Patents

Literature

33results about How to "Stripped completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing oxidized graphene

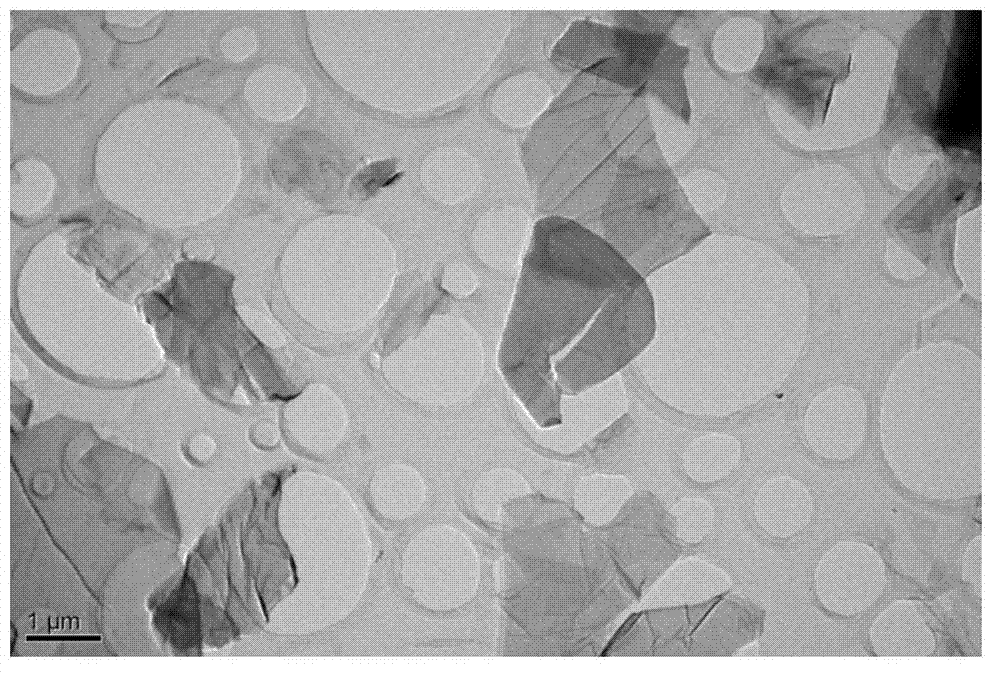

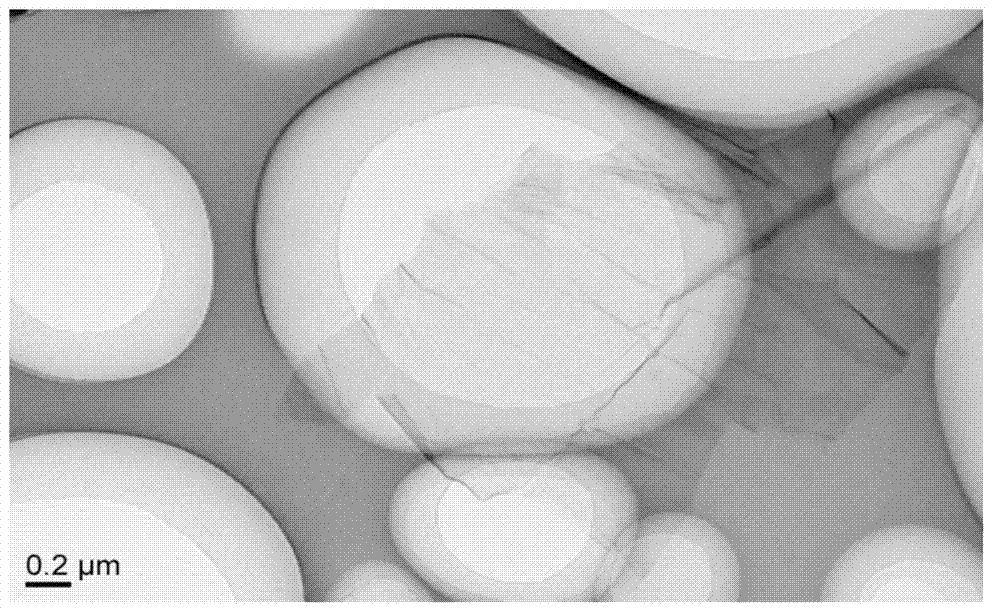

The invention belongs to a graphene preparation technology and relates to an improvement on an oxidized graphene preparation method. Preparation steps are as follows: preparing oxidized graphite; preparing an oxidized graphite aqueous solution; freezing; unfreezing; and drying. The invention provides a method for preparing the oxidized graphene through cold expansion stripping, which avoids environment pollution, is beneficial to environmental protection, has a simple process, is complete in oxidized graphite stripping, cause less damage on graphite sheets and is convenient for mass production.

Owner:北京石墨烯技术研究院有限公司

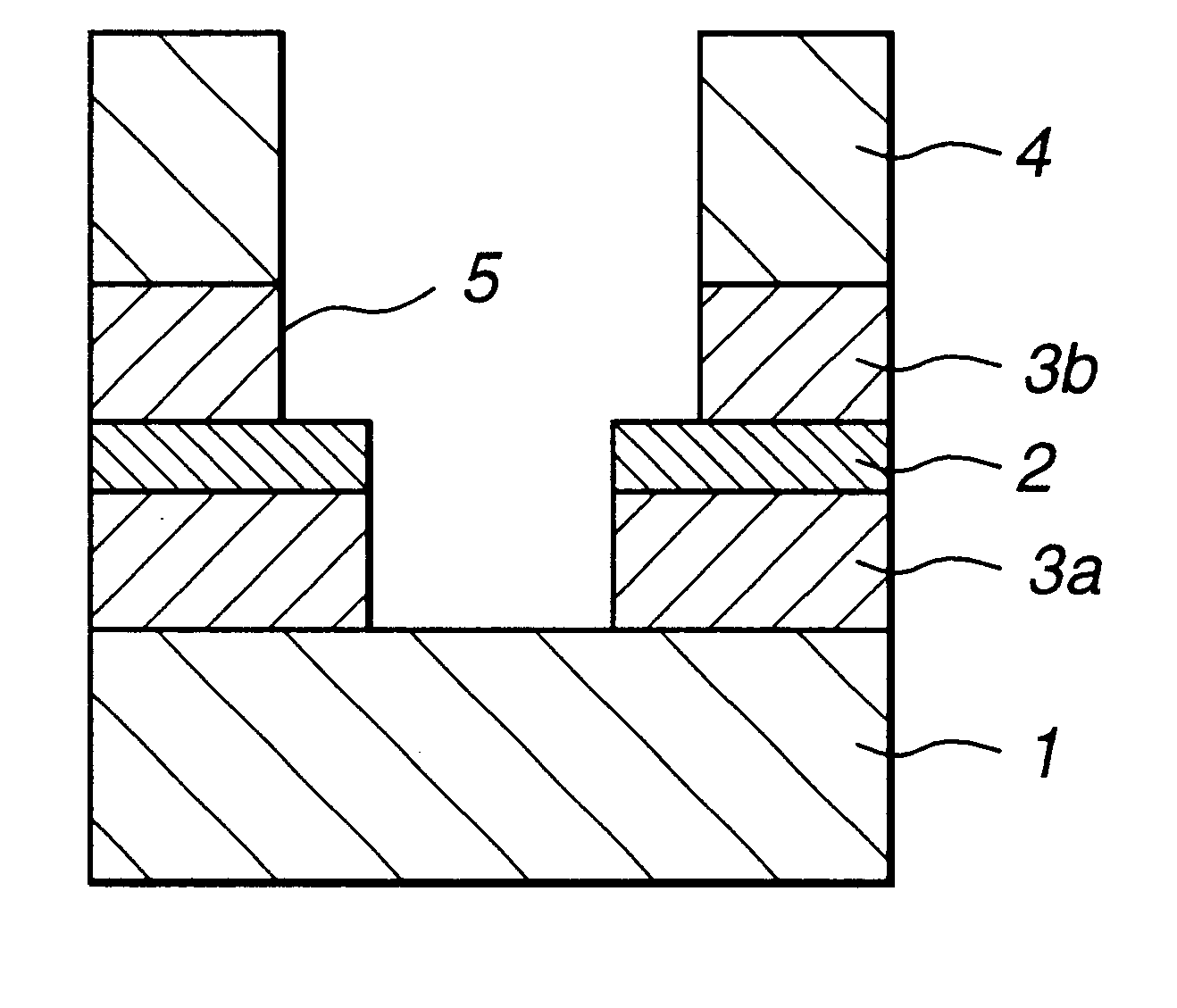

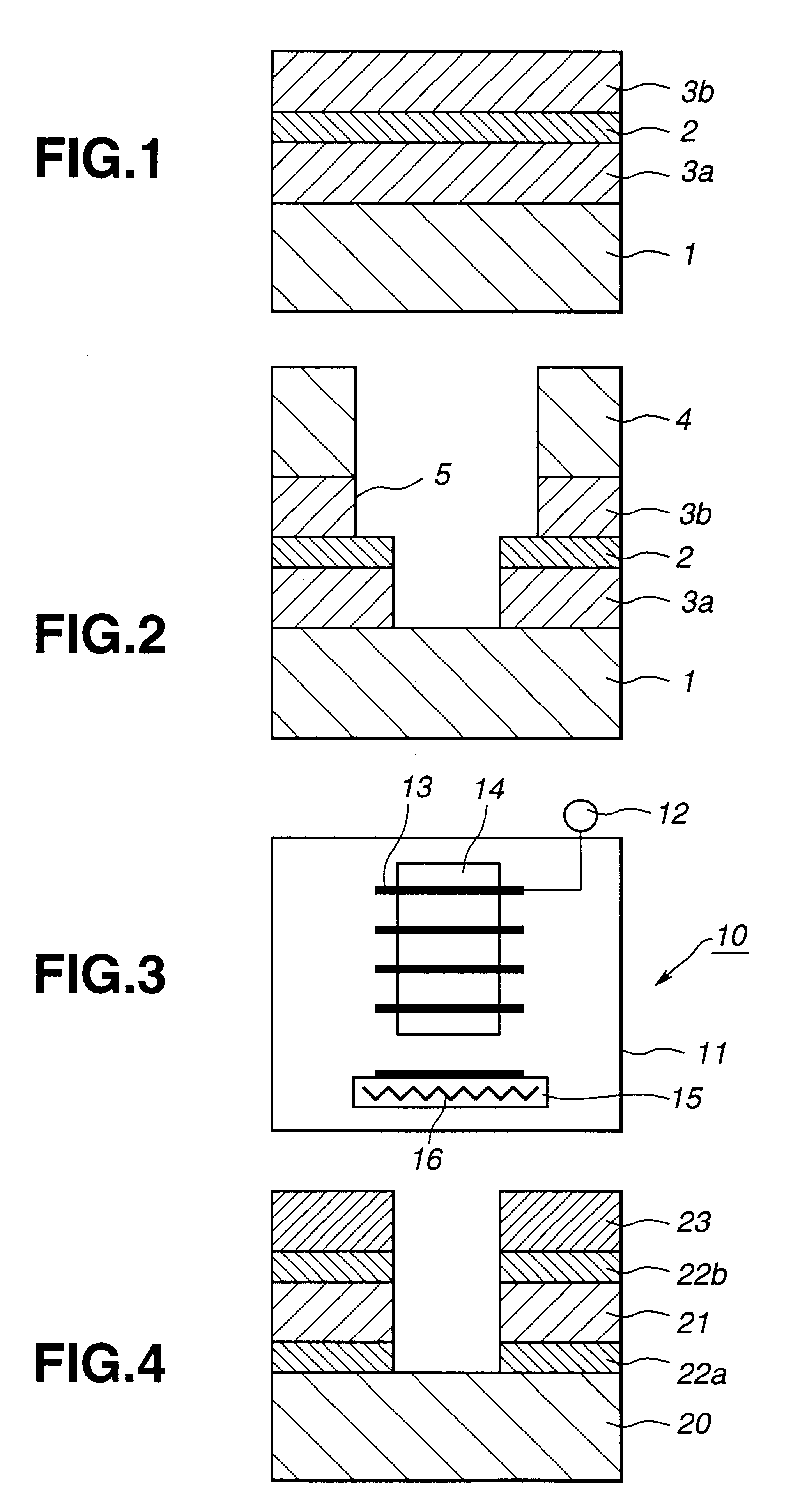

Method for stripping organic based film

InactiveUS6352937B1Reduced responseEfficient responseDecorative surface effectsSemiconductor/solid-state device manufacturingOrganic filmOrganic base

There is provided a method used for processing an organic low dielectric constant insulating film to a desired shape for enabling facilitated stripping of an organic film formed on top of the organic low dielectric constant insulating film. Specifically, there is provided a method for stripping an organic film formed on a layered unit having at least an organic low dielectric constant insulating film. This method includes generating radicals in a gas mainly composed of fluorine-based gas, and stripping the organic film by the generated radicals.

