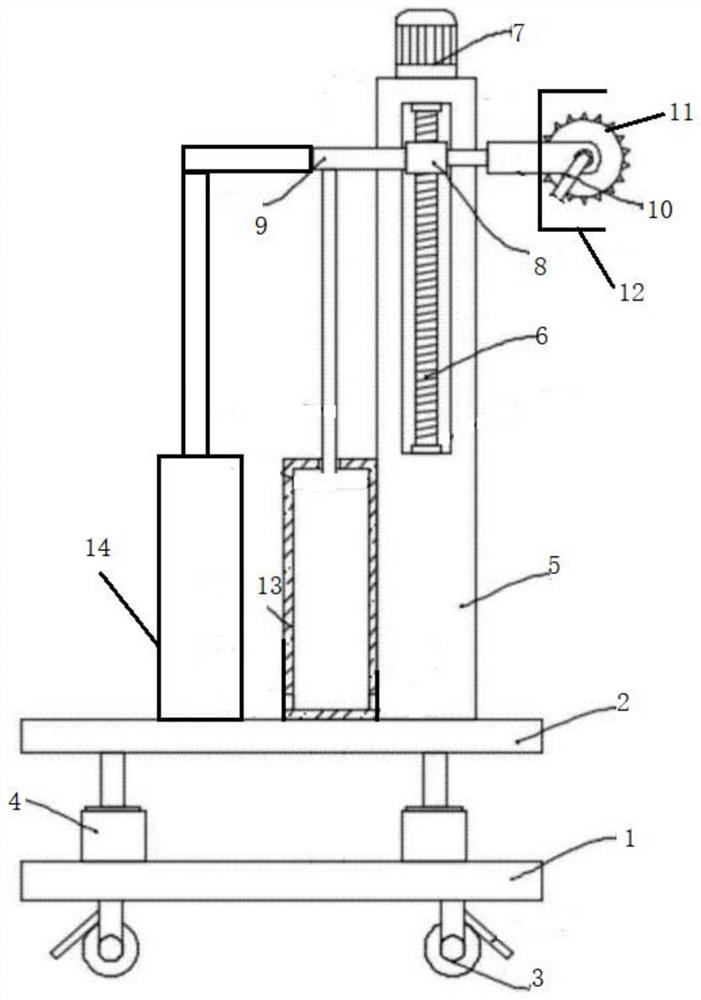

Building construction wall stripping device with dust fall and noise reduction functions

InactiveCN111764676ASimple processImprove work efficiencyUsing liquid separation agentBuilding repairsElectric machineryArchitectural engineering

The invention relates to a building construction wall stripping device with dust fall and noise reduction functions. The building construction wall stripping device comprises a support, a lifting platform and a control device, and the support and the lifting platform are provided with a lifting device; a construction frame is fixed to the right side of the top of the lifting table, a lead screw isrotationally installed on the construction frame, and a lead screw motor is installed at the top of the construction frame; the lead screw is sleeved with a lead screw sliding block matched with thelead screw for lifting; a stripping construction frame is arranged on the screw rod sliding block; a stripping tool is mounted at the front end of the stripping construction frame; and the stripping tool comprises a stripping roller, a protective cover, a dust falling device and a noise reduction structure. The wall stripping device can achieve the effects of dust falling and noise reduction in the wall surface stripping construction process, the working procedure is simplified, the working efficiency is improved, convenience is provided for construction, and the body health of constructors isguaranteed.

Owner:北京启顺京腾科技有限责任公司

Stripable paint for laser impact treatment

This invention discloses a strippable coating for laser shock processing, which is composed of carbon powders 5-15 wt.%, bonding agent 50-70 wt.%, self-drying thinner 15-35 wt.% and additive 2-5 wt.%. The thickness of the coating layer is generally 60-150 mums. The strippable coating is manufactured by: (1) placing carbon powders in a reactor, and adding bonding agent, self-drying thinner and additive; and (2) stirring uniformly, and adjusting the pH value to 7.5 with 25% ammonia solution. The strippable coating can intimately adhere to the surface of metals, and cannot be stripped during continuous laser shock process, thus having a good shock effect.

