Patents

Literature

80results about How to "Stable peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

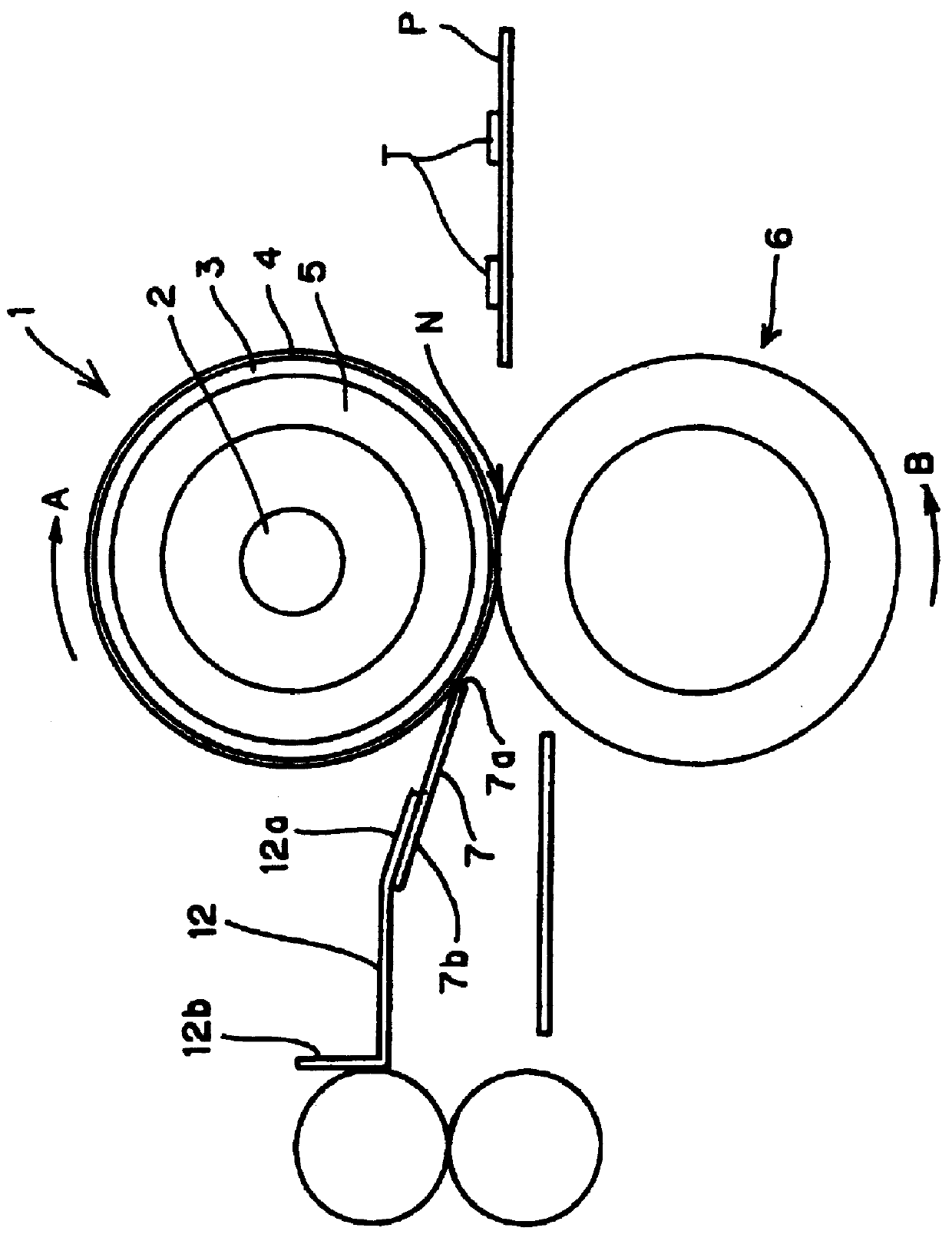

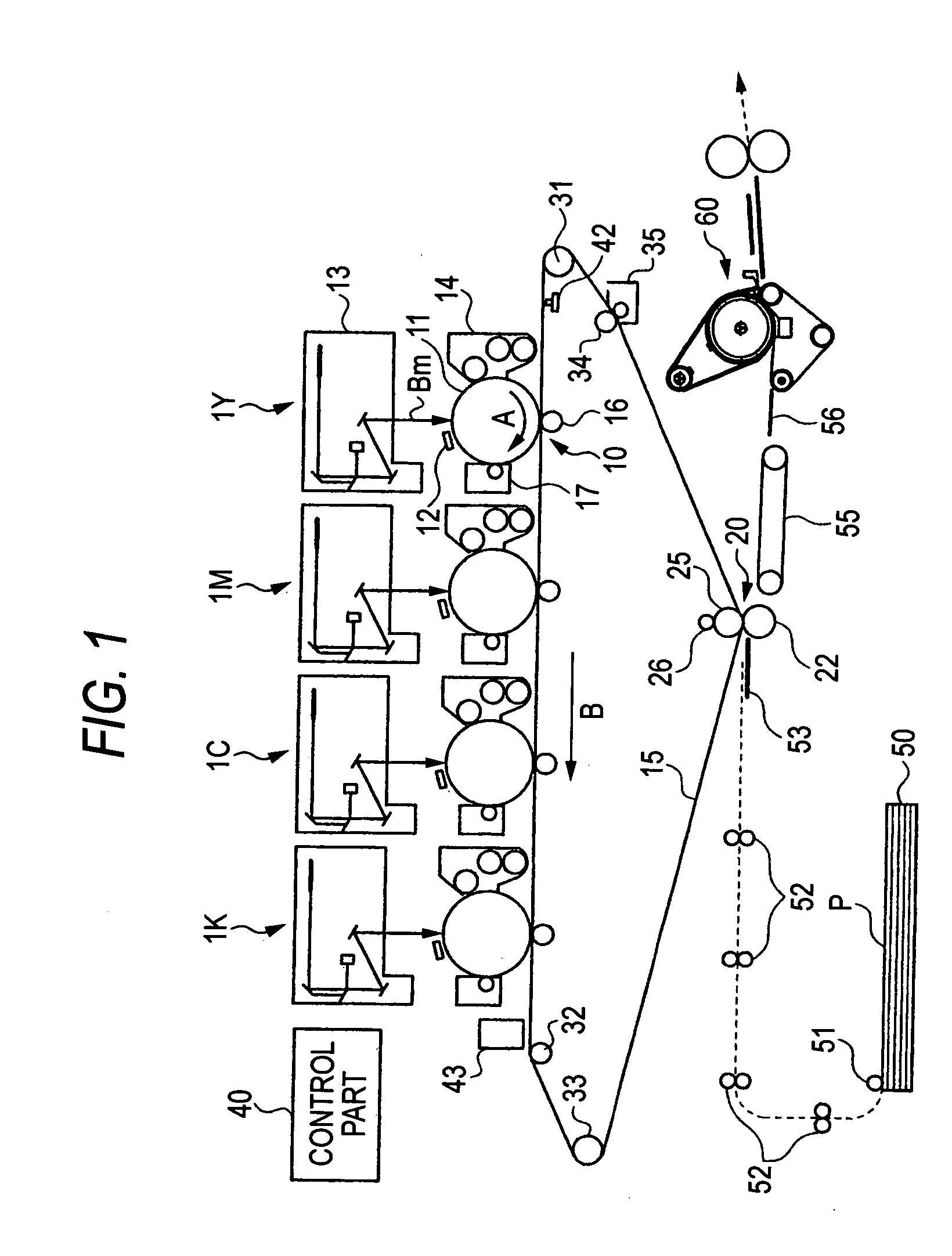

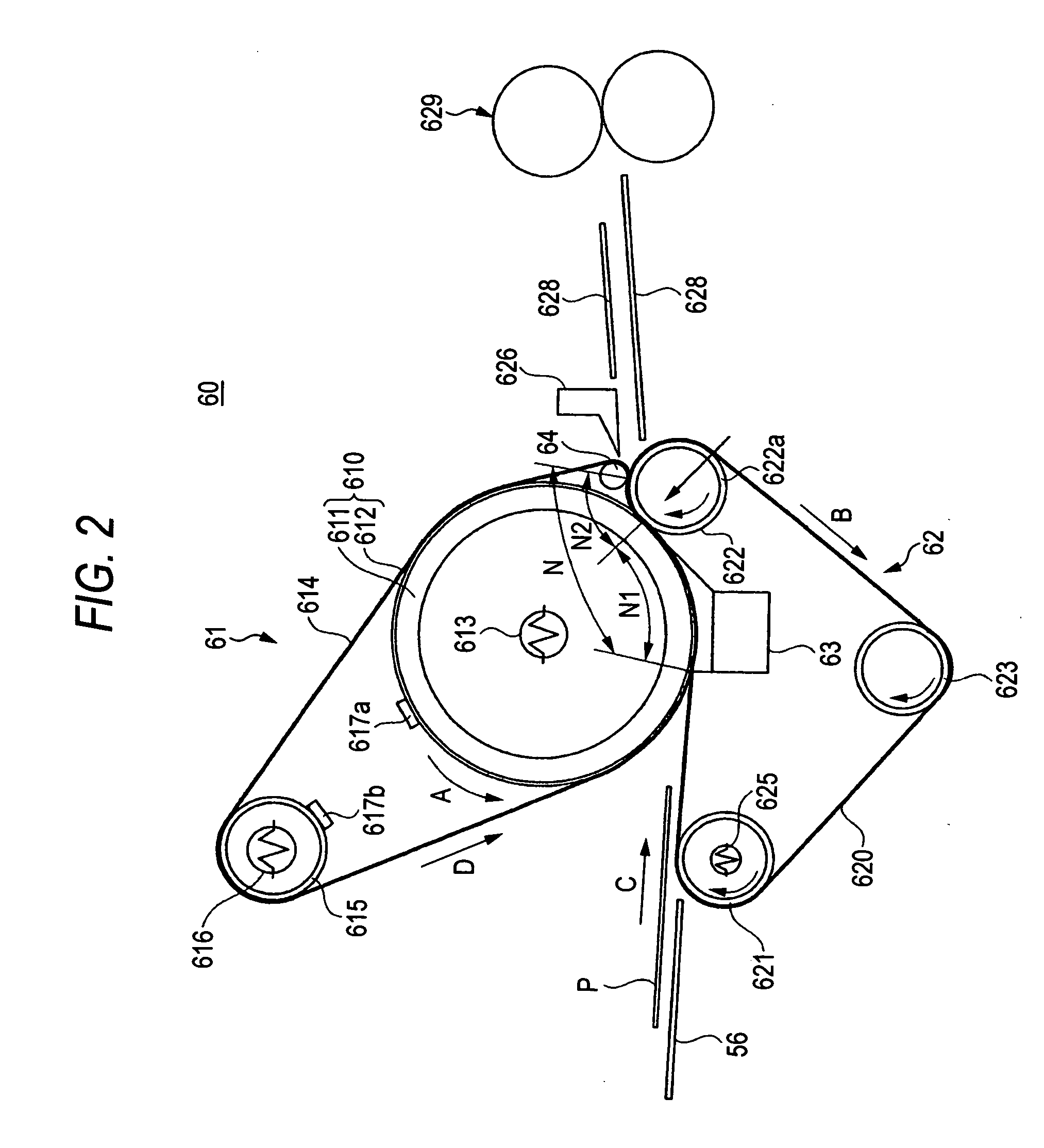

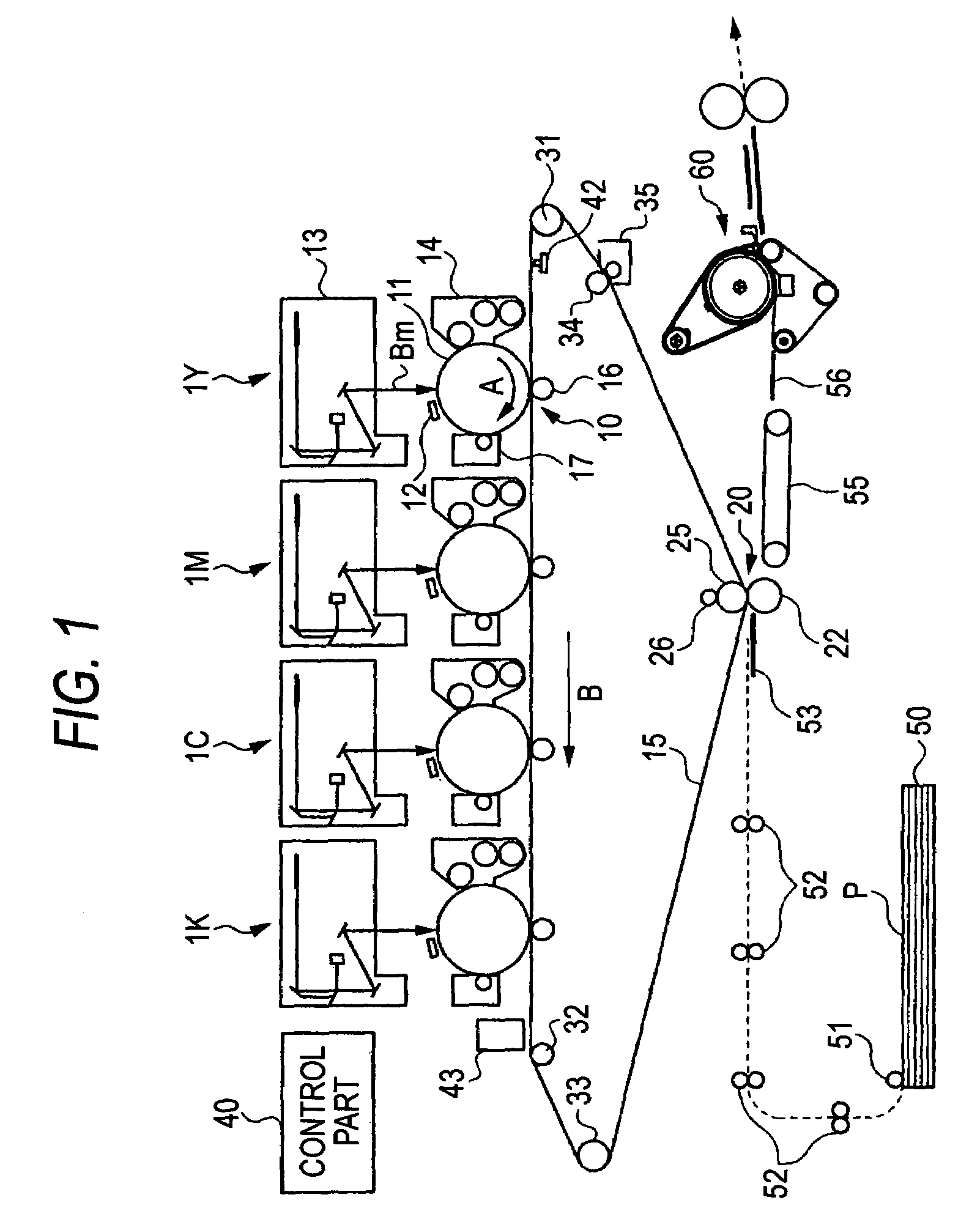

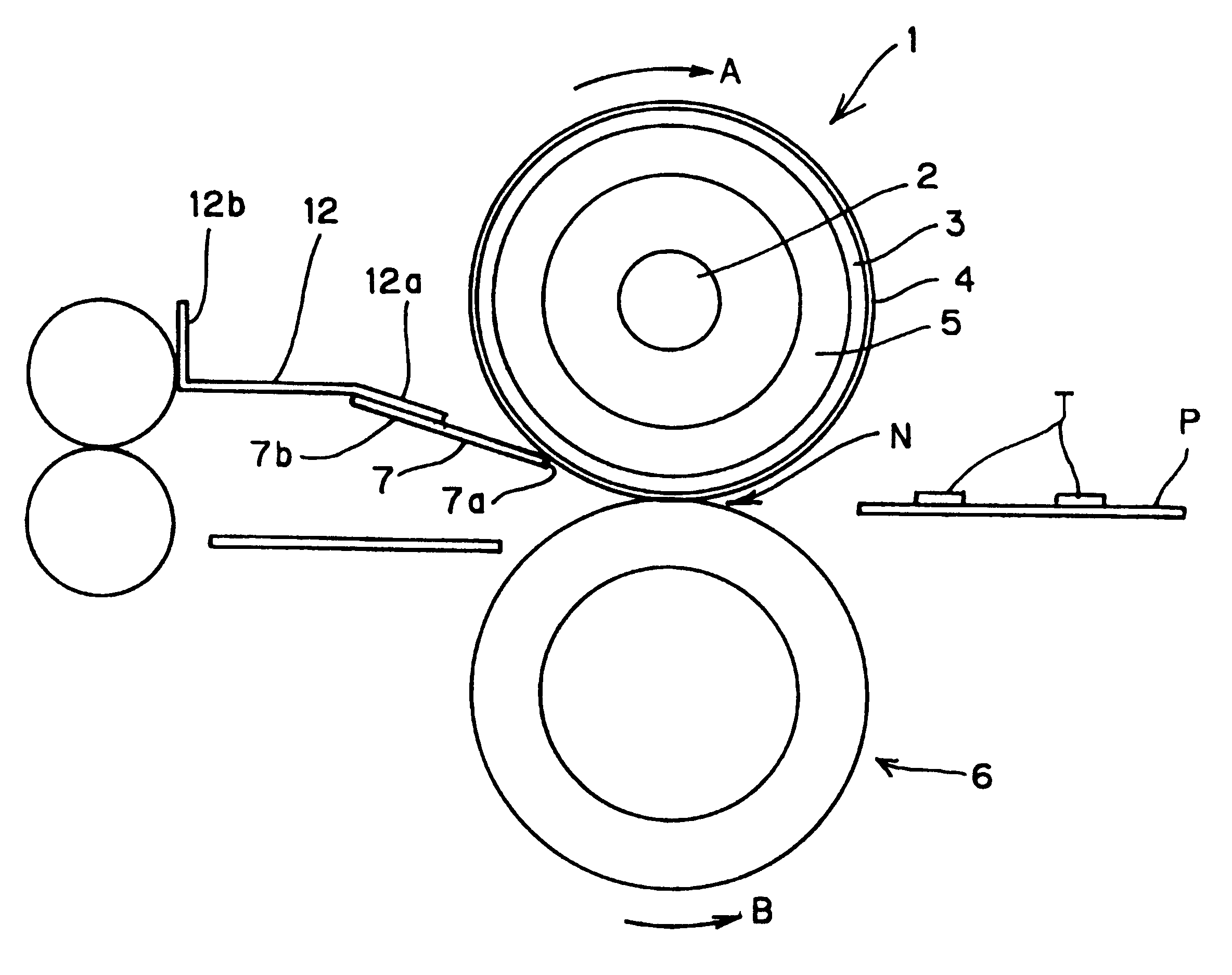

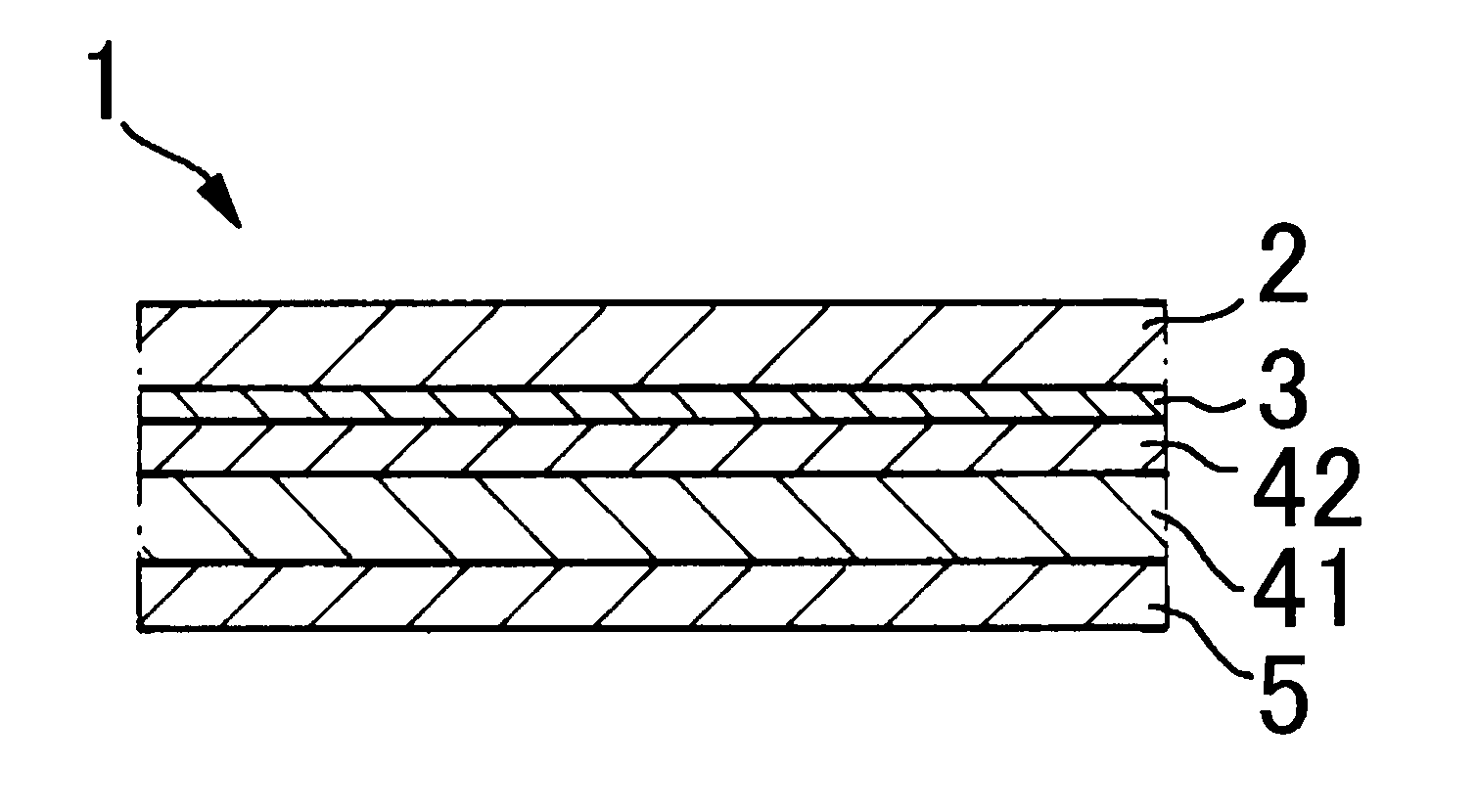

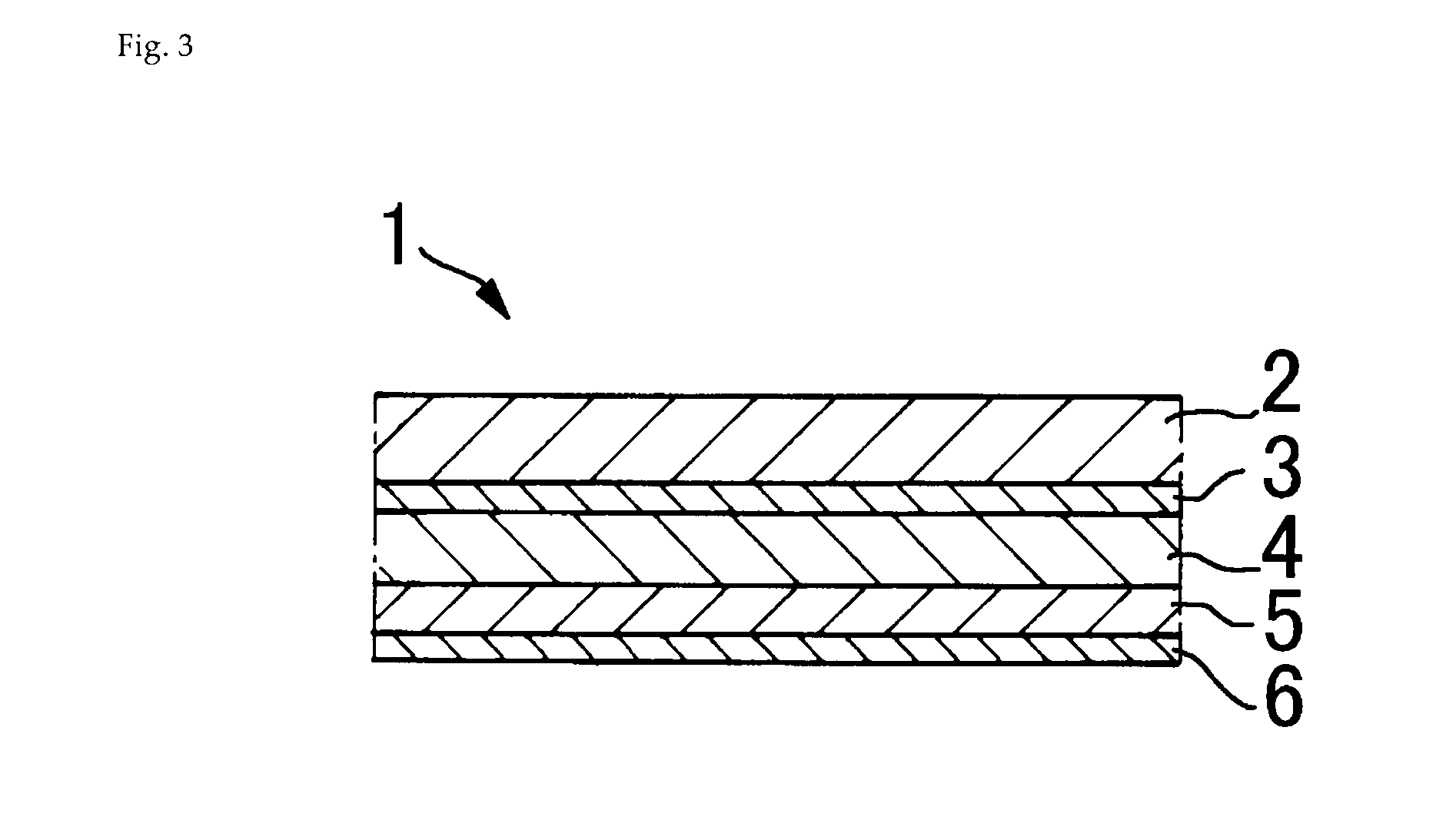

Fixing device

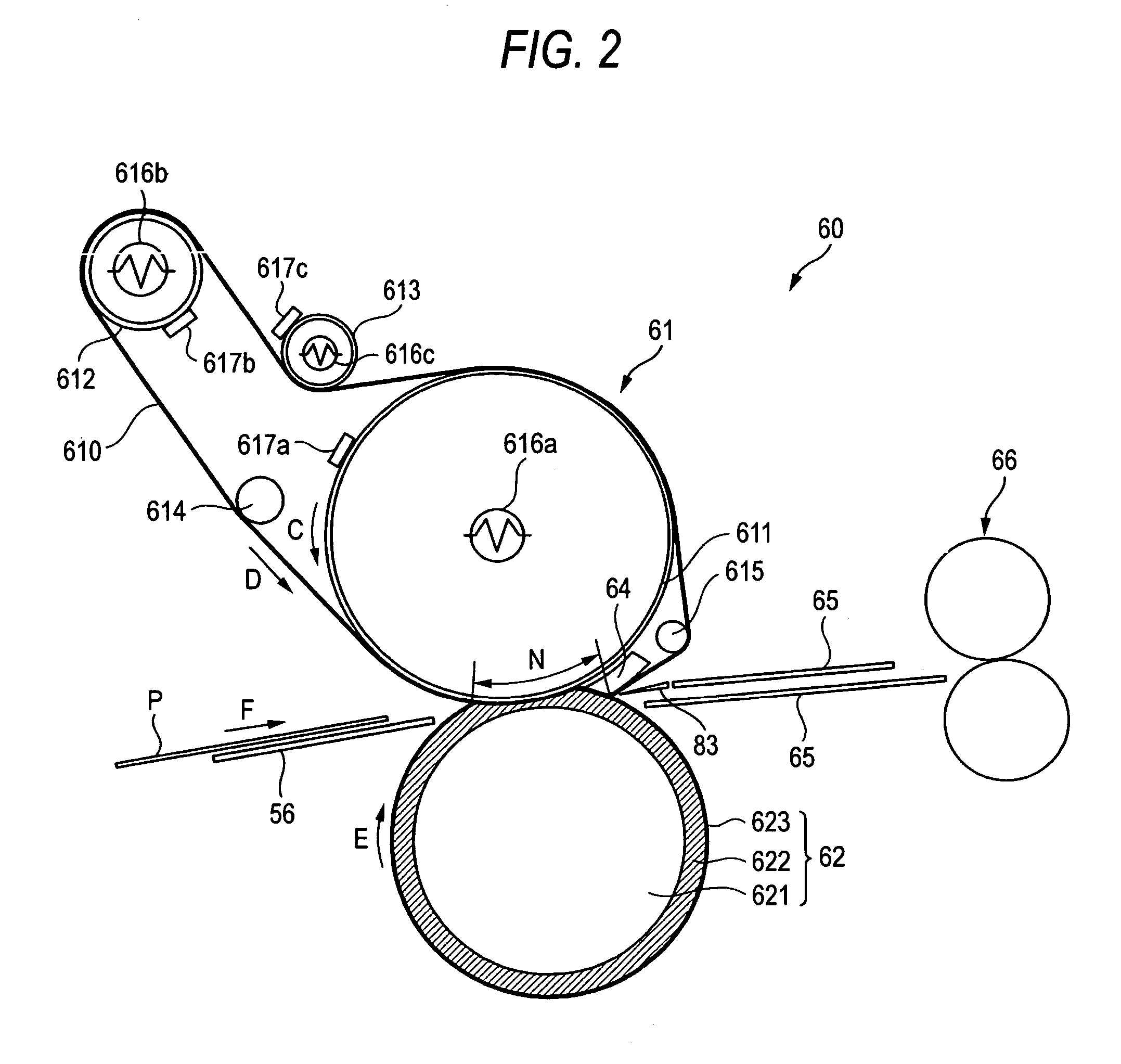

InactiveUS6029038AStable peelingElectrographic process apparatusArticle deliveryEngineeringSheet material