Owner:SONY CORP +1

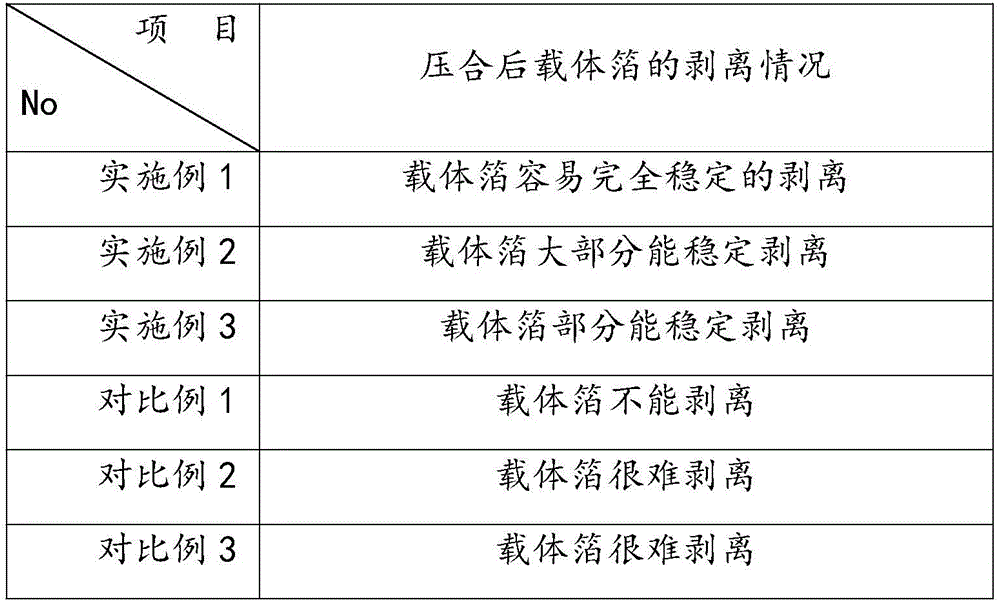

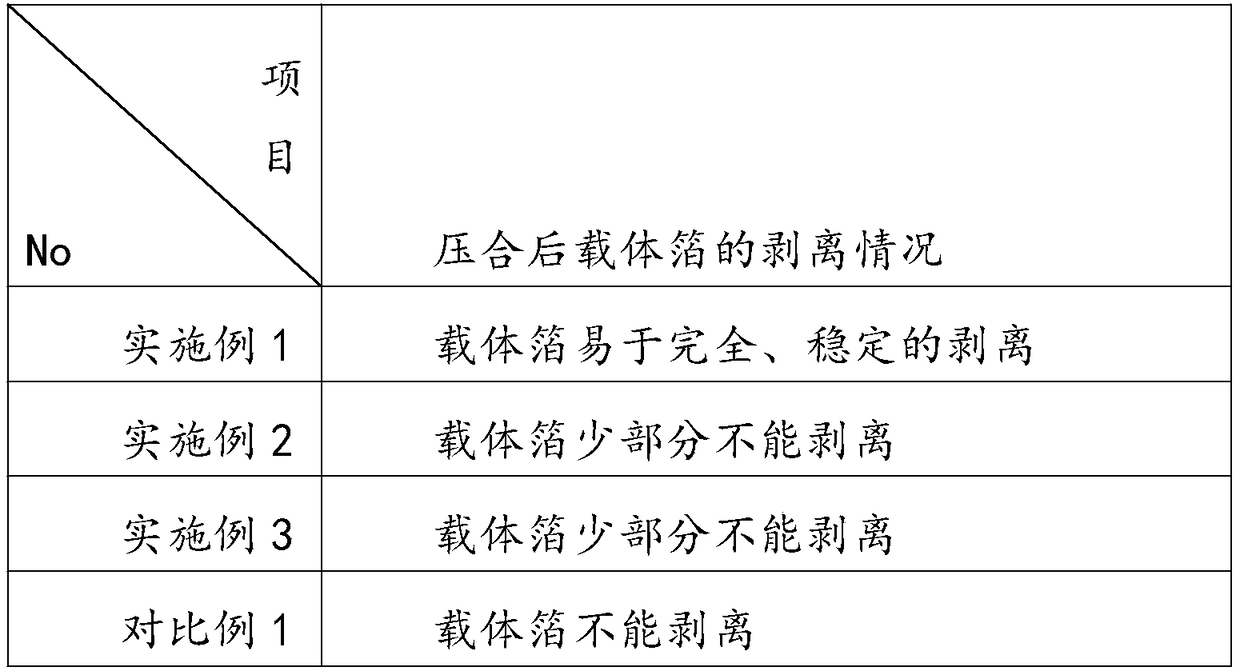

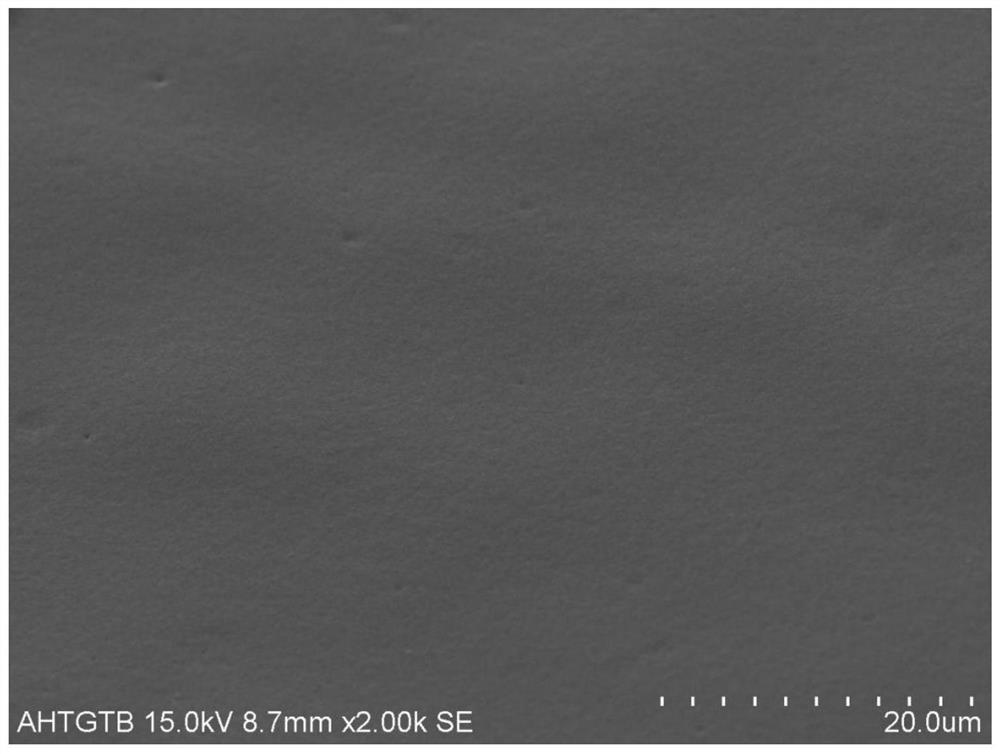

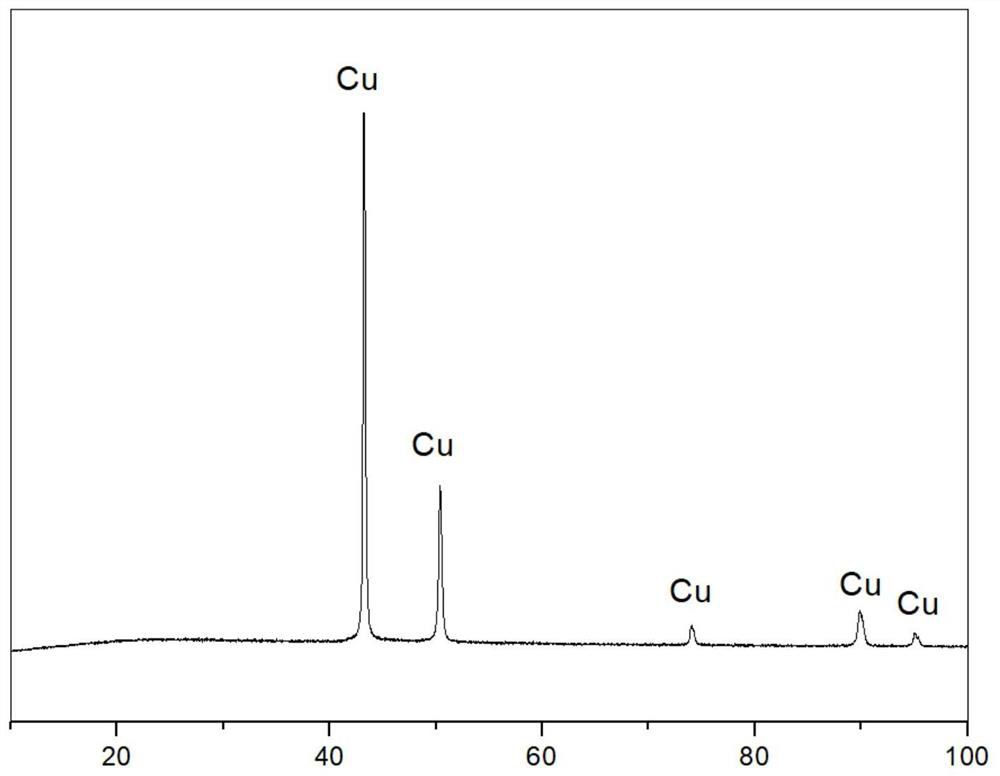

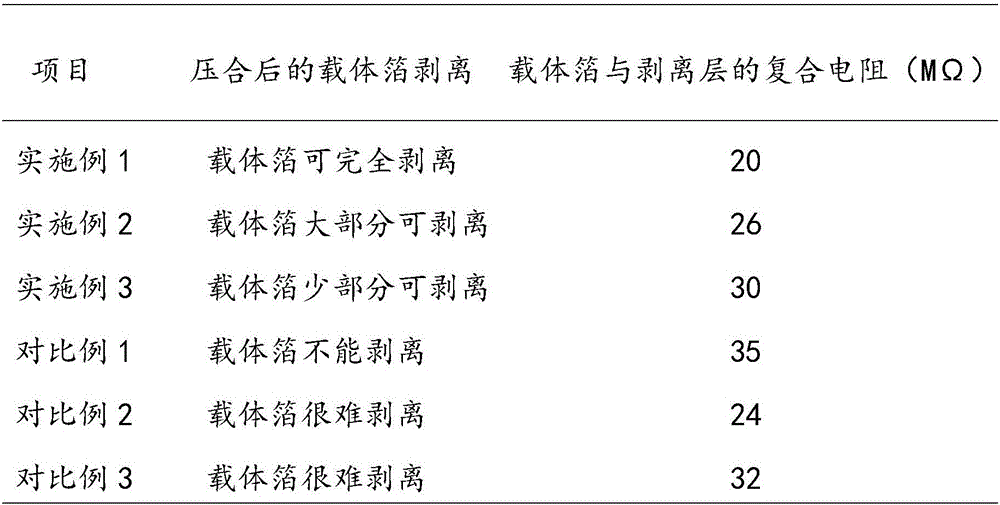

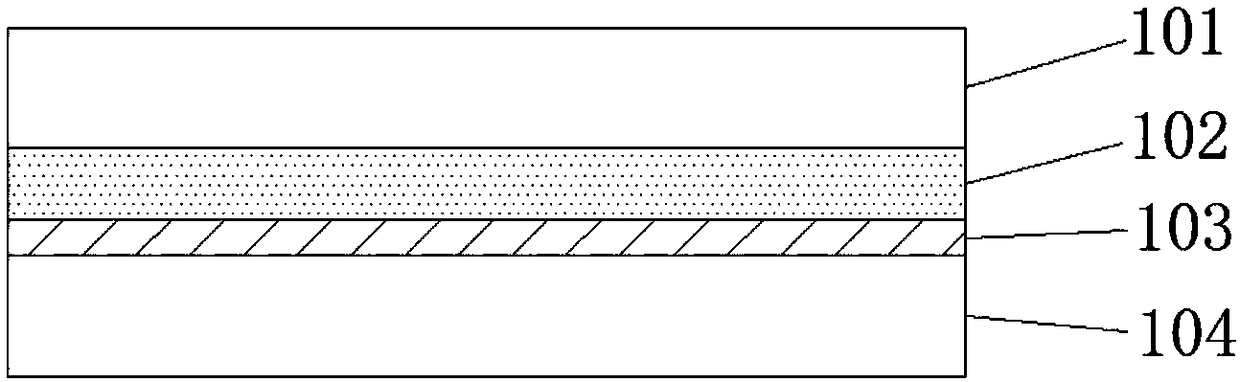

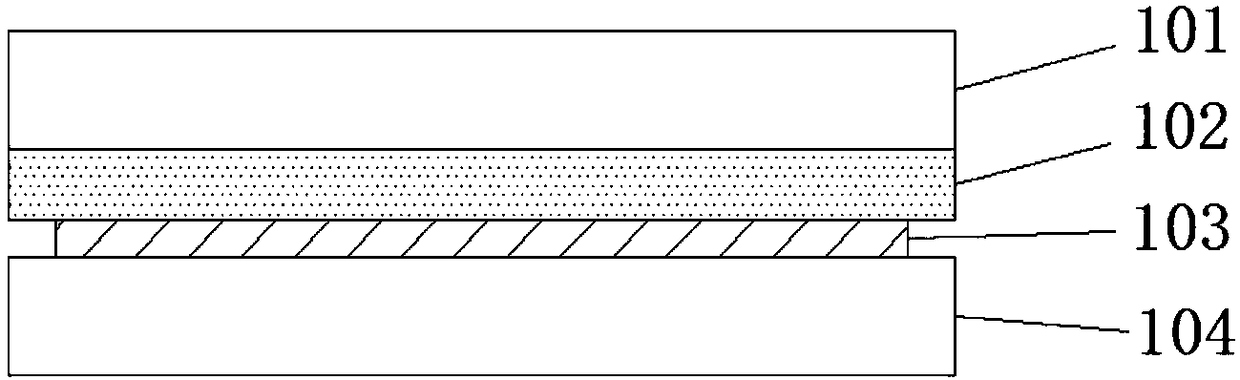

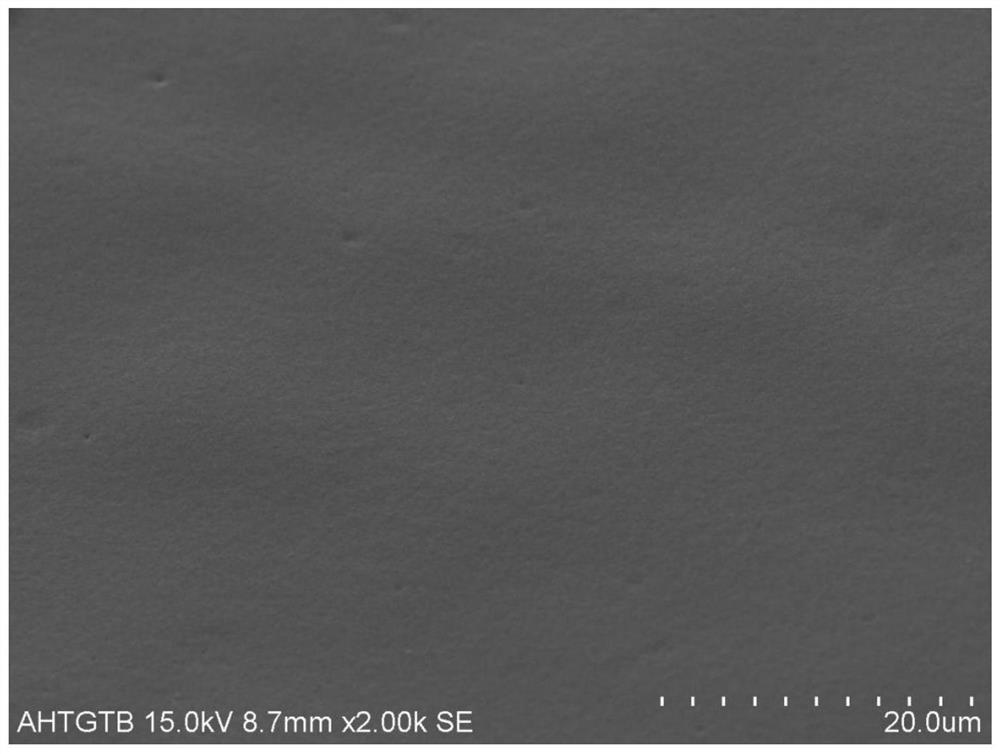

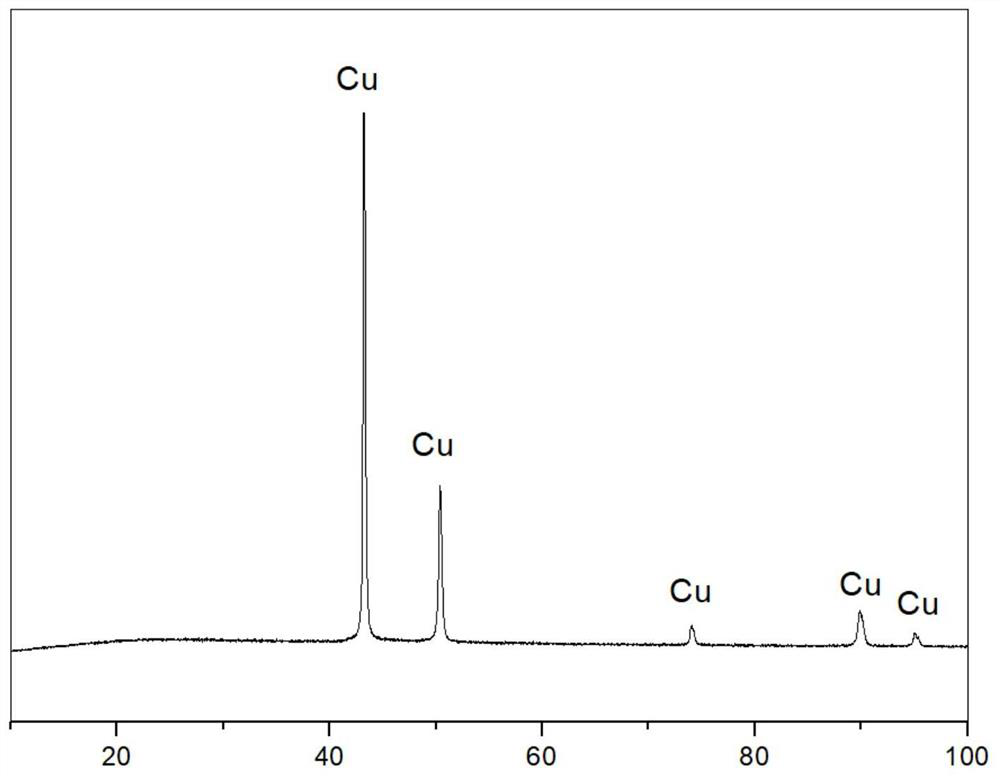

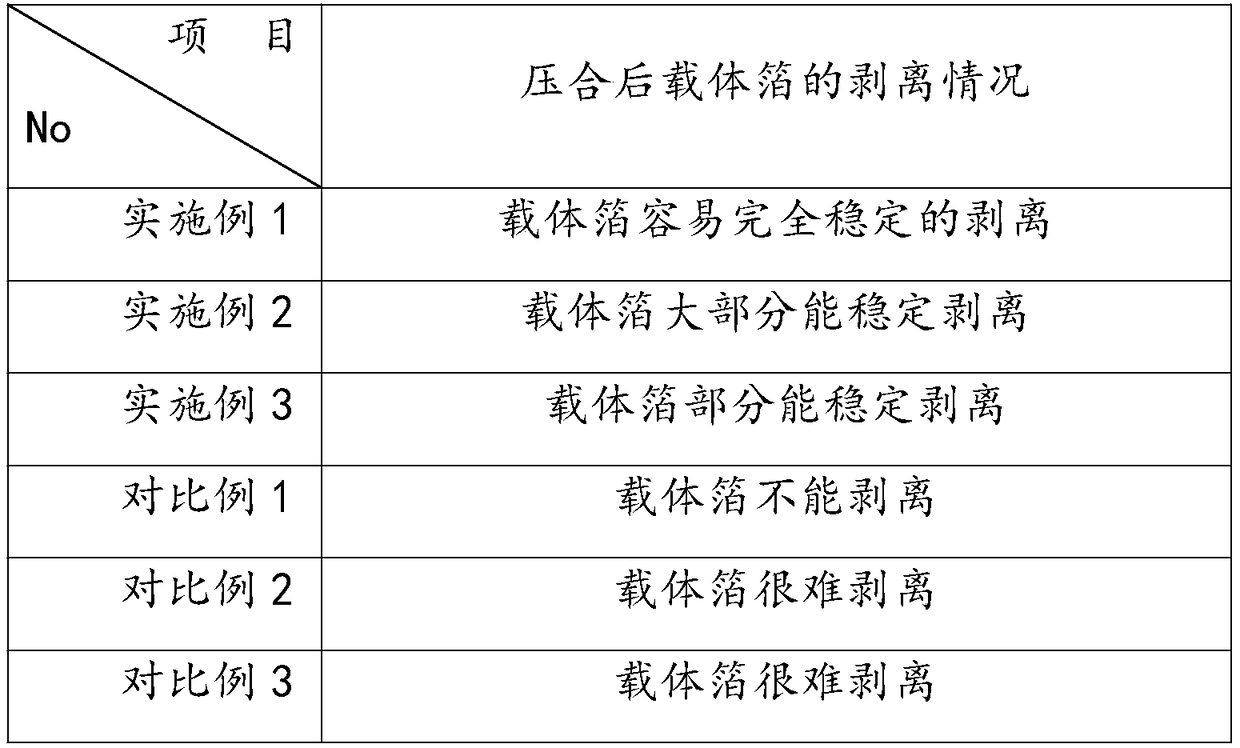

Preparing method of ultra-thin carrier copper foil capable of being stably stripped

The invention relates to a preparing method of ultra-thin carrier copper foil capable of being stably stripped. The method comprises the specific steps: firstly, a plating solution is prepared, namely, a complexing agent potassium pyrophosphate, zinc sulfate, an addition agent A and an addition agent B are dissolved in water, mixing is carried out after clarification, and the pH value of the solution is adjusted; secondly, the carrier foil is put into the plating solution in the first step, a novel nano composite zinc coating is electroplated and serves as a stripping layer, and extremely-thin electrolysis copper foil ranging from 2 micrometers to 6 micrometers is electroplated on the stripping layer, and is called as the ultra-thin carrier copper foil. After the ultra-thin carrier copper foil is cured on an insulation substrate after high-temperature pressing, through the mechanical method, the carrier foil can be completely stripped. The stripping layer prepared through the method is extremely thin and uniform, the carrier foil is easy to completely and stably strip, and the good application prospect is achieved.

Owner:SHANDONG JINBAO ELECTRONICS

Method for recovering metal elements from waste and old ternary lithium-ion battery

ActiveCN108281730AEfficient removalEfficient decompositionWaste accumulators reclaimingBattery recyclingRecovery methodOrganic acid

The invention relates to a method for recovering metal elements from a waste and old ternary lithium-ion battery, belongs to the technical field of recovery of waste and old batteries, and aims at solving the problem that the conventional method is low in recovery rate of metal elements. The method comprises the following steps: disassembling the waste and old ternary lithium-ion battery, and collecting the powder of positive electrode materials of the battery; preprocessing the powder of the positive electrode materials with a mixed solution containing biogenic organic acid and bioflavonoid;filtering, and collecting the filtrate; selectively depositing the collected filtrate; recovering at least one metal element. According to the method, the adhesive component in the positive electrodematerial can be effectively removed and decomposed, so that the metal elements can be effectively separated and dissolved out, thus the dissolving rate is effectively increased, and the subsequent recovery effect of the metal elements can be ensured.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD +1