Owner:JIANGSU UNIV

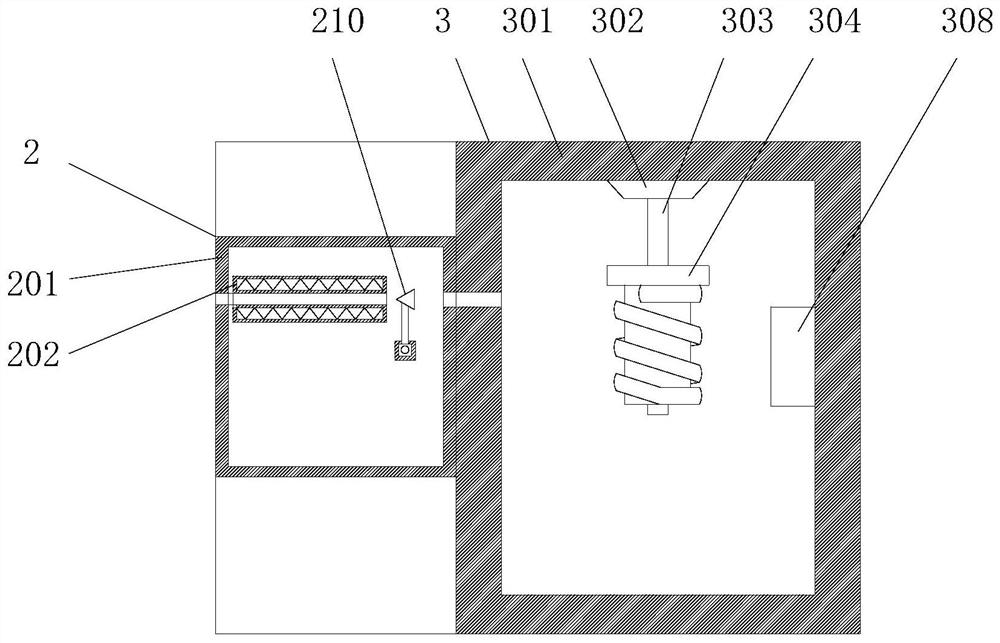

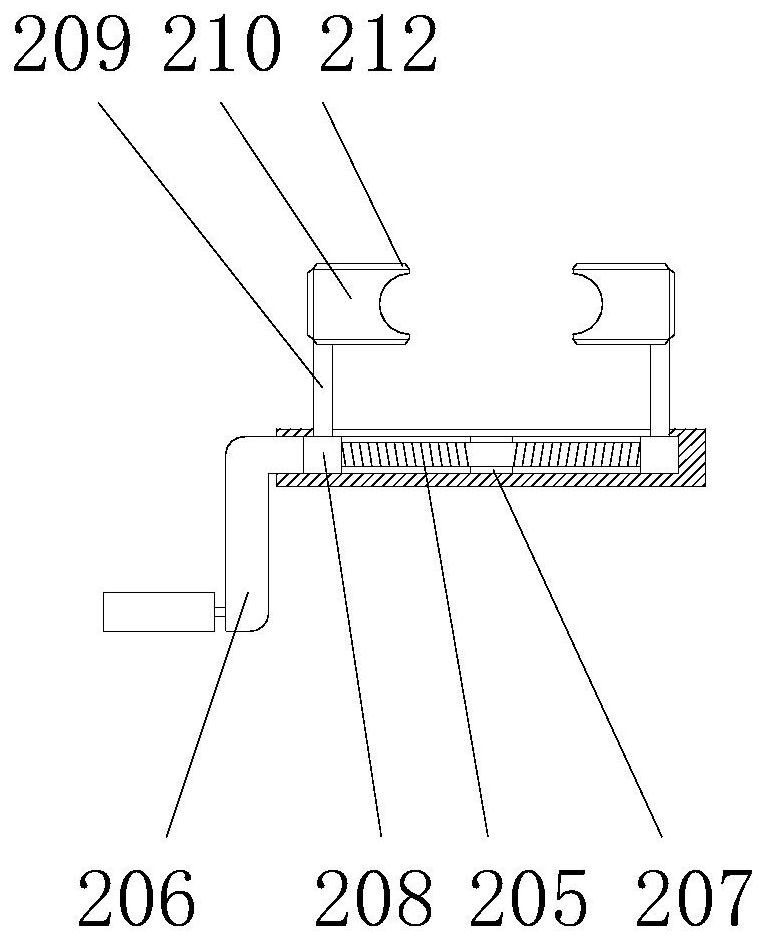

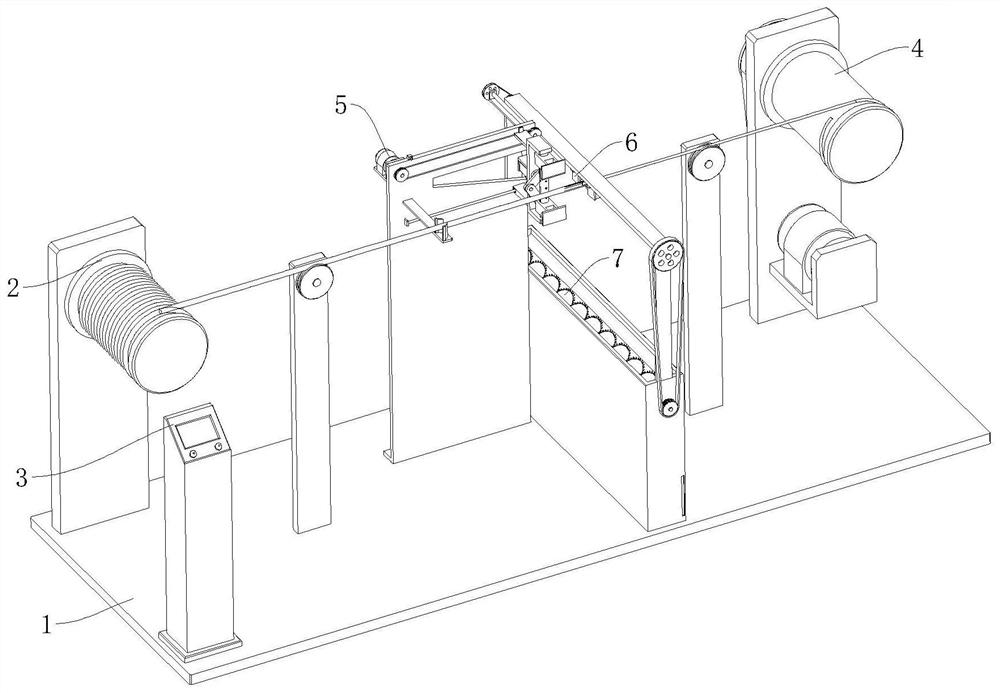

Waste cable treatment device

InactiveCN112670034AStripped thoroughlyDoes not affect operationFilament handlingBasic electric elementsCopper wireCopper-wiring

The invention discloses a waste cable processing device, and the device comprises a machine body; a peeling device is arranged at the left end of the interior of the machine body, a take-up device is arranged at the right end of the machine body, and the peeling device comprises a first box body, a heating pipe, a fixed rod, a movable groove, a threaded rod, a rocking handle, a bearing, a movable block, a fixed column, a cutting tool bit and a drawing box; a first box body is arranged on the outer side of the peeling device, and a heating pipe is arranged at the upper end of the left side in the first box body. According to the waste cable processing device, the cutting tool bit is arranged to be matched with the three-edged blade to cut open in all directions, and the auxiliary cutting tool is arranged to transversely cut off a leather sheath cut open on the left side, so the leather sheath of a waste cable is cut into chippings, and stripping of the cable and a copper wire is more complete; a separated copper wire is wound into a roller through the wire winding roller, and the heating pipe is arranged, so the leather sheath on the outer side of the cable is heated and softened, and the leather sheath on the outer side of the waste cable is cut more smoothly; the clamping piece is arranged and matched with the rotating wheel and the connecting piece, so a copper wire is prevented from being separated from the wire clamping groove.

Owner:叶开文

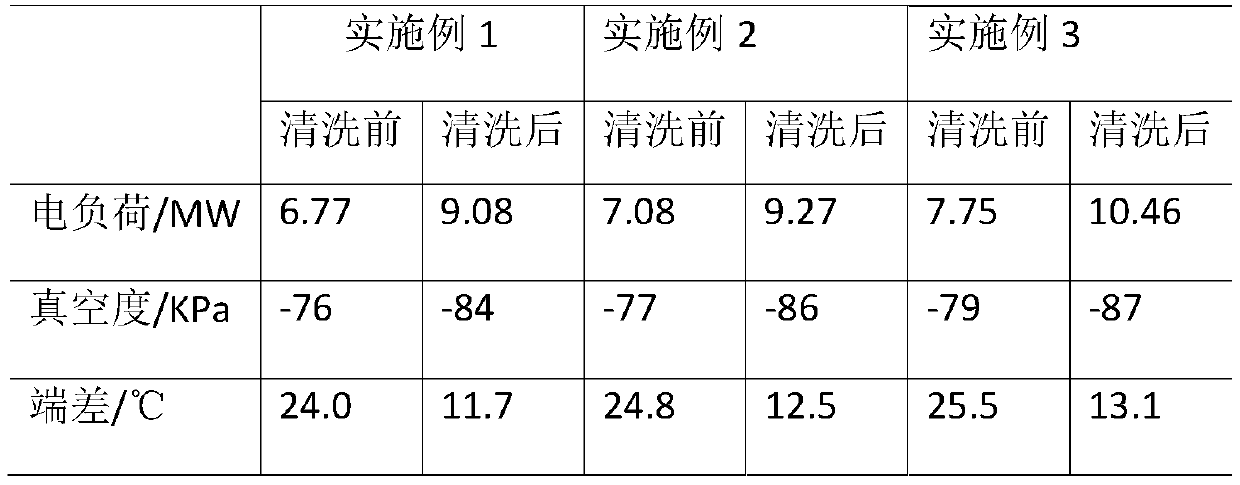

Liquor used for online cleaning of dry quenching condenser, preparation method and method for online cleaning

The invention discloses liquor used for online cleaning of a dry quenching condenser, a preparation method and a method for online cleaning, and belongs to the technical field of online cleaning of condensers. The liquor comprises, by weight, 40-70 parts of mixed acid, 10-25 parts of a corrosion inhibitor, 10-20 parts of a penetrating agent, 10-15 parts of a defoaming agent, 5-10 parts of a chelating agent and 30-50 parts of water. The mixed acid comprises sulfuric acid, sulfamic acid and 2-carboxylethic acid. The chelating agent comprises hydroxyethyl thiosuccinic acid and diethylene triaminepenlaacetic acid. Sodium succinate sulfonate serves as the penetrating agent. Polyoxyethylene octyl phenol ether serves as the defoaming agent. The liquor used for online cleaning of the dry quenching condenser is high in dirt dissolving capacity, good in cleaning effect, safe, environment-friendly and free of pollution to the environment. The method for online cleaning is short in time and low in cost, the dirt removal rate is larger than 85%, and the cleaning effect is remarkable.

