Preparation method and electrochemical performance test method of anode material graphene

A negative electrode material, graphene technology, applied in the field of negative electrode material graphene preparation, can solve the problems of unstable molecular structure, poor charge and discharge efficiency, poor dispersion effect, etc., to achieve complete peeling, high capacity retention rate, and large layer spacing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0034] The application principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

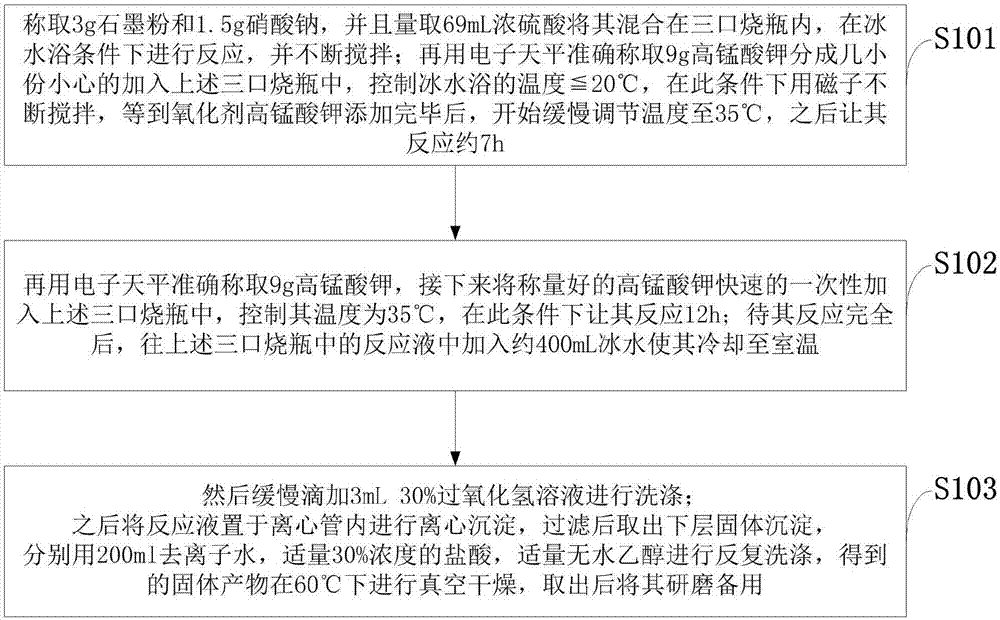

[0035] like figure 1 As shown, the preparation method of the negative electrode material graphene provided by the embodiment of the present invention comprises the following steps:

[0036] S101: Weigh 3g of graphite powder and 1.5g of sodium nitrate, and measure 69mL of concentrated sulfuric acid, mix them in a three-necked flask, react in an ice-water bath, and keep stirring; then accurately weigh 9g of permanganate with an electronic balance Potassium is divided into several small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com