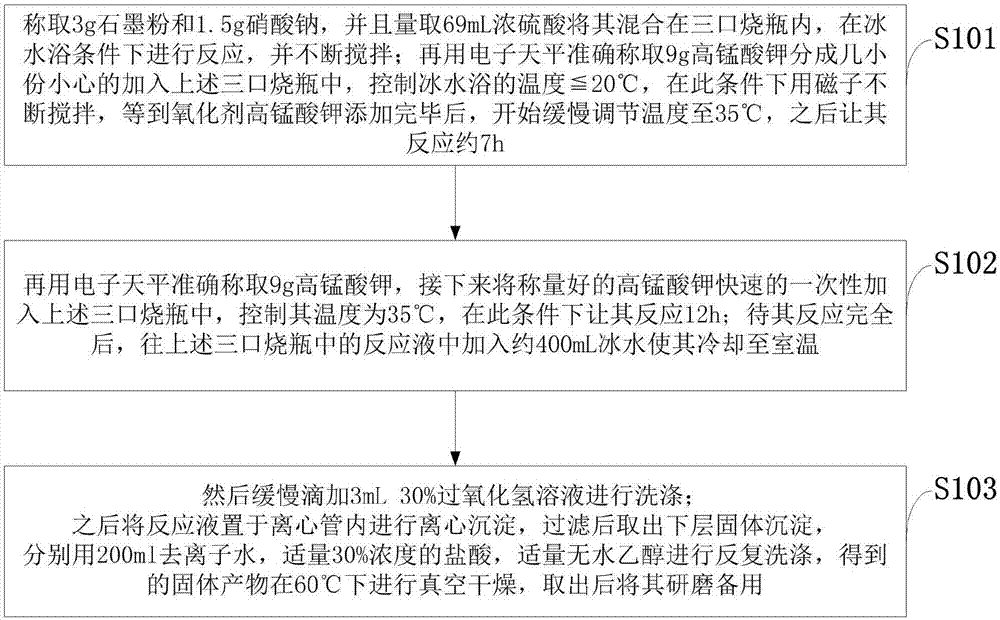

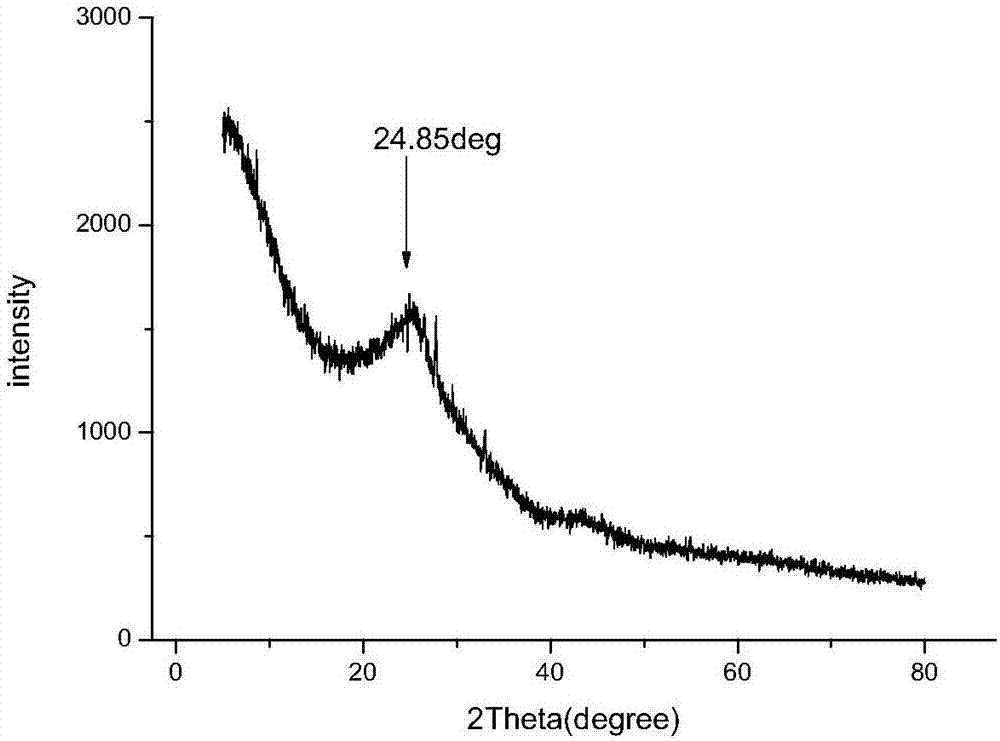

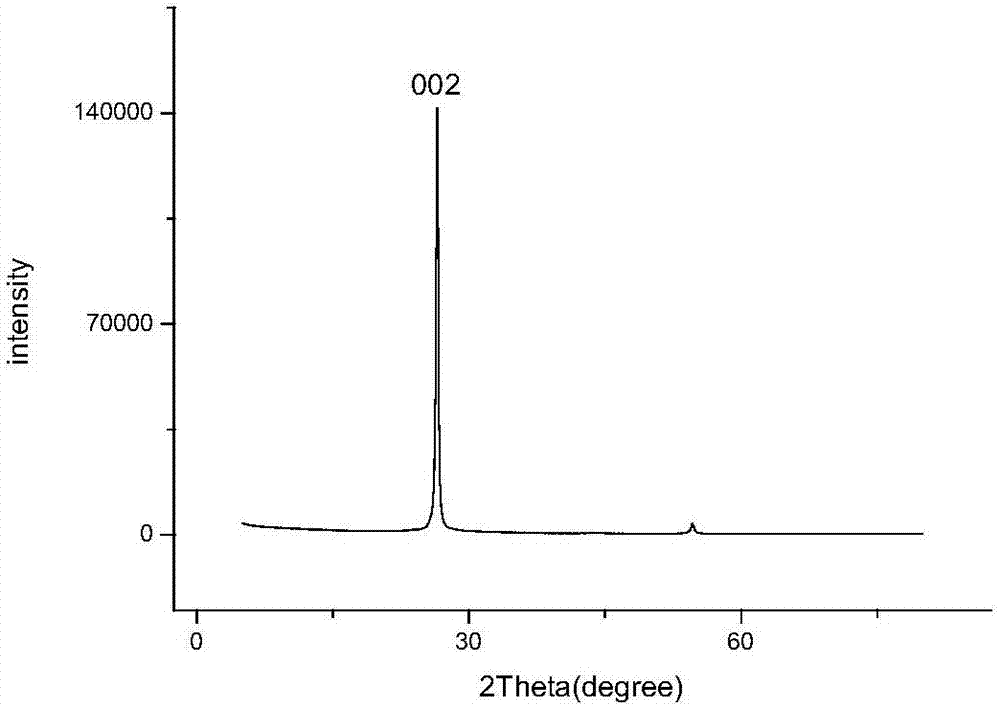

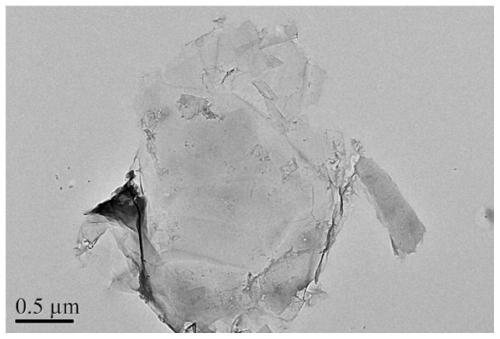

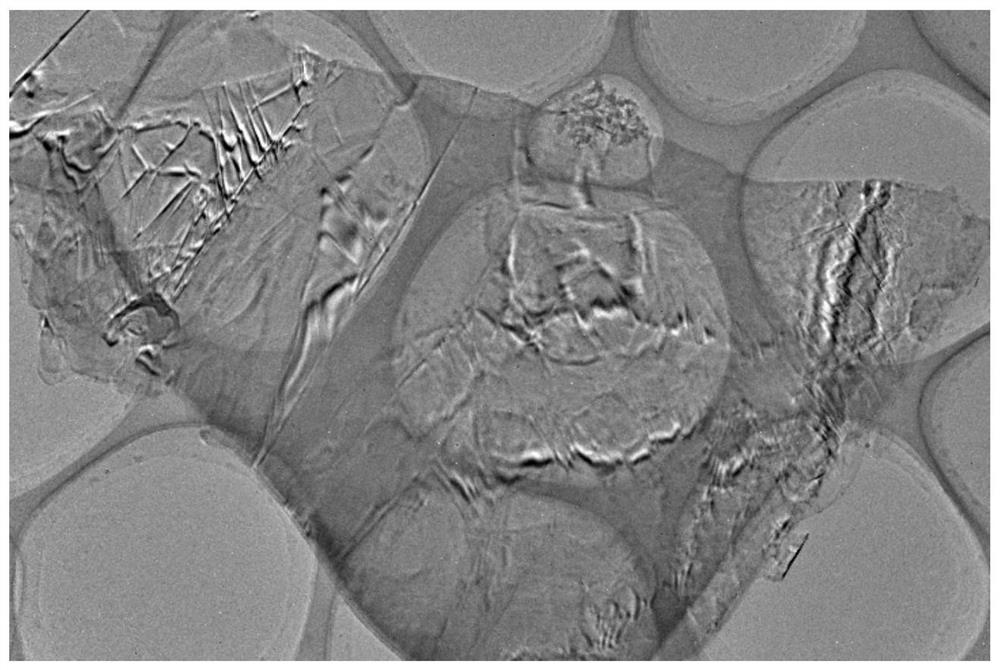

Preparation method and electrochemical performance test method of anode material graphene

InactiveCN106853965AFully oxidizedIncrease layer spacingCarbon compoundsCell electrodesWater bathsIce water

The invention discloses a preparation method and an electrochemical performance test method of an anode material graphene. The preparation method comprises the following steps: weighing a graphite powder and sodium nitrate; measuring out concentrated sulfuric acid, mixing the concentrated sulfuric acid in a three-mouth flask and reacting under the condition of a water bath; then weighing potassium permanganate, adding into the three-mouth flask and starting to adjust the temperature; adding the potassium permanganate into the three-mouth flask by two times and controlling the temperature; adding ice water and cooling a mixed solution to a room temperature; then dropwise adding 30 percent of hydrogen peroxide solution for washing; carrying out centrifugal precipitation, taking out lower-layer solid precipitation and repeatedly washing to obtain a solid product, carrying out vacuum drying, taking out the dried product, and grinding the product for later use. Graphene oxide disclosed by the invention is used as an anode material of a lithium battery, and discharged specific capacity of the graphene oxide at the temperature of 0.1DEG C is 403.4mAh / g. Furthermore, the graphene prepared by using a hydrothermal-solvent thermal reduction method is more stable in performance, the discharged specific capacity of the graphene at the temperature of 0.1DEG C is 782.8 mAh / g, and the capacity retention ratio is higher.

Owner:SHAOXING UNIVERSITY

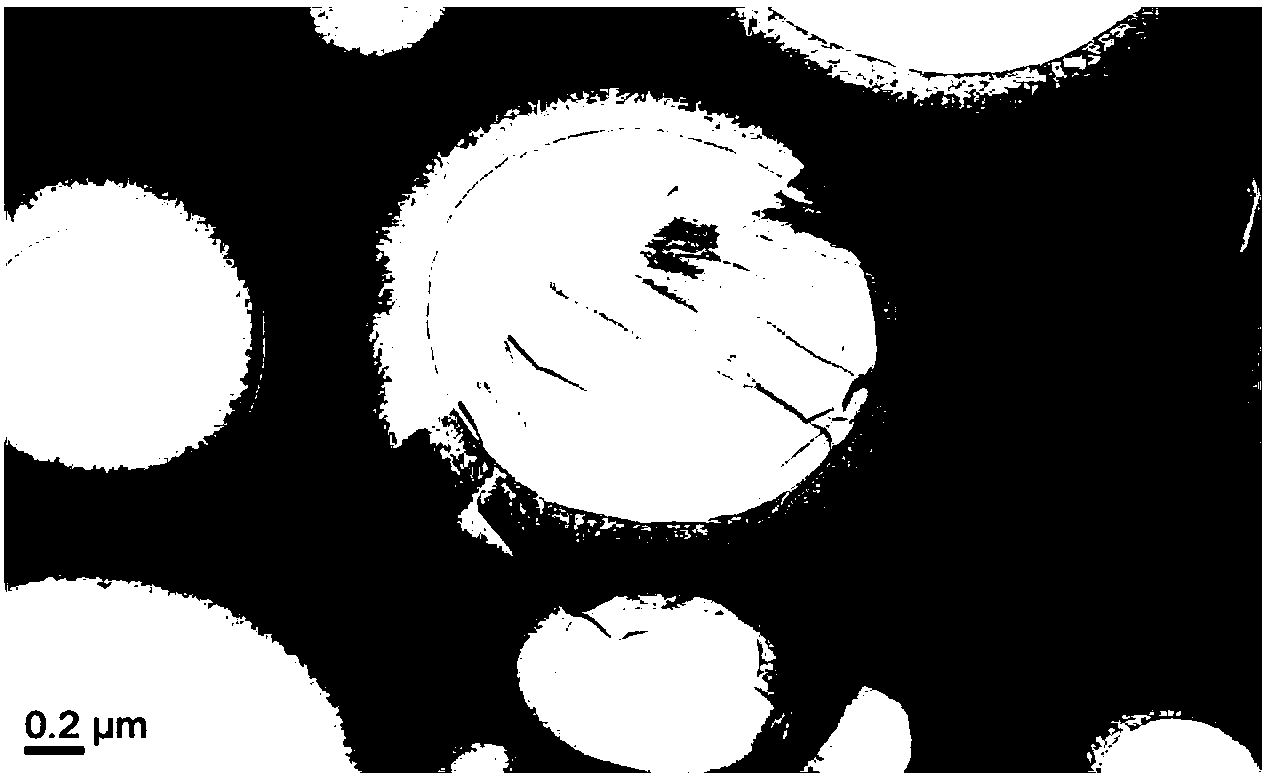

Plating solution for carrier copper foil stripping layer and preparation method of stripping layer

The invention relates to a plating solution for a carrier copper foil stripping layer and a preparation method of the stripping layer. The plating solution is prepared from components as follows: potassium bitartrate with the concentration of 20-60 g / L, zinc sulfate with the concentration of 8-16 g / L and an additive A with the concentration of 5-20 g / L and the pH of 3.0-5.0, wherein the additive Ais a mixture formed by mixing at least one of 3-(2,3-epoxy propoxy)propyl trimethoxy silane, 3-(2,3-epoxy propoxy)propyltriethoxysilane, 3-(2,3-epoxy propoxy)propyl methoxy dimethyldiethoxylsilane or3-(methylacryloyl oxy)propyl trimethoxy silane with at least one of potassium thiocyanate, monopotassium phosphate, sodium acetate or ammonium sulfate. The carrier copper foil stripping layer obtained with the adoption of the plating solution for the carrier copper foil stripping layer and the preparation method of the stripping layer is a novel nano composite zinc plating layer, is very thin anduniform and can completely and stably strip carrier foil off the pressed very thin copper foil.

Owner:胡旭日

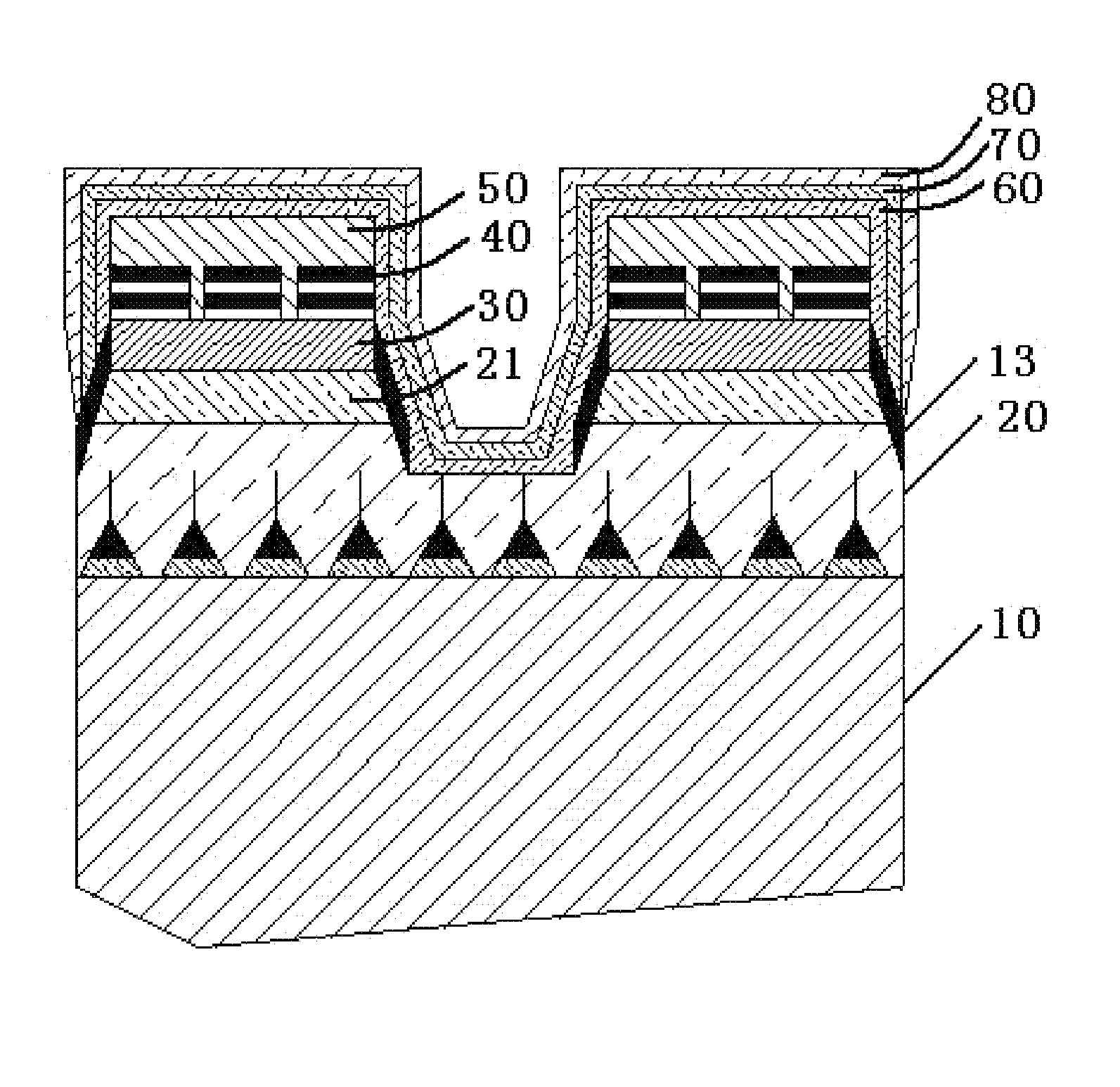

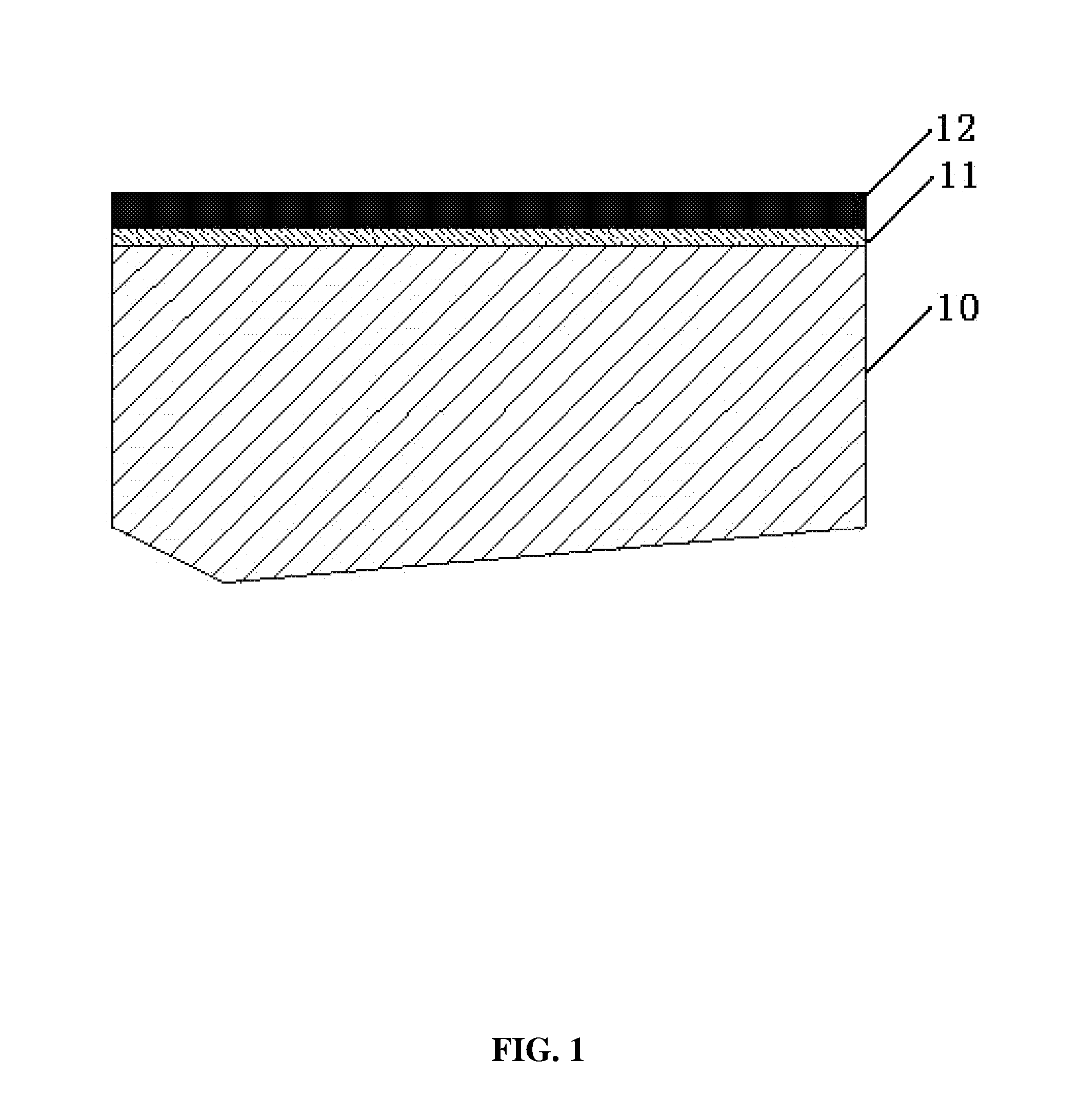

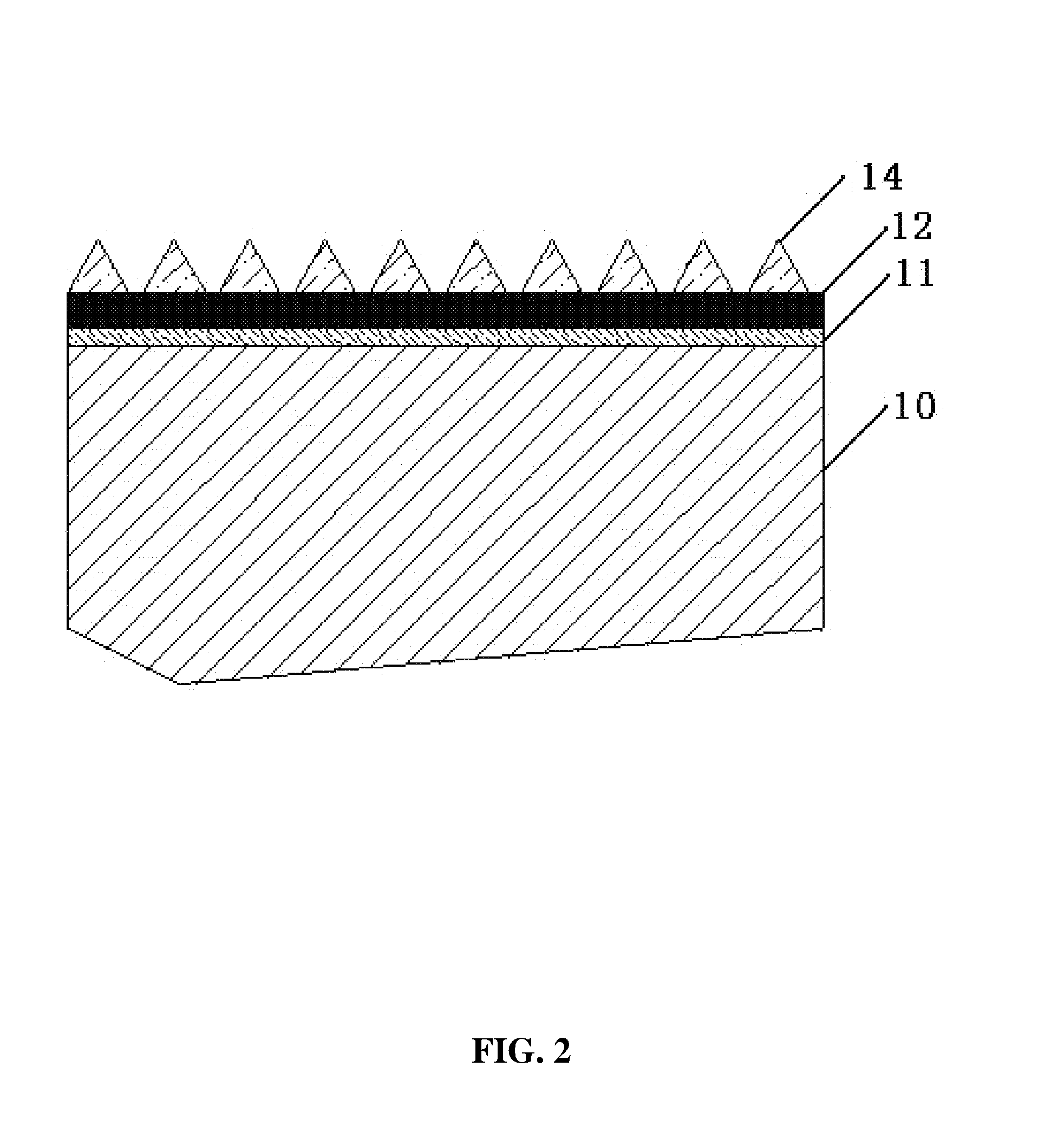

Light-emitting diode and method for preparing the same

ActiveUS20140145204A1Low damageGood performanceSolid-state devicesSemiconductor/solid-state device manufacturingElectrically conductiveMetal

A method for preparing a light-emitting diode having a vertical structure by stripping a GaN base epitaxial layer and a sapphire substrate by a wet process, the method including: a) preparing a graphical growth substrate; b) growing a GaN base light-emitting diode epitaxial layer on the graphical growth substrate, the GaN base light-emitting diode epitaxial layer from the bottom to the top successively including a N-type GaN layer and a P-type GaN layer; c) successively forming a transparent and electrically conductive film, an omni-directional reflection layer, an electrically conductive reflection layer, and a passive metal protection layer from the bottom to the top on the GaN base light-emitting diode epitaxial layer; and d) removing the first layer of stable material with a high melting point of the growth substrate by dry etching, exposing the N-type GaN layer, and preparing an N electrode on the N-type GaN layer.