Owner:FUJIFILM BUSINESS INNOVATION CORP

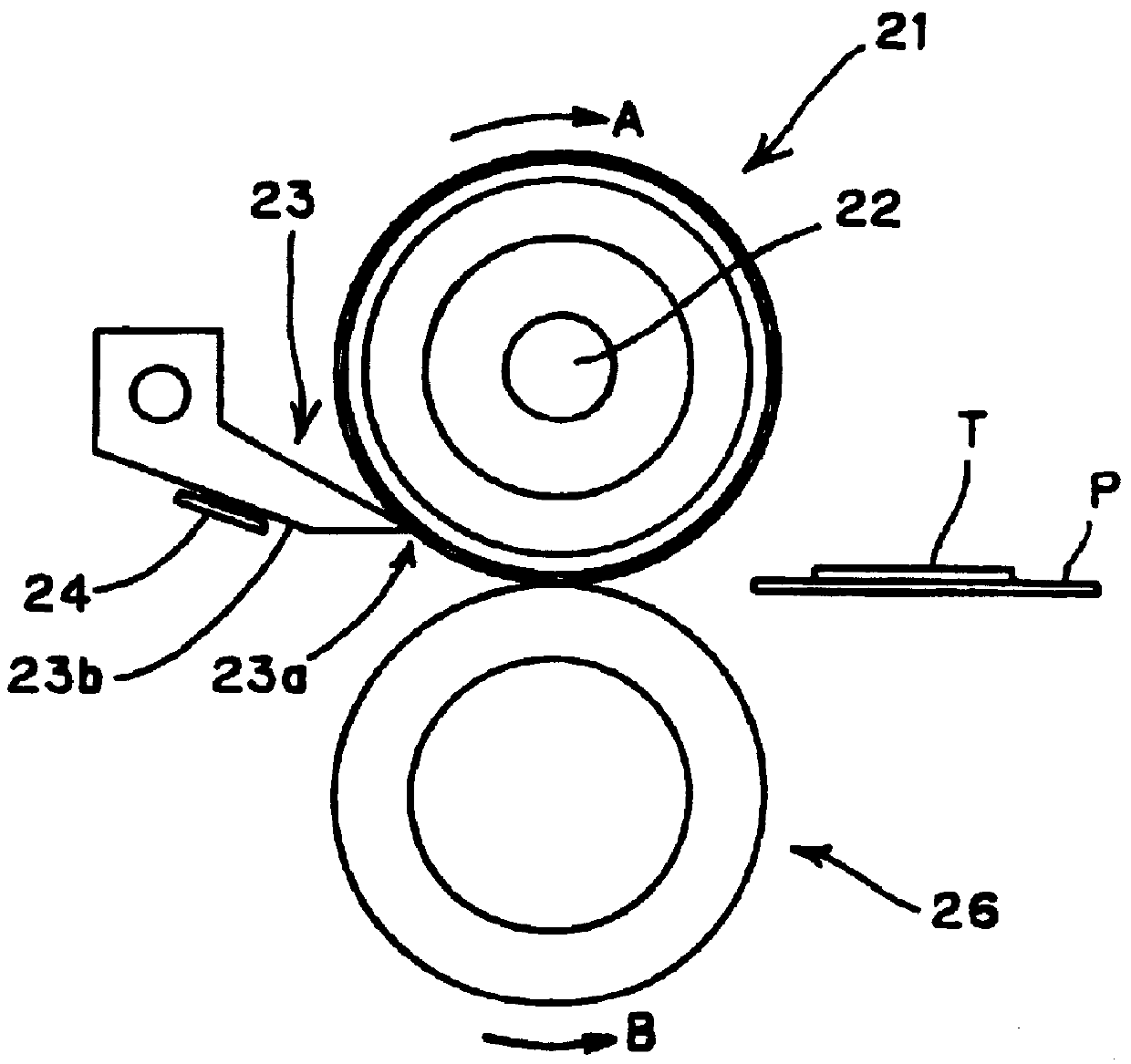

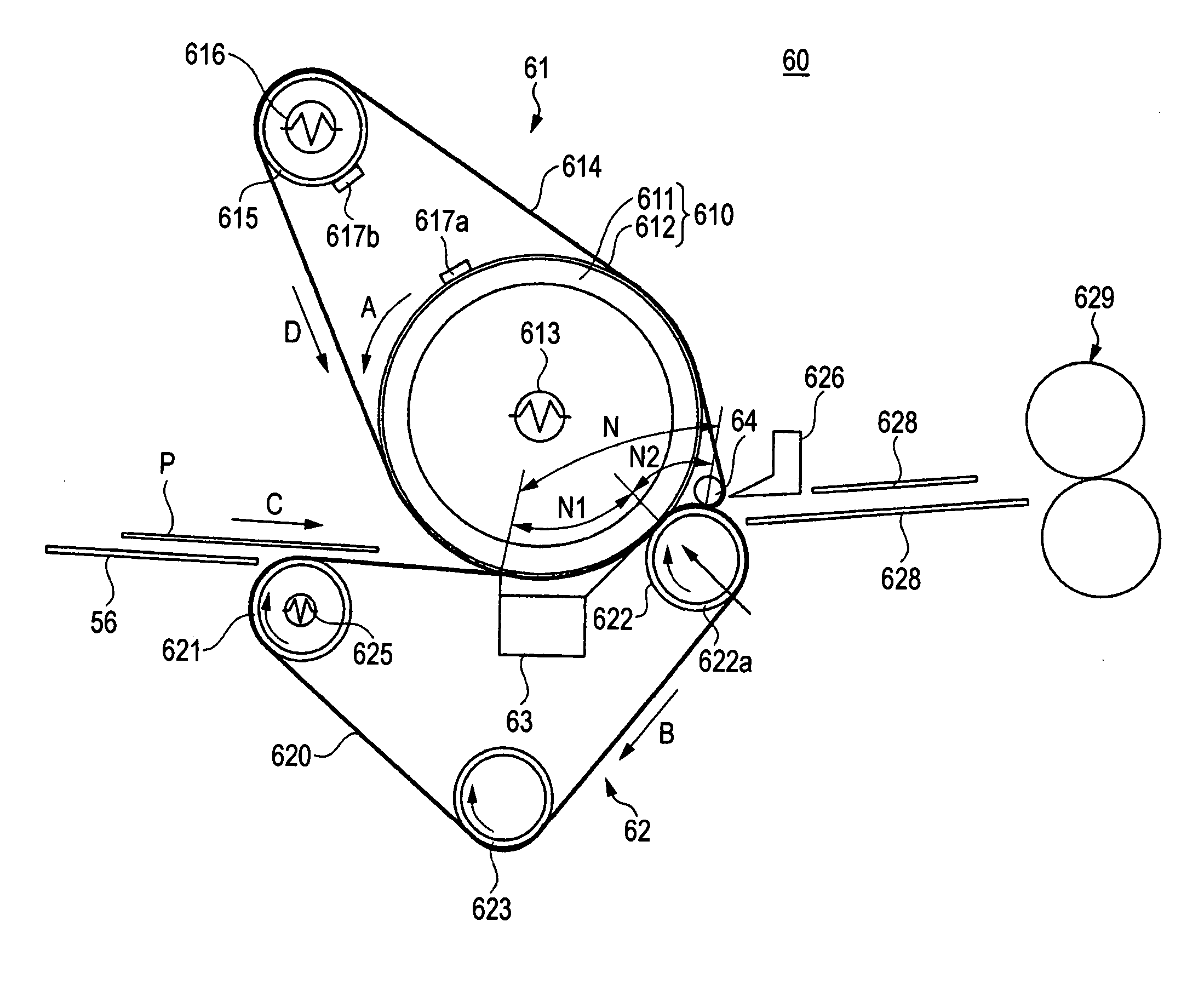

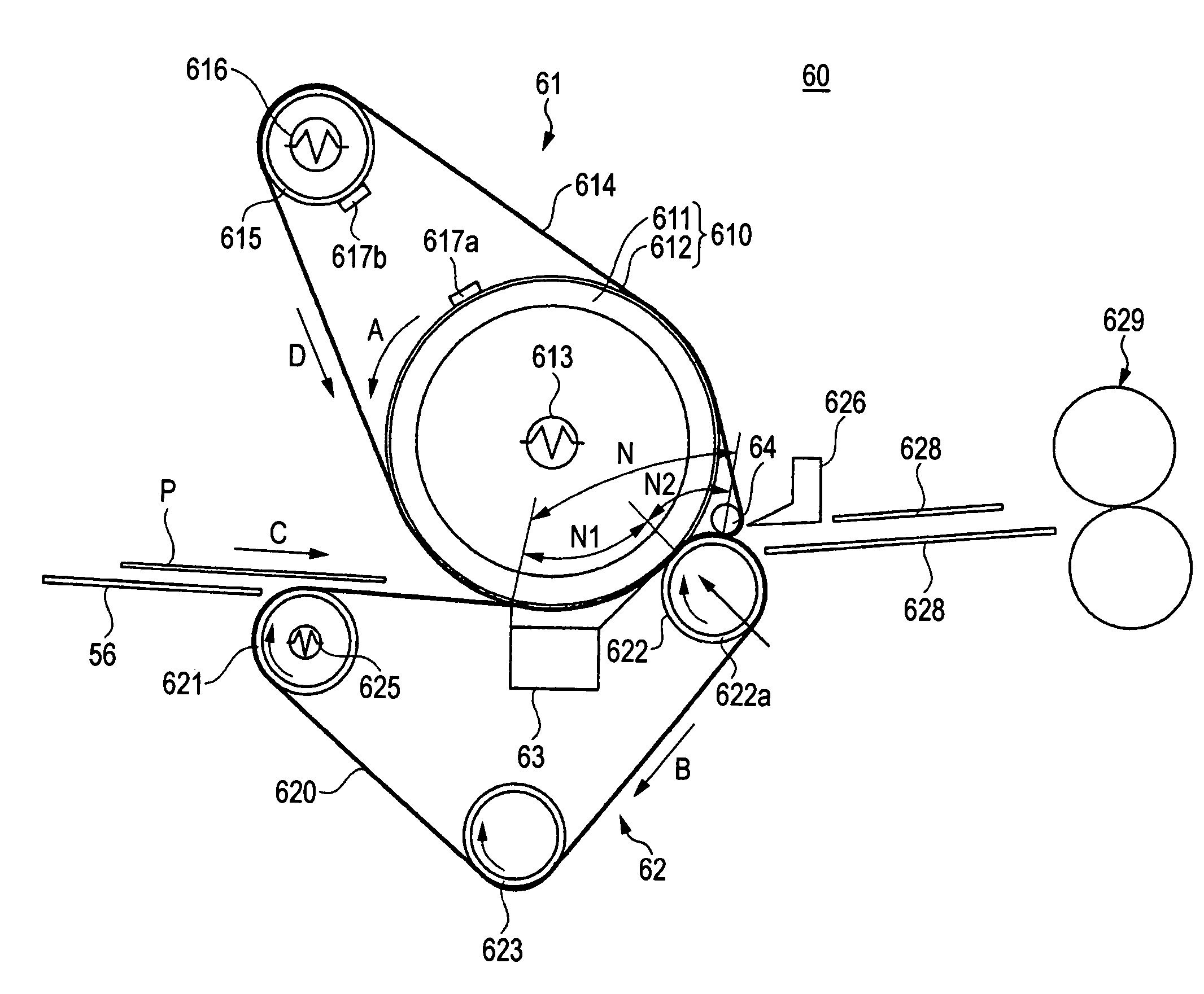

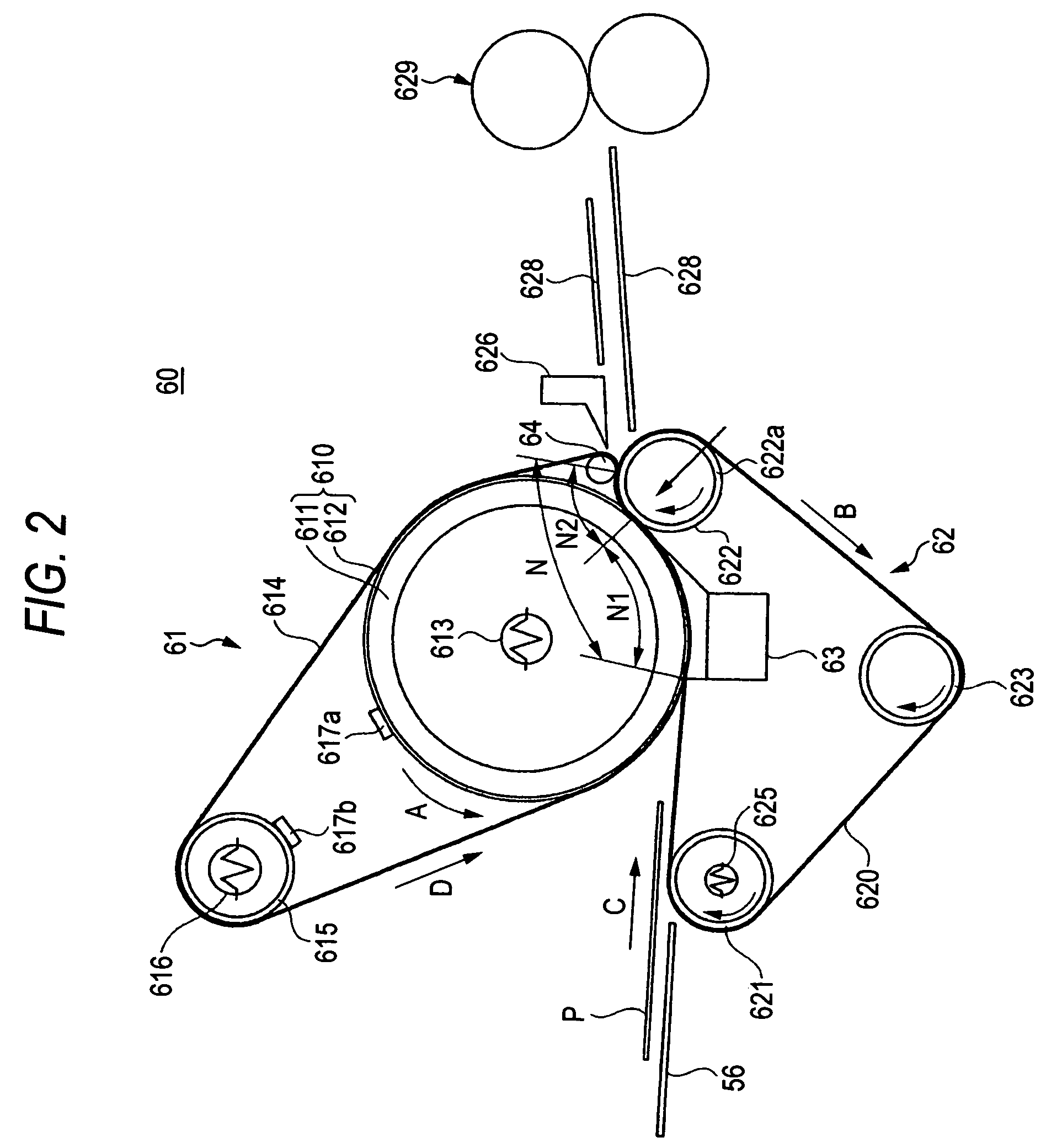

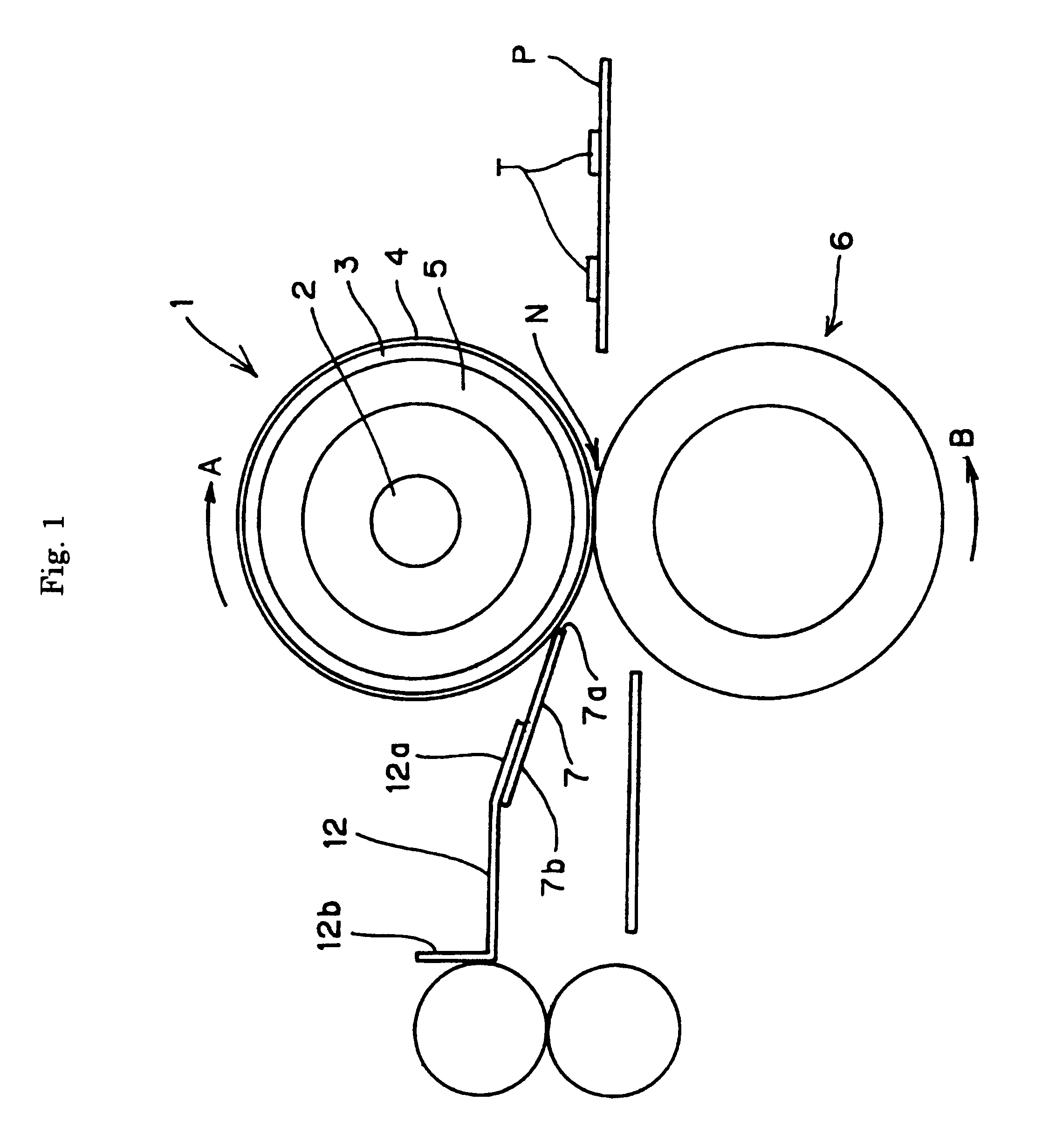

Fixing device and image forming apparatus

InactiveUS20050220507A1Deal with speedingInhibitionElectrographic process apparatusImage formationEngineering

