Communication cable separation and recovery device

A technology of separation and recovery, recovery device, applied in the direction of recycling technology, electronic waste recycling, electrical components, etc., can solve the problems of burning, skin adhesion, incomplete peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

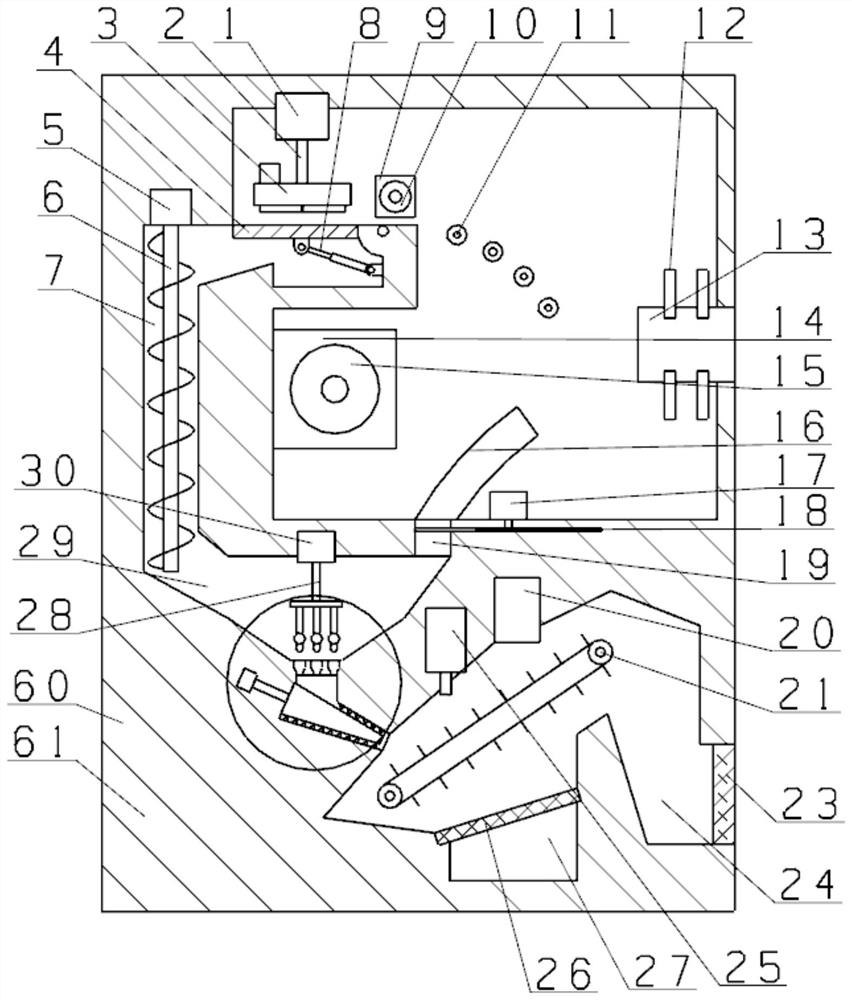

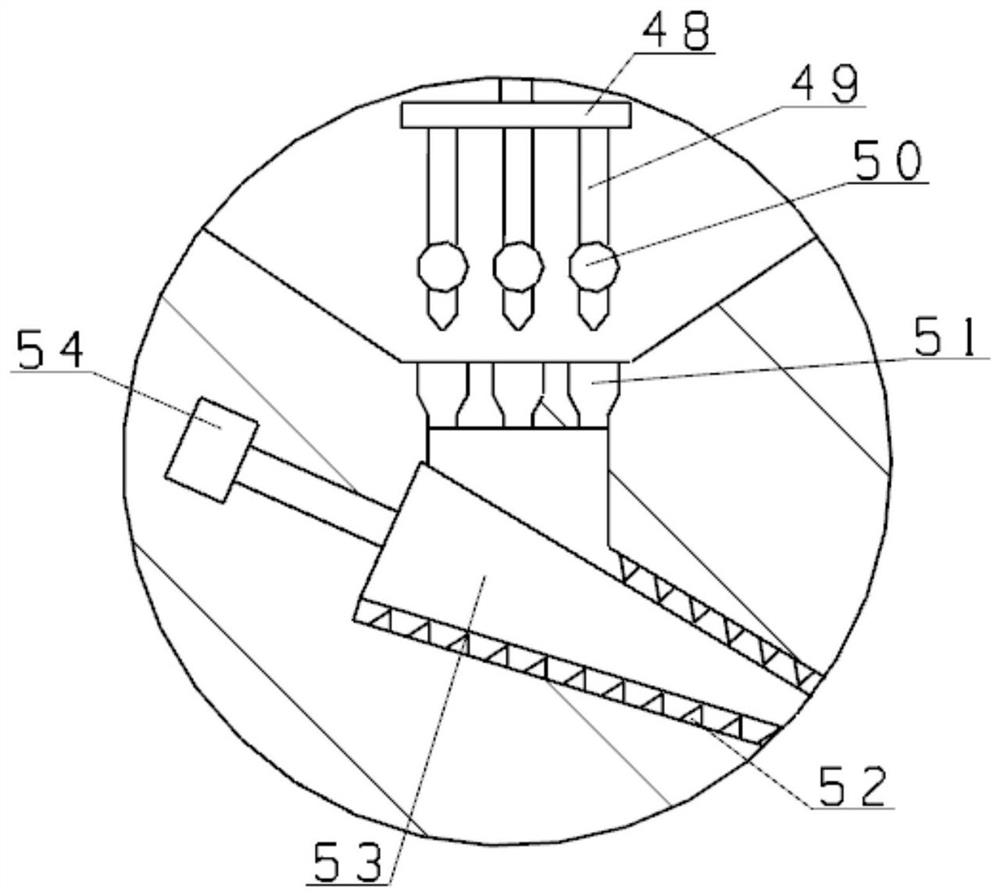

[0025] see Figure 1~Figure 6 As shown, a communication cable separation and recovery device includes a recovery device 60, and the recovery device 60 includes a box body 61, and the box body 61 is connected to a stripping device 13 through a connecting plate 12, and the stripping device 13 It includes a housing 31, a linear cylinder 62 is arranged inside the housing 31, a first motor 45 is fixedly installed on the inner wall of the housing 31, the output shaft of the first motor 45 is connected with a first gear 43, and the first The gear 43 is connected with the second gear 47 through the ring gear 32, the ring gear 32 is connected with the limit frame 46 fixedly connected with the housing 31, and the first gear 43 and the second gear 47 are equipped with a threaded shaft 41 , the threaded shaft 41 is threadedly connected with a moving sleeve 42, the moving sleeve 42 is slidably connected with a fixed frame 34, one end of the fixed frame 34 is connected with a fixed cylinder...