Owner:HC SEMITEK CORP

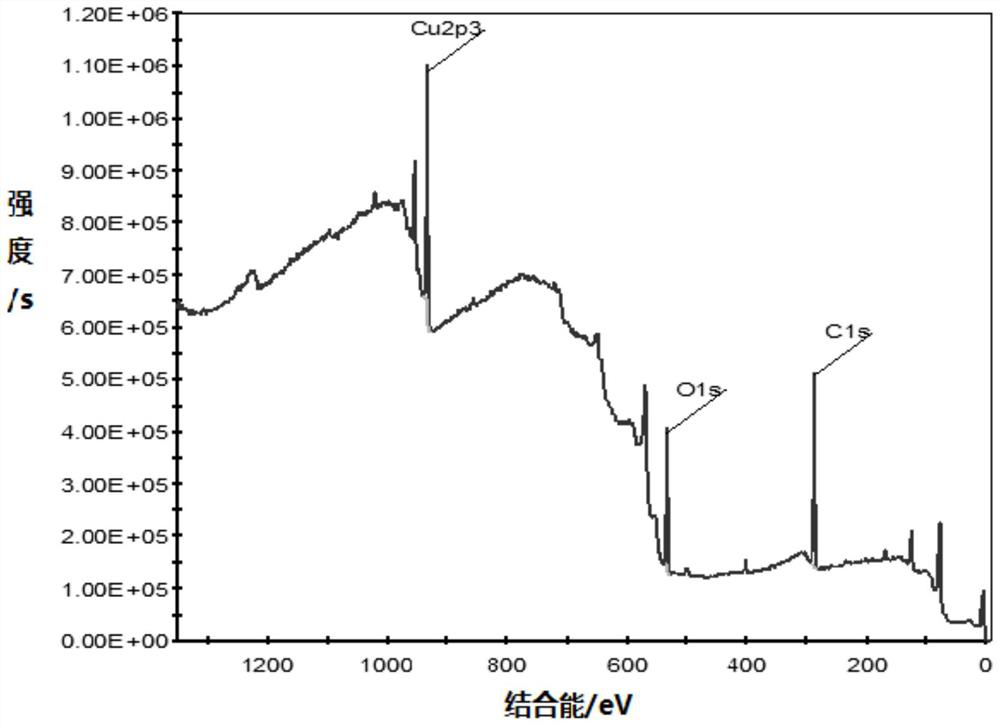

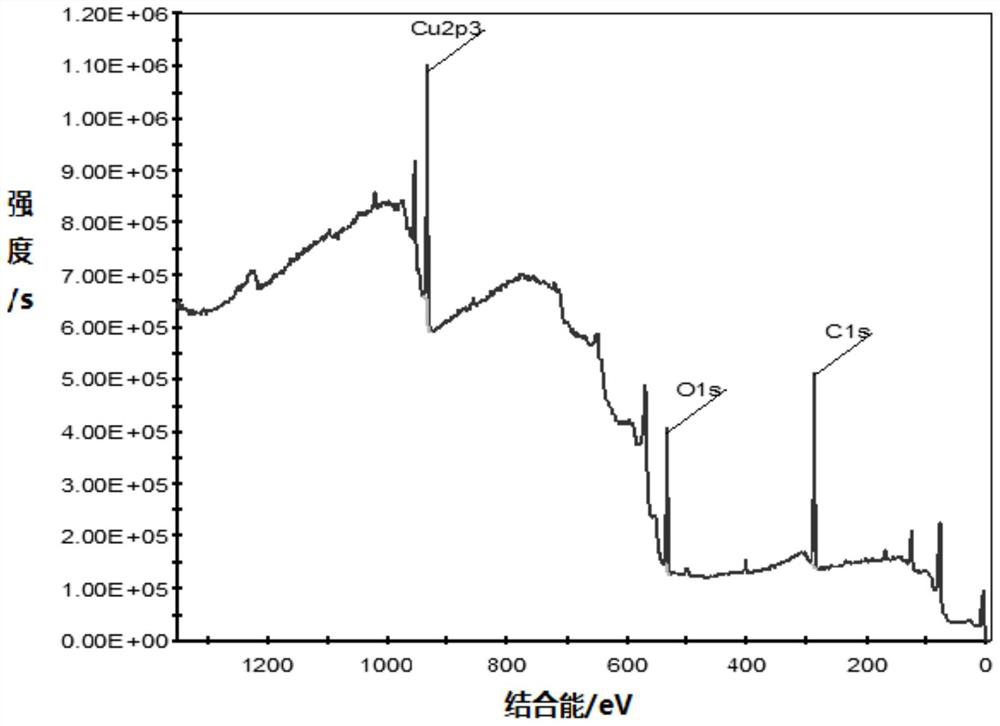

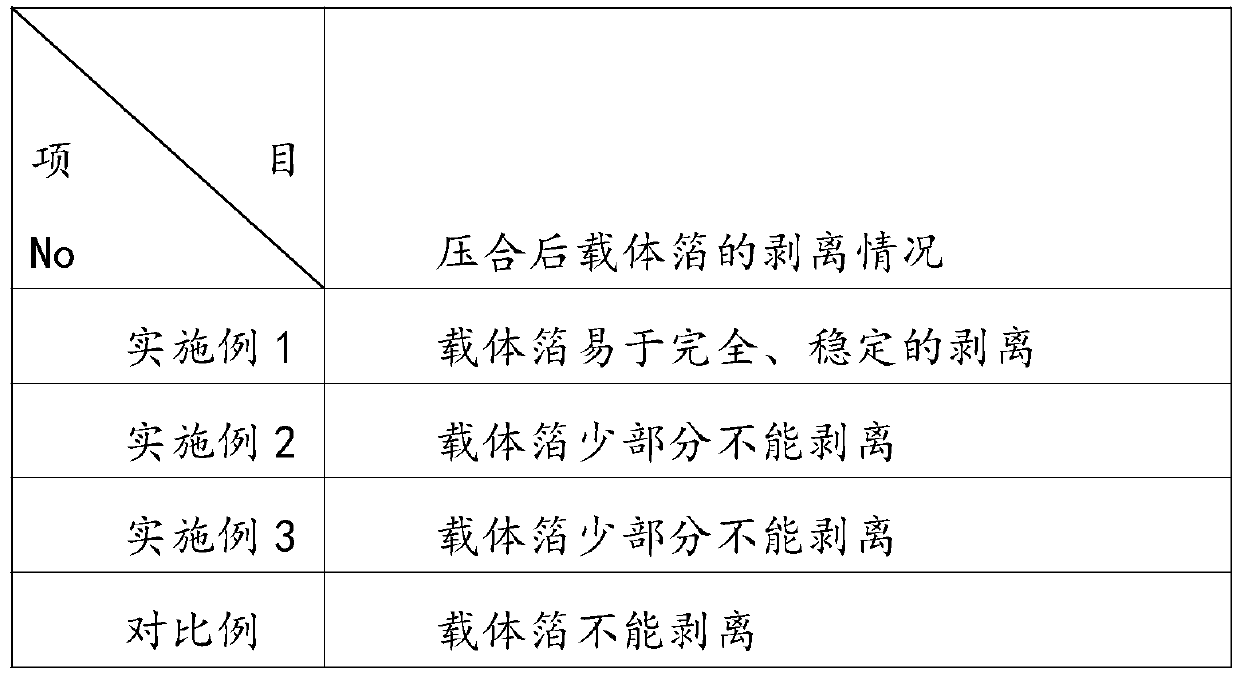

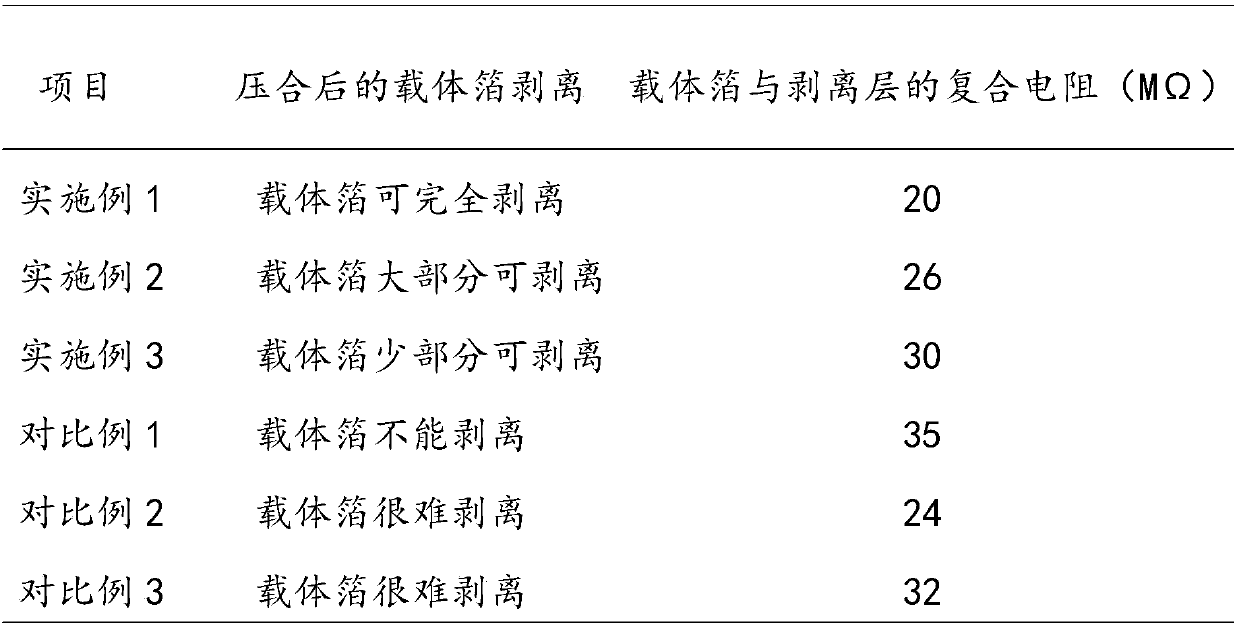

Preparation method of easy-to-peel ultra-thin carrier-attached copper foil with pure interface

ActiveCN112853408AUniform surfaceImprove performanceElectroforming processesPhysical chemistrySurface roughness

The invention relates to the technical field of electronic materials, in particular to a preparation method of an easy-to-peel ultra-thin carrier-attached copper foil with a pure interface. The carrier copper foil provided by the invention comprises a composite stripping layer containing an alloy layer and an organic layer, particularly, the alloy layer is obtained by electroplating an alloy liquid containing a complexing agent and at least one soluble sulfate, and the organic layer is obtained by coating organic liquid containing organic matters. Therefore, a composite stripping layer which is uniform in surface and stable in performance is formed on the upper surface of the copper foil, and the composite stripping layer has the characteristics of stable stripping performance and easy stripping after high-temperature pressing; meanwhile, the ultra-thin carrier-attached copper foil prepared by a specific method has the characteristics of easiness in stripping, fine crystal grains, compact structure, uniform thickness and pure interface, for example, the thickness of the ultra-thin copper foil is 2-6 [mu]m, the surface roughness is less than or equal to 2.5 [mu]m, and the stripping strength between the ultra-thin copper foil and the carrier copper foil is far lower than that between the ultra-thin copper foil and an insulating plate.

Owner:JIANGXI UNIV OF SCI & TECH +2

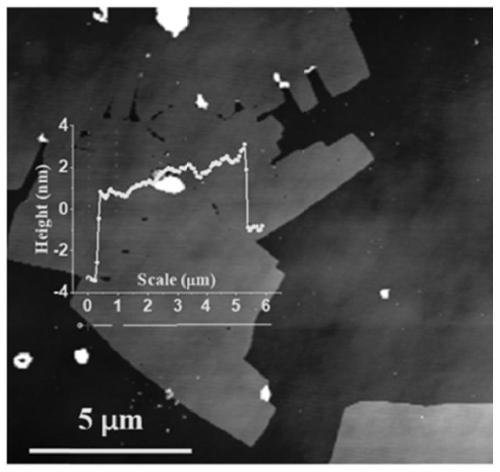

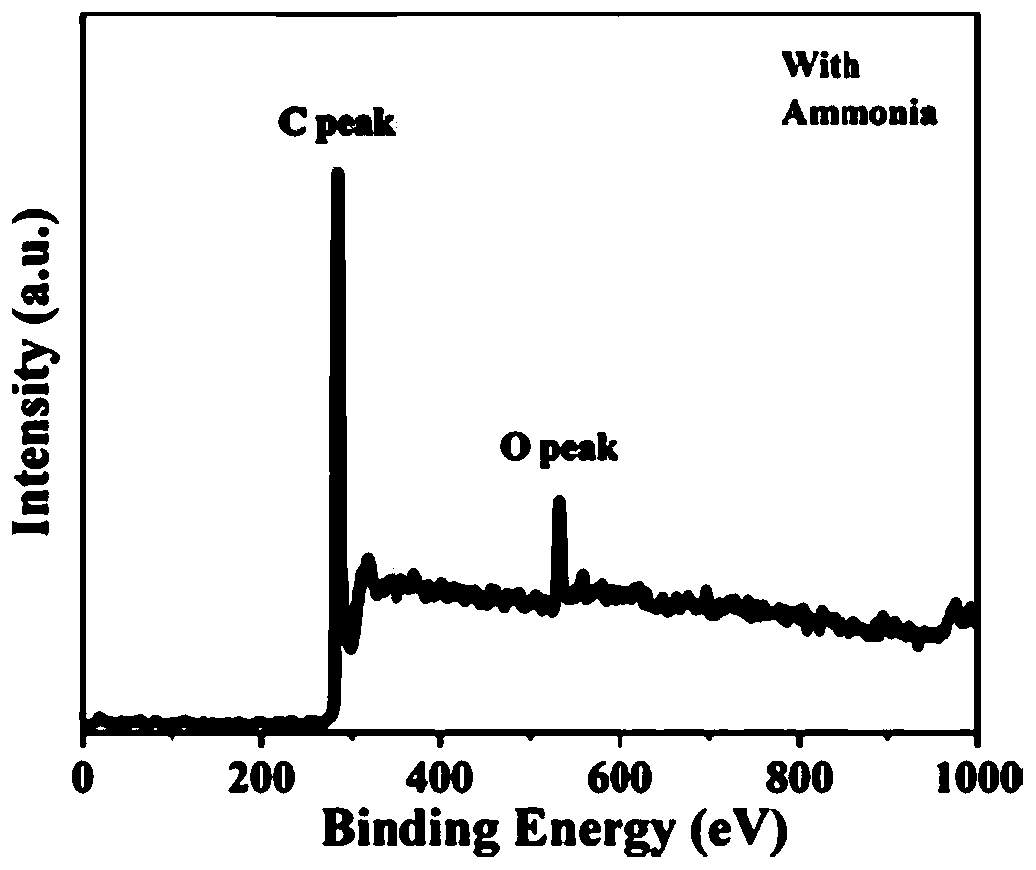

Method for preparing high-intrinsic-degree graphene by electrolysis

The invention belongs to the technical field of inorganic material preparation, and particularly relates to a preparation method of high-intrinsic-degree grapheme. The preparation method comprises thefollowing steps that a graphite material is prepared into a positive electrode; sulfate is prepared into an electrolyte, firstly the electrode is pretreated under the condition of an applied voltage,then the pH of a solution is adjusted to be alkaline by adding ammonia water, and electrolytic stripping of the graphite positive electrode is performed at a certain temperature; and an electrolyzedproduct is subjected to solid-liquid separation and drying to obtain the high-intrinsic-degree grapheme. Lower oxidation activity of a solvent to the graphite material can be ensured by controlling the pH value of the electrolyte, the reduction of the oxidation degree of the product grapheme is facilitated, and the improvement of the quality of the grapheme is further facilitated. The grapheme isprepared form conventional chemical raw materials, the raw materials are low in cost and easy to obtain, and industrialization is convenient.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD

Preparation method of ultrathin carrier copper foil

ActiveCN106757181AImprove conductivityEasy to operateElectroforming processesOrganic filmElectrolysis

The invention relates to a preparation method of ultrathin carrier copper foil. The preparation method specifically comprises the following steps that (1) a plating solution is prepared, specifically, a complexing agent sodium gluconate, potassium dichromate, an additive A and an additive B are dissolved in water correspondingly and mixed after being clarified, and the pH value of the solution is adjusted; (2) carrier foil is soaked into an organic solution of a silane coupling agent, and a layer of organic film is formed through adsorption; and (3) the carrier foil is placed into the plating solution in the step (1), a layer of novel nanoscale composite chrome plating layer is formed through electroplating to serve as a peeling layer, then ultrathin electrolytic copper foil which is 2-5 microns thick is electroplated on the peeling layer, and the ultrathin carrier copper foil is obtained. The ultrathin carrier copper foil is subjected to high-temperature pressing and cured on an insulating substrate, and then the carrier foil can be completely removed through peeling by means of a mechanical method. The peeling layer prepared through the method is ultrathin and uniform, the carrier foil can be peeled easily, completely and stably, and the preparation method has great application prospects.