Owner:SICHUAN DAXING ENERGY

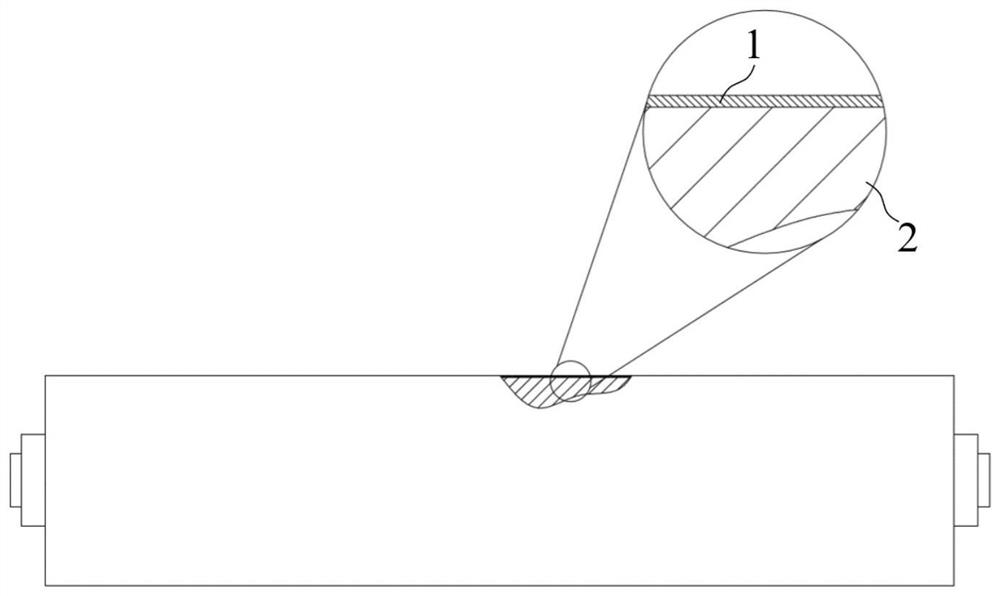

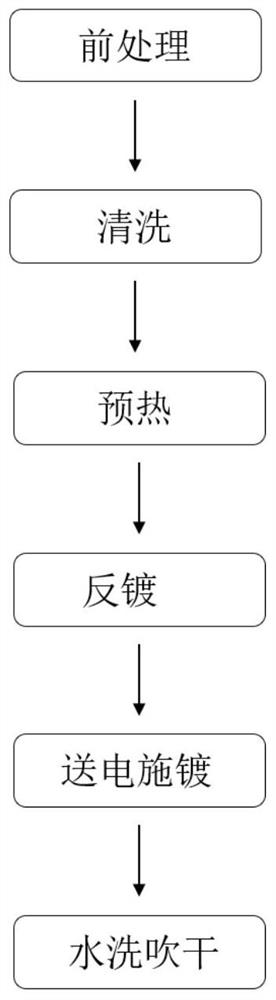

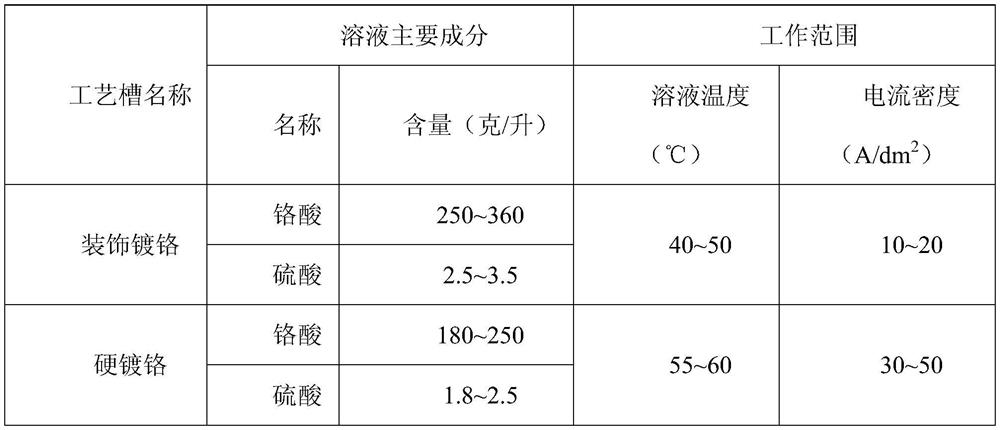

Temper mill applying chromium-plated roller

PendingCN112222194AIncrease the temperature of the roll bodyGuaranteed smoothRollsMetal rolling arrangementsStrip steelChrome plating

The invention discloses a temper mill applying a chromium-plated roller, and belongs to the field of forming equipment. The roller of the temper mill adopts the chromium-plated roller with the diameter of 450 mm. Through the improvement of the present invention, the single rolling time of the roller can be prolonged by 3-10 times, the roller replacement downtime is shortened, the operation rate isimproved, the abrasion resistance of the chromium-plated roller is improved, the uniformity of the surface roughness of strip steel in the rolling period is improved, the surface hardness of the chromium-plated roller is further improved, roller surface scratches are reduced, the surface quality of the strip steel and the cleanliness of the plate surface are improved, and the lubricating capacityof the roller is improved.

Owner:江苏友富薄板科技有限公司

Acid pickling assistant for removing residual thick-layer black oil spots on cold-drawn steel pipe and preparing method

The invention discloses an acid pickling assistant for removing residual thick-layer black oil spots on a cold-drawn steel pipe. The acid pickling assistant comprises, by mass percent, 30%-50% of sulfuric acid with the mass concentration being 98%, 2%-5% of hydrofluoric acid with the mass concentration being 50%, 2%-5% of methanesulfonic acid, 2%-5% of phosphoric acid with the mass concentration being 85%, 2%-5% of oxalic acid, 2%-5% of oleic acid, 1%-3% of tartaric acid, 0.5%-1.5% of urotropin, 1.5%-3.5% of a QYL-211A acid degreasing, oil removing and rust removing restraining acid mist three-in-one surfactant, 1.5%-3.5% of a QYL-290 deposition carbon removing surface active agent, 1.5%-3.5% of JFC and the balance tap water. An existing production line does not need to be changed, the acid pickling assistant only needs to be added into an existing out-line line acid washing and oil removing two-in-one bath solution, the residual thick-layer black oil spots on the cold-drawn steel pipe can be rapidly and thoroughly peeled, and the product quality is guaranteed.

Owner:DALIAN SANDAAOKE CHEM

Corn stigma stripping device for corn processing

ActiveCN112970436AEasy to placeOrderly rowsHarvestersSaving energy measuresAgricultural engineeringMechanical engineering

The invention discloses a corn stigma stripping device for corn processing, and relates to the technical field of grain processing equipment. The corn stigma stripping device for corn processing comprises a protective shell, wherein the left end and the right end of the inner side of the protective shell are rotationally connected with a conveying belt through rotating shafts; the lower side surface of the protective shell is fixedly connected with a first support; second supports are arranged on the front side and the rear side of the left side of the protective shell side by side; and the upper sides of the inner sides of the second supports are rotationally connected with electric conveying rollers in parallel through rotating shafts. The corn stigma stripping device for corn processing is a fructus xanthii imitating mechanism, in the corn stigma stripping process, the position of an oval shell can be continuously changed according to the gap and the size of corn kernels at contact points, the position of a soft spine of a stigma pulling mechanism can be changed according to different contact points, a connecting rope drives a hook spine to continuously move, corn stigma can be effectively hooked, the corn stigma among some irregular corn kernels can be easily hooked out and stripped, so that the corn stigma can be stripped more thoroughly.

