A kind of black phosphorus nanosheet and its preparation method and application

A technology of nano-sheets and black phosphorus, which is applied in the field of black phosphorus nano-sheets and its preparation, can solve the problem of high oxidation degree of black phosphorus, and achieve the effect of multiple layers, high oxidation degree, and complete peeling of black phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

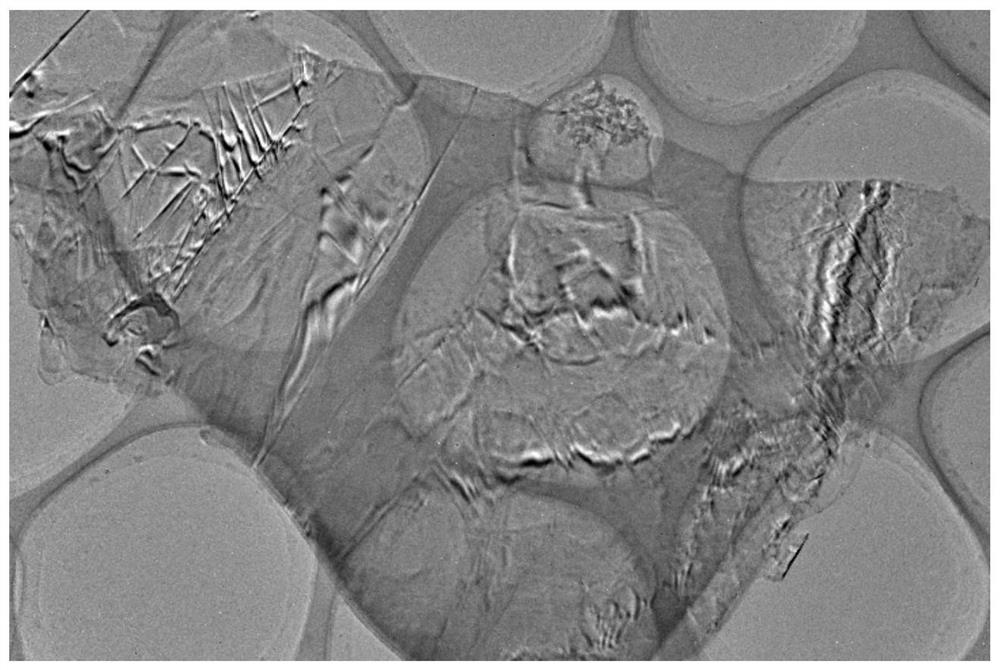

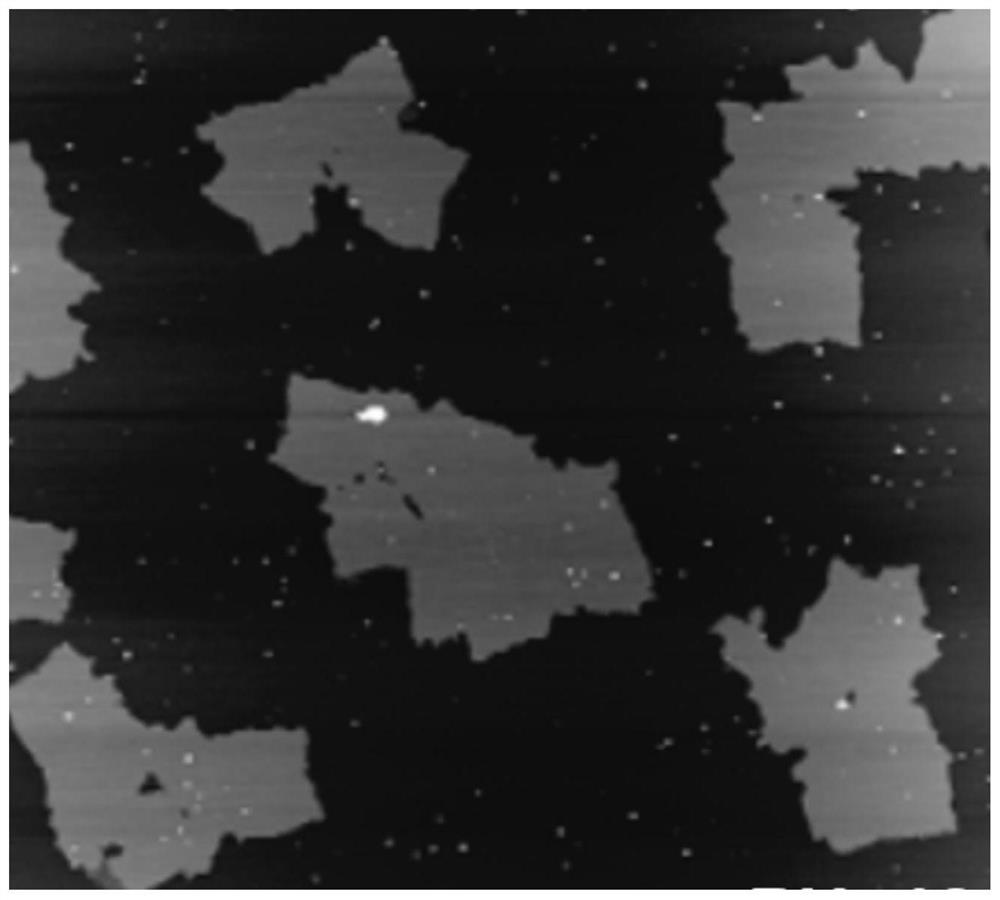

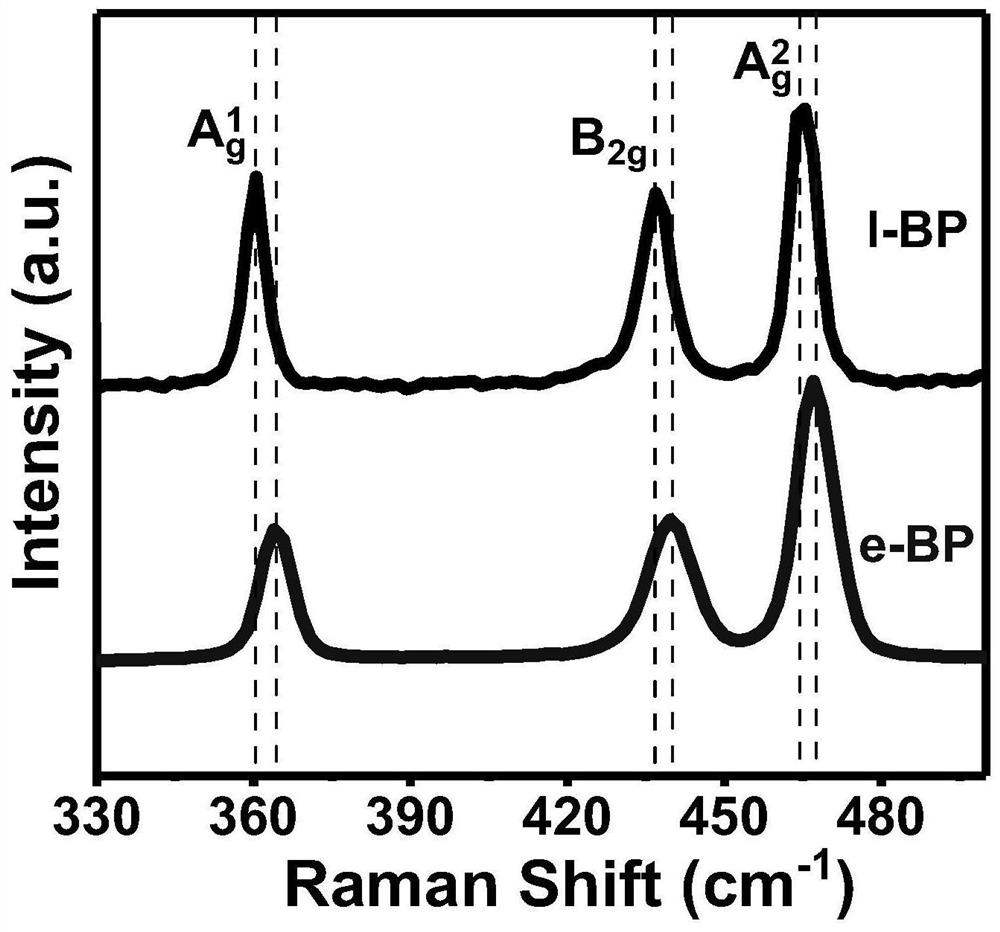

[0052] The method for preparing black phosphorus nanosheets of the present invention uses black phosphorus sheets as electrolytic anodes to construct an electrochemical reaction system together with an inert electrode and an alkaline aqueous electrolyte. The inert electrode can be a platinum electrode or a gold electrode or a carbon rod, Wherein, the alkaline aqueous electrolyte comprises an N-N dimethylformamide solution in which epoxy resin is dissolved.

[0053] Wherein, the epoxy resin is E44 or E51, wherein the mass ratio of epoxy resin to N-N dimethylformamide is 0.1-2%, preferably 0.5-1%. The volume ratio of the N-N dimethylformamide solution dissolved with epoxy resin to the alkaline aqueous electrolyte C is 1:50-1:200, preferably 1:100-1:120. The inventor has proved through a large number of experiments that the addition of epoxy resin is preferably 0.1-2%, and there is almost no effect within this range, but more than 2% will affect the conductivity of the electrolyt...

Embodiment 1

[0061] The preparation method of the present embodiment black phosphorus nanosheets comprises the following steps:

[0062] Step S101, selection of electrodes