Owner:SHANDONG JINBAO ELECTRONICS

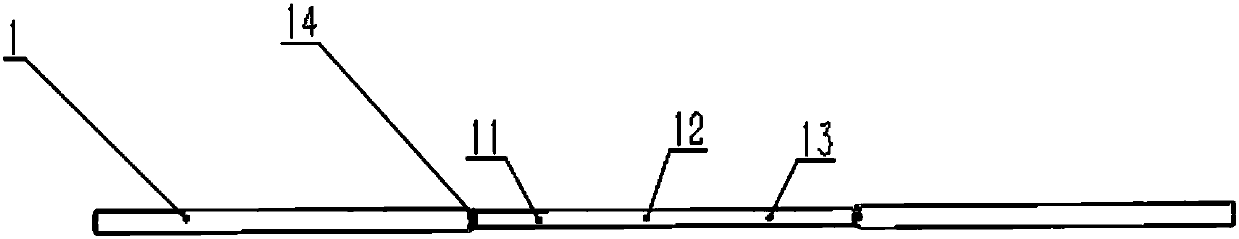

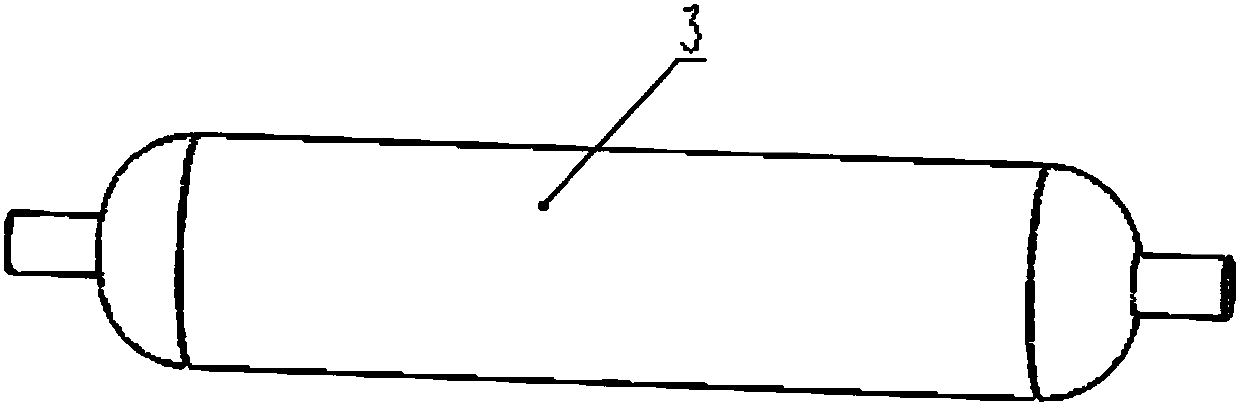

Double-clad fiber cladding light stripping heat radiation device based on chemical etching method

ActiveCN107681420AStripped completelyNo lossActive medium shape and constructionLaser cooling arrangementsFiberEtching

The present invention discloses a double-clad fiber cladding light stripping heat radiation device based on a chemical etching method. The device comprises a double-clad fiber, a heat conduction metalhousing and a quartz glass tube. A corrosion portion of a double-clad fiber is arranged at the center of the quartz glass tube and is fixed, and the heat conduction metal housing sleeves the outer wall of the quartz glass tube, and two ends of the heat conduction metal housing are fixed. The stripping degree of the double-clad fiber is increased by degrees, the stripping degree of a first sectionis 30%, the stripping degree of a second section is 50%, and the stripping degree of a third section is above 99%. The double-clad fiber cladding light stripping heat radiation device based on the chemical etching method performs subsection stripping of absorbed residual cladding light to achieve thorough stripping of the cladding light, temperature is uniformly distributed, a bearing power of the device can reach above 100% through adoption of water cooling, there is no loss for fiber core light, and therefore good output light beam quality is ensured.

Owner:NANJING UNIV OF SCI & TECH

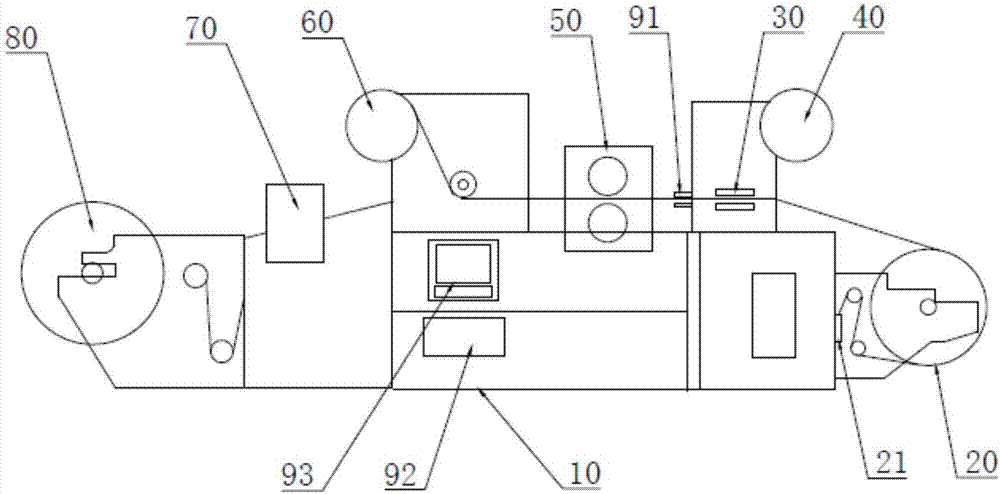

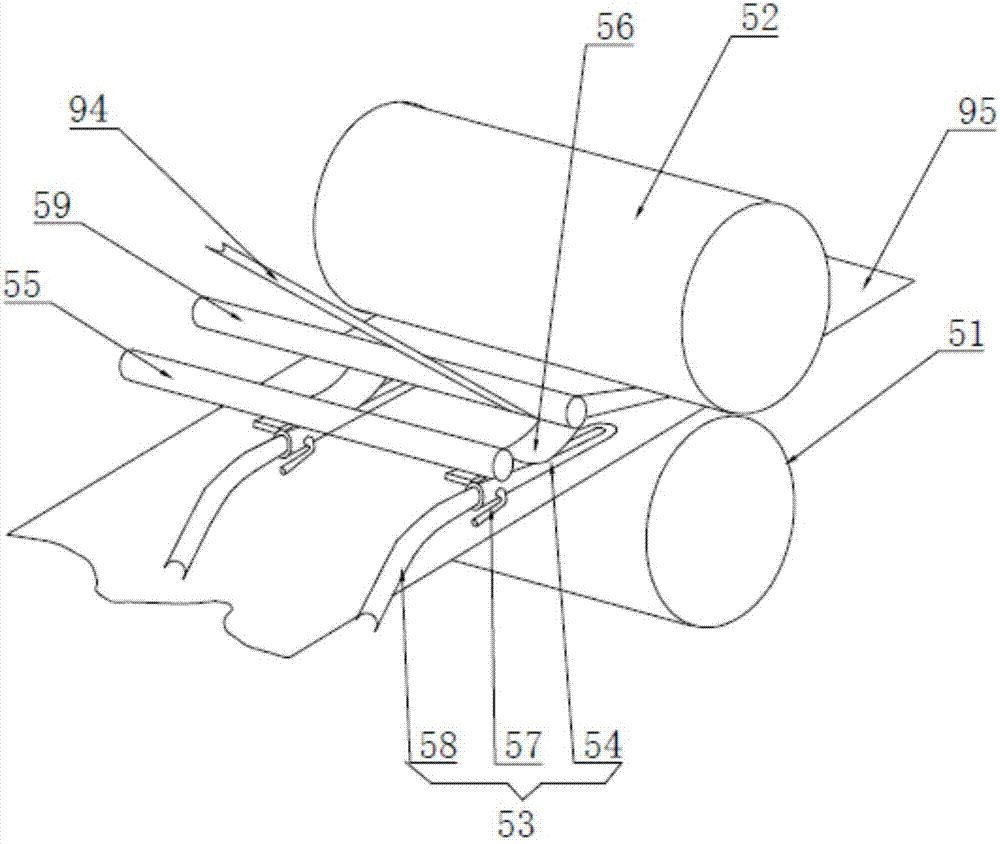

Rotary bronzing machine

InactiveCN107571618AImprove applicabilityIncrease the scope of purchaseRotary pressesBronze printingElectric machineryDistance sensors

The invention discloses a rotary bronzing machine. The rotary bronzing machine comprises a rack and further comprises an unwinding device, a deviation rectifying device, a bronzing material storage device, a bronzing device, a waste film collecting device, a drying device and a winding device which are arranged on the rack. The bronzing device comprises a printing roller, an impressing roller anda cooler. A bronzing material is arranged between the printing roller and the impressing roller. A printing substrate is arranged between the bronzing material and the printing roller. The cooler comprises a gas conveying nozzle with the opposite moving direction of the printing substrate. The gas conveying nozzle is arranged between the bronzing material and the printing substrate. A sensor usedfor detecting passing of the printing substrate is arranged between the bronzing device and the deviation rectifying device. An unwinding tension device is connected to the rear end of the unwinding device. A winding tension device is connected to the front end of the winding device. The deviation rectifying device comprises a deviation-rectifying correcting frame and a servo motor for driving thedeviation-rectifying correcting frame to make movement. Distance sensors are arranged on the two sides of the deviation rectifying device. According to the rotary bronzing machine, the probability ofthe trailing and water ripple phenomena can be decreased by a large margin, the printing quality is good, and the printing efficiency is high.

Owner:SICHUAN JINSHI PRINTING

Multi-coating circuit board and production method thereof

InactiveCN103716988AImprove conductivityImprove wear resistancePrinted circuit manufactureElectrical connection printed elementsSolderabilityGold layer

The invention discloses a multi-coating circuit board. The key part surface is covered with a nickel layer of 100 to 200mil. The nickel layer is covered with a gold layer of 1 to 3mil. The pad and the circuit are covered with a silver layer of 8 to 16mil. The invention further discloses a production method of the multi-coating circuit board. Different coatings can be simultaneously electroless-plated on the same circuit board. According to the creative invention, the surfaces of the circuit and the pad of the same circuit board are respectively covered with different metal layers; the nickel gold layer which has the characteristics of good conductivity, easy OSP processing and low solderability is plated on the surface of the circuit which has the characteristics of high conductivity demand and no solderability demand; the pad part with a high solderability demand is covered with the silver layer with strong solderability; and the produced circuit board pad has the advantages of high solderability, good circuit conductive effect, good OSP processing effect and the like, wherein the advantages are not realized by the existing products.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

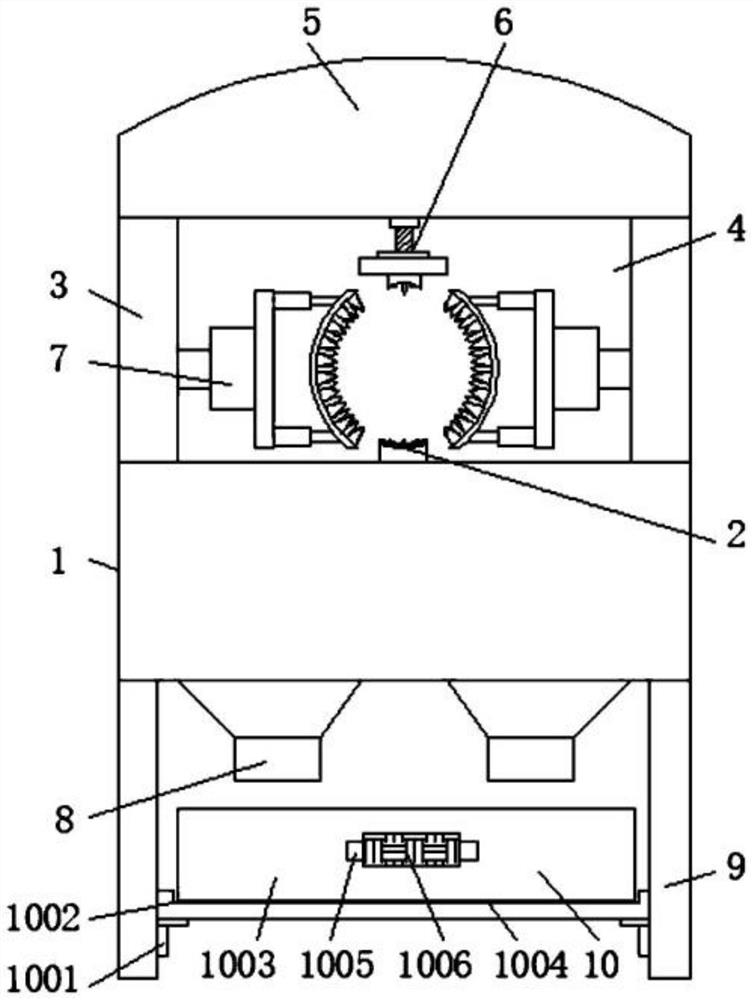

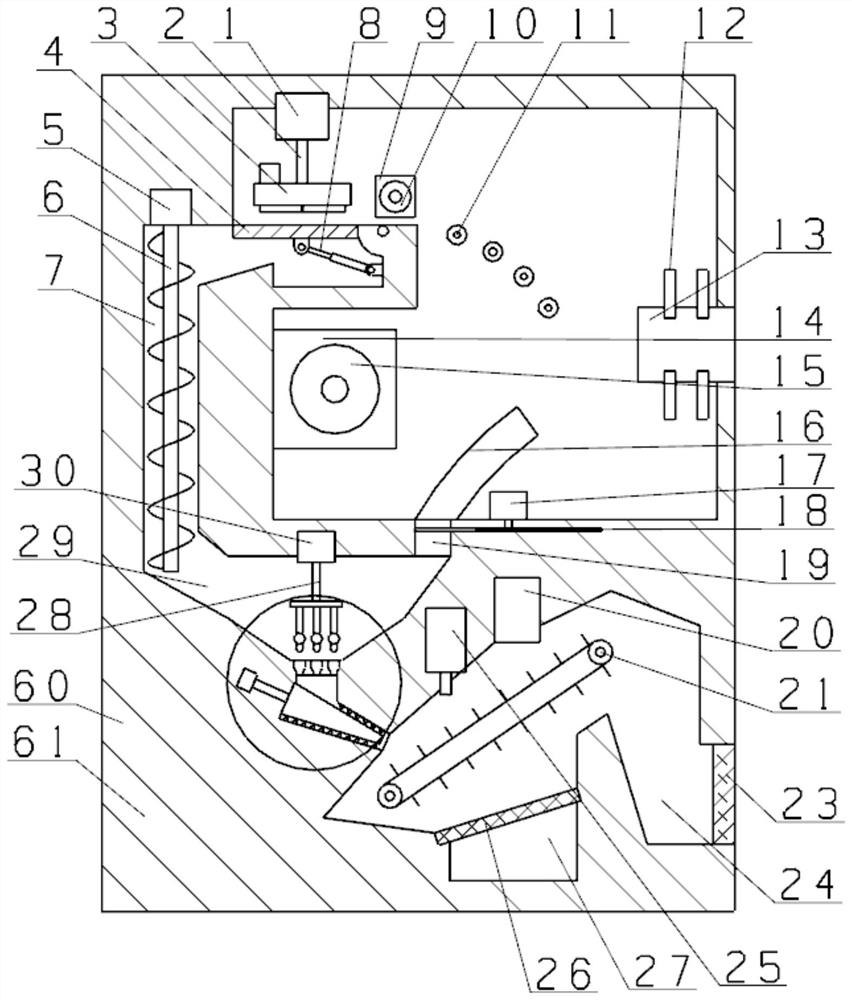

Coconut coat removing equipment and method for coconut vendor

InactiveCN111789267AAffect aestheticsEasy to removeHuskingHullingStructural engineeringMechanical engineering

The invention relates to the technical field of coconut coat removing, and in particular relates to coconut coat removing equipment and method for a coconut vendor. The coconut coat removing device comprises a storage box, wherein a coconut rotary positioning mechanism is fixedly connected to the bottom of an inner cavity of the storage box, supporting plates are fixedly connected to side faces ofthe top of the storage box, the tops of the supporting plates are fixedly connected with the bottom of the top plate, a coconut position limiting mechanism is arranged in the top plate, a telescopicsurrounding coat stripping mechanism is fixedly connected to the side faces of the supporting plates, a discharging pipe is fixedly connected to the bottom of the storage box, supporting legs are fixedly connected to side faces of the bottom of the storage box, and a coconut coat collecting mechanism is fixedly connected to side faces of the supporting legs. The coconut coat removing equipment issuitable for removing coconut coats, and has the advantages that the coconut coats can be rapidly removed, the coconut coats are removed more thoroughly, the appearance of a coconut is prevented frombeing affected by coconut coat residues, the removed coconut coats are collected, and meanwhile, the coconut is punched, so that a suction pipe can be inserted conveniently to suck coconut juice.

