Liquor used for online cleaning of dry quenching condenser, preparation method and method for online cleaning

A technology for condenser and dry quenching, which is applied in the field of condenser on-line cleaning and on-line cleaning, can solve the problems such as the ineffective cleaning effect of the condenser cleaning liquid and the inconvenient on-line cleaning of the condenser, so as to shorten the cleaning time. Time, low toxicity, high water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

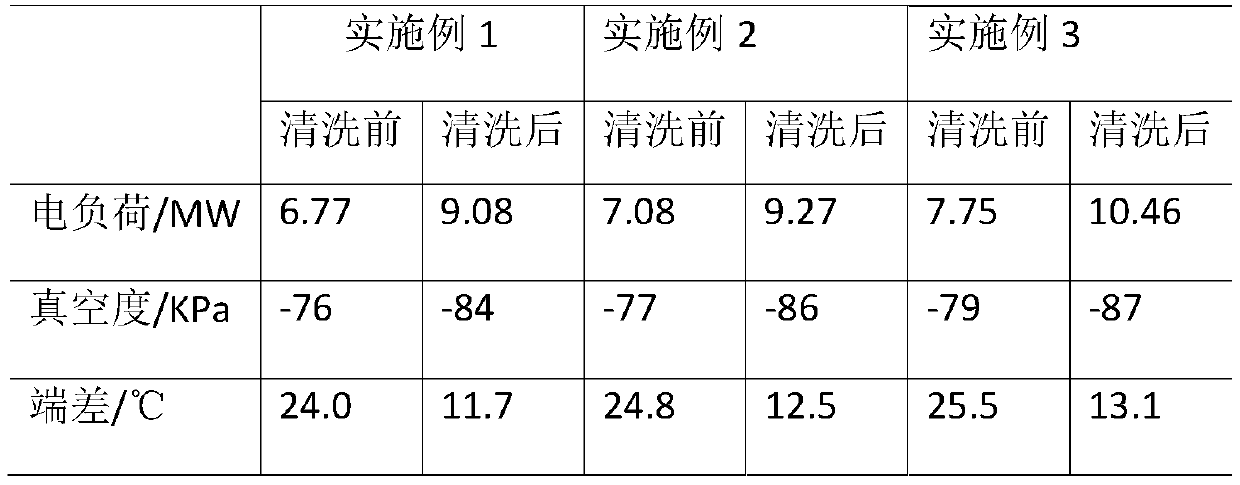

Embodiment 1

[0028] The medicinal solution for on-line cleaning of CDQ condensers in this embodiment includes: in parts by weight, 40 parts of mixed acid, 10 parts of corrosion inhibitor, 10 parts of penetrant, 10 parts of defoamer, 5 parts of chelating agent 30 parts of water and 30 parts;

[0029] Wherein, the mixed acid includes: sulfuric acid, sulfamic acid and 2-carboxyethyl phosphoric acid, and their respective mass ratios are 1:0.8:0.6;

[0030] The chelating agent includes: hydroxyethylthiosuccinic acid and diethyltriaminepentaacetic acid, and their respective mass ratios are 1:0.1;

[0031] The penetrating agent is: sodium succinate sulfonate; the defoaming agent is polyoxyethylene octylphenol ether;

[0032] The corrosion inhibitors include: urotropine, tolyltriazole, ammonium thiocyanate and 1,3-dithiosemicarbazide, and their respective mass ratios are 1:0.5:0.75:0.5.

[0033] The preparation method of the medicinal solution for online cleaning of the coke dry quenching conden...

Embodiment 2

[0036] The medicinal solution for on-line cleaning of CDQ condensers in this embodiment includes: in parts by weight, 50 parts of mixed acid, 15 parts of corrosion inhibitor, 13 parts of penetrating agent, 11 parts of defoamer, 6 parts of chelating agent parts and 35 parts of water;

[0037] Wherein, the mixed acid includes: sulfuric acid, sulfamic acid and 2-carboxyethyl phosphoric acid, and their respective mass ratios are 1:0.85:0.65;

[0038] The chelating agent includes: hydroxyethylthiosuccinic acid and diethyltriaminepentaacetic acid, and their respective mass ratios are 1:0.15;

[0039] The penetrating agent is: sodium succinate sulfonate; the defoaming agent is polyoxyethylene octylphenol ether;

[0040] The corrosion inhibitors include: urotropine, tolyltriazole, ammonium thiocyanate and 1,3-dithiosemicarbazide, and their respective mass ratios are 1:0.6:0.8:0.6.

[0041] The preparation method of the medicinal solution for online cleaning of the coke dry quenching...

Embodiment 3

[0044]The medicinal solution for on-line cleaning of CDQ condensers in this embodiment includes: in parts by weight, 55 parts of mixed acid, 17 parts of corrosion inhibitor, 15 parts of penetrating agent, 12 parts of defoamer, 7 parts of chelating agent 40 parts and 40 parts of water;

[0045] Wherein, the mixed acid includes: sulfuric acid, sulfamic acid and 2-carboxyethyl phosphoric acid, and their respective mass ratios are 1:0.9:0.7;

[0046] The chelating agent includes: hydroxyethylthiosuccinic acid and diethyltriaminepentaacetic acid, and their respective mass ratios are 1:0.2;

[0047] The penetrating agent is: sodium succinate sulfonate; the defoaming agent is polyoxyethylene octylphenol ether;

[0048] The corrosion inhibitors include: urotropine, tolyltriazole, ammonium thiocyanate and 1,3-dithiosemicarbazide, and their respective mass ratios are 1:0.65:0.85:0.7.

[0049] The preparation method of the medicinal solution for online cleaning of the coke dry quenchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com