Owner:FUJIFILM BUSINESS INNOVATION CORP

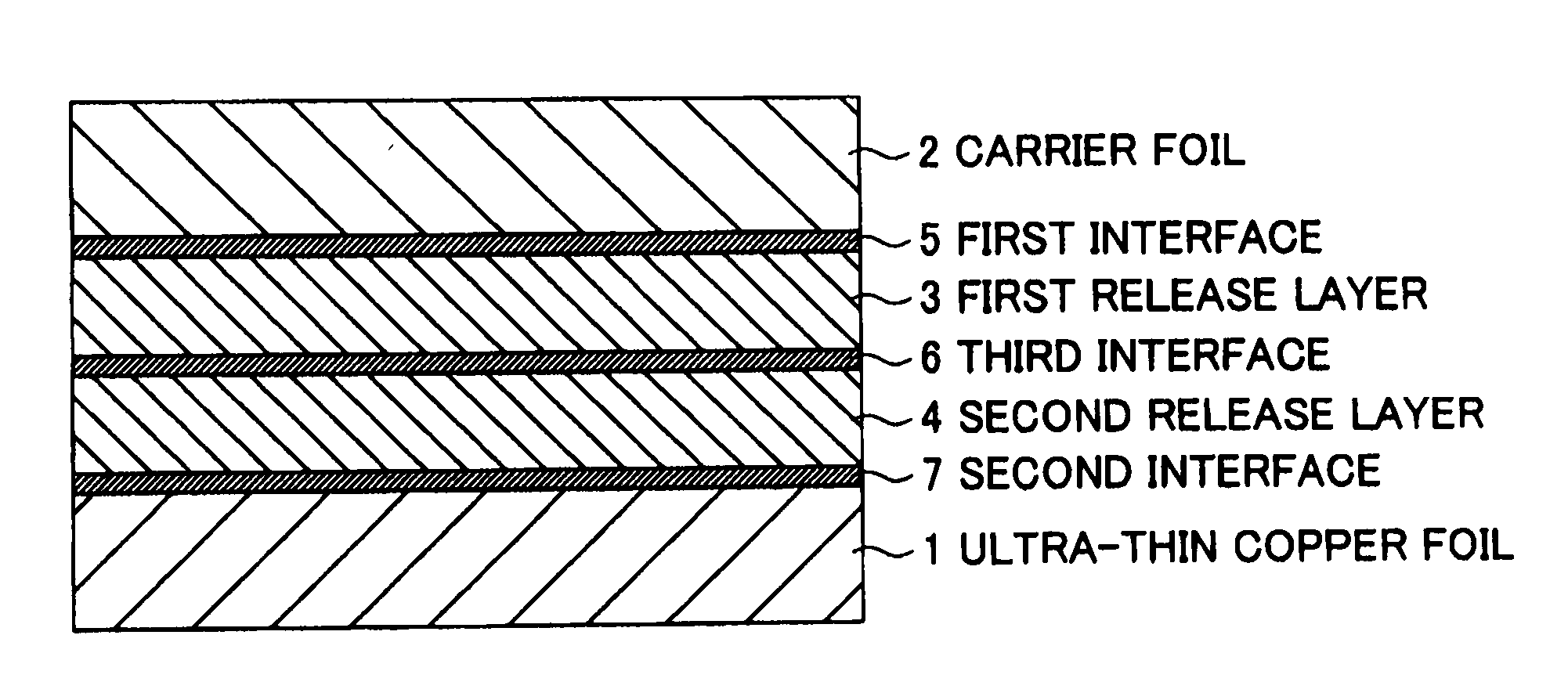

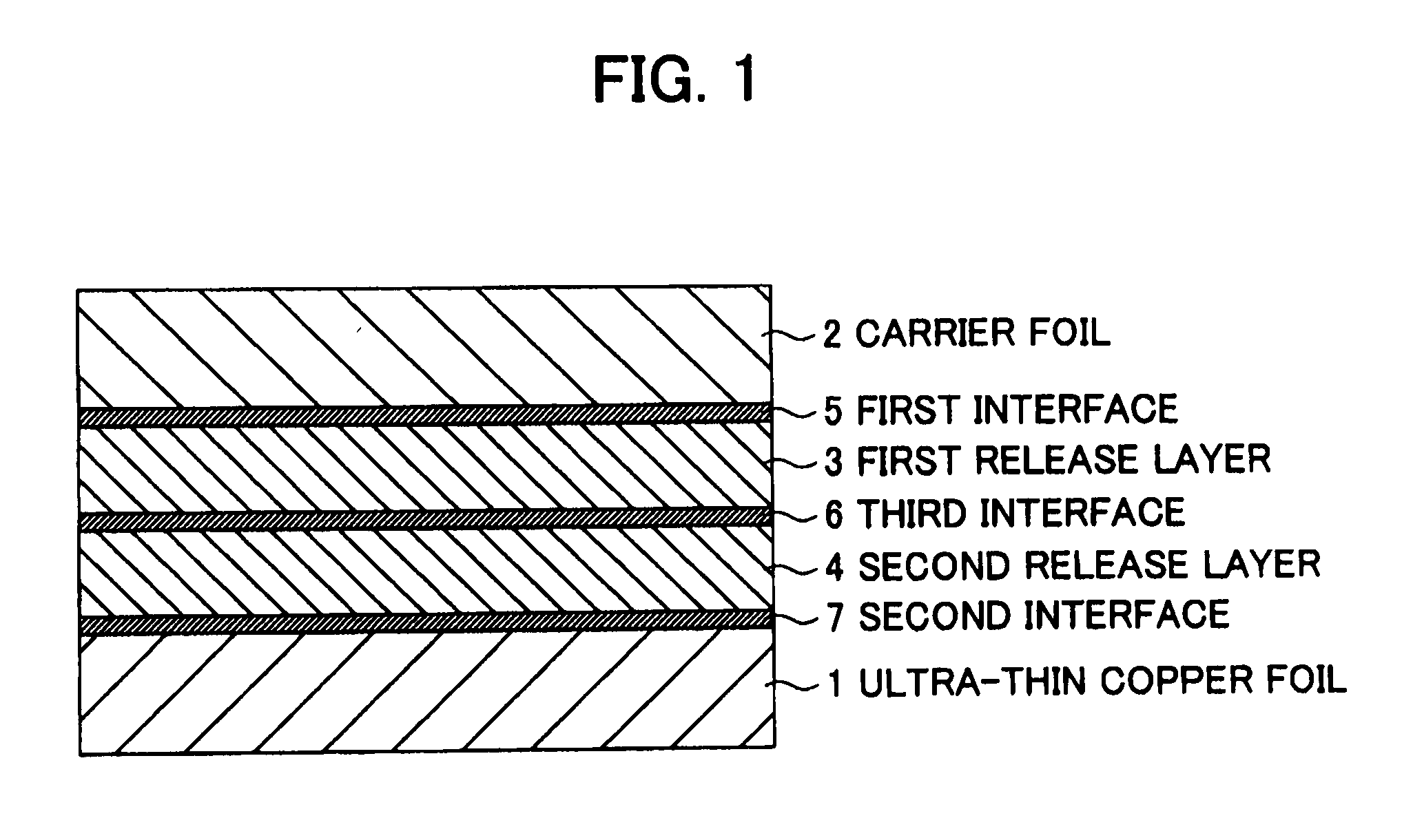

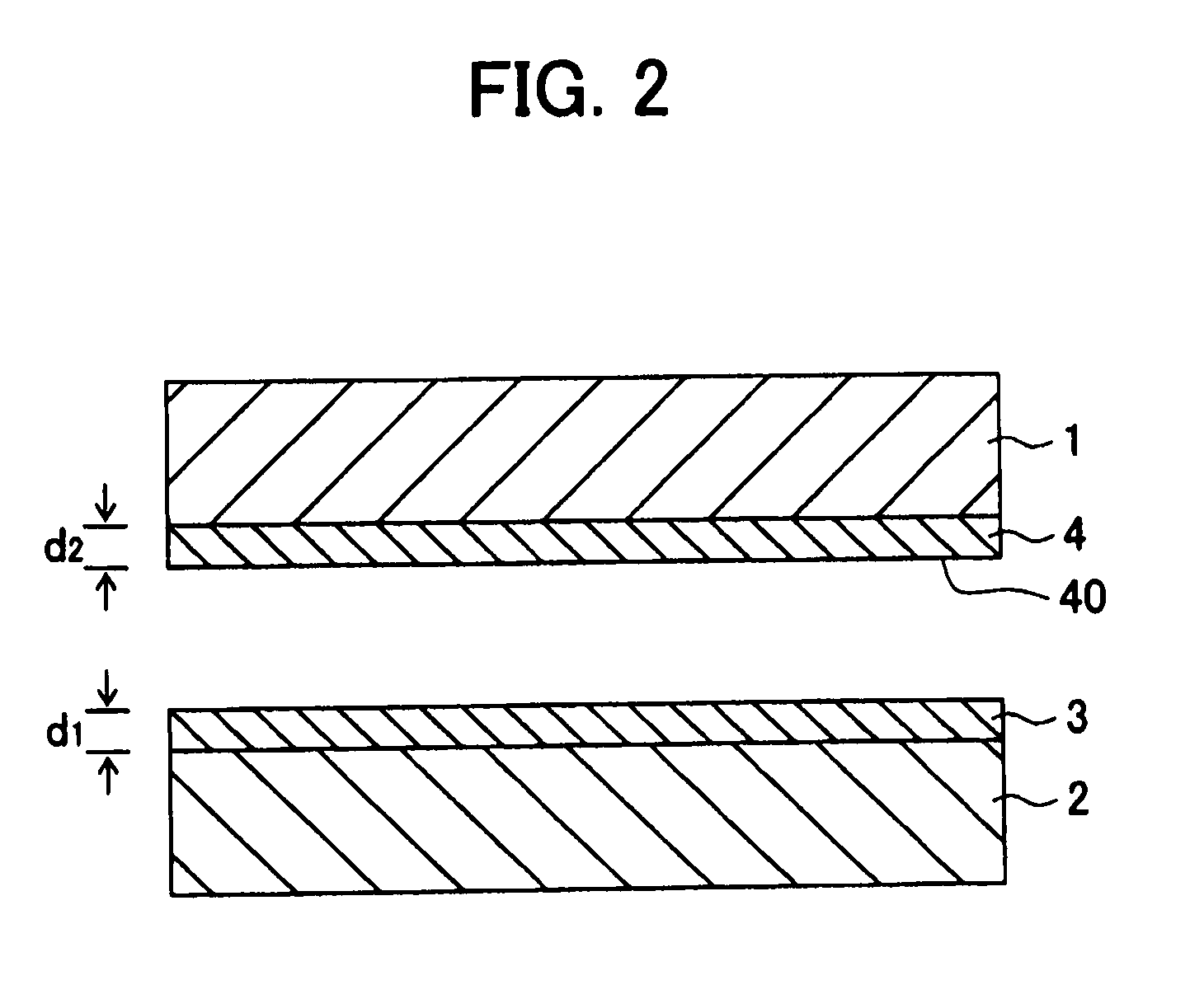

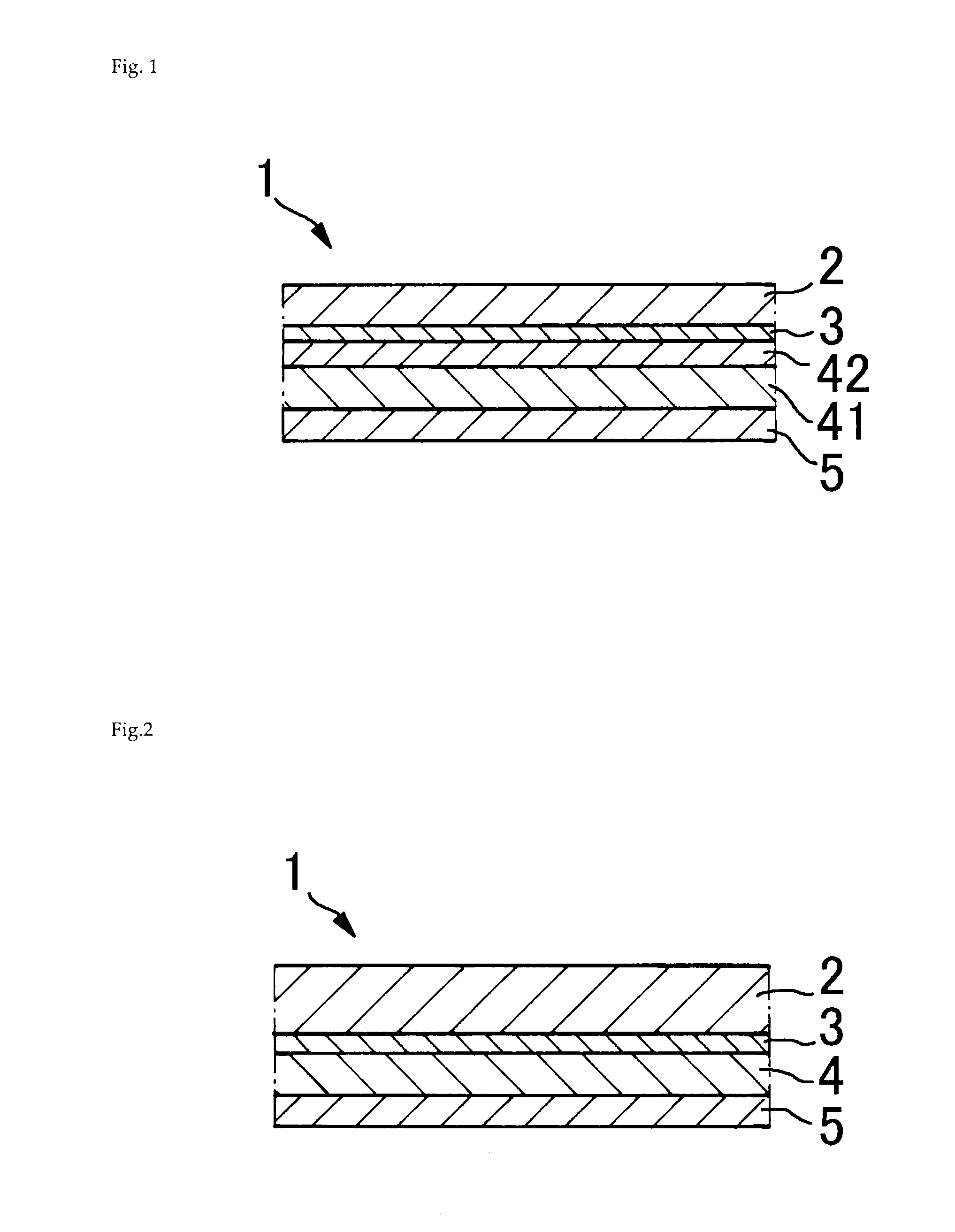

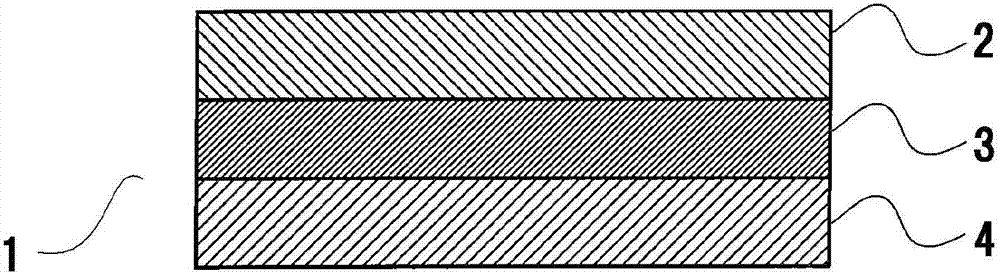

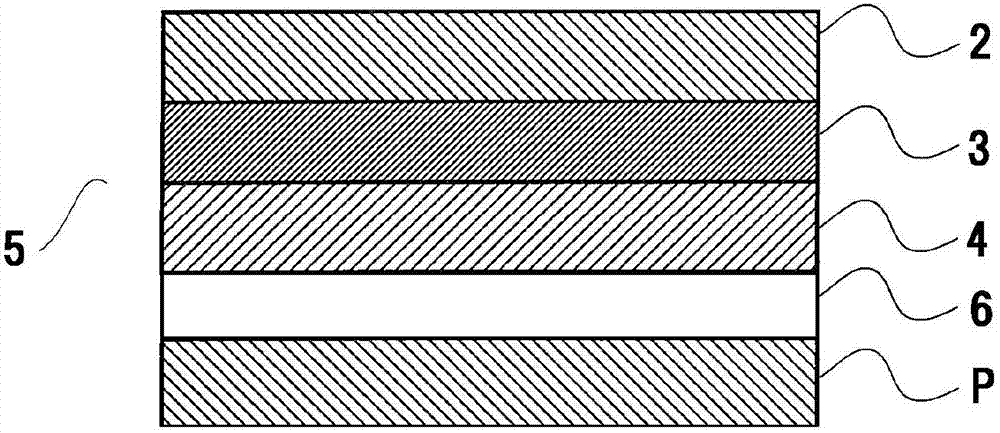

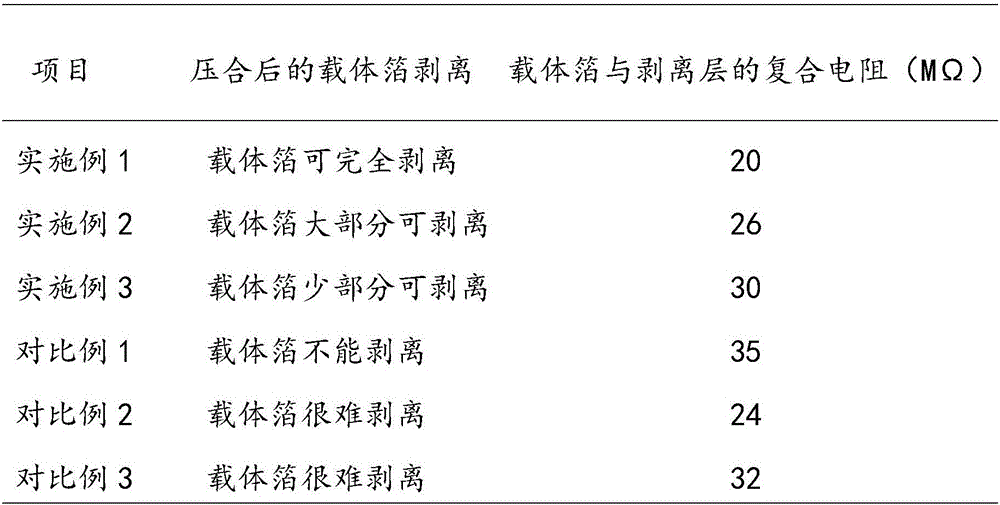

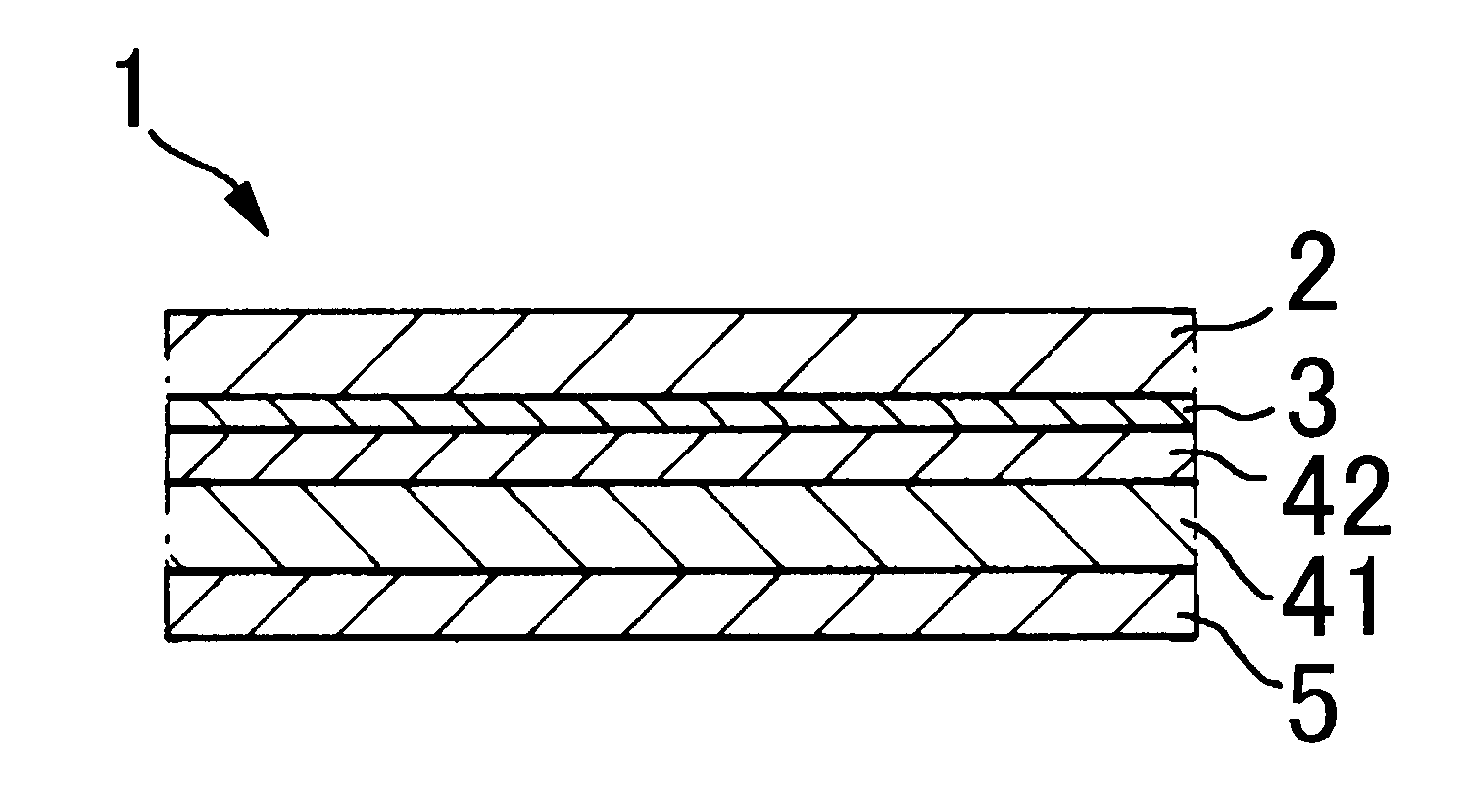

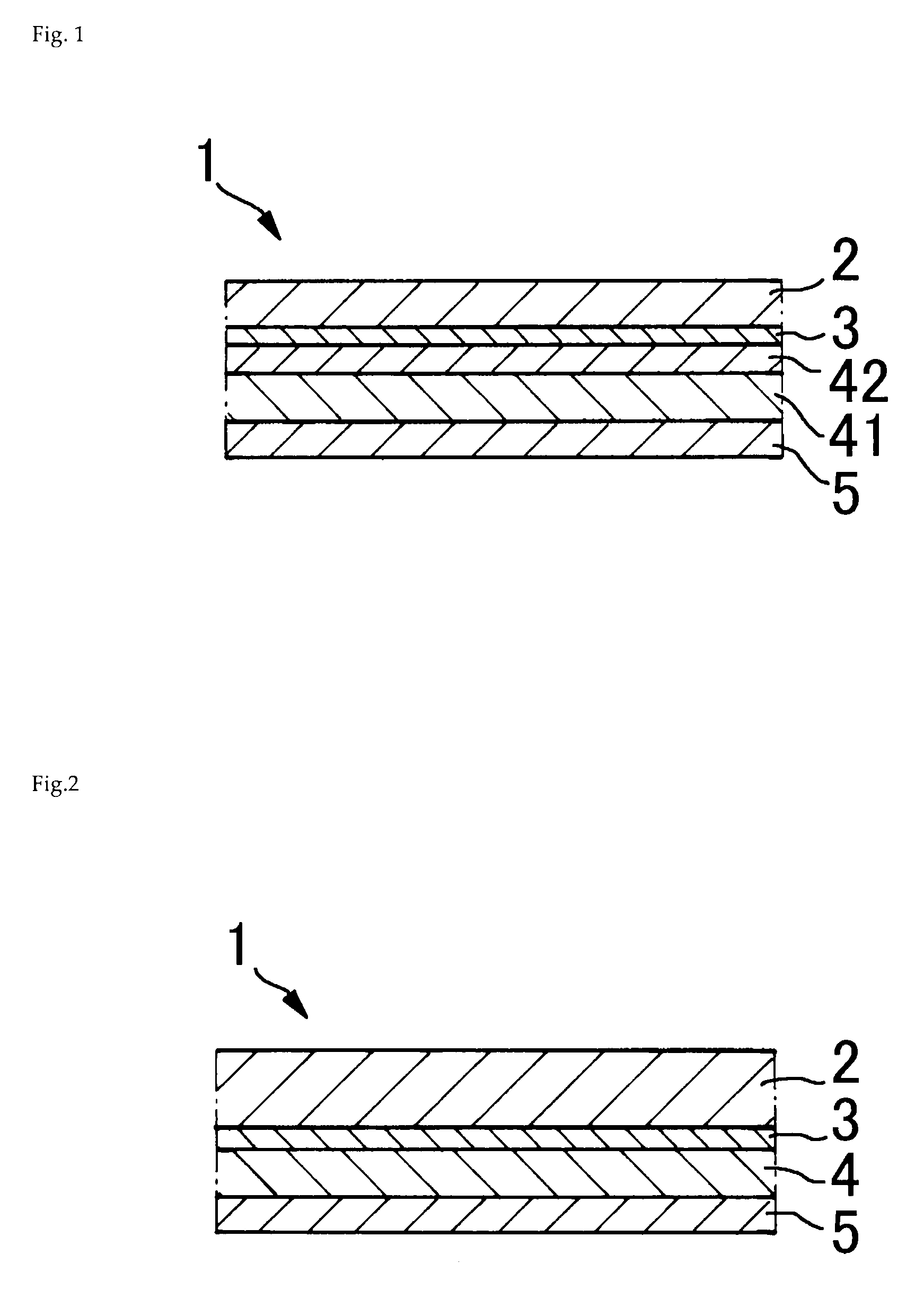

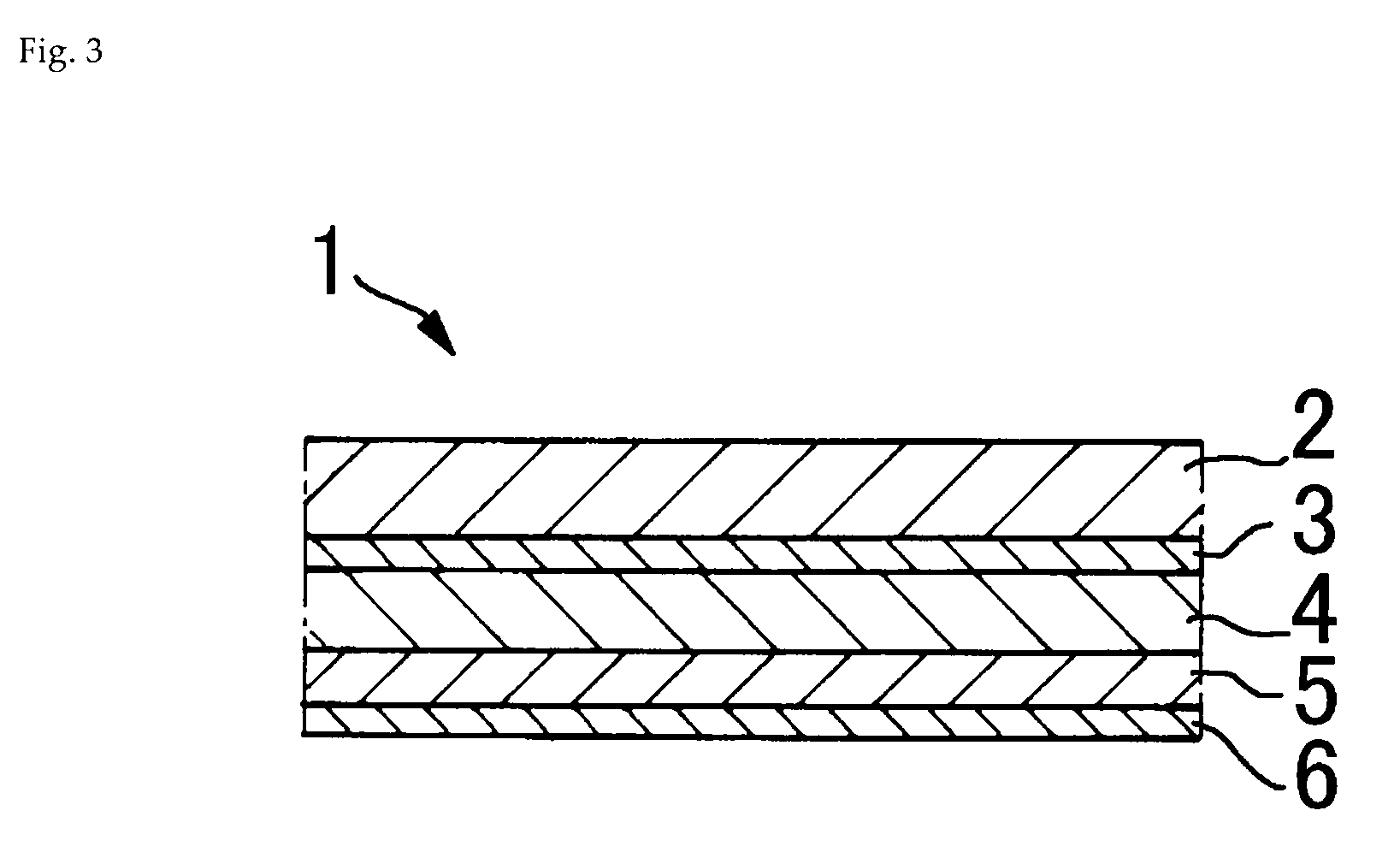

Ultra-thin copper foil with carrier and copper-clad laminate board or printed circuit board substrate

ActiveUS20110209903A1Resistant to blisteringEasy to peelThin material handlingCircuit precursor manufactureCopper foilUltimate tensile strength

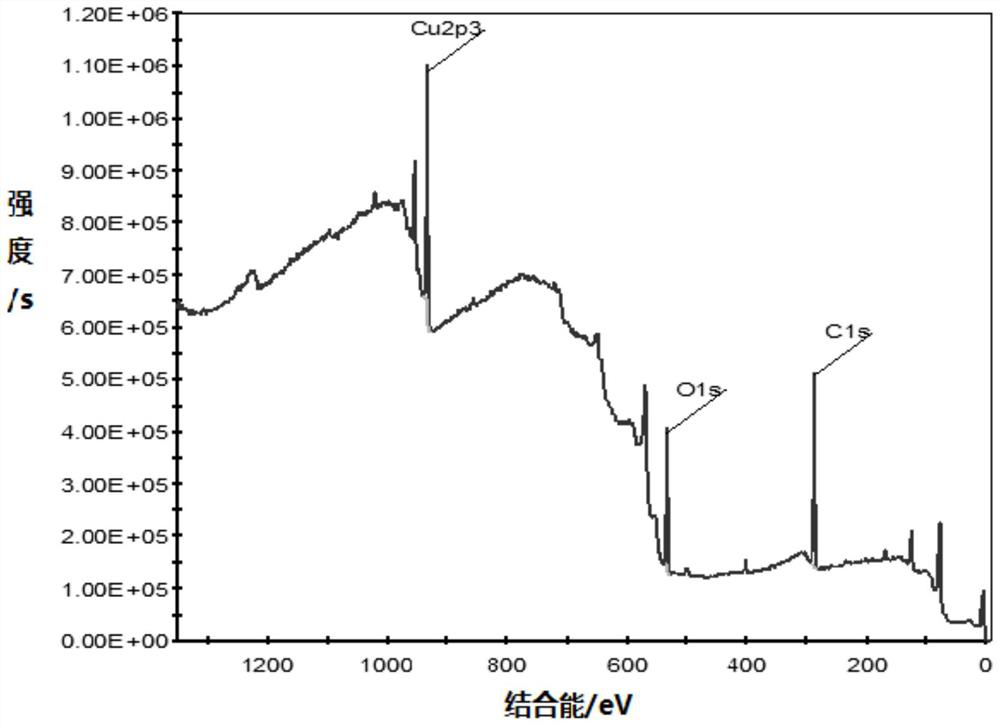

The invention has as its object to provide an ultra-thin copper foil with a carrier which suppresses occurrence of blistering and is stable in peeling strength, in particular provides an ultra-thin copper foil with a carrier enabling easy peeling of a carrier foil from an ultra-thin copper foil even under a high temperature environment. As means for that, there is provided an ultra-thin copper foil with a carrier comprised of a carrier foil, a release layer, and a copper foil, wherein the release layer is formed by a first release layer disposed on the carrier foil side and a second release layer disposed on the ultra-thin copper foil side, there is a first interface between the carrier foil and the first release layer, a second interface between the ultra-thin copper foil and the second release layer, and a third interface between the first release layer and the second release layer, and the peeling strengths at the interfaces are first interface>third interface, and second interface>third interface.