Owner:潘换成

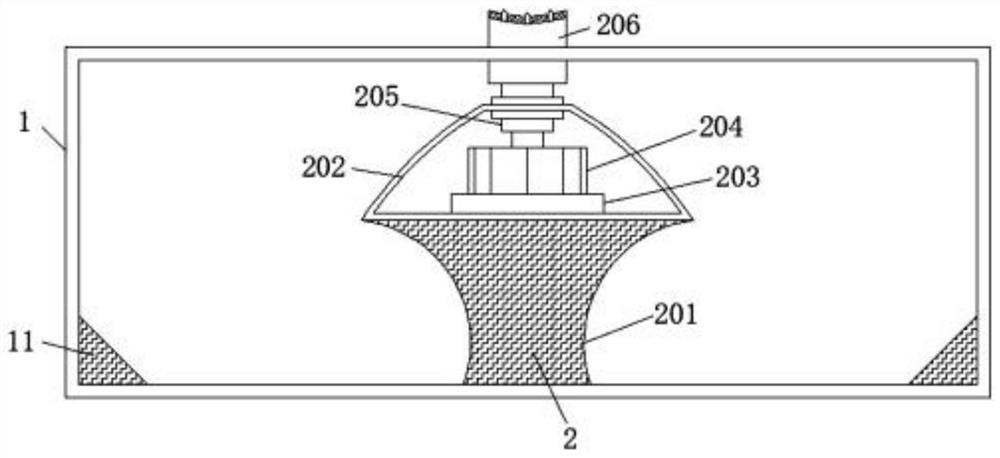

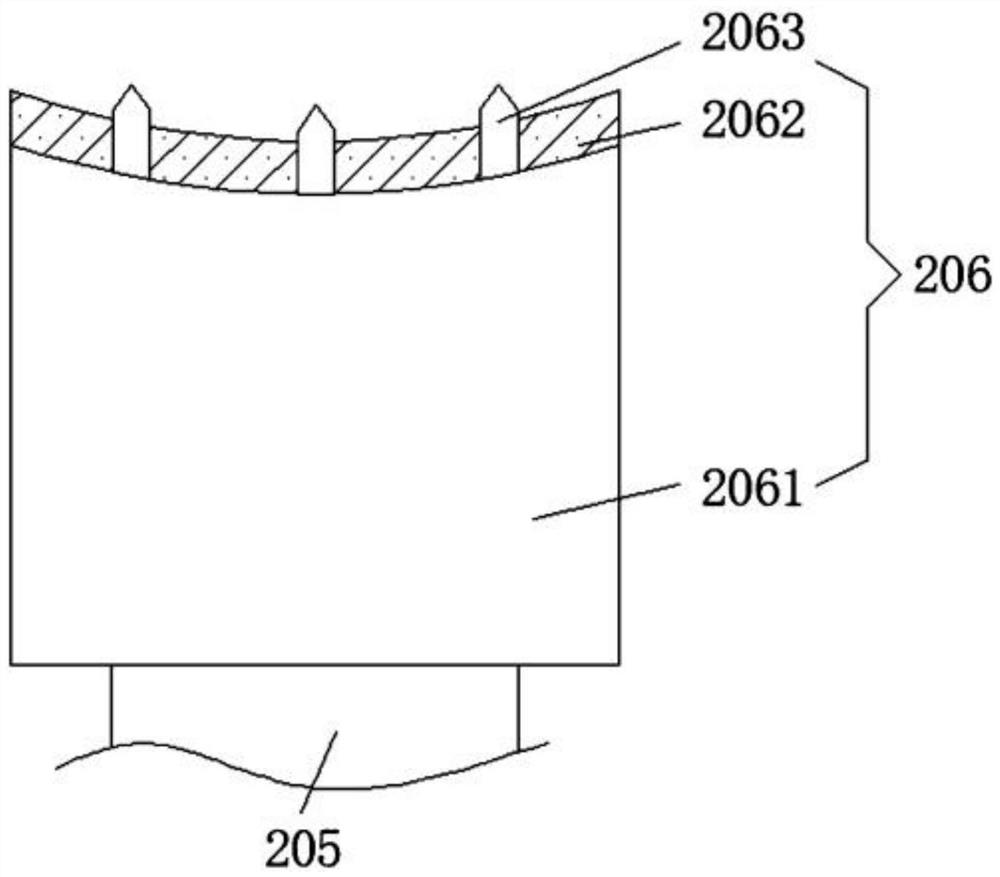

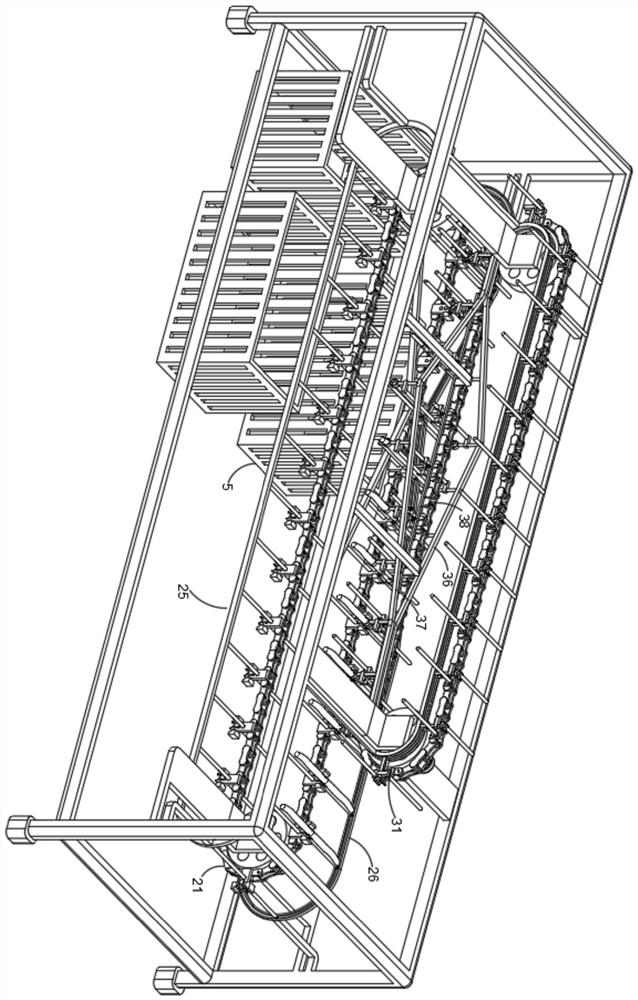

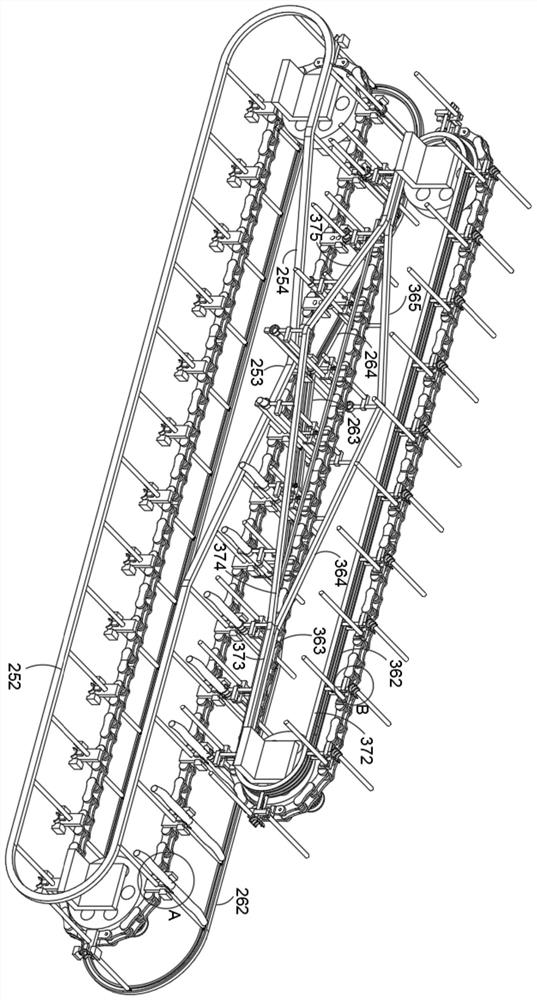

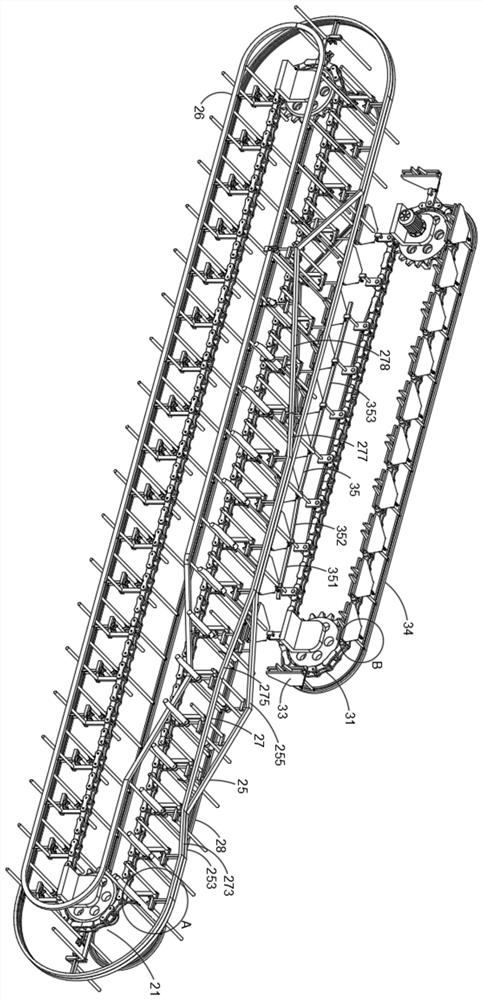

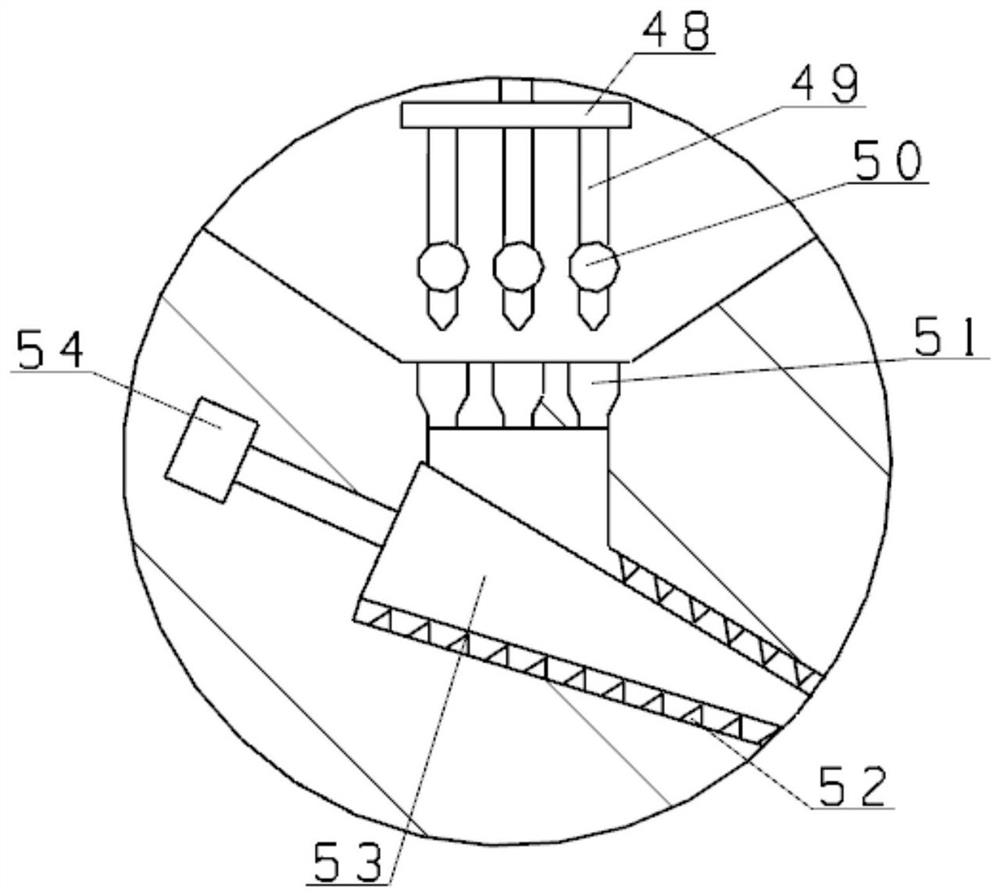

Medicinal material core-pulling device

InactiveCN113509384AImprove core pulling efficiencyImprove product qualityPharmaceutical product form changeMedicinal herbsChain link

The invention relates to a medicinal material core-pulling device which comprises a rack, a bearing device is arranged on the rack, a core-pulling device is arranged on the lateral upper portion of the bearing device, and a core-pulling channel is formed between the bearing device and the core-pulling device; the bearing device comprises a rotary chain a, a bearing plate which is driven by the rotary chain a to rotate, and a lower core-pulling mechanism a and a lower core-pulling mechanism b which are arranged on the bearing plate, and the core-pulling device comprises a rotary chain b, a pressing mechanism which is driven by the rotary chain b to rotate, and an upper core-pulling mechanism a and an upper core-pulling mechanism b which are arranged on the pressing mechanism; the lower core-pulling mechanism a and the upper core-pulling mechanism a as well as the lower core-pulling mechanism b and the upper core-pulling mechanism b are in one-to-one correspondence in upper and lower positions when being conveyed to pass through the core-pulling channel; the problems that existing morinda officinalis processing consumes manpower, operation and control are inconvenient, and product quality is uneven are solved.

Owner:王文洪

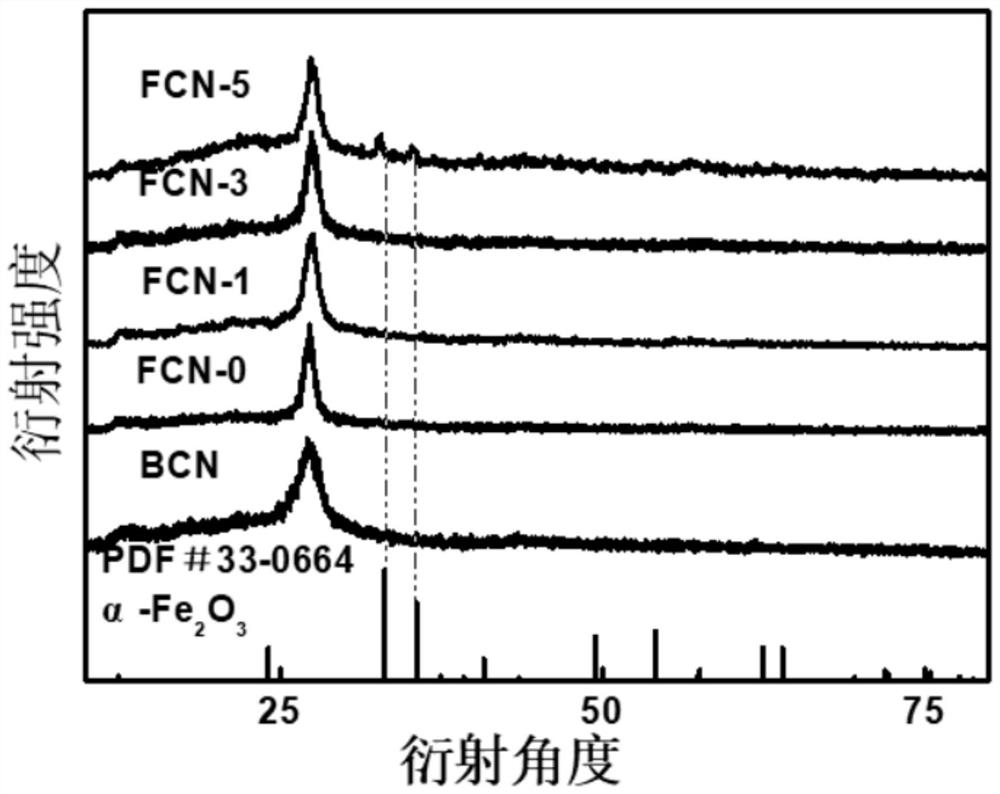

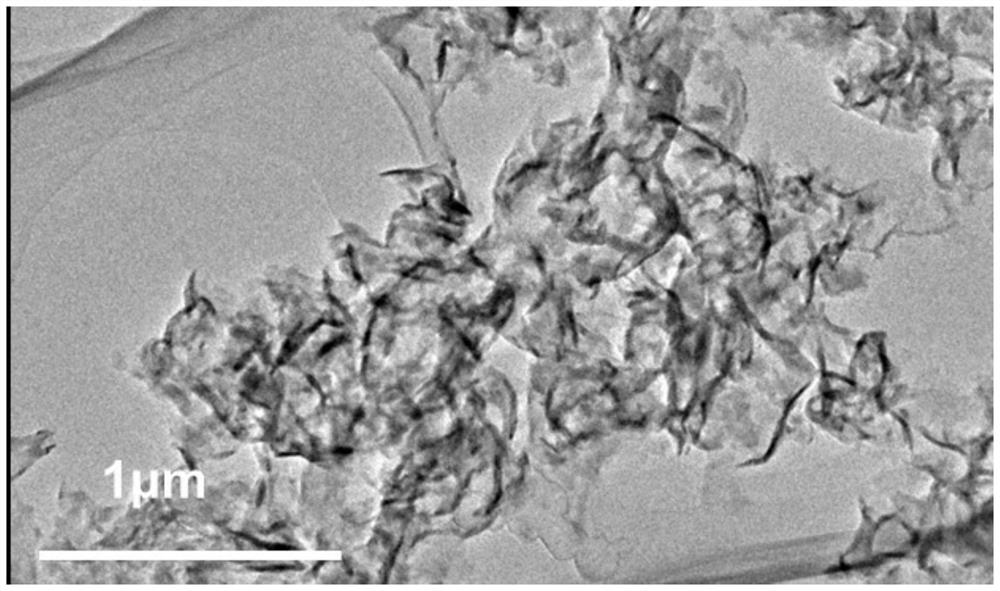

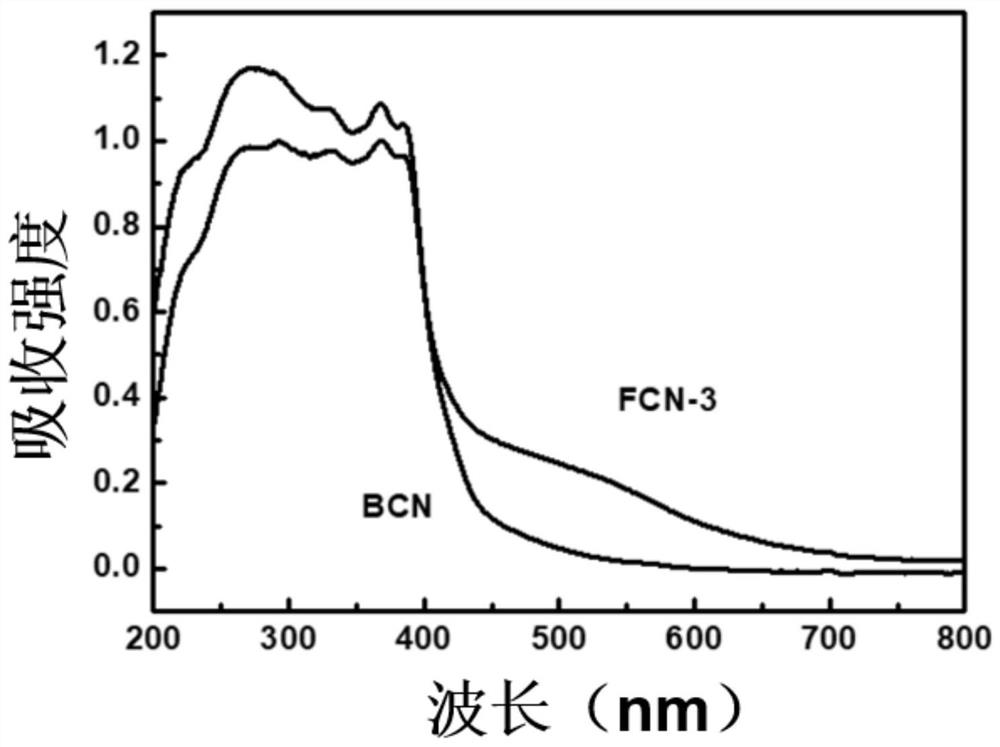

Ultrathin-structure carbon nitride-iron oxide photocatalyst and preparation method thereof

InactiveCN112742434AEvenly distributedEffective Photocatalytic DecompositionPhysical/chemical process catalystsHydrogen productionPtru catalystPhysical chemistry

The invention discloses an ultrathin-structure carbon nitride-iron oxide photocatalyst and a preparation method of the carbon nitride-iron oxide photocatalyst; prepared carbon nitride and an iron salt solution are mixed, dried and put into a muffle furnace to be calcined, and the ultrathin-structure carbon nitride-iron oxide photocatalyst is obtained after calcination. The method is easy to operate and high in yield, the obtained photocatalyst can effectively catalyze water decomposition to produce hydrogen under visible light, and the method is an efficient and economical photocatalyst preparation method.

Owner:TIANJIN UNIV

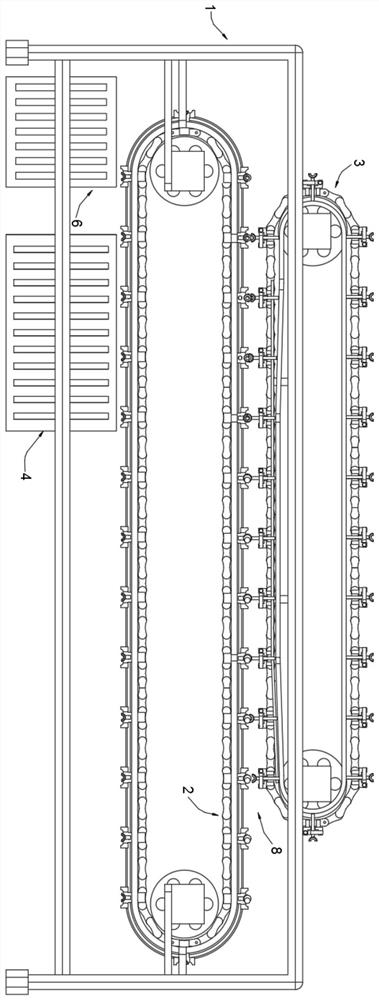

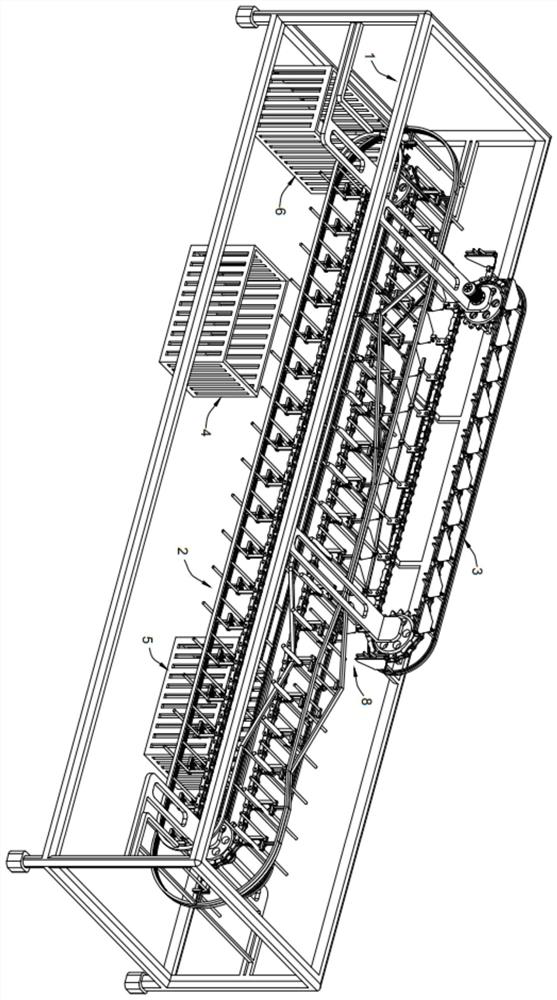

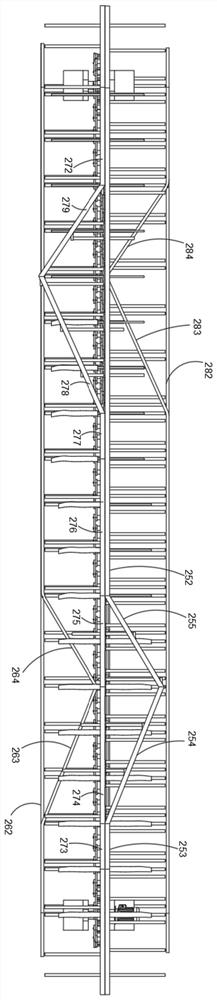

Production line for medicinal material core pulling

PendingCN113509383AImprove efficiencyImprove product qualityPharmaceutical product form changePhysicsMedicinal herbs

The invention relates to a production line for medicinal material core pulling. The production line comprises a rack, a core pulling device is arranged on the rack, the core pulling device comprises a rotary chain a, bearing blocks driven by the rotary chain a to rotate, right core pulling mechanisms and left core pulling mechanisms, the right core pulling mechanisms and the left core pulling mechanisms are arranged on the bearing blocks, and a clamping device is arranged above the side of the core pulling device. A clamping channel is formed between the core pulling device and the clamping device; each right core-pulling mechanism comprises an upper core-pulling assembly a and a lower core-pulling assembly a, the lower core-pulling assembly a bears morinda officinalis, each left core-pulling mechanism comprises an upper core-pulling assembly b and a lower core-pulling assembly b, and the clamping device comprises a rotary chain b and clamping mechanisms driven by the rotary chain b to rotate. The bearing blocks and the clamping mechanisms are in one-to-one correspondence in the vertical direction when the bearing blocks and the clamping mechanisms pass through the clamping channel; the problems that existing morinda officinalis processing consumes manpower, operation and control are inconvenient, and product quality is uneven are solved.