[0063] The black phosphorus single crystal is pressed into a black phosphorus sheet with a thickness of 3 mm, which is used as the anode during electrolysis; the platinum electrode is selected as the cathode of the electrolysis;

[0064] Step S102, preparing alkaline aqueous electrolyte

[0065] Select ammonium sulfate to be mixed with 1mol / L ammonium sulfate solution A and 1mol / L ammonium sulfate solution B; in ammonium sulfate solution B, add 2mL of 30% mass fraction of Ammonia water adjusted the pH value of the ammonium sulfate solution B to 9, stirred the mixed solution at a constant speed for 15 minutes, and ultrasonicated it for 5 minutes at 25°C and a power of 50W to obtain an alkaline aqueous electrolyte solution C;

[0066] Step S103, reaction stripping

[0067] In a constant temperature environment at 0°C;...

Embodiment 2

[0100] The preparation method of the present embodiment black phosphorus nanosheets comprises the following steps:

[0101] Step S101, selection of electrodes

[0102] The black phosphorus powder is pressed into a black phosphorus sheet with a thickness of 4 mm, which is used as the anode during electrolysis; the gold electrode is selected as the cathode of the electrolysis;

[0103] Step S102, preparing alkaline aqueous electrolyte

[0104] Select ammonium bisulfate to mix 0.6mol / L ammonium bisulfate solution A and 0.6mol / L ammonium bisulfate solution B; 3mL of 30% ammonia water was used to control the pH value of ammonium bisulfate solution B to 10, and the mixed solution was stirred at a uniform speed for 15 minutes, and ultrasonicated at 25°C and 40W for 5 minutes to obtain alkaline water electrolyte solution C ;

[0105] Step S103, reaction stripping

[0106] In a constant temperature environment at 2°C; black phosphorus flakes are used as the anode, gold electrodes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com