Method for adsorbing and stripping off antimony from antimony-containing wastewater

A waste water, neutral technology, applied in the field of antimony recovery, can solve the problems of antimony stripping (difficult separation, low adsorption removal efficiency, low adsorption removal efficiency, etc., achieve high use value and application prospect, improve adsorption removal efficiency, adsorption removal high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]A method for adsorbing and stripping antimony from antimony-containing wastewater, comprising the following steps:

[0040] S1. Using an ion exchange resin loaded with manganese-zirconium to adsorb antimony in antimony-containing wastewater; the concentration of antimony in the antimony-containing wastewater is 0.05-1g / L;

[0041] S2, using the composite regeneration eluent to elute the ion exchange resin loaded with manganese-zirconium after absorbing antimony in step S1, strip the antimony out, enter the solution, and make the ion-exchange resin loaded with manganese-zirconium after absorbing antimony The exchange resin is regenerated, and the antimony entering the solution is used for subsequent antimony recycling;

[0042] Wherein, in step S1, the preparation method of the ion exchange resin loaded with manganese-zirconium comprises the following steps:

[0043] A1. Preparation of manganese-zirconium loading solution:

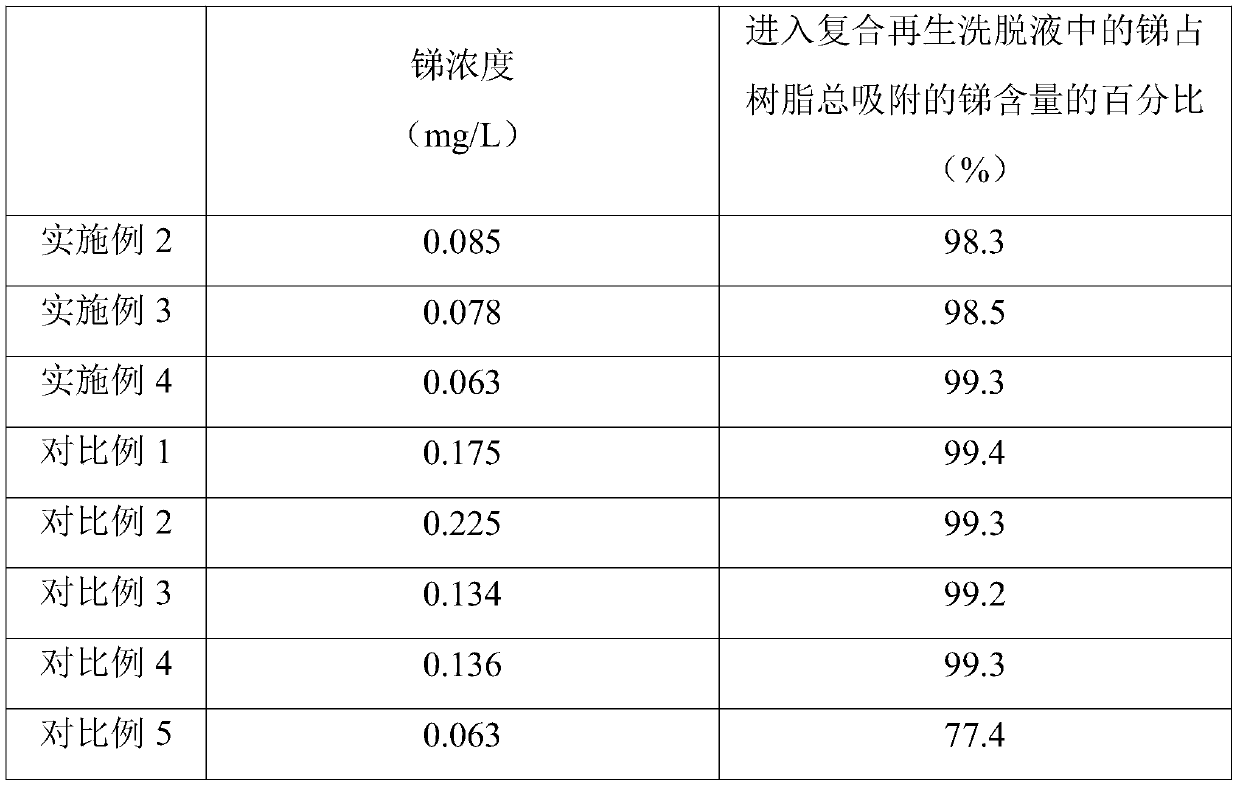

Embodiment 2

[0058] A method for adsorbing and stripping antimony from antimony-containing wastewater, comprising the following steps:

[0059] S1, using an ion exchange resin loaded with manganese-zirconium to adsorb antimony in the antimony-containing wastewater; the concentration of antimony in the antimony-containing wastewater is 0.05g / L;

[0060] S2, using the composite regeneration eluent to elute the ion exchange resin loaded with manganese-zirconium after absorbing antimony in step S1, strip the antimony out, enter the solution, and make the ion-exchange resin loaded with manganese-zirconium after absorbing antimony The exchange resin is regenerated, and the antimony entering the solution is used for subsequent antimony recycling;

[0061] Wherein, in step S1, the preparation method of the ion exchange resin loaded with manganese-zirconium comprises the following steps:

[0062] A1. Preparation of manganese-zirconium loading solution:

Embodiment 3

[0075] A method for adsorbing and stripping antimony from antimony-containing wastewater, comprising the following steps:

[0076] S1, using an ion exchange resin loaded with manganese-zirconium to adsorb antimony in the antimony-containing wastewater; the concentration of antimony in the antimony-containing wastewater is 1g / L;

[0077] S2, using the composite regeneration eluent to elute the ion exchange resin loaded with manganese-zirconium after absorbing antimony in step S1, strip the antimony out, enter the solution, and make the ion-exchange resin loaded with manganese-zirconium after absorbing antimony The exchange resin is regenerated, and the antimony entering the solution is used for subsequent antimony recycling;

[0078] Wherein, in step S1, the preparation method of the ion exchange resin loaded with manganese-zirconium comprises the following steps:

[0079] A1. Preparation of manganese-zirconium loading solution:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com