Owner:王文洪

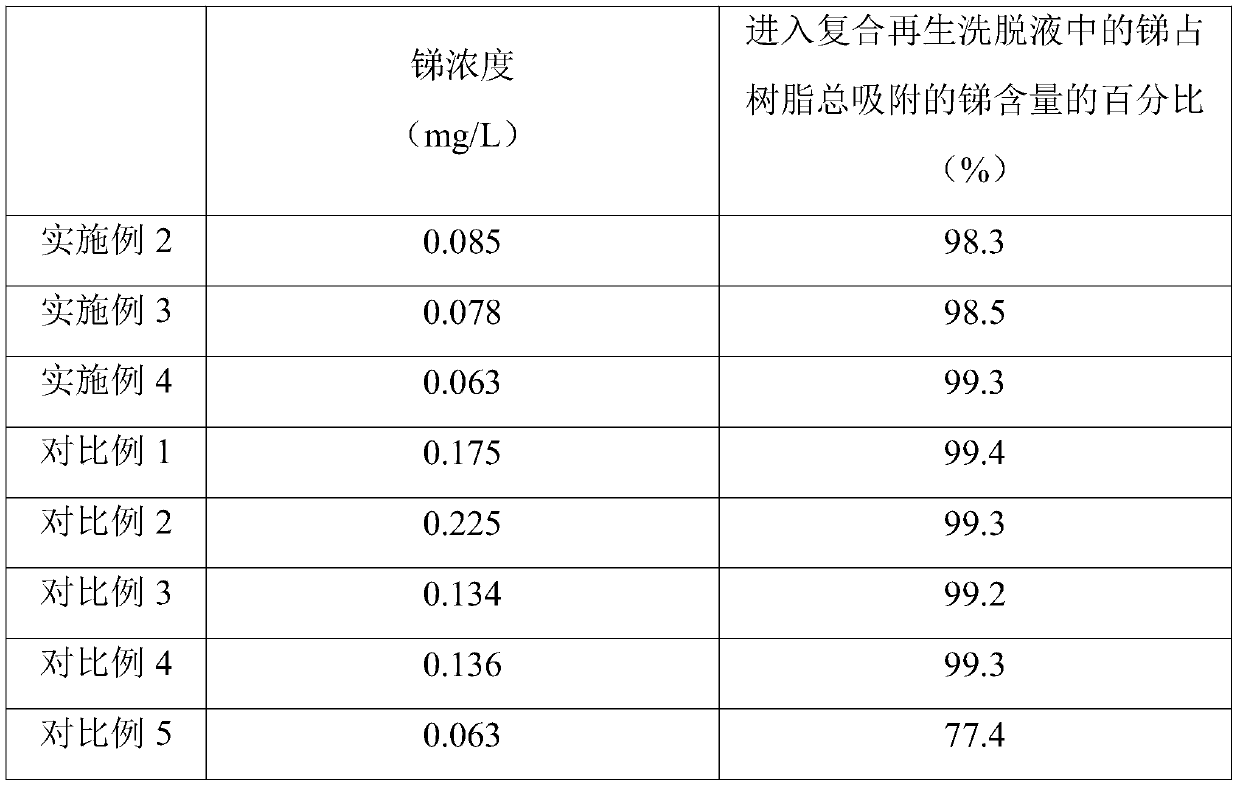

Method for adsorbing and stripping off antimony from antimony-containing wastewater

PendingCN110316793AReduce productionAdsorption stripping is fast and efficientSpecific water treatment objectivesWater contaminantsWastewaterPhysical chemistry

The invention discloses a method for adsorbing and stripping off antimony from antimony-containing wastewater. The method includes the following steps of S1, adsorbing antimony in the antimony-containing wastewater through ion exchange resin loaded with manganese and zirconium; S2, eluting the ion exchange resin loaded with manganese and zirconium obtained after antimony adsorption in the step S1through compound regenerated eluent to strip off antimony and make the antimony enter a solution so that the antimony-adsorbed ion exchange resin loaded with manganese and zirconium can be regeneratedand the antimony entering the solution can be used for subsequent antimony recycling. According to the method, the antimony in the antimony-containing wastewater is adsorbed through the specially-made ion exchange resin loaded with manganese and zirconium, the adsorption capacity of the antimony in the antimony-containing wastewater is high, the adsorption speed is high, and the adsorption removal efficiency is high; after antimony adsorption, the ion exchange resin is eluted through the special compound regenerated eluent, the antimony is rapidly and efficiently stripped off, and the adsorption and removal efficiency of the antimony in the antimony-containing wastewater is further improved.

Owner:JIAXING CHANGRUN LINE CO LTD

Communication cable separation and recovery device

InactiveCN112331424ANot easy to stickStripped completelyBasic electric elementsElectronic waste recyclingHydraulic cylinderElectric machine

The invention relates to the technical field of communication cable separation and recovery processing, in particular to a communication cable separation and recovery device which comprises a recoverydevice. The recovery device comprises a box body, the box body is connected with a wire stripping device through a connecting plate, and a second motor is arranged in the middle of the box body. An output shaft of the second motor is connected with a take-up roller, a guide pipe is arranged in the box body, and the guide pipe is connected with a cutting cavity. A blade is arranged in the cuttingcavity, a third motor is arranged in the box body, and an output shaft of the third motor is fixedly connected with the blade. The cutting cavity is connected with an inclined hopper cavity, the inclined hopper cavity is connected with a conveying pipe cavity, and a guide roller is arranged in the box body. A first hydraulic cylinder is installed at the upper left portion of the box body and is connected with a pressing and cutting knife through a first hydraulic rod. The communication cable separation and recovery device is sufficient in cutting depth, skin is not prone to adhesion, peeling is complete, crushing and recycling treatment is achieved, and transportation and follow-up processing treatment are facilitated.

Owner:孙玲

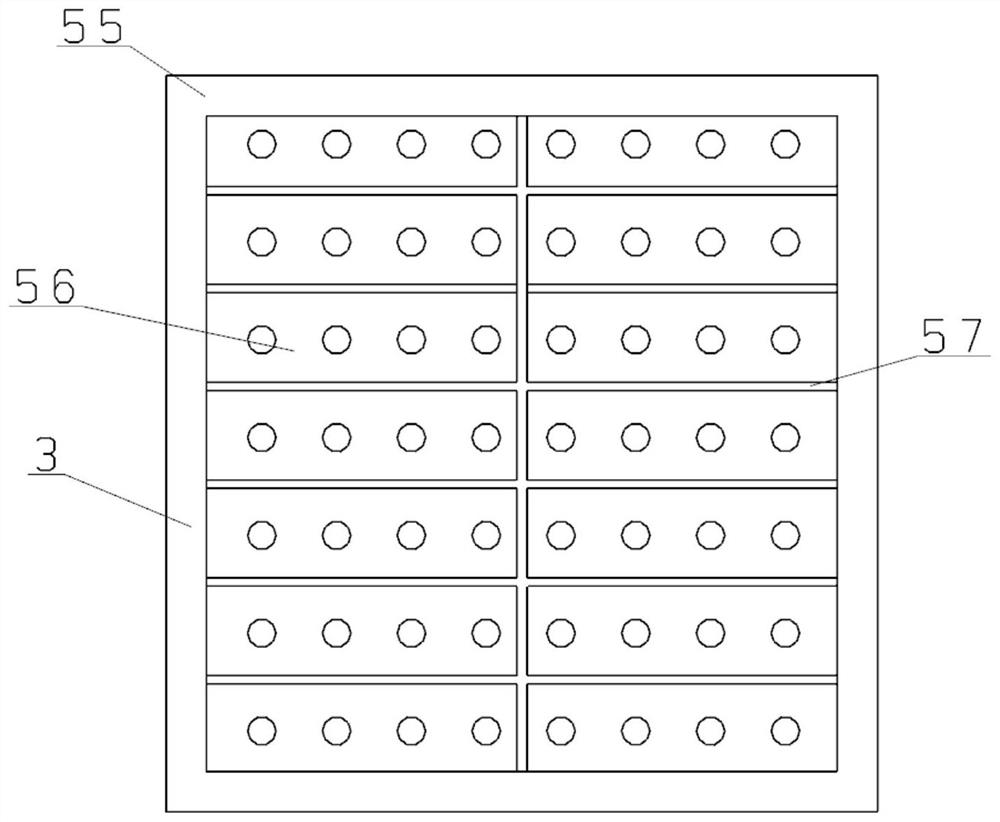

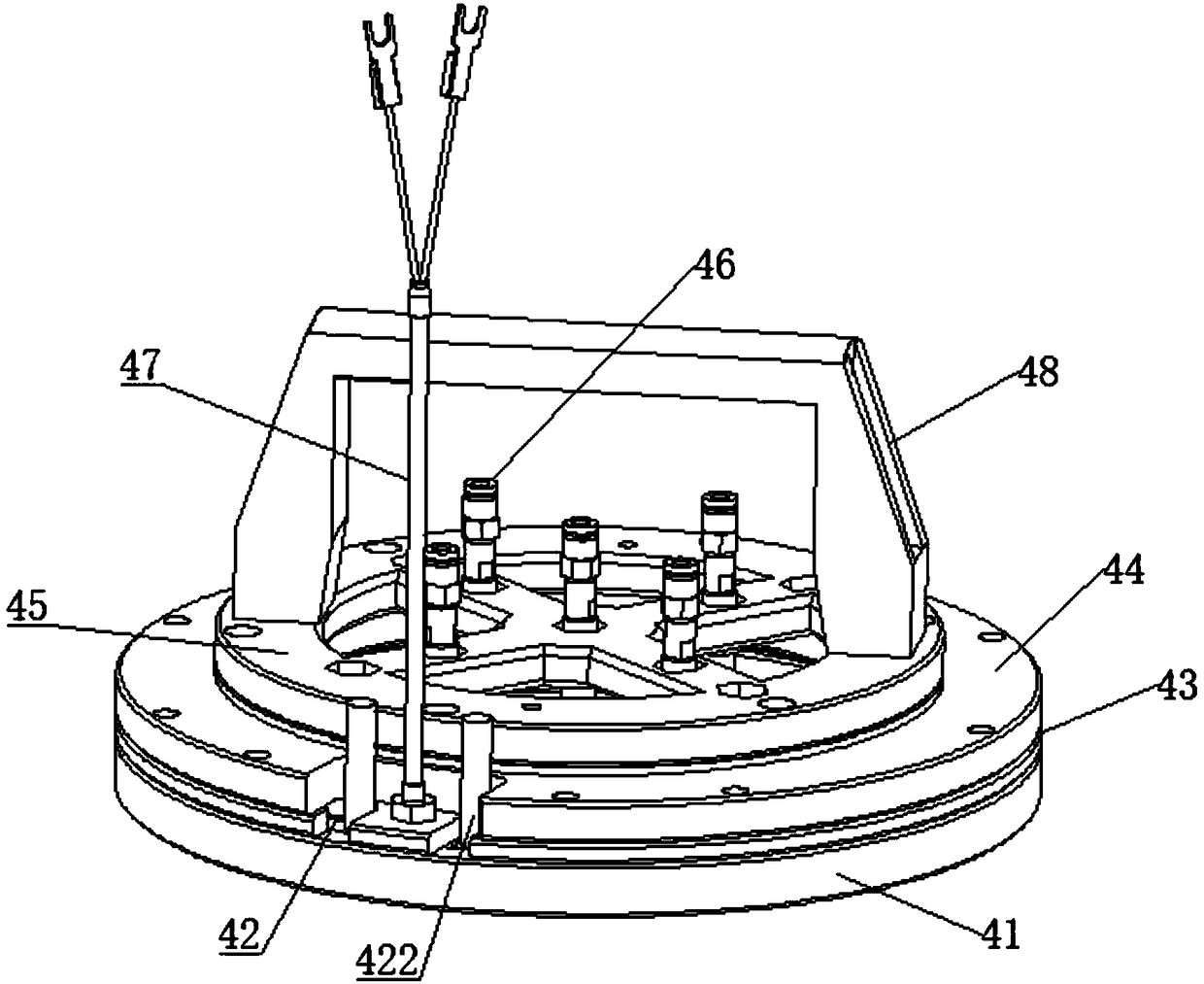

Vacuum heating system, and wafer stripping device and method

ActiveCN108346597AStripped completelyEasy to carrySemiconductor/solid-state device manufacturingLaser beam welding apparatusThermal insulationEngineering

The invention discloses a vacuum heating system, and a wafer stripping device and method. The vacuum heating system comprises a heating ring fixing plate, a heating ring, a thermal insulation plate, asuction nozzle fixing plate and a plurality of vacuum suction nozzles, wherein the heating ring fixing plate is in an annular shape and is provided with a circle of annular groove; the heating ring is in the annular shape and is arranged in the groove of the heating ring fixing plate; the thermal insulation plate is in the annular shape and is arranged above the heating ring; the suction nozzle fixing plate is arranged above the thermal insulation plate; and the plurality of vacuum suction nozzles are symmetrically and uniformly arranged on the suction nozzle fixing plate and are used for adsorbing a stripped wafer and removing the wafer. In the invention, through arranging the vacuum heating system, a bonding layer material can be heated in an area where the wafer is bonded and can be melted so that the wafer is completely stripped. Simultaneously, through the vacuum suction nozzles of the vacuum heating system, the stripped wafer can be adsorbed so that the wafer is convenient to carry, the wafer is prevented from be damaged and the yield rate of wafer stripping is increased.

Owner:深圳市大族半导体装备科技有限公司

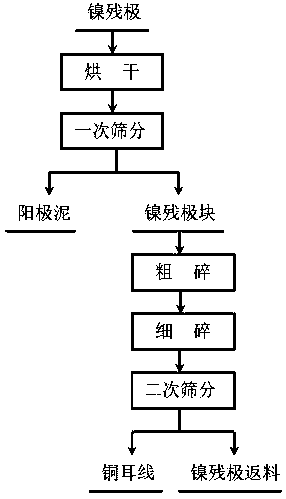

Nickel residual electrode treatment method

ActiveCN109930178AReduce adhesionHelp removePhotography auxillary processesElectrolysis componentsSulfoniumCopper

The invention discloses a nickel residual electrode treatment method. The treatment method comprises the steps that (1) a nickel residual electrode is dried under continuous and quantitative feeding conditions until the anode mud moisture content of the surface of the nickel residual electrode is 8%-12% by weight, first-time screening is carried out, anode mud is removed, the anode mud and a nickel residual electrode block are obtained, and the anode mud is sent to an anode mud bin to be stacked; (2) the nickel residual electrode block in the step (1) is firstly coarsely crushed until the particle size is smaller than or equal to 150 mm, a part of a copper lug wire is peeled off, then fine crushing is carried out until the particle size of is smaller than or equal to 35 mm, and the copperlug wire in the nickel residual electrode is completely peeled off; and (3) the copper lug wire peeled in the step (2) and the nickel residual electrode block are subjected to secondary screening, thecopper lug wire is sorted out, the copper lug wire is sent to a copper lug wire bin to be stacked, and the nickel residual electrode with the copper lug wire sorted out returns to a casting system tobe used for casting a high-sulfonium anode plate. The nickel residual electrode treatment method is good in nickel residual electrode crushing effect, complete in nickel and copper separation, high in anode mud screening rate and short in process flow.

Owner:JINCHUAN GROUP LIMITED

A preparation method of an ultra-thin copper foil with a carrier that is easy to peel and has a clean interface

ActiveCN112853408BUniform surfaceImprove performanceElectroforming processesOrganic layerSurface roughness

The invention relates to the technical field of electronic materials, in particular to a method for preparing an extremely thin copper foil with a carrier that is easy to peel off and has a clean interface. The carrier copper foil provided by the present invention includes a composite peeling layer comprising an alloy layer and an organic layer, especially the alloy layer is obtained by electroplating an alloy solution containing a complexing agent and at least one soluble sulfate, and the organic layer is obtained by electroplating The organic liquid containing organic matter is obtained by coating treatment, thereby forming a composite peeling layer with uniform surface and stable performance on the upper surface of the copper foil, which has the characteristics of stable peeling performance and easy peeling after high-temperature pressing; at the same time, using the specific The ultra-thin copper foil with carrier prepared by the method has the characteristics of easy peeling, fine grain, dense structure, uniform thickness, and clean interface. For example, the thickness of the ultra-thin copper foil is 2‑6μm, and the surface roughness is ≤2.5μm The peel strength between the ultra-thin copper foil and the carrier copper foil is much lower than that between the ultra-thin copper foil and the insulating board.