Owner:吉林省陆路雪食品有限公司

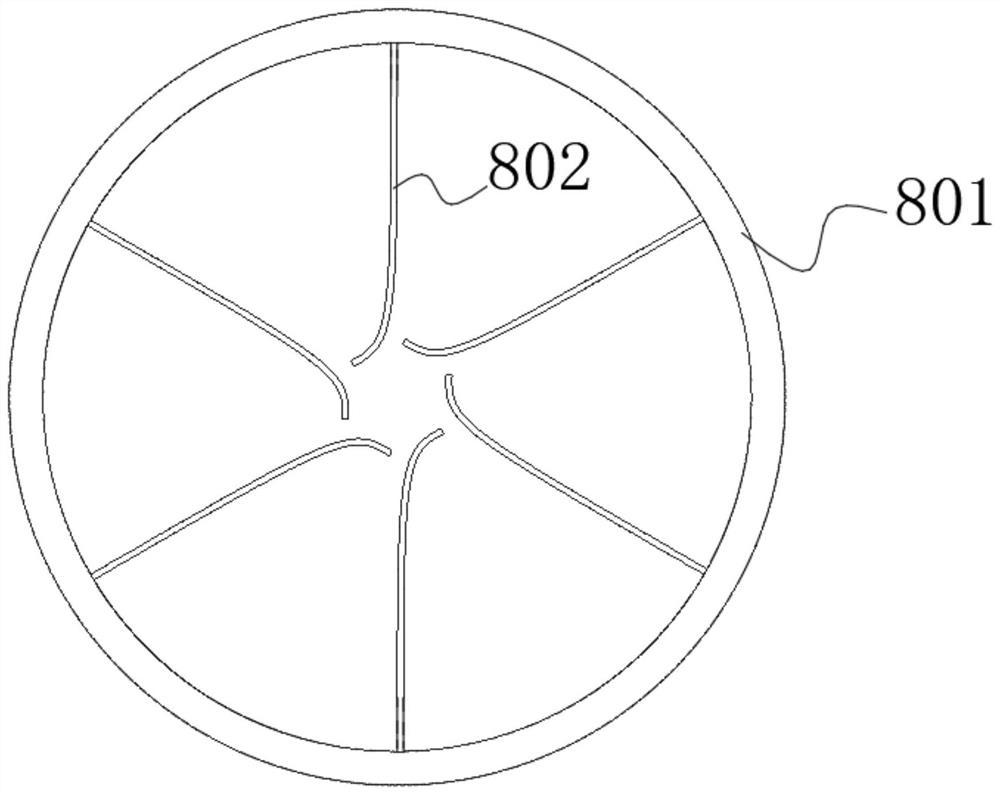

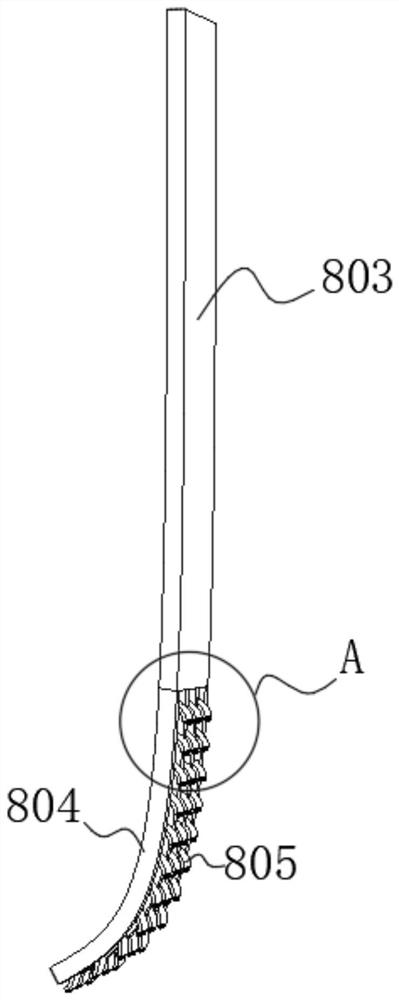

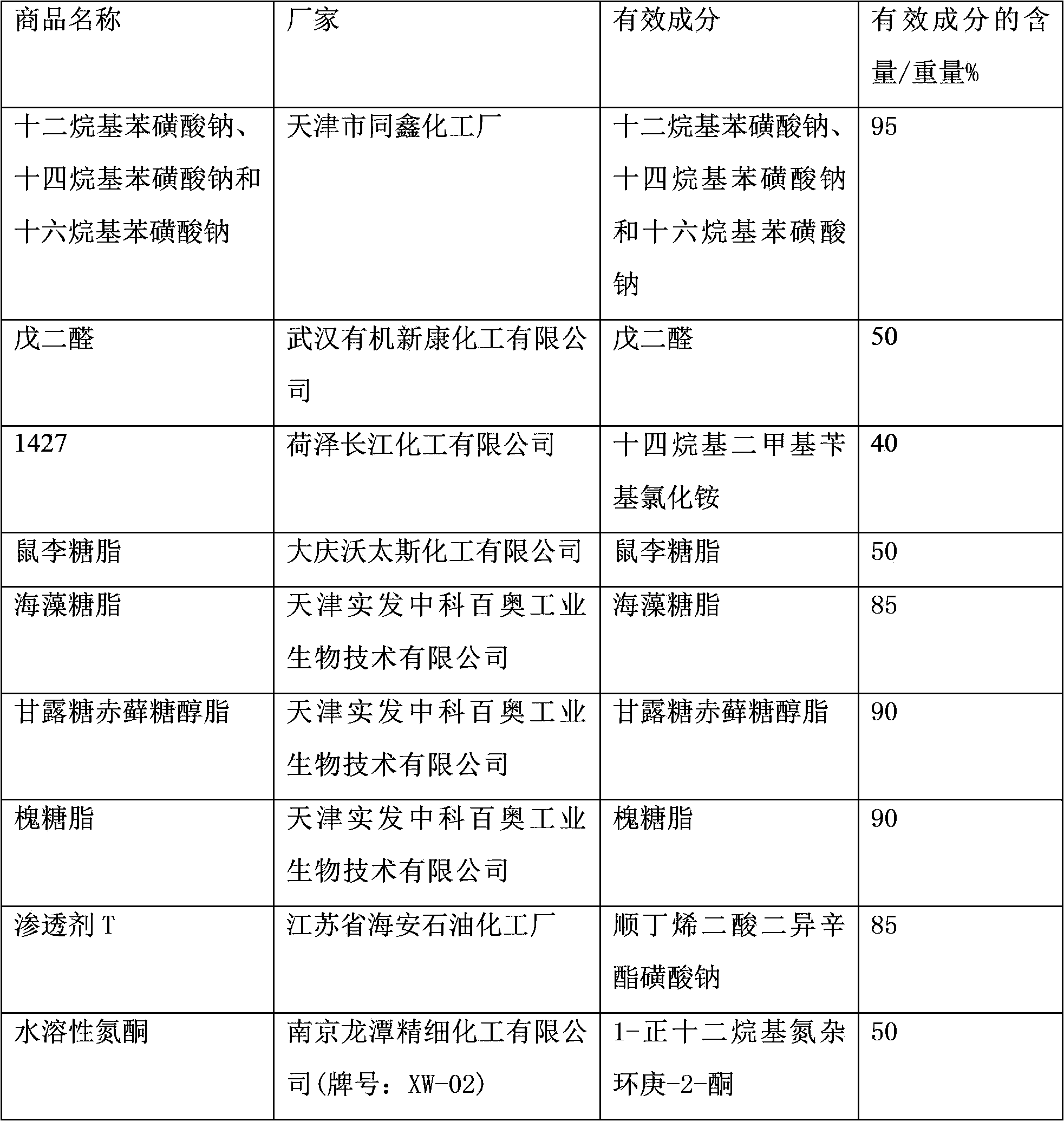

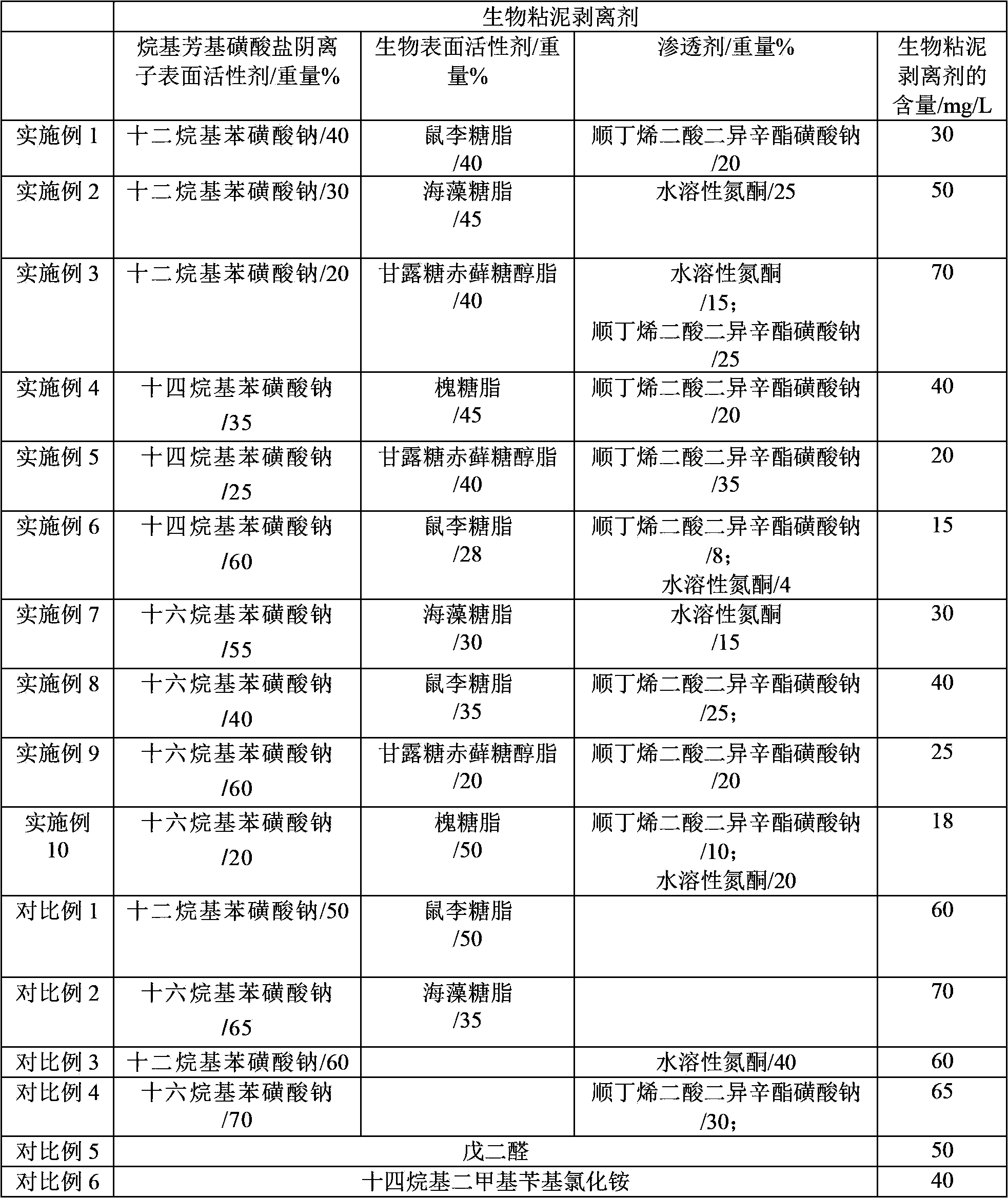

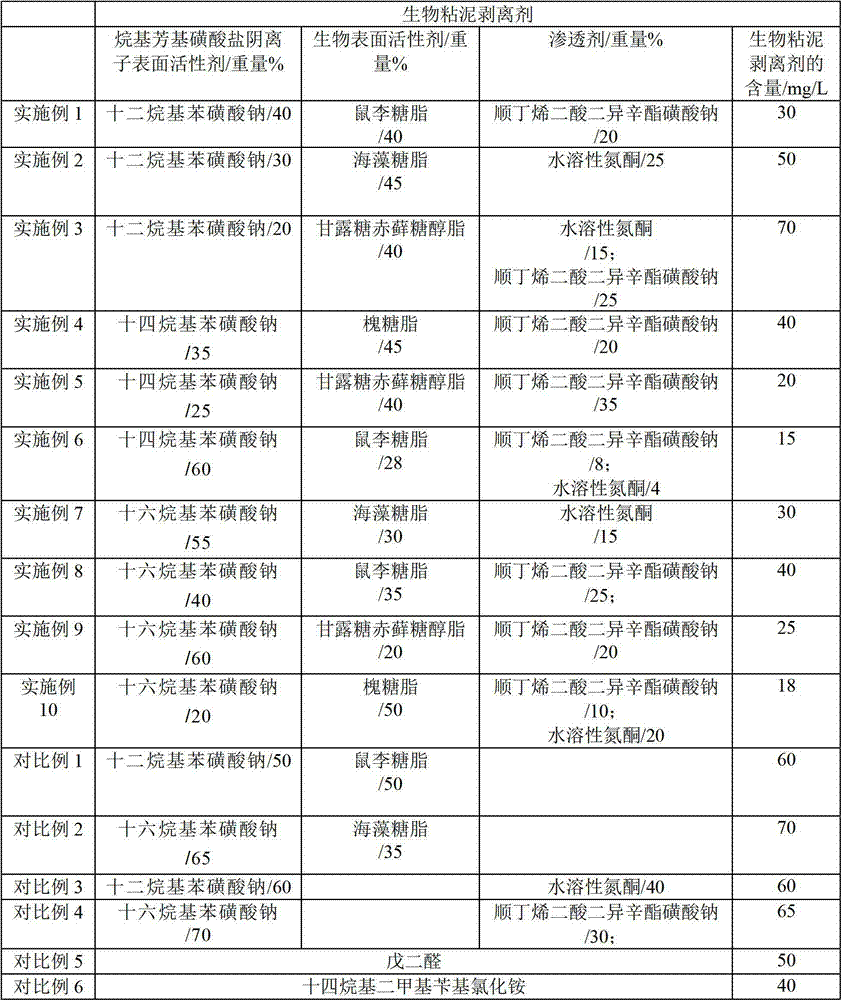

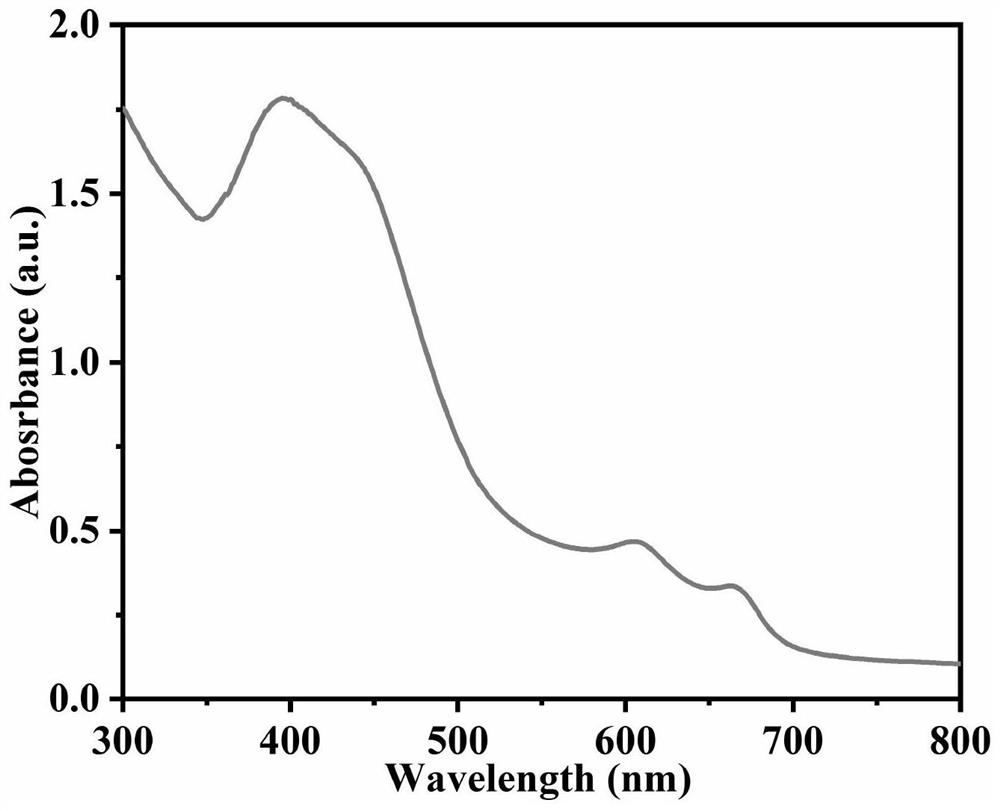

Circulating cooling water biological slime stripping agent and method for stripping slime in circulating cooling water system

ActiveCN103771595AStripped thoroughlyReduce depositionNon-ionic surface-active compoundsOrganic detergent compounding agentsChemical synthesisSulfonate

The invention discloses a circulating cooling water biological slime stripping agent. Specifically, the biological slime stripping agent contains an alkylaryl sulfonate anionic surfactant, a biological surfactant and a penetrating agent. The invention also provides a method for stripping slime in a circulating cooling water system. The method includes putting the circulating cooling water biological slime stripping agent into circulating cooling water. The biological slime stripping agent provided by the invention can effectively strip the biological slime deposited on the equipment