Preparation method of high-impact-strength polypropylene kettle internal alloy

A technology of high-impact polypropylene and alloys in kettles, which is applied in the field of preparation of alloys in high-impact polypropylene kettles, can solve problems such as reduced rigidity, and achieve improved rigidity-toughness balance characteristics, good fluidity, and not easy to stick to kettles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The reactor for preparing the high-impact polypropylene inner alloy is a steel pressure-resistant reactor with a mechanical stirring device and a temperature control jacket, and the volume of the reactor is 0.8L. There are gaseous monomer feed ports and valves on the bottom and cover of the reactor, and catalyst feed ports, pressure gauges and exhaust lines with pressure controllers are also located on the cover.

[0036] Before the reaction, the temperature of the kettle was raised to 100°C, and the kettle was evacuated for 2 hours through the catalyst feed port to remove moisture and air in the kettle, and then the temperature of the kettle was lowered to 20-50°C, and the stirring speed was adjusted to 300 rpm. Fill the polymerization grade propylene to 0.1~0.2MPa (absolute pressure, the following are absolute pressure) through the gaseous monomer feed port of the kettle cover, and add 100mL n-heptane and cocatalyst Al(C 2 h 5 ) 3 (2M n-heptane solution), external e...

Embodiment 2

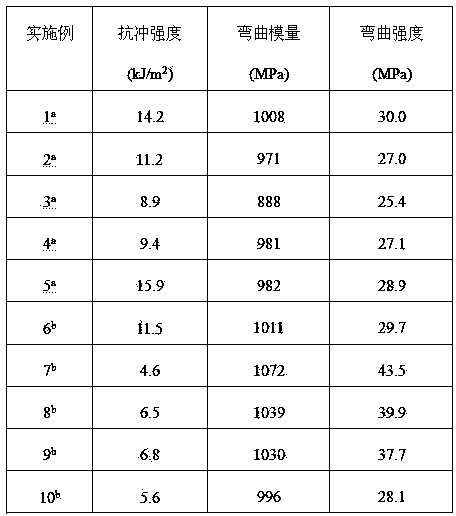

[0041] In embodiment 2, the main catalyst consumption is 67.5 mg, before the copolymerization stage starts, the cocatalyst Al ( i -C 4 h 9 ) 3 with Al(C 2 h 5 ) 3 The molar ratio of dicyclopentyldimethoxysilane to diphenyldimethoxysilane is 0.43:1, and the rest of the operating procedures and polymerization conditions are the same as in Example 1. The catalytic efficiency of the polymerization reaction was 1.93 kg polymer / g catalyst. The polymerization product is a free-flowing fine powder particle, wherein the content of ethylene-propylene random copolymer is 17.0% (wt). The mechanical properties test results of the polymer products are listed in Table 1.

[0042]

Embodiment 3

[0044] In embodiment 3, the amount of main catalyst is 58.7 mg, before the copolymerization stage starts, add co-catalyst Al ( i -C 4 h 9 ) 3 , Al( i -C 4 h 9 ) 3 with Al(C 2 h 5 ) 3The mol ratio is 0.25:1, and all the other operating procedures and polymerization conditions are the same as in Example 1. The catalytic efficiency of the polymerization reaction was 2.33 kg polymer / g catalyst. The polymerization product is a free-flowing fine powder particle, wherein the content of ethylene-propylene random copolymer is 16.0% (wt). The mechanical properties test results of the polymer products are listed in Table 1.

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com