Owner:FURUKAWA ELECTRIC CO LTD

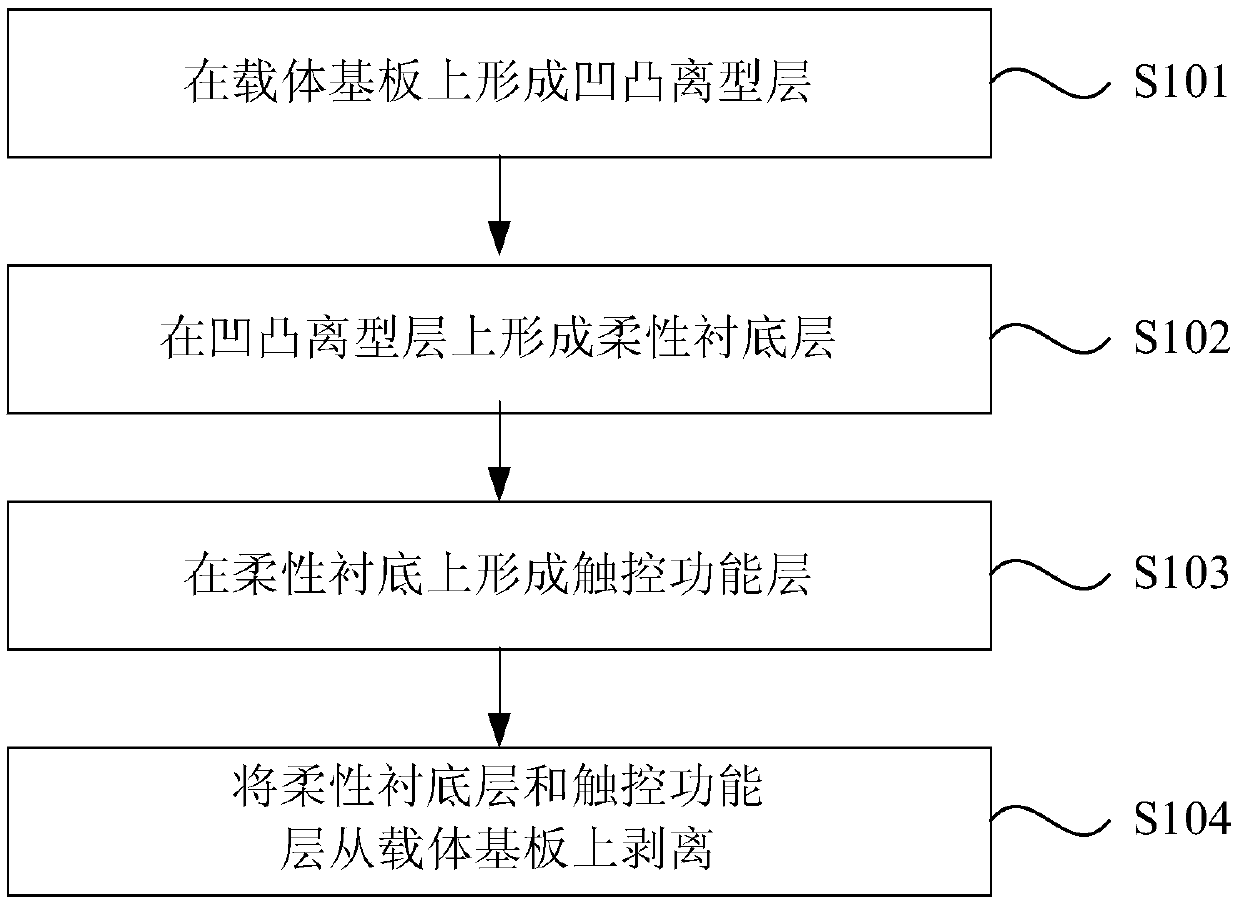

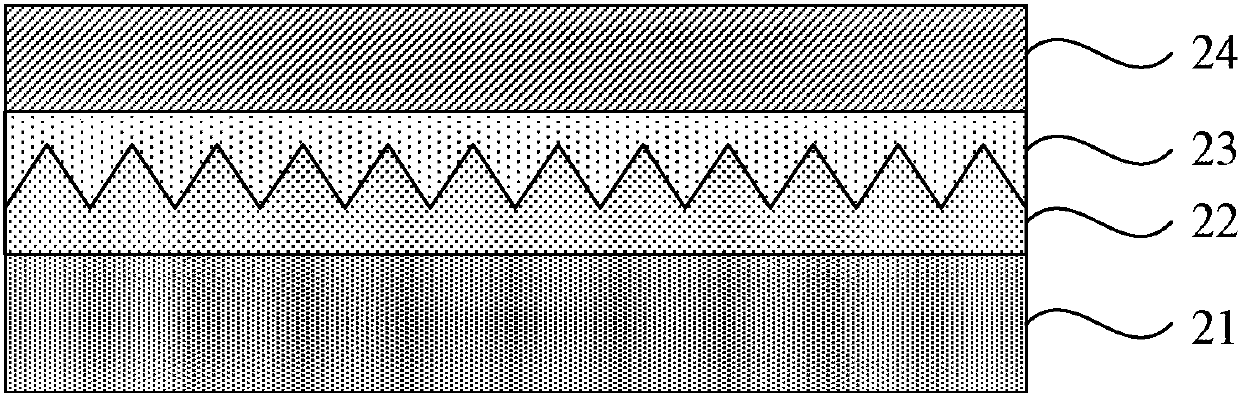

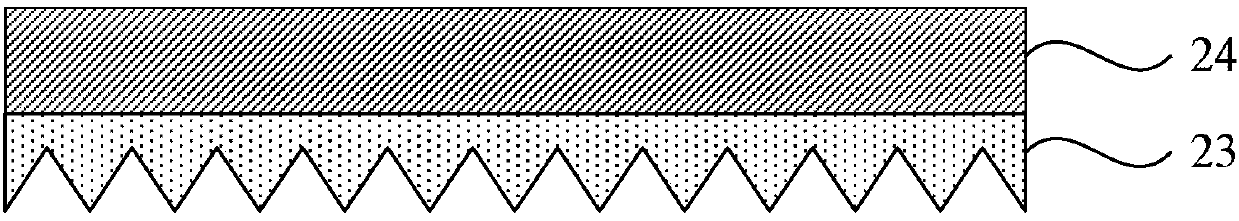

Preparation method of flexible touch substrate and flexible touch substrate

ActiveCN107831941AIncrease roughnessPrevent misalignment and fall offInput/output processes for data processingComputer scienceDislocation

The invention discloses a preparation method of a flexible touch substrate and the flexible touch substrate. The method comprises the steps that a concave-convex release layer is formed on a carrier substrate; a flexible substrate layer is formed on the concave-convex release layer; a touch functional layer is formed on the flexible substrate layer; and the flexible substrate layer and the touch functional layer are stripped from the carrier substrate. According to the method, the concave-convex release layer is arranged on the carrier substrate, the roughness between the flexible substrate layer and the carrier substrate can be enhanced, dislocation and disengagement of the flexible substrate layer are prevented, it is guaranteed that the flexible touch substrate is stably fixed to the carrier substrate at a preparation stage, the flexible touch substrate can be conveniently stripped at a stripping stage, damage to the touch substrate in the striping process is avoided, and the yieldand efficiency of flexible touch substrate release are improved.

Owner:无锡品源知识产权顾问有限公司

Fixing device and image forming apparatus

InactiveUS7155155B2InhibitionStable peelingElectrographic process apparatusImage formationEngineering

Owner:FUJIFILM BUSINESS INNOVATION CORP

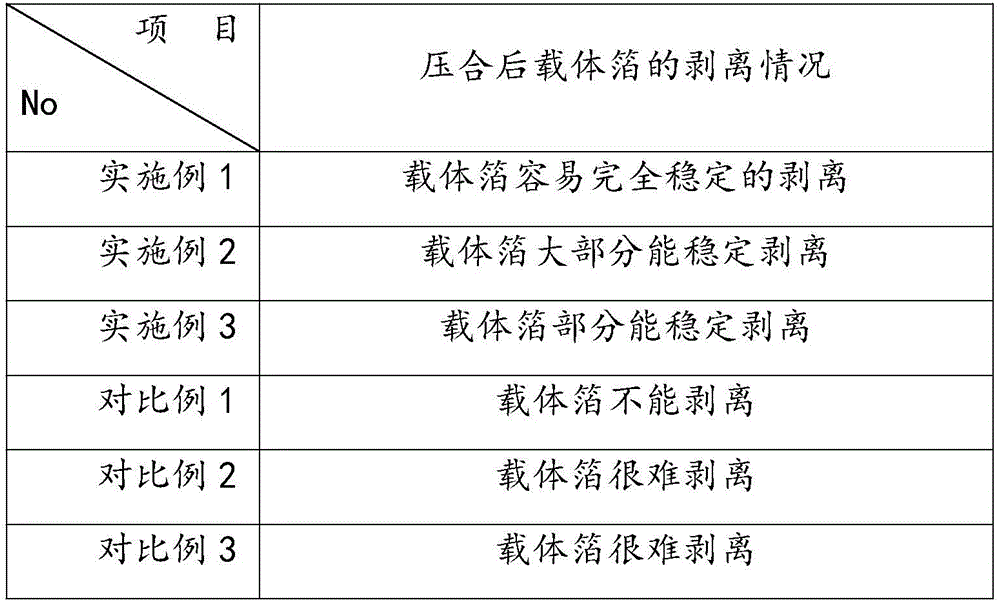

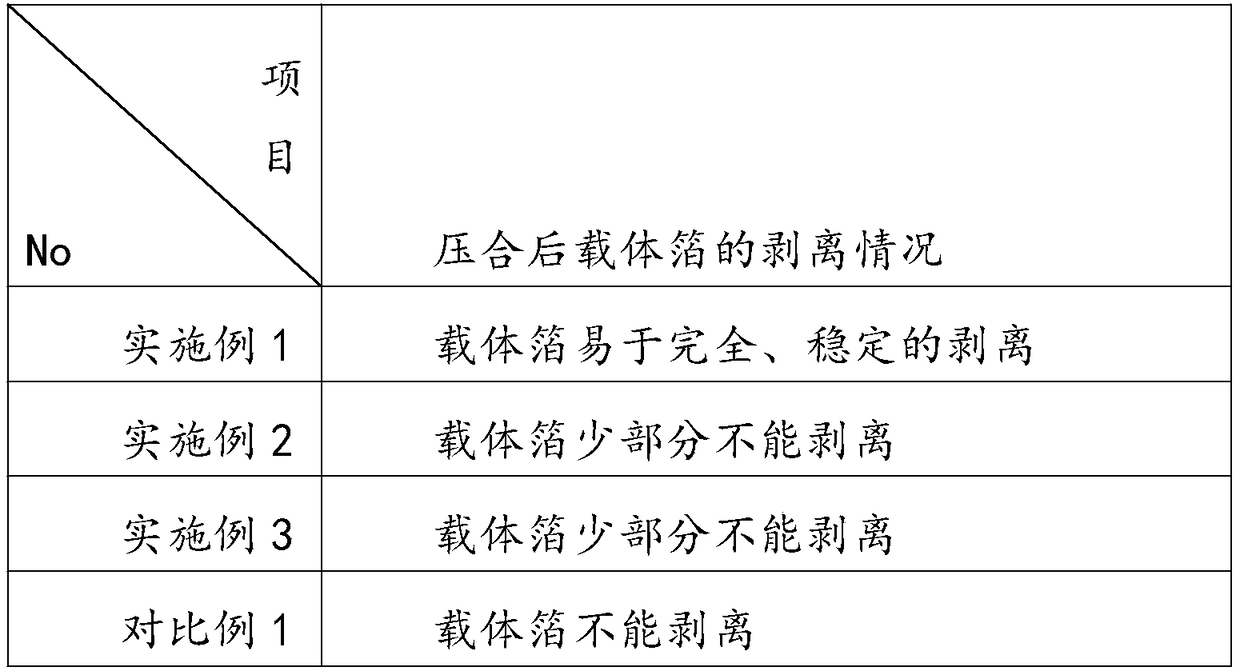

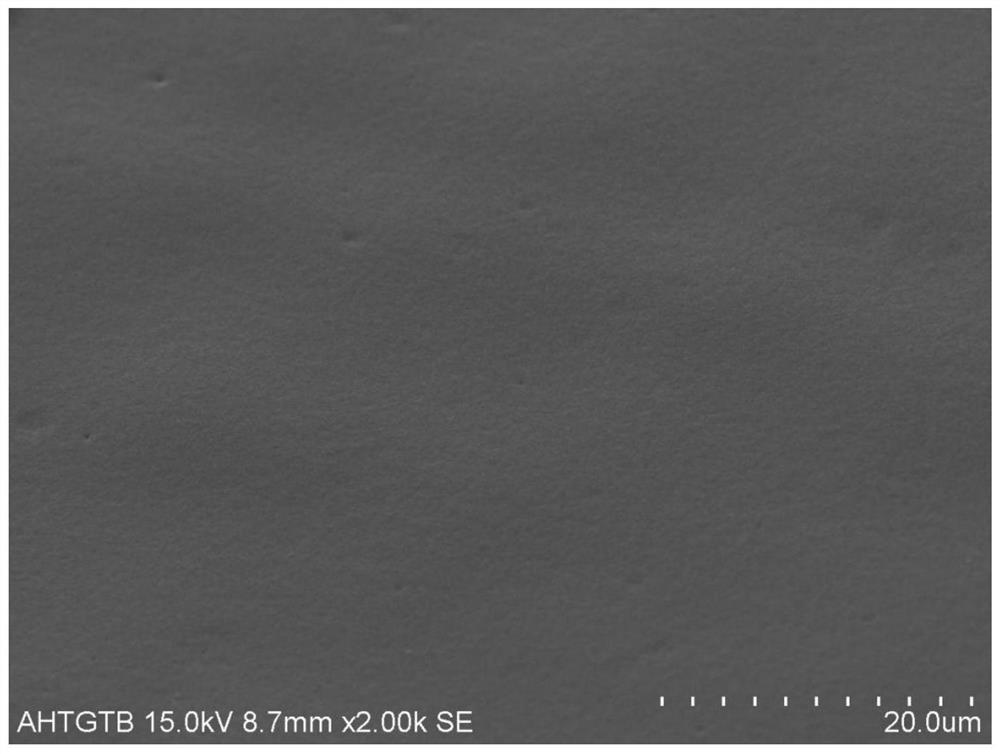

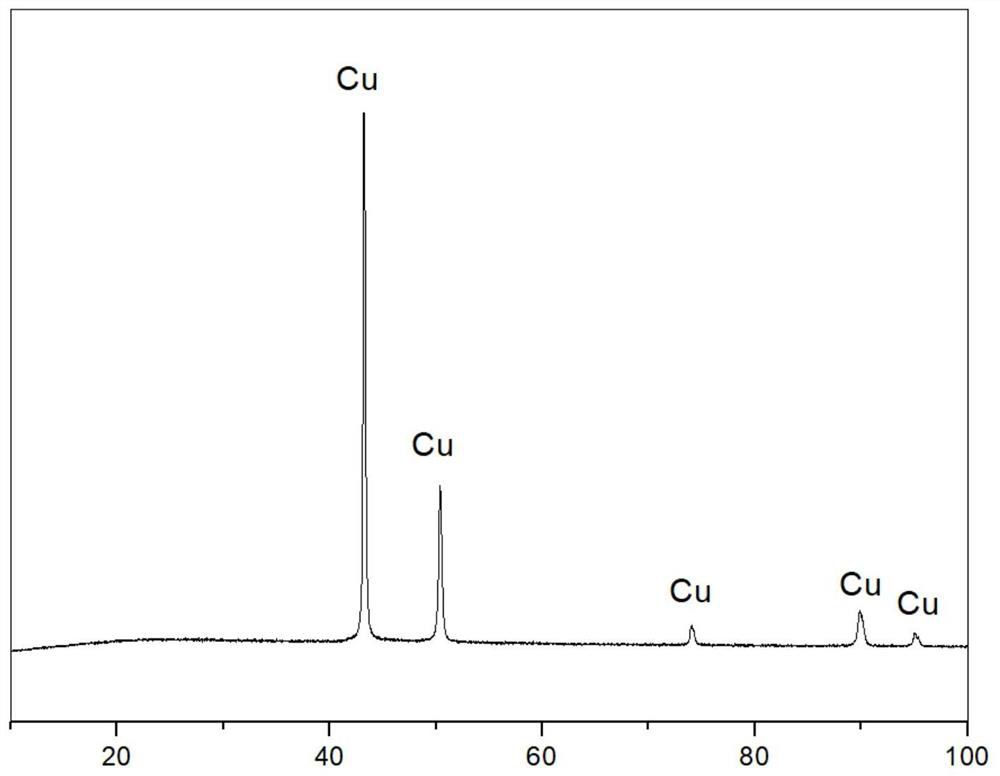

Preparing method of ultra-thin carrier copper foil capable of being stably stripped

The invention relates to a preparing method of ultra-thin carrier copper foil capable of being stably stripped. The method comprises the specific steps: firstly, a plating solution is prepared, namely, a complexing agent potassium pyrophosphate, zinc sulfate, an addition agent A and an addition agent B are dissolved in water, mixing is carried out after clarification, and the pH value of the solution is adjusted; secondly, the carrier foil is put into the plating solution in the first step, a novel nano composite zinc coating is electroplated and serves as a stripping layer, and extremely-thin electrolysis copper foil ranging from 2 micrometers to 6 micrometers is electroplated on the stripping layer, and is called as the ultra-thin carrier copper foil. After the ultra-thin carrier copper foil is cured on an insulation substrate after high-temperature pressing, through the mechanical method, the carrier foil can be completely stripped. The stripping layer prepared through the method is extremely thin and uniform, the carrier foil is easy to completely and stably strip, and the good application prospect is achieved.