and pipeline inner walls of a circulating cooling water system. And by adopting the biodegradable and environmental friendly biological surfactant to replace parts of chemical synthesis surfactants, the dosage of chemical synthesis surfactants can be reduced, and at the same time, a good biological slime stripping effect can be achieved, and secondary pollution to the environment can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biological slime stripping agent for circulating cooling water and method for stripping slime in circulating cooling water system

ActiveCN103773614BStripped thoroughlyReduce depositionOrganic detergent compounding agentsSurface-active detergent compositionsChemical synthesisSynthetic surfactant

The invention discloses a remover for removing biological slime in recirculated cooling water. The remover contains a polysorbate nonionic surfactant, a biosurfactant and an osmotic agent. The biosurfactant is a glycolipid-type biosurfactant. The invention also provides a method for removing biological slime in a recirculated cooling water system by the remover. The method comprises putting the remover into the recirculated cooling water. The remover effectively removes biological slime deposited on the equipment and pipes of the recirculated cooling water system, effectively improves effects of removing biological slime of the recirculated cooling water system, reduces a synthetic surfactant use amount, and reduces draining environment pollution caused by use of the synthetic surfactant.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rework liquid medicine, preparation method thereof, and rework device

PendingCN110161812AStripped thoroughlyExcellent reworkabilityPhotosensitive material processingNon-linear opticsTetramethylammonium hydroxideHydroxylamine

The invention provides a rework liquid medicine, a preparation method thereof, and a rework device. The rework liquid medicine contains the following components in parts by weight: 20-30 parts of deionized water; 3-10 parts of tetramethylammonium hydroxide; 30-45 parts of dimethyl sulfoxide; 1-5 parts of N-methyl pyrrolidone; 10-20 parts of diethylene glycol-methyl ether; and 1-5 parts of hydroxylamine. The substrate reworking effect can be improved.