Embodiment 2

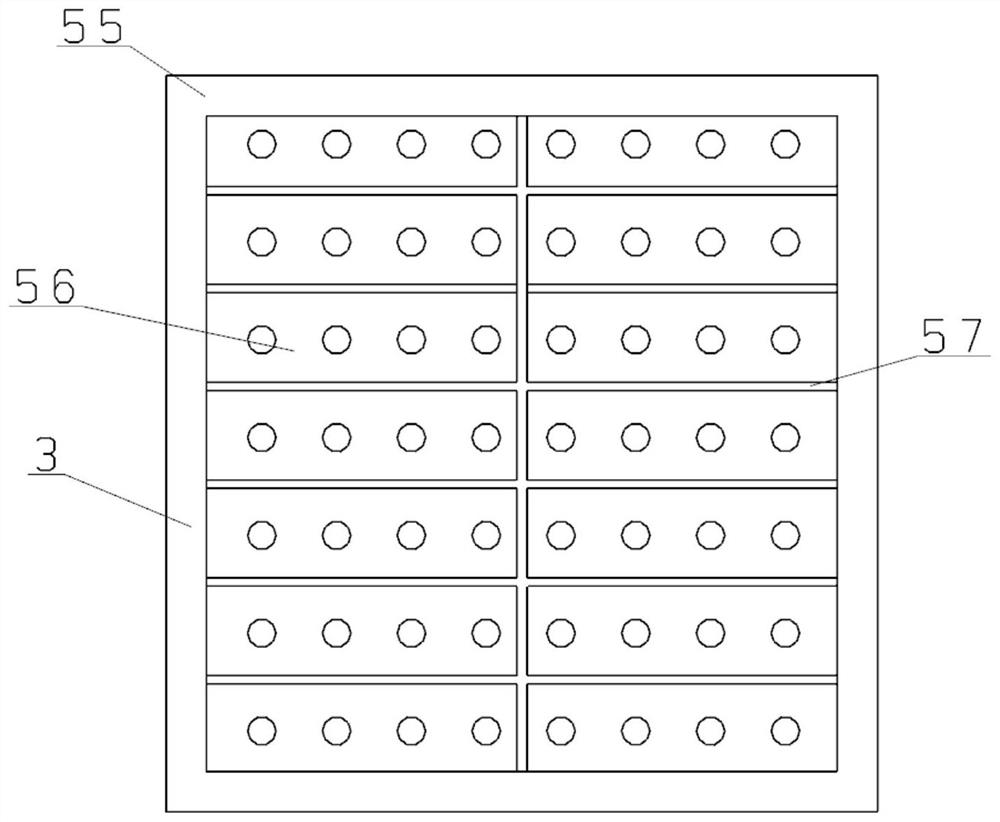

[0033] On the basis of embodiment one, refer to figure 1 , image 3 , Figure 4 , the press cutter 3 includes a knife rest 55, the knife rest 55 is provided with a recoil air pump 58 communicating with the lower chamber of the knife rest 55, an orifice 56 is arranged under the knife rest 55, and the hole A cross knife 57 is arranged under the plate 56; when the cut skin is stuck on the cross knife 57, the recoil air pump 58 inflates into the pressure cutter 3, and the high-speed air flow passes through the orifice plate 56, and the skin stuck on the cross knife 57 Blow down to prevent the cross knife 57 from being stuck by the outer skin.

[0034] Working principle: In the process of use, when using the device, the inner core is connected to the take-up roller 15, the upper layer of skin is under the pressure cutter 3, the lower layer of skin enters the conduit 16, and the device is started, driven by the second motor 14 , the inner core pulls the cable to move, while the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com