Owner:SHANDONG JINBAO ELECTRONICS

Fixing device

InactiveUS6236829B1Stable peelingElectrographic process apparatusArticle deliveryMechanical engineeringEngineering

Owner:FUJIFILM BUSINESS INNOVATION CORP

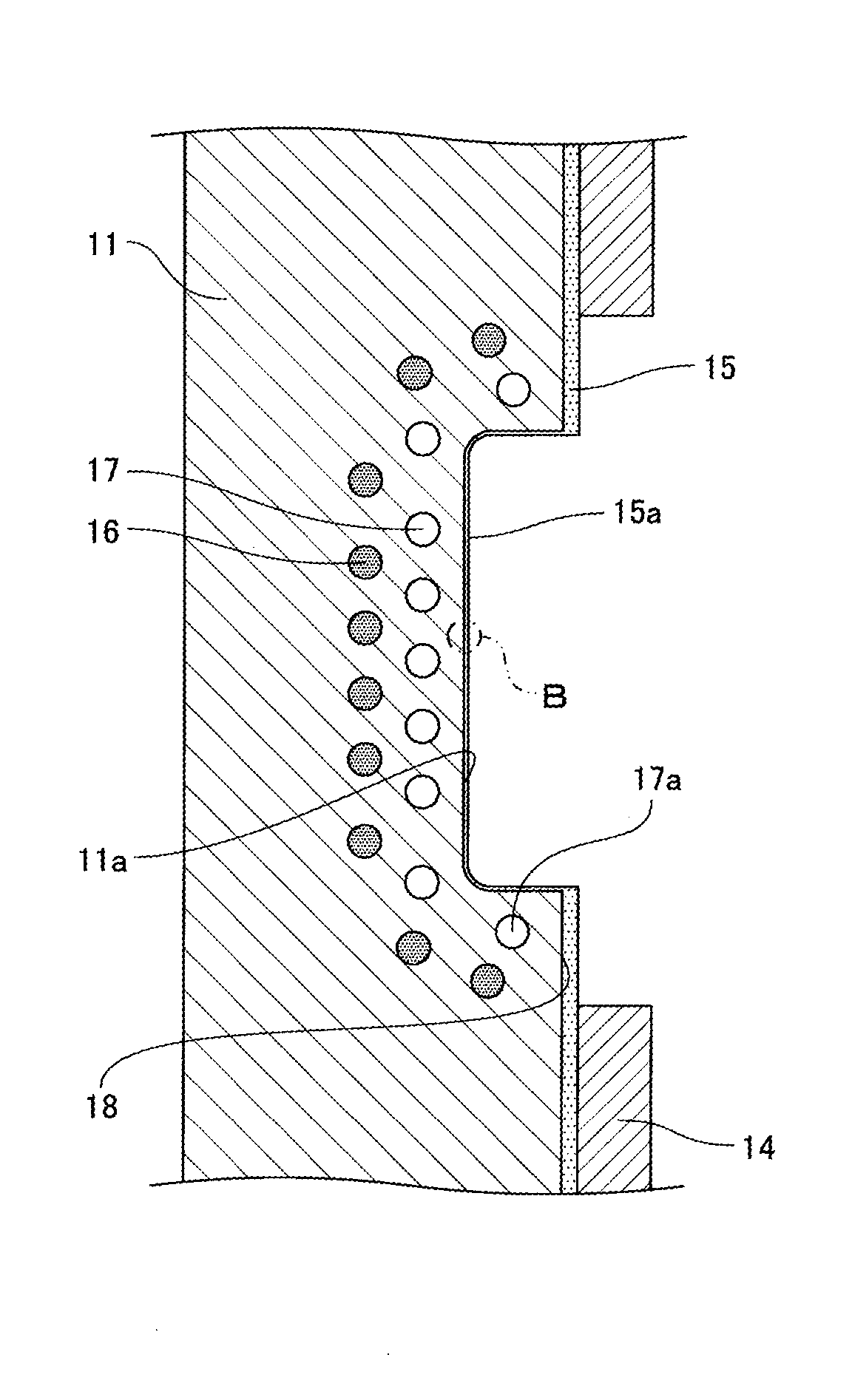

Cover film

ActiveUS20120003429A1Not susceptibleStable peelingFlexible coversWrappersChemistryLow-density polyethylene

A cover film comprising a substrate layer, an intermediate layer comprising a resin composition containing 50% by mass or more of a metallocene linear low-density polyethylene resin having a density of 0.900 to 0.940×103 kg / m3, and a sealant layer comprising an ethylene-type copolymerized resin containing 50 to 85% by mass of an olefin component.

Owner:DENKA CO LTD

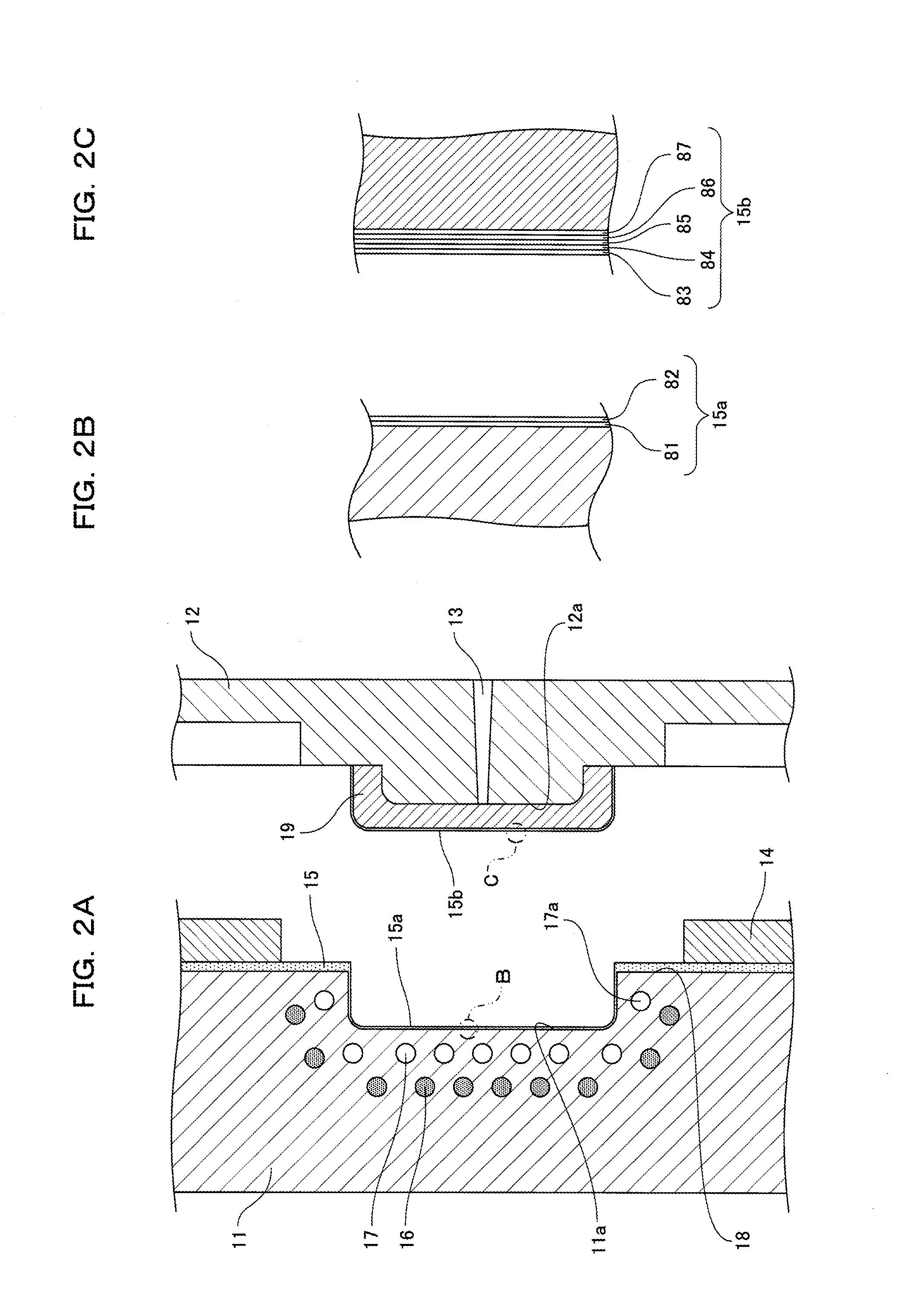

Injection molding method and injection mold assembly

InactiveUS20130334727A1Reduce deteriorationLess deteriorated designLaminationLamination apparatusShell moldingInjection molding machine