Owner:CHENGDU ZHONGDIAN PANDA DISPLAY TECH CO LTD

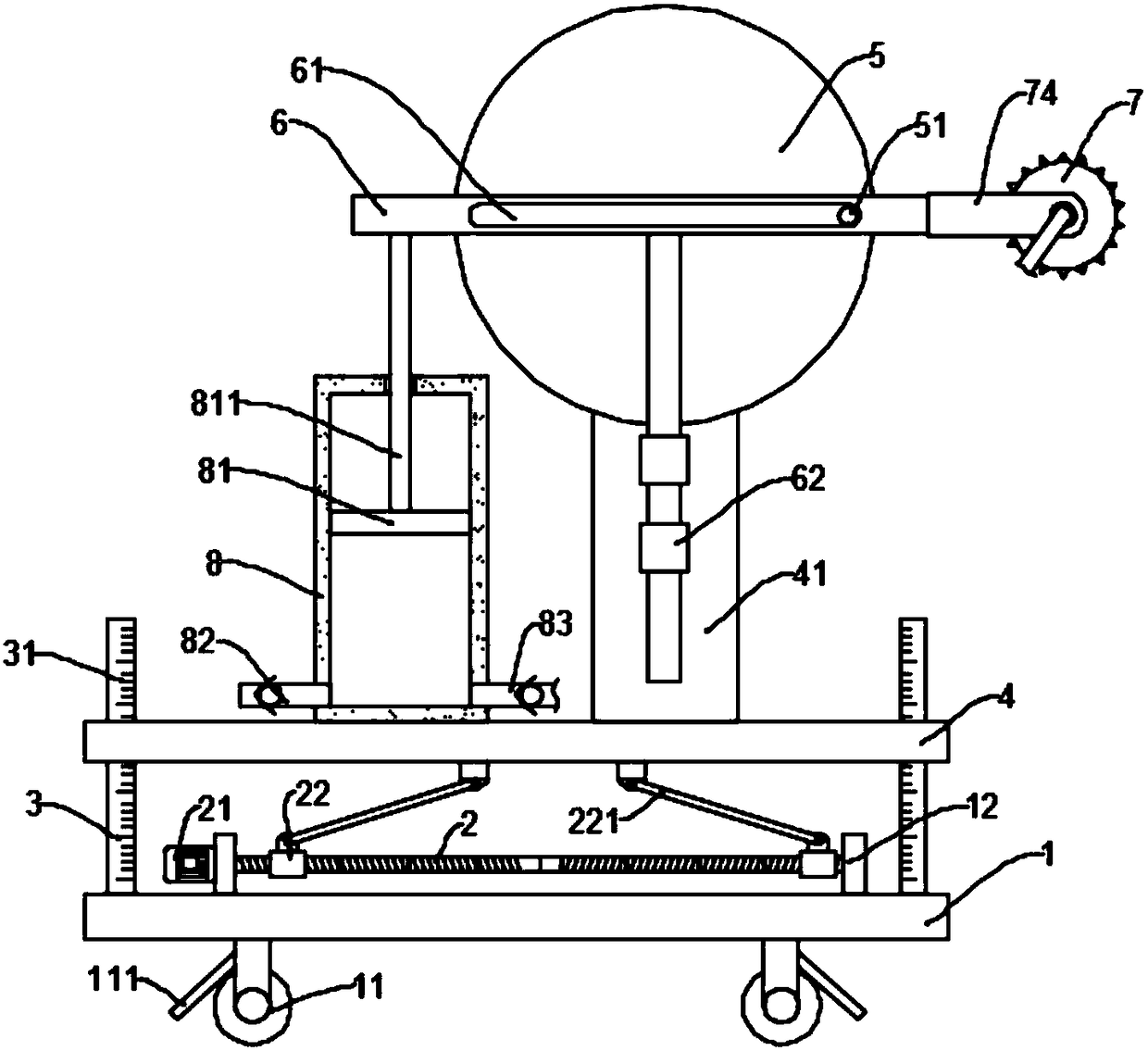

Wall surface stripping device with reciprocating-motion-type stripping roll

The invention discloses a wall surface stripping device with a reciprocating-motion-type stripping roll. The wall surface stripping device comprises a base, a working table, a disc, a T-shaped rod, the stripping roll and a cylinder body. According to the wall surface stripping device, by arranging a bi-directional lead screw and a matching assembly of the bi-directional lead screw, the height of the working table can be conveniently adjusted, and through transmission of the lead screw, moving of the working table is more stable and easy to control; by arranging a guide rod, the stability of the whole structure is improved, a scale line is arranged on the guide rod, and thus the displacement of the working table can be learned more intuitively by a worker; and by arranging the reciprocating-motion-type stripping roll, stripping of the stripping roll for the wall surface is more thorough, the wall surface stripping effect is ensured, meanwhile blowing and sweeping work can be completed while the wall surface is stripped, thus the two working procedures are conducted simultaneously, and the working efficiency is improved.

Owner:SHENZHEN CHENGHONG ENTERPRISE MANAGEMENT CO LTD

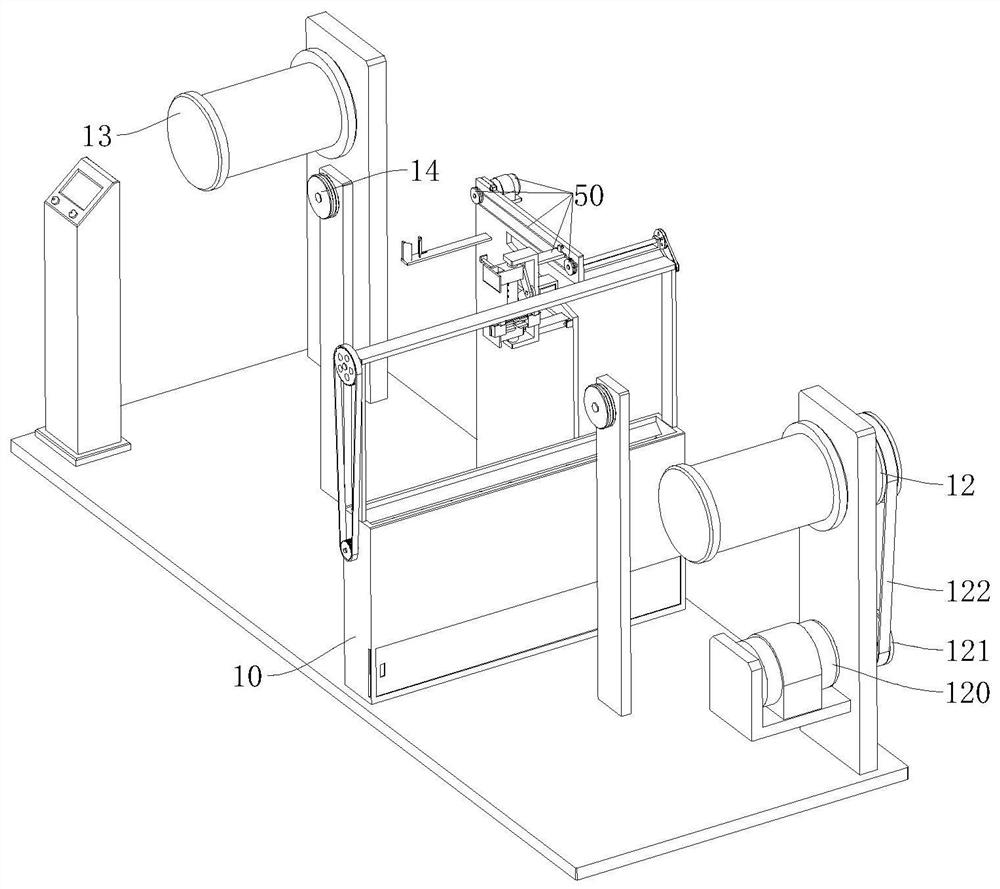

Cable sheath and core wire stripping and recycling equipment

ActiveCN113299442AReduce laborReduce security risksBasic electric elementsElectronic waste recyclingStructural engineeringKnife blades

The invention relates to the technical field of cable recycling, in particular to cable sheath and core wire stripping and recycling equipment which comprises a base and an unwinding roller and further comprises a controller, a winding roller, a cutting-up mechanism, a pulling mechanism and a crushing mechanism, the cutting-up mechanism comprises a sliding assembly, a telescopic assembly and two cutters, and the pulling mechanism comprises a distance changing assembly and two electric clamping jaws. The crushing mechanism comprises a transmission assembly and a plurality of rotating blades, the rotating blades are arranged at the top of the inner side of the treatment box at equal intervals through a second rotating shaft, the transmission assembly is arranged between the variable-pitch assembly and the rotating blades in a sleeving mode, and the sliding assembly, the telescopic assembly and the two electric clamping jaws are electrically connected with the controller. According to the cable sheath and core wire stripping and recycling equipment, the stripping efficiency is higher, the power consumption is smaller, the manufacturing cost is lower, meanwhile, environmental pollution can be effectively avoided, and the secondary utilization rate of resources can be effectively increased.

Owner:芜湖市科特电线电缆有限公司

Circulating cooling water biological slime stripping agent and method for stripping slime in circulating cooling water system

ActiveCN103771595BStripped thoroughlyReduce depositionOrganic detergent compounding agentsNon-ionic surface-active compoundsChemical synthesisSulfonate

The invention discloses a circulating cooling water biological slime stripping agent. Specifically, the biological slime stripping agent contains an alkylaryl sulfonate anionic surfactant, a biological surfactant and a penetrating agent. The invention also provides a method for stripping slime in a circulating cooling water system. The method includes putting the circulating cooling water biological slime stripping agent into circulating cooling water. The biological slime stripping agent provided by the invention can effectively strip the biological slime deposited on the equipment and pipeline inner walls of a circulating cooling water system. And by adopting the biodegradable and environmental friendly biological surfactant to replace parts of chemical synthesis surfactants, the dosage of chemical synthesis surfactants can be reduced, and at the same time, a good biological slime stripping effect can be achieved, and secondary pollution to the environment can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-concentration high-dispersity ultrathin molybdenum disulfide dispersion liquid and preparation method thereof

PendingCN112591797AGood dispersionDisperse thoroughlyMolybdenum sulfidesHigh concentrationCrystal structure

The invention discloses a high-concentration high-dispersity ultrathin molybdenum disulfide dispersion liquid and a preparation method thereof. Molybdenum disulfide is used as a raw material, ionic liquid crystal is used as an auxiliary agent, the raw material and the auxiliary agent are dispersed in deionized water according to a specific proportion, and a water-based high-concentration high-dispersity ultrathin molybdenum disulfide dispersion liquid is prepared by adopting an ultrasonic mode. The prepared molybdenum disulfide dispersion liquid can be stably stored for a long time at normal temperature, the preparation process is simple and efficient, the production period is short, and the method is suitable for large-scale production; and the molybdenum disulfide prepared by adopting water as a solvent has no residual organic matters on the surface, is low in production cost, environment-friendly and high in safety coefficient, does not destroy the crystal structure of molybdenum disulfide, and has a very high application value.