Owner:JIANGXI UNIV OF SCI & TECH +2

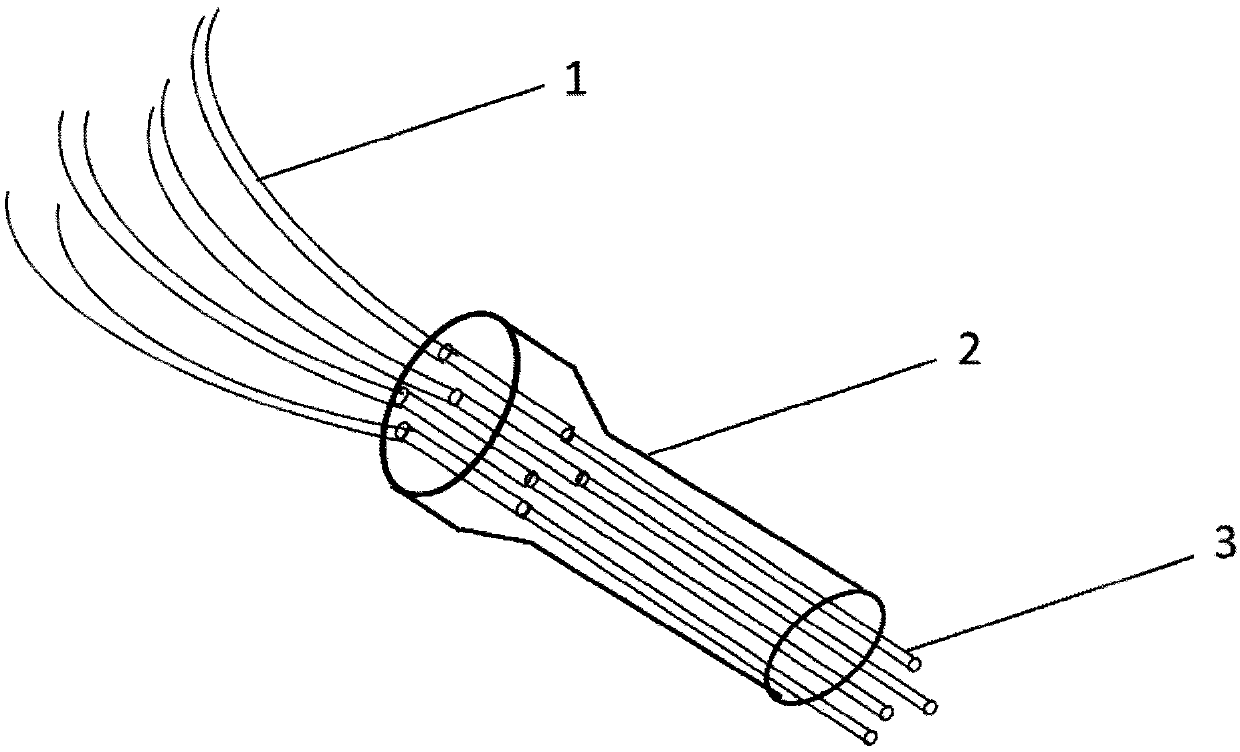

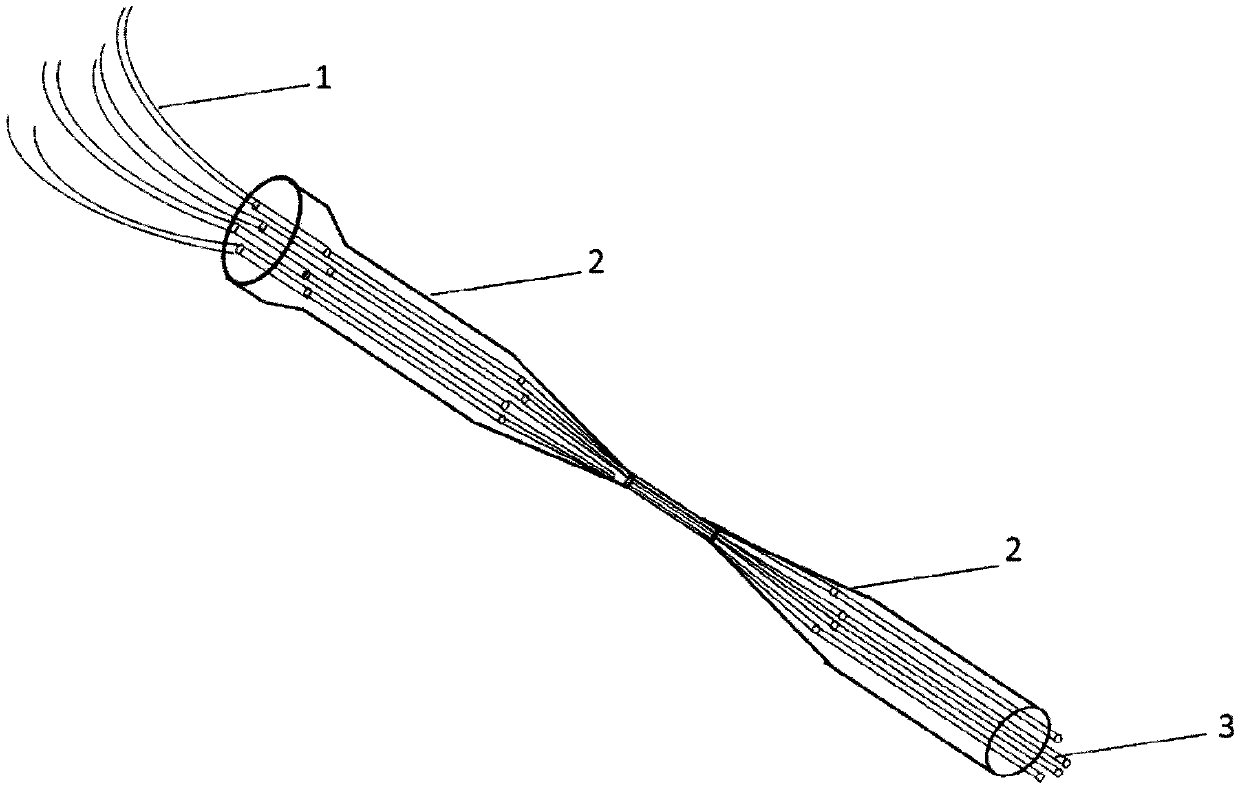

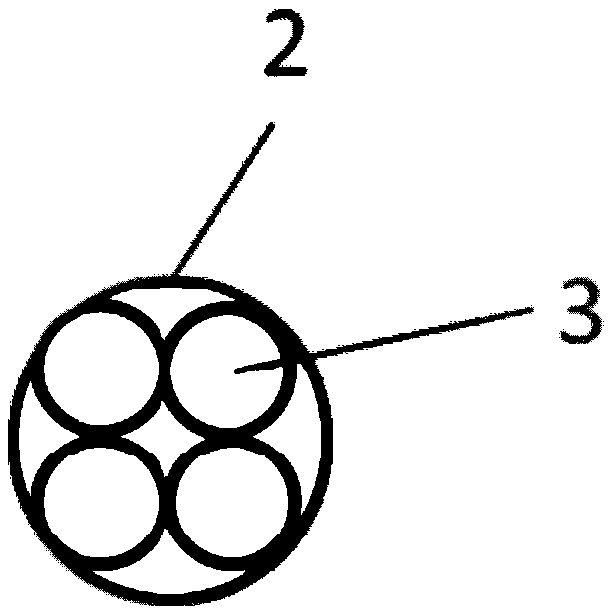

Pulling method of array optical fiber optical tweezers

ActiveCN109669246ANo damageReduce intensityCoupling light guidesNeutron particle radiation pressure manipulationSprayerTweezers

The invention relates to a pulling method of array optical fiber optical tweezers. A coating layer at one end of each optical fiber is removed, and bare optical fibers are threaded into a quartz tubein bundles; the quartz tube is fixed to a tapering clamp, the external moving velocity and the flame moving velocity of the tapering clamp is controlled to conduct test pulling, the insertion loss ofthe obtained array optical tweezers is detected, the flame sprayer nozzle height is adjusted, the heated temperature of the quartz tube is precisely controlled, the insertion loss meets the requirements, after the flame sprayer nozzle height and the flame moving velocity are determined, the external moving velocity of the tapering clamp is controlled to subjected to variable speed tapering from slow to fast, and the optical fiber tweezers with the taper angle of 30 degrees-45 degrees are obtained. According to the pulling method of the array optical fiber optical tweezers, the quartz tube perfectly constrains optical fiber bundles, optical fibers of the array optical fiber optical tweezers are closely arranged and symmetrical relative to the center line, and the efficiency is significantlyimproved; and the heated temperature of the quartz tube is adjusted through the flame sprayer nozzle height, the temperature adjustment accuracy is less than 0.5 DEG C, quick tapering at multiple variable speed ensures the index of the insertion loss of the array optical fiber optical tweezers is qualified, and the test pulling time is shortened.

Owner:NO 34 RES INST OF CHINA ELECTRONICS TECH GRP

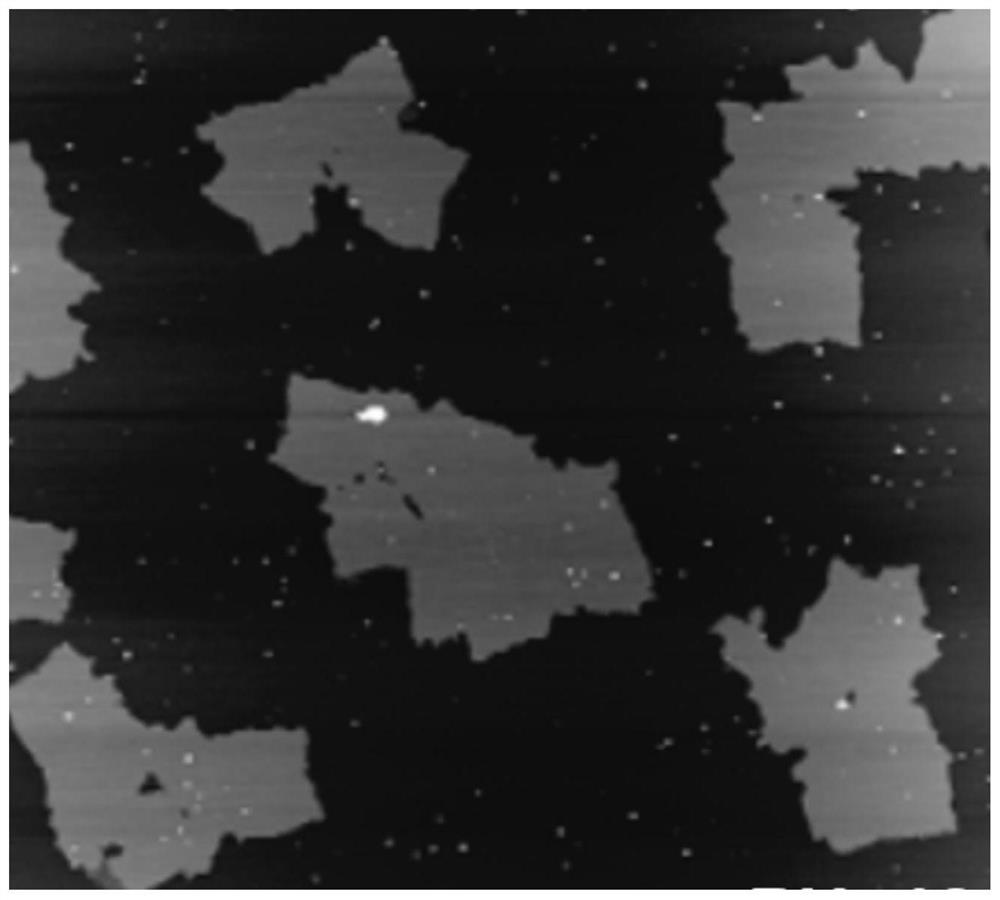

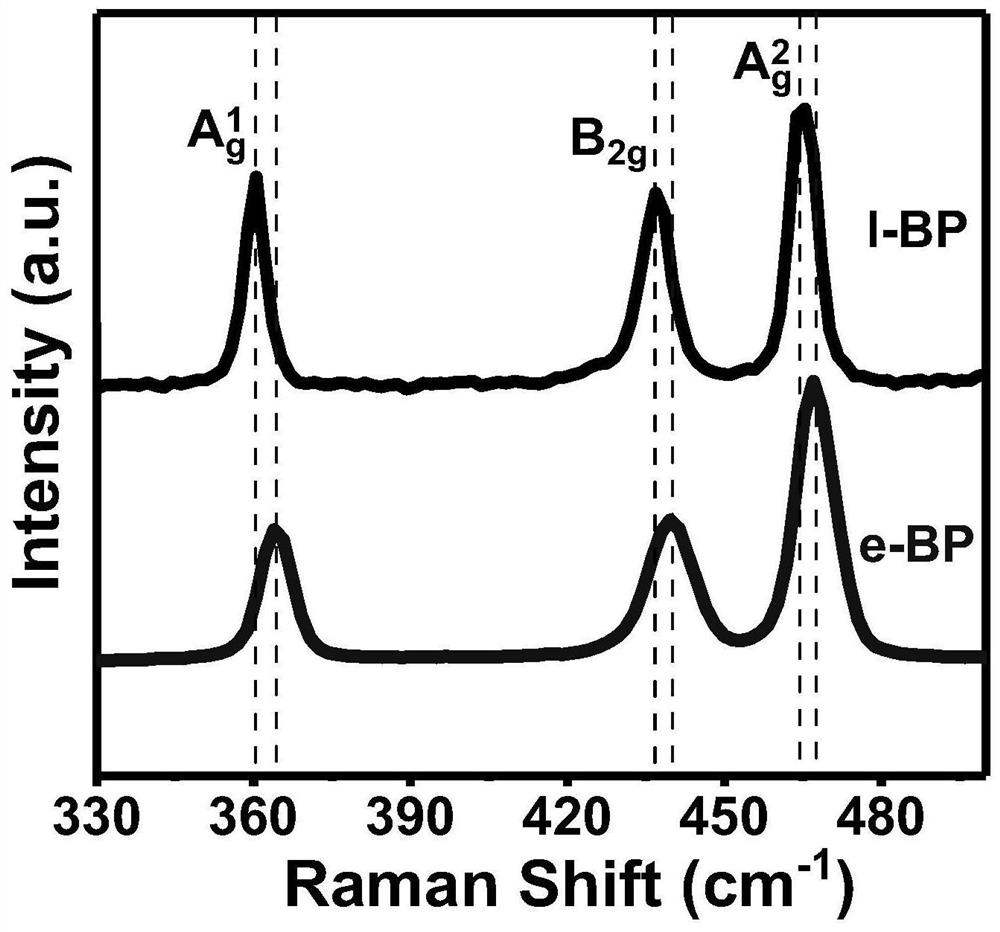

A kind of black phosphorus nanosheet and its preparation method and application

ActiveCN111533096BStripped completelyStable structureMaterial nanotechnologyPhosphorus preparationEpoxyElectrolytic agent

The invention discloses a black phosphorus nanosheet and its preparation method and application, belonging to the technical field of functional material production. In this method, a black phosphorus sheet is used as an electrolytic anode, and an electrochemical reaction system is jointly constructed with an inert electrode and an alkaline aqueous electrolyte, wherein the alkaline aqueous electrolyte contains N-N dimethylformamide dissolved in an epoxy resin solution. In the alkaline aqueous electrolyte, the structure of the prepared black phosphorus nanosheets tends to be more stable, not easy to break, and the degree of oxidation is reduced. The peeling is more complete.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD

Optical fiber buncher drawing method

InactiveCN106855649AReduce intensityAvoid damageGlass making apparatusBundled fibre light guideEngineeringHeating temperature

The invention provides an optical fiber buncher drawing method comprising the following steps that a bare optical fiber bundle of which the optical fiber coating layer is removed penetrates into a quartz tube with the two ends arranged outside the ports of the quartz tube, wherein the internal diameter of the quartz tube just allows penetration of the bare optical fiber bundle; and the two ends of the quartz tube in which the optical fiber bundle penetrates are arranged in a tapering clamp to be fixed, and the tapered quartz tube and the internal optical fiber bundle form an integrated optical fiber buncher. According to the method, the flame jet tube height is adjusted to change the heating temperature of the quartz tube so as to reduce the inserting loss. A height adjusting frame of the spiral structure is additionally arranged below the flame jet tube so as to quantitatively adjust the height in a grading way. The optimal flame jet tube height of the buncher of the qualified drawing inserting loss can be obtained through multiple types of drawing and adjustment. The horn mouth of one end of the quartz tube effectively protects the optical fiber bundle. The optical fiber bundle can be perfectly constrained by the quartz tube to be optimally and closely arranged so that the duty ratio and the inter-core parallelism can be enhanced and the efficiency can be substantially enhanced; and the heating temperature of the quartz tube is progressively and accurately controlled so that the optical fiber buncher of the qualified inserting loss is ensured to be obtained through tapering and the adjustment time can be shortened.

Owner:NO 34 RES INST OF CHINA ELECTRONICS TECH GRP +2

A preparation method of stable peelable ultra-thin carrier copper foil

The invention relates to a preparing method of ultra-thin carrier copper foil capable of being stably stripped. The method comprises the specific steps: firstly, a plating solution is prepared, namely, a complexing agent potassium pyrophosphate, zinc sulfate, an addition agent A and an addition agent B are dissolved in water, mixing is carried out after clarification, and the pH value of the solution is adjusted; secondly, the carrier foil is put into the plating solution in the first step, a novel nano composite zinc coating is electroplated and serves as a stripping layer, and extremely-thin electrolysis copper foil ranging from 2 micrometers to 6 micrometers is electroplated on the stripping layer, and is called as the ultra-thin carrier copper foil. After the ultra-thin carrier copper foil is cured on an insulation substrate after high-temperature pressing, through the mechanical method, the carrier foil can be completely stripped. The stripping layer prepared through the method is extremely thin and uniform, the carrier foil is easy to completely and stably strip, and the good application prospect is achieved.

Owner:SHANDONG JINBAO ELECTRONICS

Plating solution for carrier copper foil peeling layer and preparation method of peeling layer

The invention relates to a plating solution for a carrier copper foil stripping layer and a preparation method of the stripping layer. The plating solution is prepared from components as follows: potassium bitartrate with the concentration of 20-60 g / L, zinc sulfate with the concentration of 8-16 g / L and an additive A with the concentration of 5-20 g / L and the pH of 3.0-5.0, wherein the additive Ais a mixture formed by mixing at least one of 3-(2,3-epoxy propoxy)propyl trimethoxy silane, 3-(2,3-epoxy propoxy)propyltriethoxysilane, 3-(2,3-epoxy propoxy)propyl methoxy dimethyldiethoxylsilane or3-(methylacryloyl oxy)propyl trimethoxy silane with at least one of potassium thiocyanate, monopotassium phosphate, sodium acetate or ammonium sulfate. The carrier copper foil stripping layer obtained with the adoption of the plating solution for the carrier copper foil stripping layer and the preparation method of the stripping layer is a novel nano composite zinc plating layer, is very thin anduniform and can completely and stably strip carrier foil off the pressed very thin copper foil.

Owner:胡旭日

Method for preparing oxidized graphene

The invention belongs to a graphene preparation technology and relates to an improvement on an oxidized graphene preparation method. Preparation steps are as follows: preparing oxidized graphite; preparing an oxidized graphite aqueous solution; freezing; unfreezing; and drying. The invention provides a method for preparing the oxidized graphene through cold expansion stripping, which avoids environment pollution, is beneficial to environmental protection, has a simple process, is complete in oxidized graphite stripping, cause less damage on graphite sheets and is convenient for mass production.

Owner:北京石墨烯技术研究院有限公司

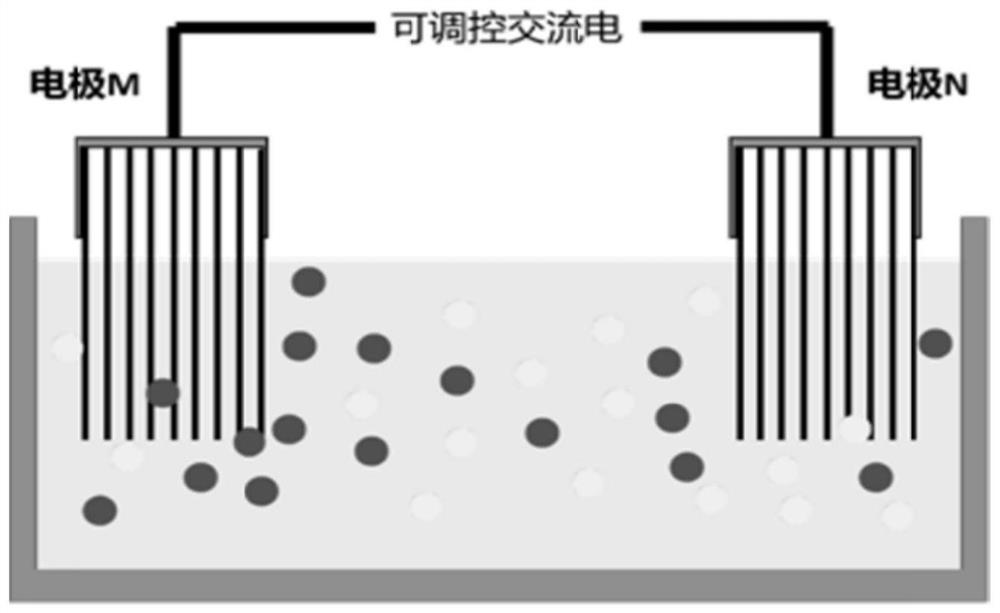

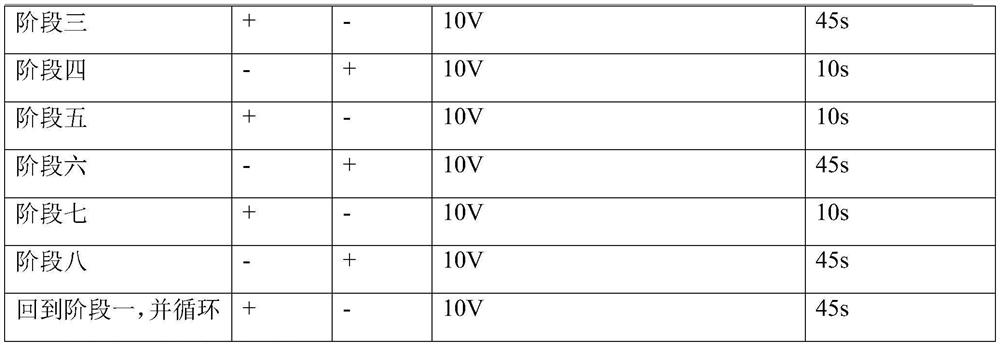

A method for electrochemically preparing graphene

ActiveCN111470499BStripped completelyImprove intercalation stripping effectGrapheneElectrolytic agentCapacitance

The invention belongs to the technical field of inorganic material preparation, and in particular relates to a method for preparing graphene. The method comprises the following steps: preparing a graphite material into an electrode; preparing an ammonium salt into an electrolyte; Pretreatment, followed by adding ammonia water to conduct electrolytic exfoliation of the graphite cathode at a certain temperature; then solid-liquid separation and drying of the electrolyzed product to obtain graphene of different qualities; by precisely controlling the parameters of the alternating current, both graphene The intercalation exfoliation of ZnO can effectively avoid the oxidation of graphene during the intercalation process; at the same time, the problem of low intercalation efficiency due to the contribution of electrode capacitance to the general alternating current during intercalation has also been solved. In the present invention, conventional chemical raw materials are used to prepare graphene, the raw material cost is low and easy to obtain, and the industrialization is convenient.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD

A kind of preparation method of ultra-thin carrier copper foil

The invention relates to a preparation method of ultrathin carrier copper foil. The preparation method specifically comprises the following steps that (1) a plating solution is prepared, specifically, a complexing agent sodium gluconate, potassium dichromate, an additive A and an additive B are dissolved in water correspondingly and mixed after being clarified, and the pH value of the solution is adjusted; (2) carrier foil is soaked into an organic solution of a silane coupling agent, and a layer of organic film is formed through adsorption; and (3) the carrier foil is placed into the plating solution in the step (1), a layer of novel nanoscale composite chrome plating layer is formed through electroplating to serve as a peeling layer, then ultrathin electrolytic copper foil which is 2-5 microns thick is electroplated on the peeling layer, and the ultrathin carrier copper foil is obtained. The ultrathin carrier copper foil is subjected to high-temperature pressing and cured on an insulating substrate, and then the carrier foil can be completely removed through peeling by means of a mechanical method. The peeling layer prepared through the method is ultrathin and uniform, the carrier foil can be peeled easily, completely and stably, and the preparation method has great application prospects.

Owner:SHANDONG JINBAO ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com