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

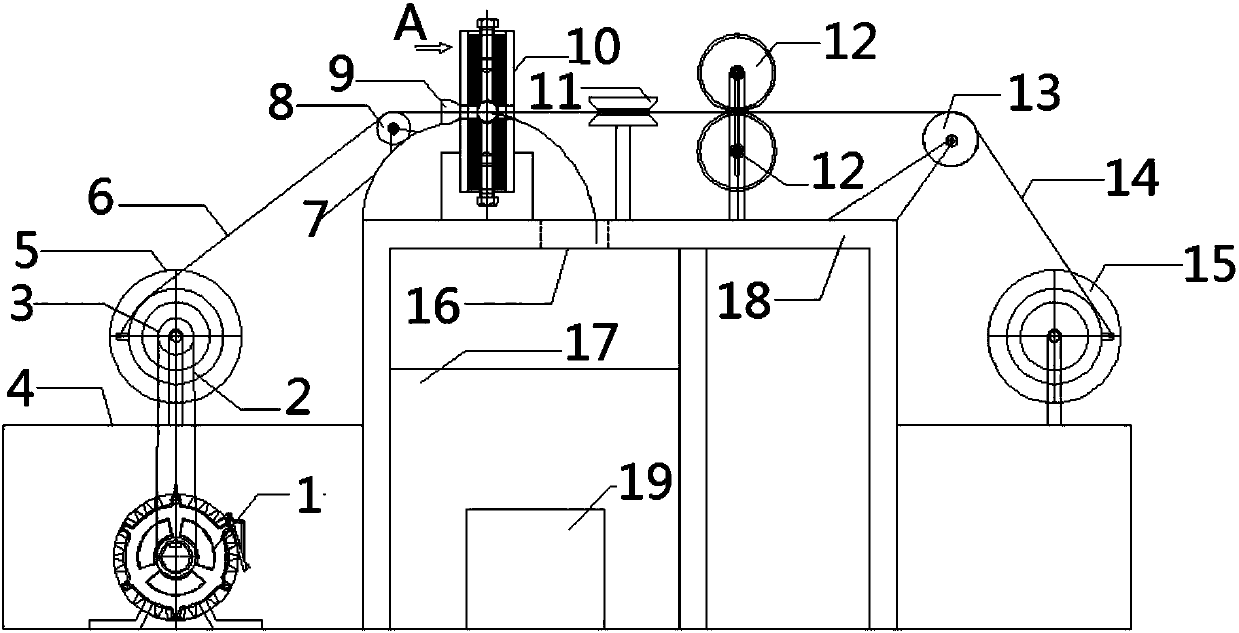

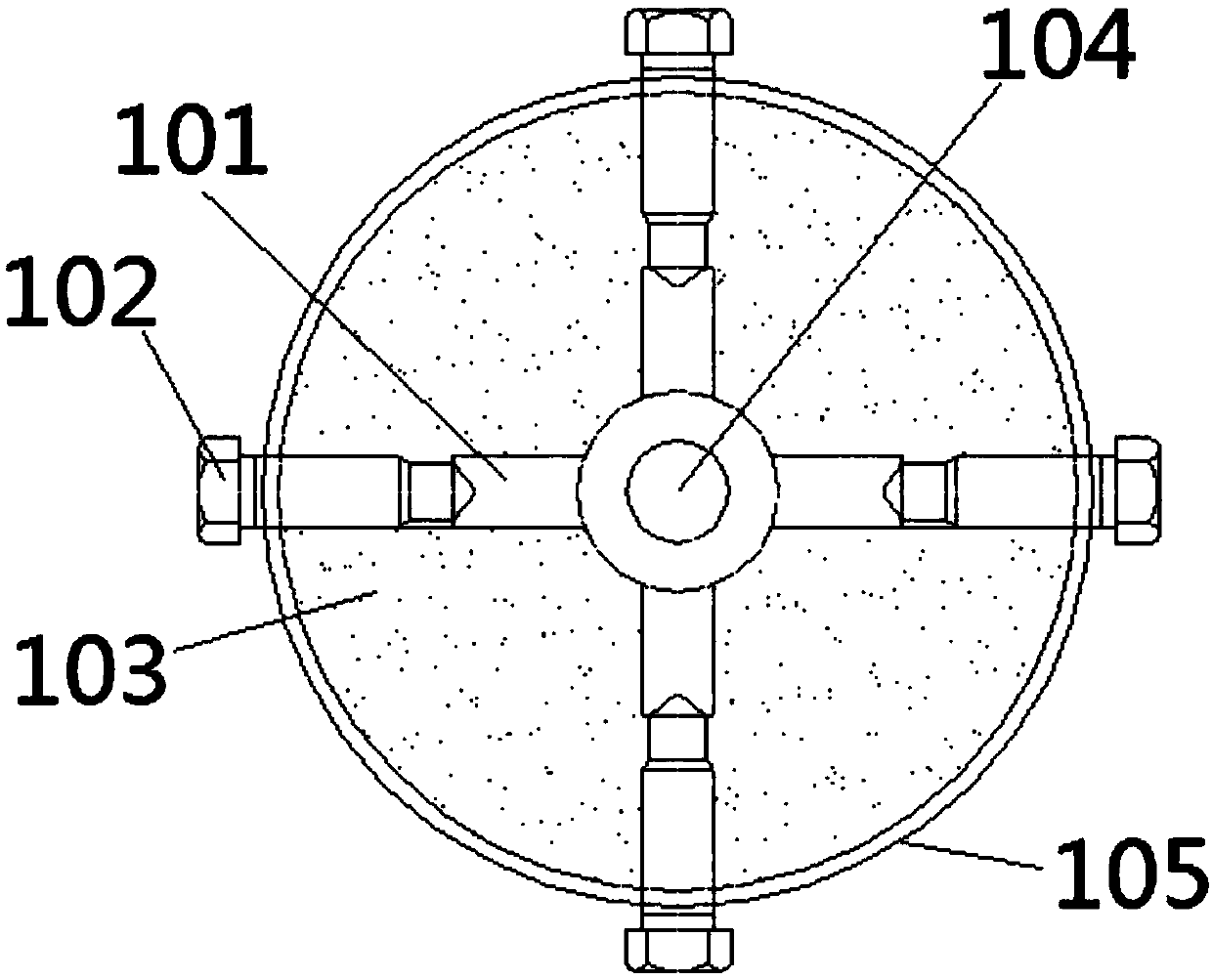

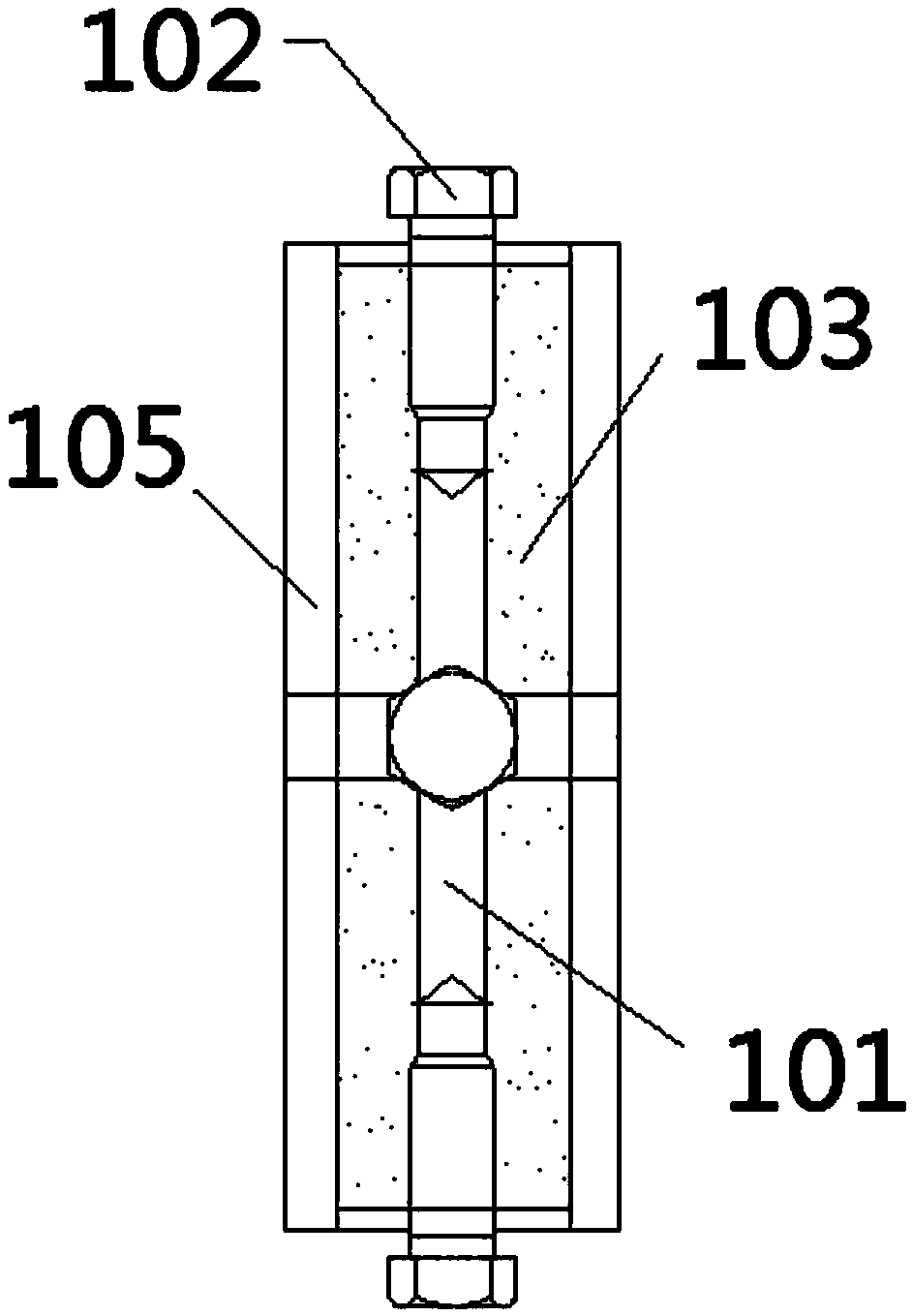

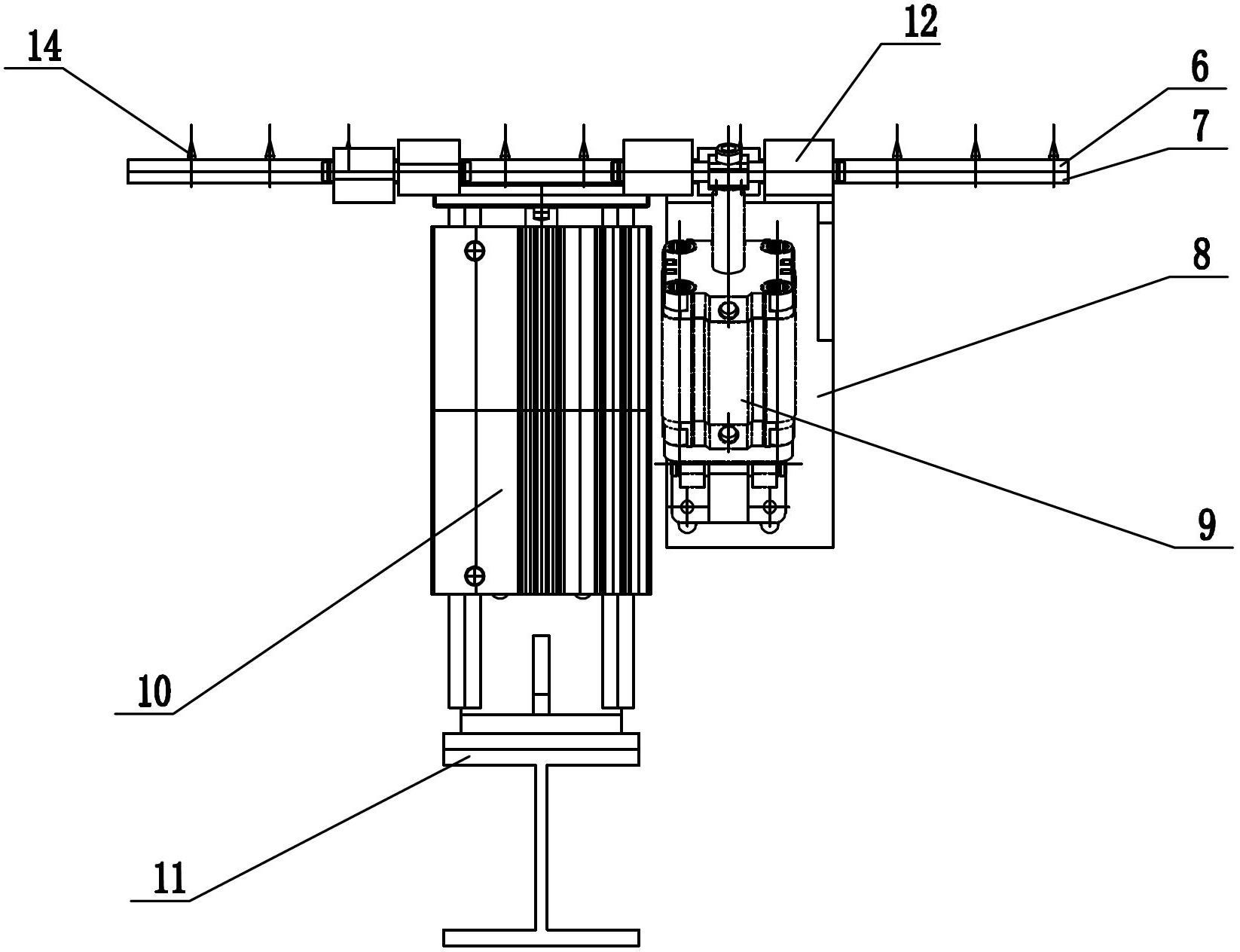

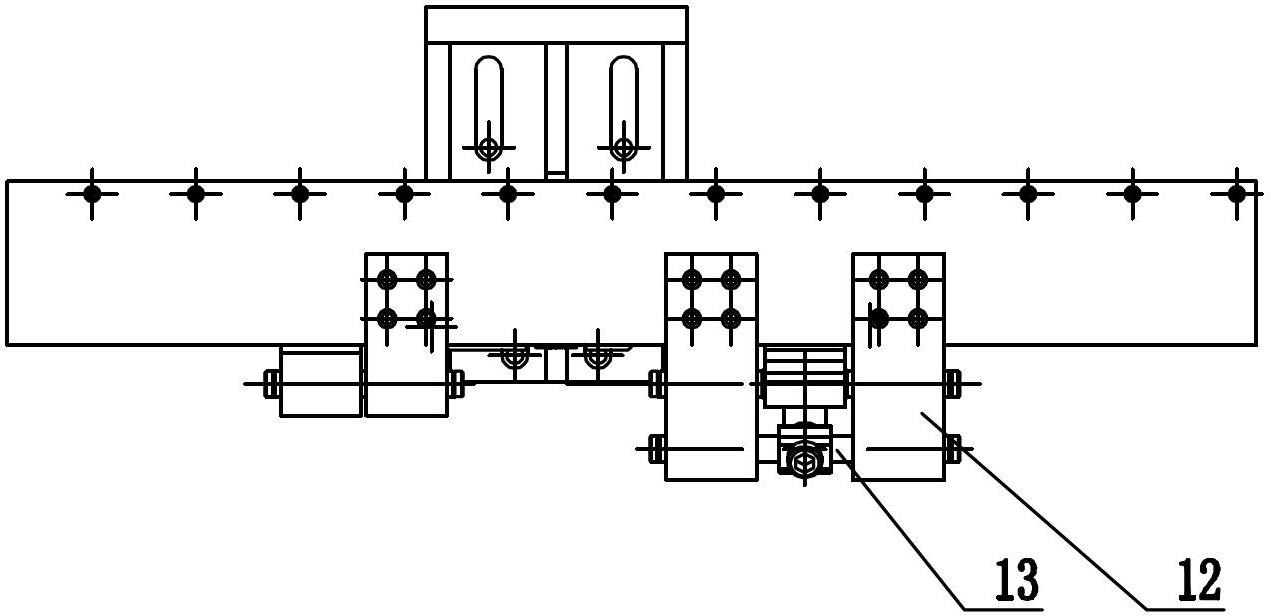

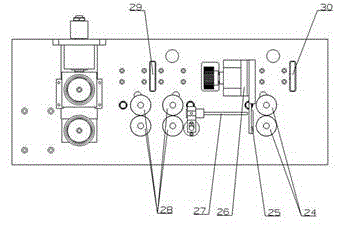

Waste electric wire stripping and core taking device

InactiveCN107681561AQuick peelStable peelingBasic electric elementsApparatus for removing/armouring cablesConductor CoilElectric wire

The invention discloses a waste electric wire stripping and core taking device. The device comprises a work bench. A top of the work bench is successively provided with a passive winding mechanism, afixed pulley, two adjusting wheels, a horizontal wheel, a knife rest, a protective cover, a support wheel and an active winding mechanism in a detection arrangement mode. The two adjusting wheels arevertically arranged from top to bottom. The protective cover is arranged on an electric wire passing hole of the knife rest and is located at an outgoing line direction. One end of a waste electric wire is wound around the passive winding mechanism and the other end successively passes through the fixed pulley, a central section gap of the two adjusting wheels, the horizontal wheel, the electric wire passing hole, the protective cover, the support wheel and the active winding mechanism. The knife rest comprises a circular framework and a plurality of cutter heads. A frame core is arranged in the circular framework. A central section of the frame core is provided with the electric wire passing hole. The cutter heads are fixedly arranged between the circular framework and the frame core through a fixing component. End portions of the cutter heads can be extended into the electric wire passing hole. An axial direction of the electric wire passing hole is parallel to an axial direction ofthe circular framework. The waste electric wire stripping and core taking device can high-efficiently strip the waste electric wire.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Cover film

InactiveUS20090246518A1Stable peelingGood heat sealing performanceSynthetic resin layered productsBagsPolyesterUltimate tensile strength

To provide a cover film with which the temperature range of a sealing iron to obtain peel strength is wide and stability of peel strength is good at the time of peeling, and which is excellent in heat sealing properties to a carrier tape.A cover film comprising a substrate layer and a sealant layer, wherein the substrate layer is made of a biaxially oriented polyester and / or a biaxially oriented polypropylene, the sealant layer contains a hydrogenated resin (a) of a block copolymer of an aromatic vinyl compound and a conjugated diene type hydrocarbon compound, the amount of the aromatic vinyl compound in the resin (a) is at least 20 mass % and at most 45 mass %, and the flowability of the resin (a) is from 1 to 20 g / 10 min at a temperature of 230° C. under a load of 2.16 kgf by a measurement method stipulated in JIS K 7210.