Owner:SHAANXI UNIV OF SCI & TECH

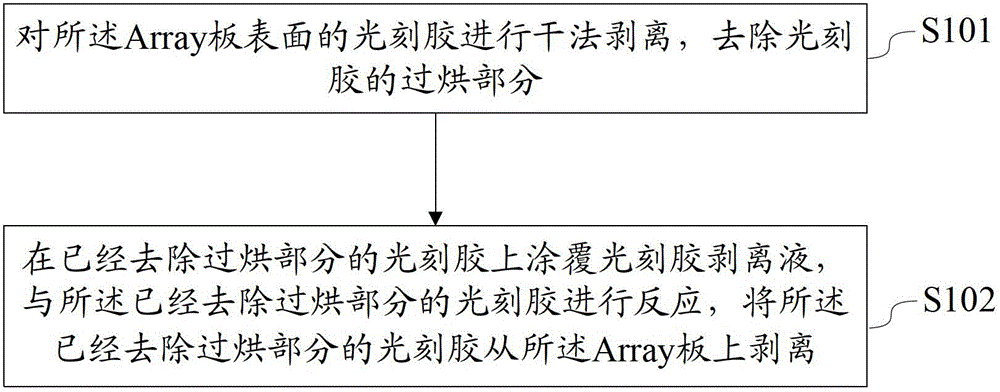

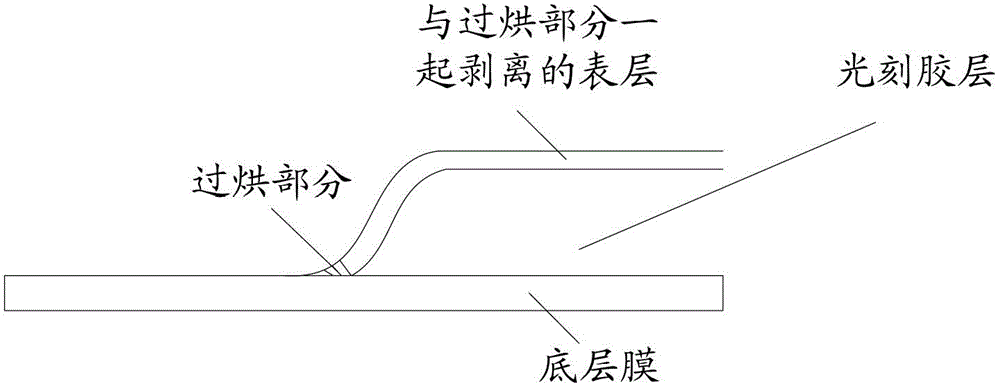

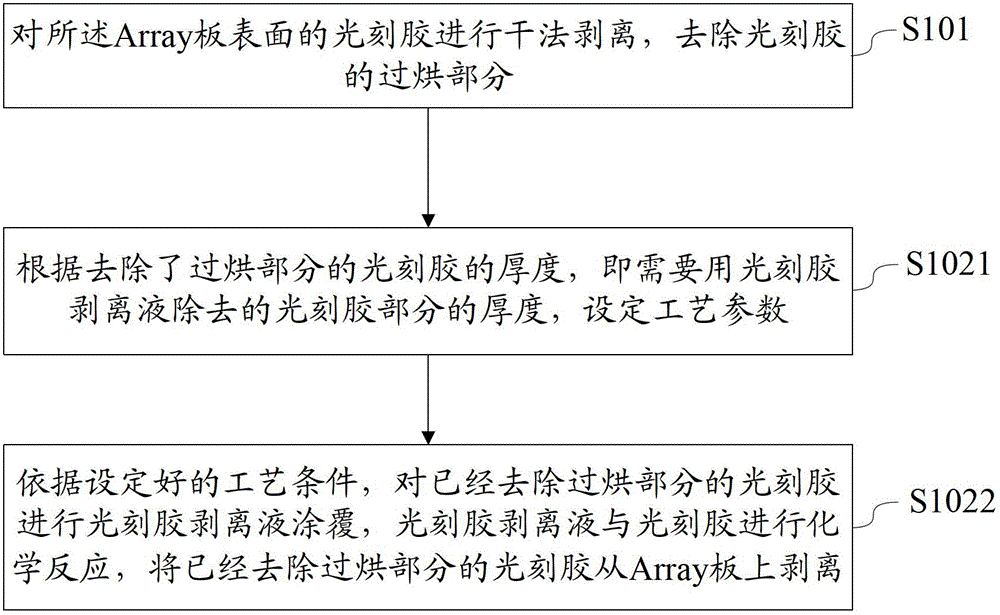

Method for stripping photoresist on Array plate

The application discloses a method for stripping a photoresist on an Array plate, which is used for stripping and repairing the photoresist on the Array plate. The method comprises the steps of conducting dry-method stripping on the photoresist on the surface of the Array plate, and removing the over-baking part of the photoresist; coating photoresist stripper on the photoresist with the removed over-baked part, and carrying out a reaction on the photoresist stripper and the photoresist with the removed over-baked part, and stripping the photoresist with the removed over-baked part from the Array plate. The method for stripping the photoresist on the Array plate provided by the application is used for stripping and repairing the photoresist on the Array plate, the photoresist is subjected to the dry-method stripping, an extremely thin layer of over-baked photoresist in the post-baking process can be removed, then the residual photoresist is stripped by utilizing the photoresist stripping liquid, and then the photoresist on the Array plate can be stripped thoroughly.

Owner:TRULY SEMICON

A kind of preparation method of tungsten disulfide nanosheet

ActiveCN108285173BStripped thoroughlyOptimizing Process ParametersMaterial nanotechnologyPhysical/chemical process catalystsFiltrationStrong acids

The invention provides a method for preparing tungsten disulfide nanosheets. The steps include: (1) mixing and stirring tungsten disulfide and strong acid, fully infiltrating them, and then adding ferrate or metal peroxide to react; (2) reacting The reactants obtained are slowly added dropwise to deionized water for dilution; (3) the diluted liquid is ultrasonically treated in an ultrasonic dispersing device; (4) the dispersed liquid is allowed to stand to remove the precipitate that has not been peeled off or Tungsten disulfide with low peeling degree; (5) The upper liquid after standing is subjected to suction filtration, and the obtained material is first washed with hydrochloric acid, and then washed with deionized water until neutral; (6) Finally, the obtained product is dried Process to obtain tungsten disulfide nanosheets. The method of the present invention prepares tungsten disulfide nanosheets through the reaction of strong acid and ferrate or metal peroxide and ultrasonic peeling, which is safe, stable, pollution-free, easy to obtain raw materials, easy to operate, simple equipment, high yield, and high product quality. good.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com