Owner:DENKA CO LTD

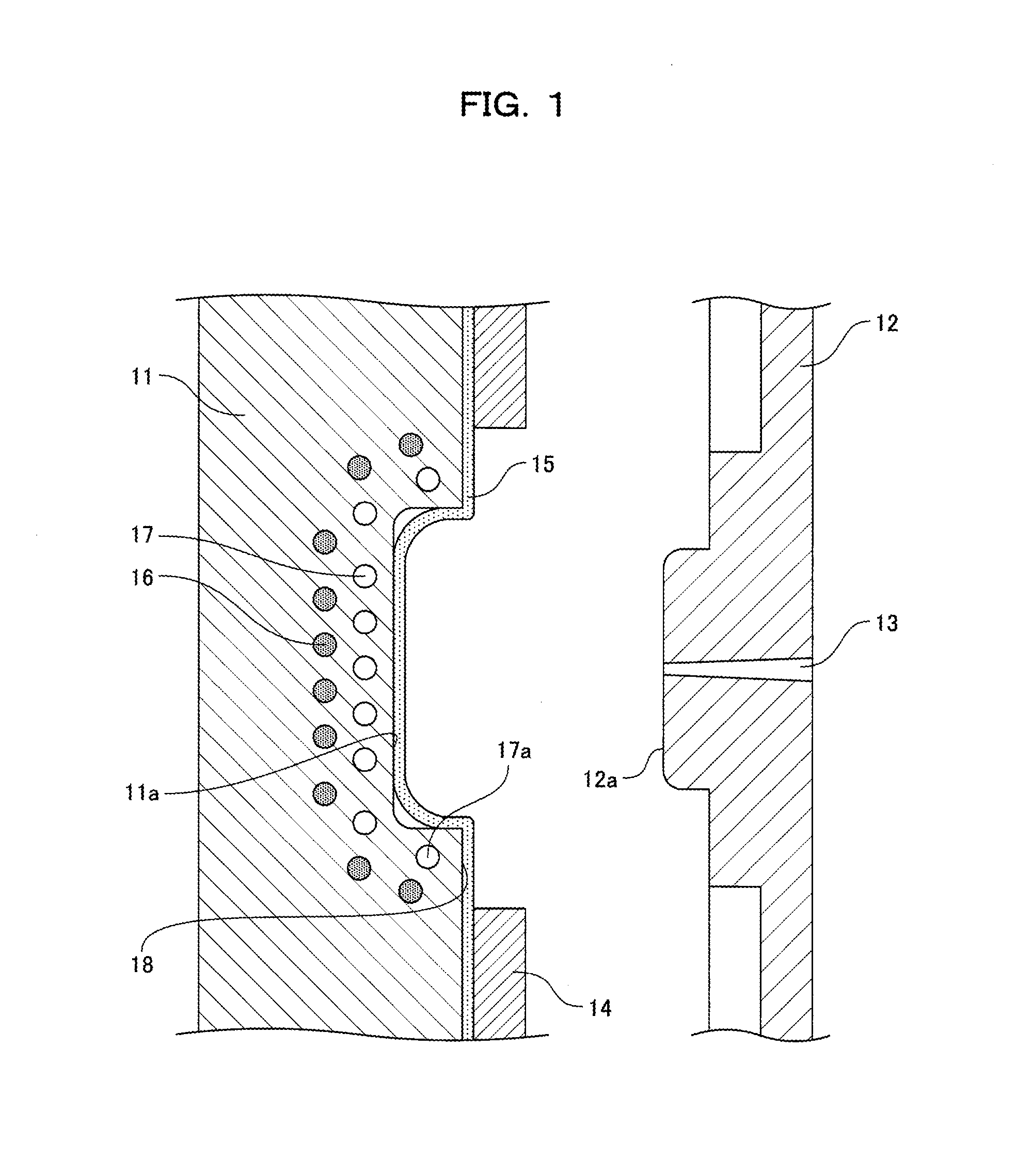

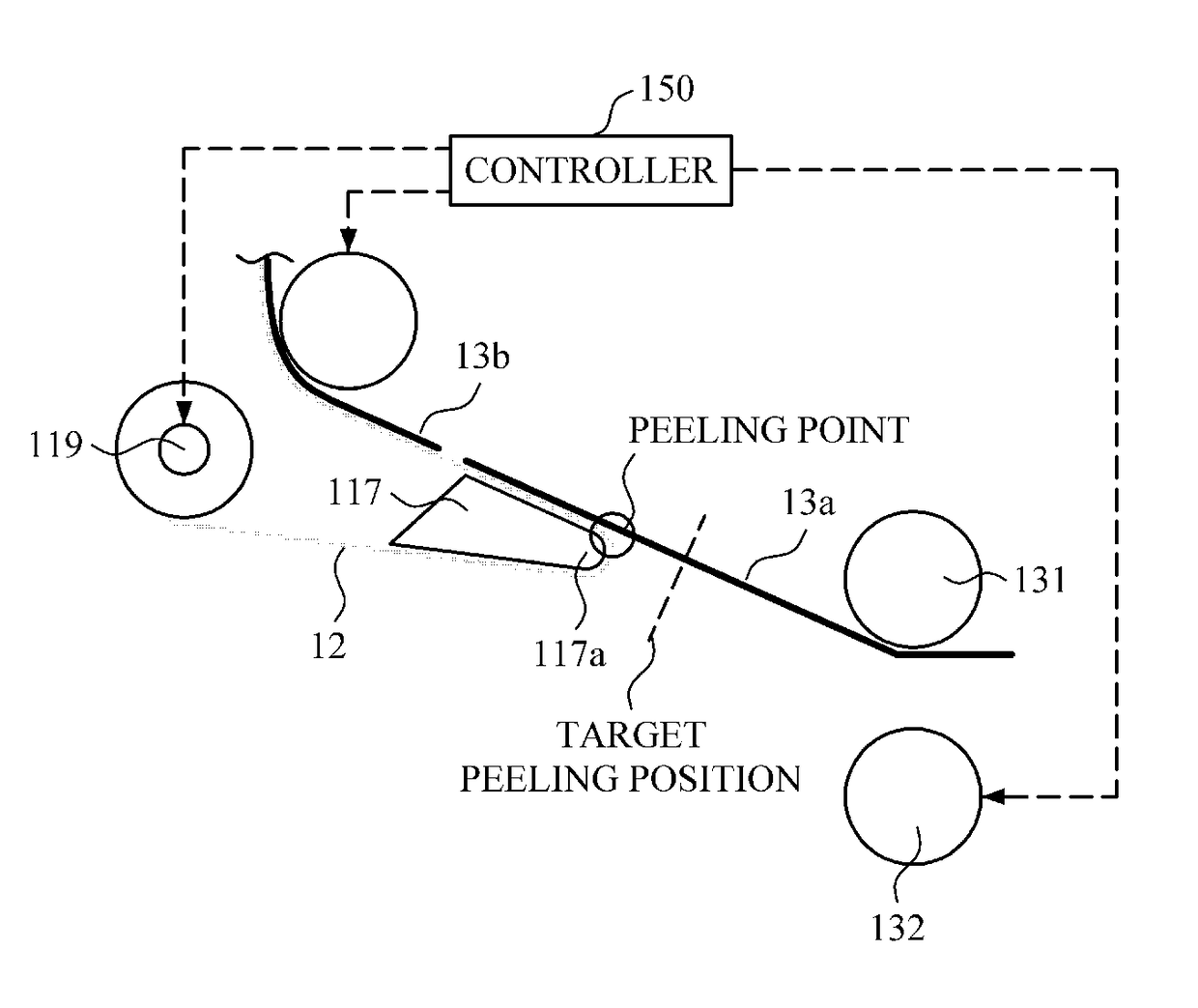

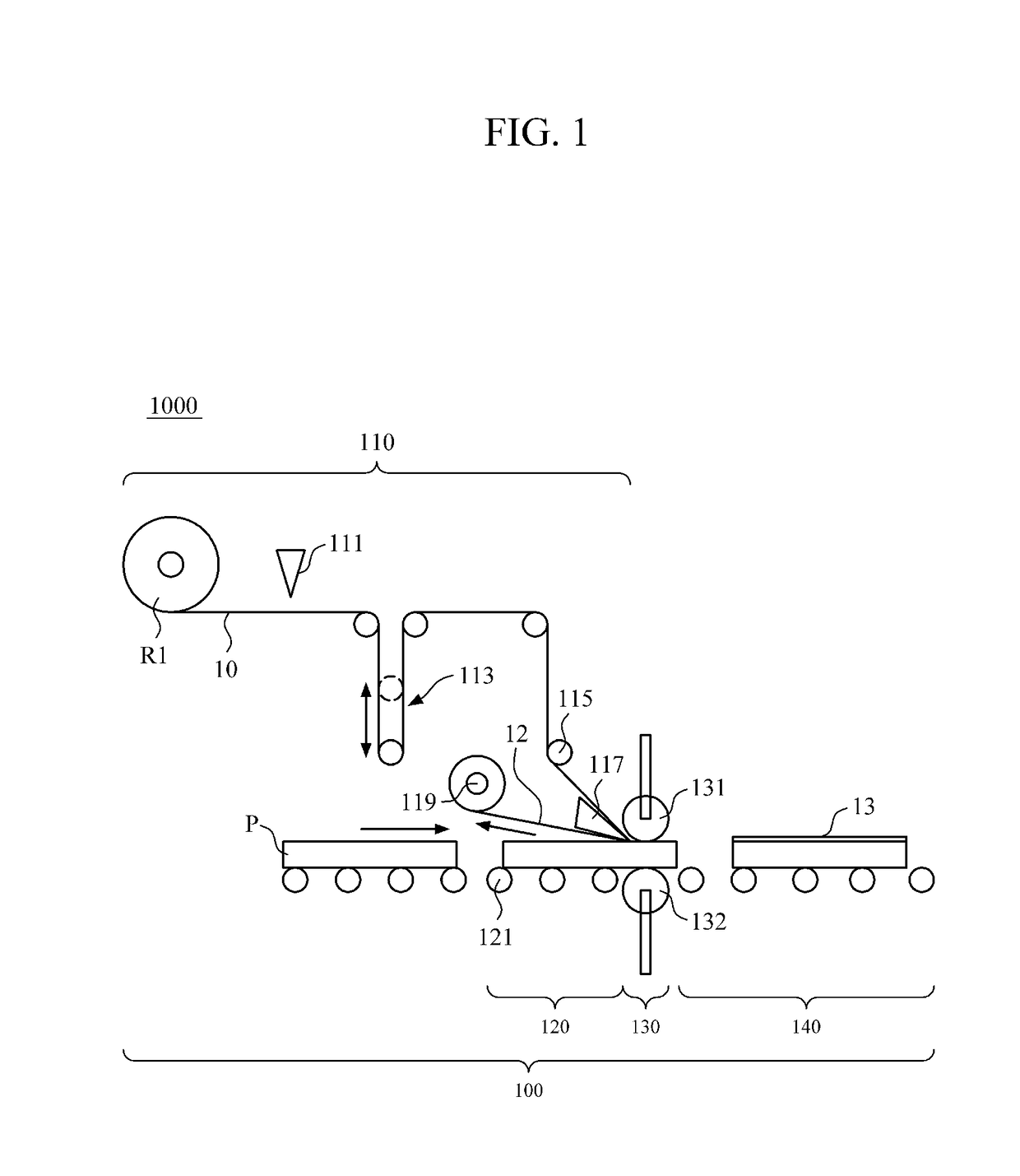

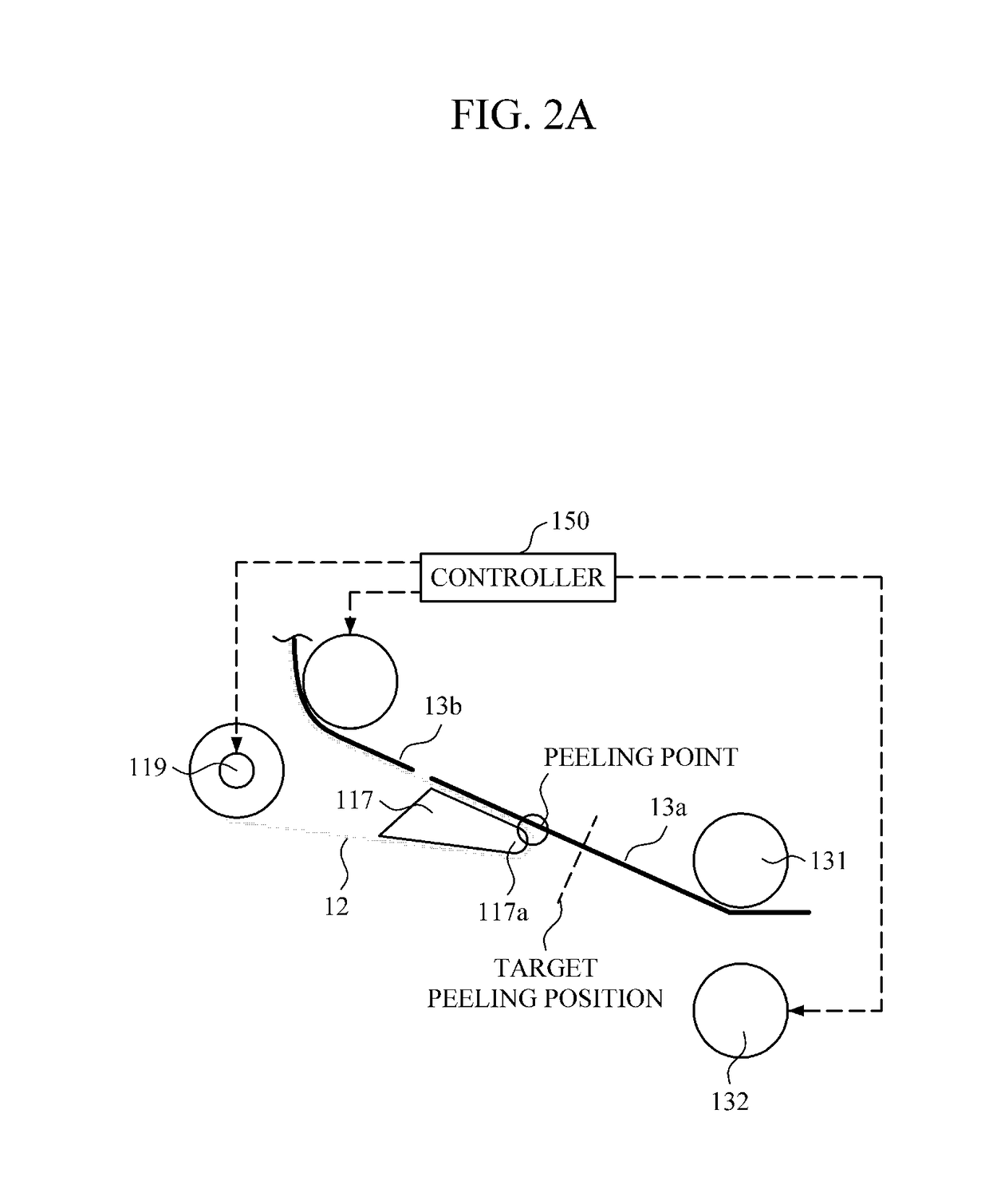

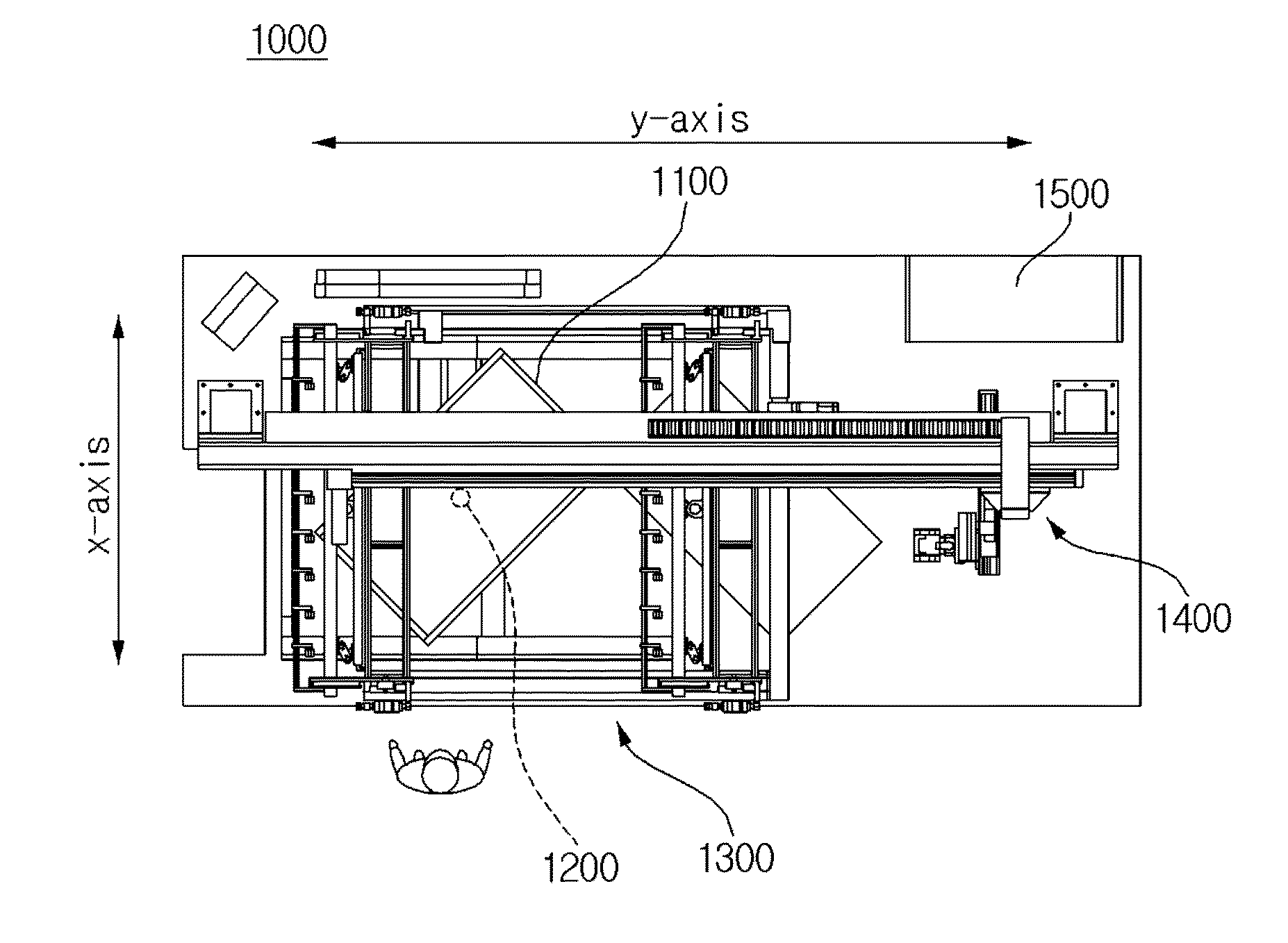

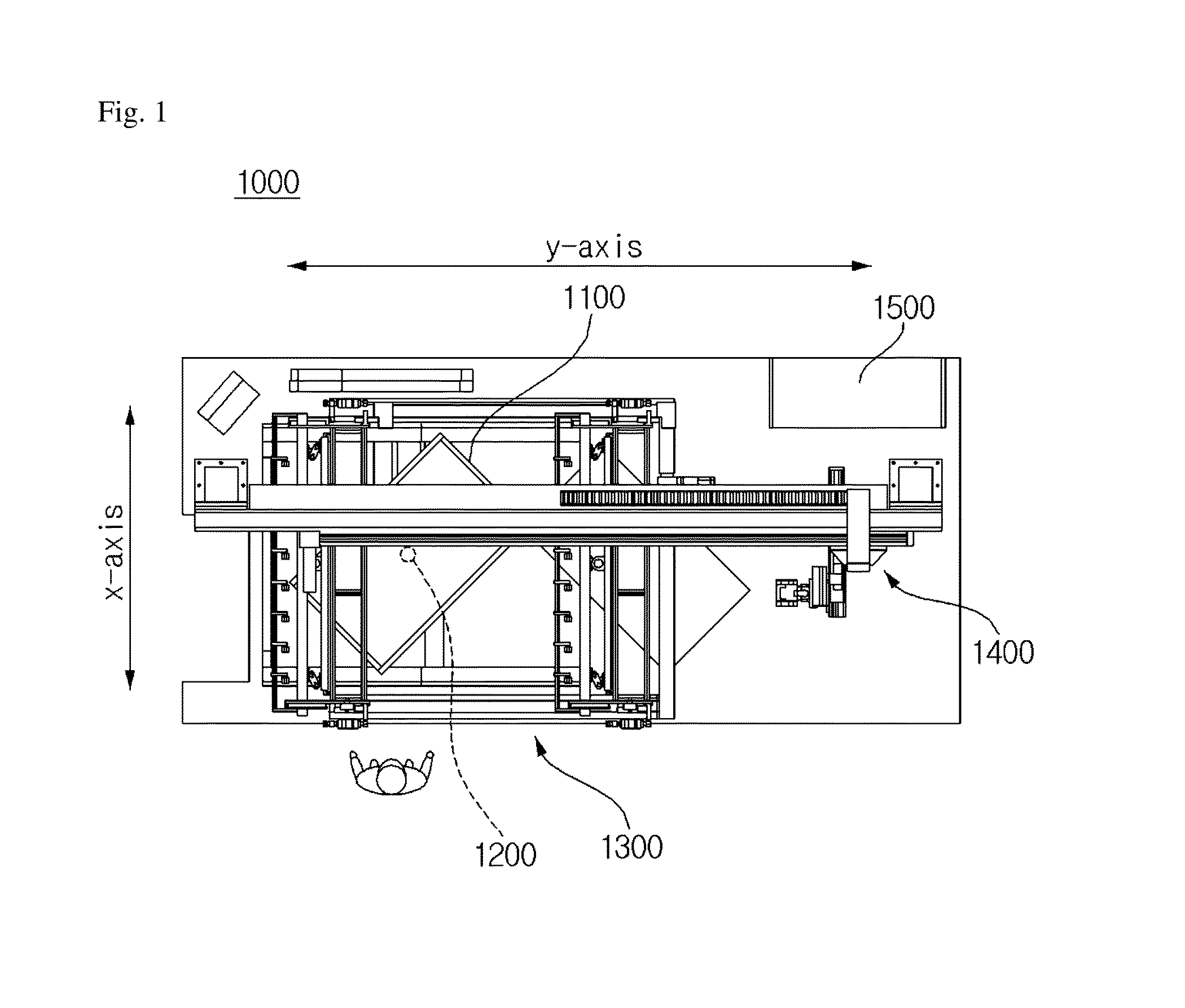

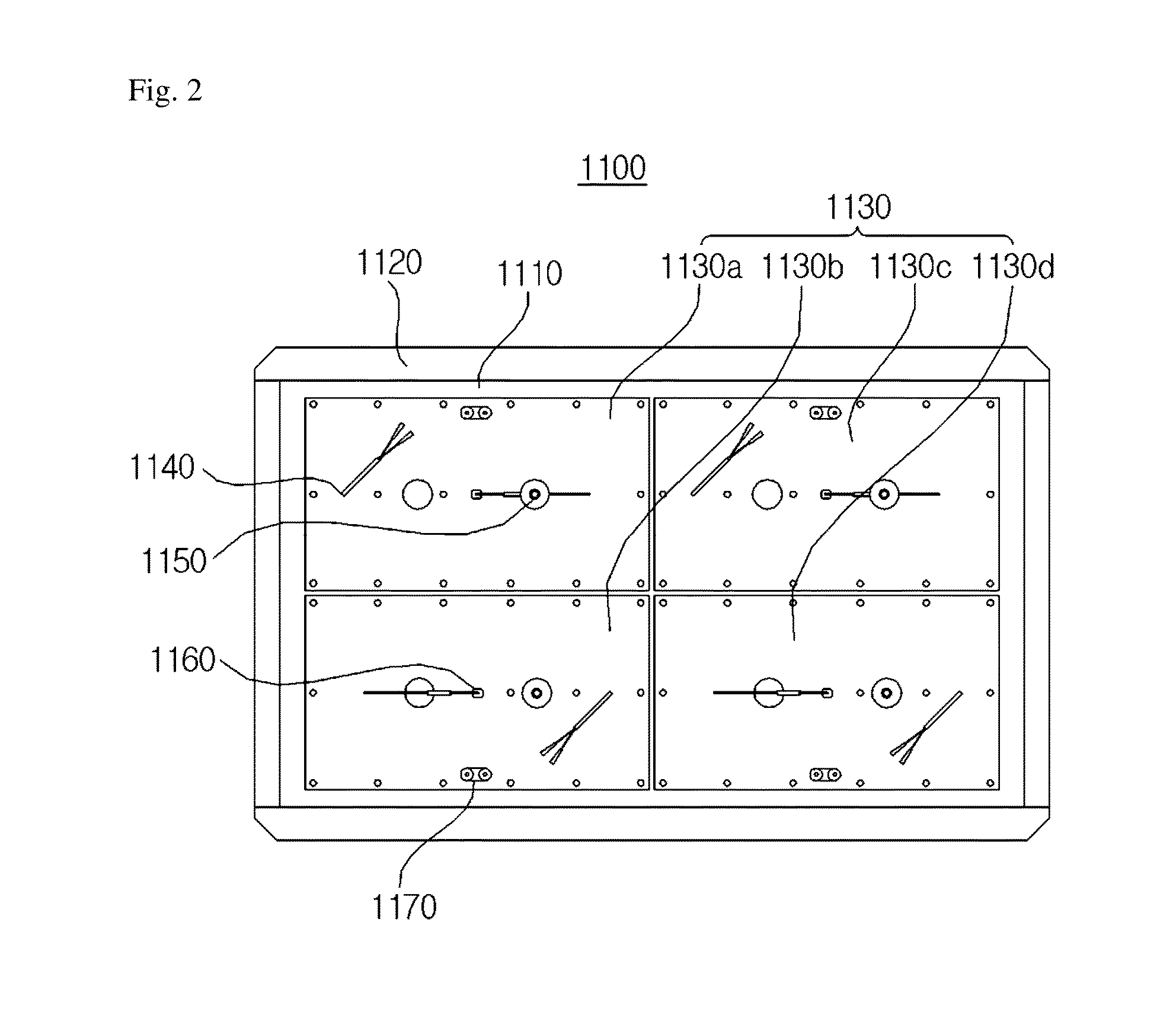

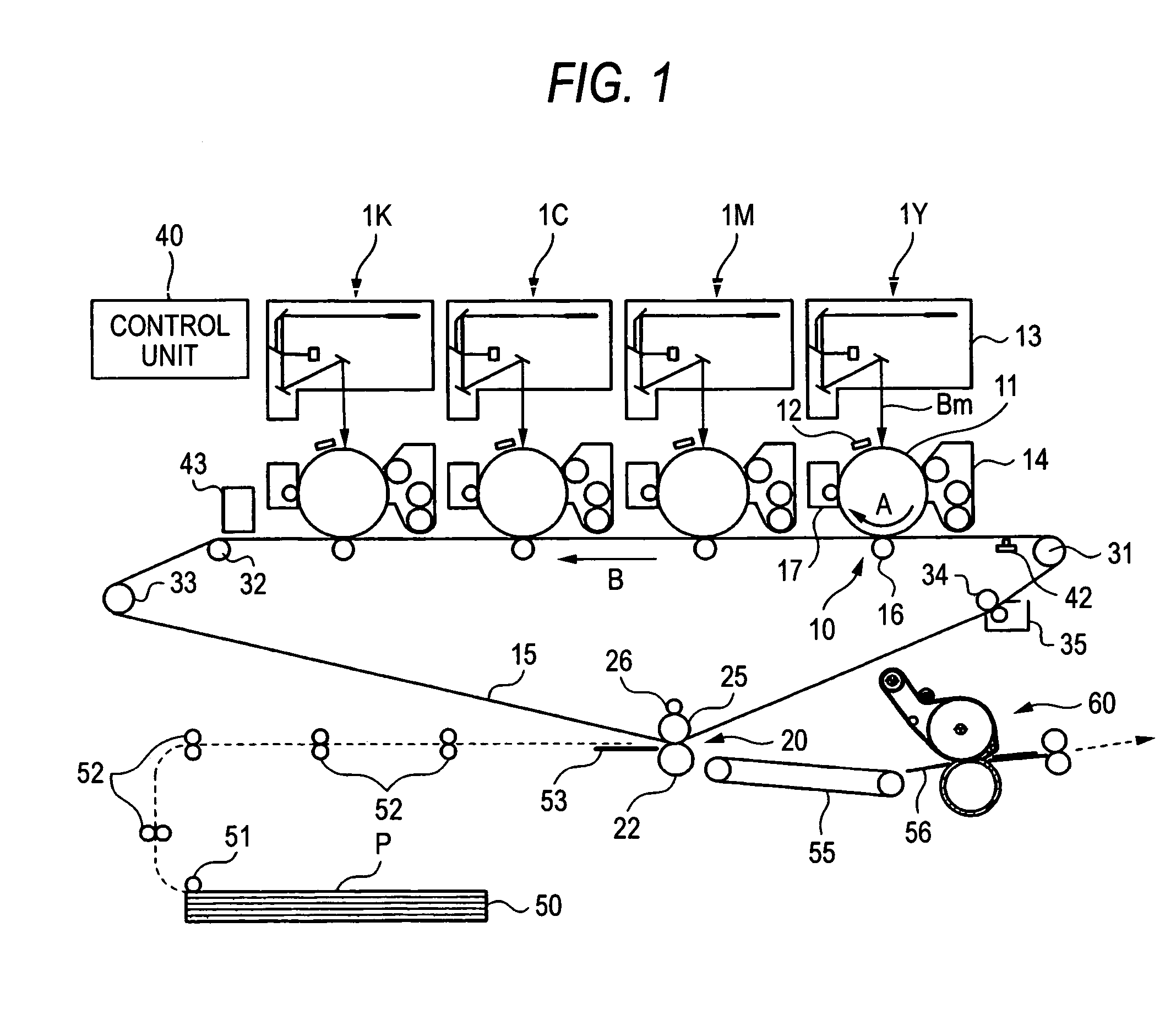

System and method for continuously manufacturing optical display device

ActiveUS20170348957A1Stable peelingInhibition of attachmentLamination ancillary operationsControlling laminationCompletion timeDisplay device

Provided is a system for continuously manufacturing an optical display device includes: a feeding unit which transfers and feeds an optical film, wherein the optical film includes a release film which is extended in a longitudinal direction, and a plurality of sheet pieces of a polarization film which is arranged in a longitudinal direction and includes an adhesive layer, wherein the sheet pieces of a polarization film is adhered to the release film through the adhesive layer so that the sheet piece of the polarization film is peeled from the release film; a peeling unit which peels the sheet pieces of the polarization film from the release film by folding back inwardly the release film of the optical films fed by the feeding unit; a winding unit which winds the release film from which the sheet piece of the polarization film is peeled by the peeling unit; a laminating unit which laminates on the panel the sheet piece of the polarization film peeled from the release film, while transferring the panel; and a control unit which controls at least one of the feeding unit, the winding unit, and the laminating unit so that the peeling point where the sheet piece of the polarization film is peeled from the release film is formed at a target peeling position spaced apart from the front end of the peeling unit by a predetermined distance toward the laminating unit, and a rear end of a first sheet piece and a front end of a second sheet piece which are connected to each other by adhesion of the adhesive layer are spaced apart and separated from each other between a complete peeling time when the first sheet piece is completely peeled from the release film and a laminating completion time when the first sheet piece is completely laminated, wherein the first piece and the second piece of the polarization film are adjacent to each other with the first sheet piece positioned downstream in a feeding direction.

Owner:SHANJIN OPTOELECTRONICS SUZHOU CO LTD

Plating solution for carrier copper foil stripping layer and preparation method of stripping layer

The invention relates to a plating solution for a carrier copper foil stripping layer and a preparation method of the stripping layer. The plating solution is prepared from components as follows: potassium bitartrate with the concentration of 20-60 g / L, zinc sulfate with the concentration of 8-16 g / L and an additive A with the concentration of 5-20 g / L and the pH of 3.0-5.0, wherein the additive Ais a mixture formed by mixing at least one of 3-(2,3-epoxy propoxy)propyl trimethoxy silane, 3-(2,3-epoxy propoxy)propyltriethoxysilane, 3-(2,3-epoxy propoxy)propyl methoxy dimethyldiethoxylsilane or3-(methylacryloyl oxy)propyl trimethoxy silane with at least one of potassium thiocyanate, monopotassium phosphate, sodium acetate or ammonium sulfate. The carrier copper foil stripping layer obtained with the adoption of the plating solution for the carrier copper foil stripping layer and the preparation method of the stripping layer is a novel nano composite zinc plating layer, is very thin anduniform and can completely and stably strip carrier foil off the pressed very thin copper foil.

Owner:胡旭日

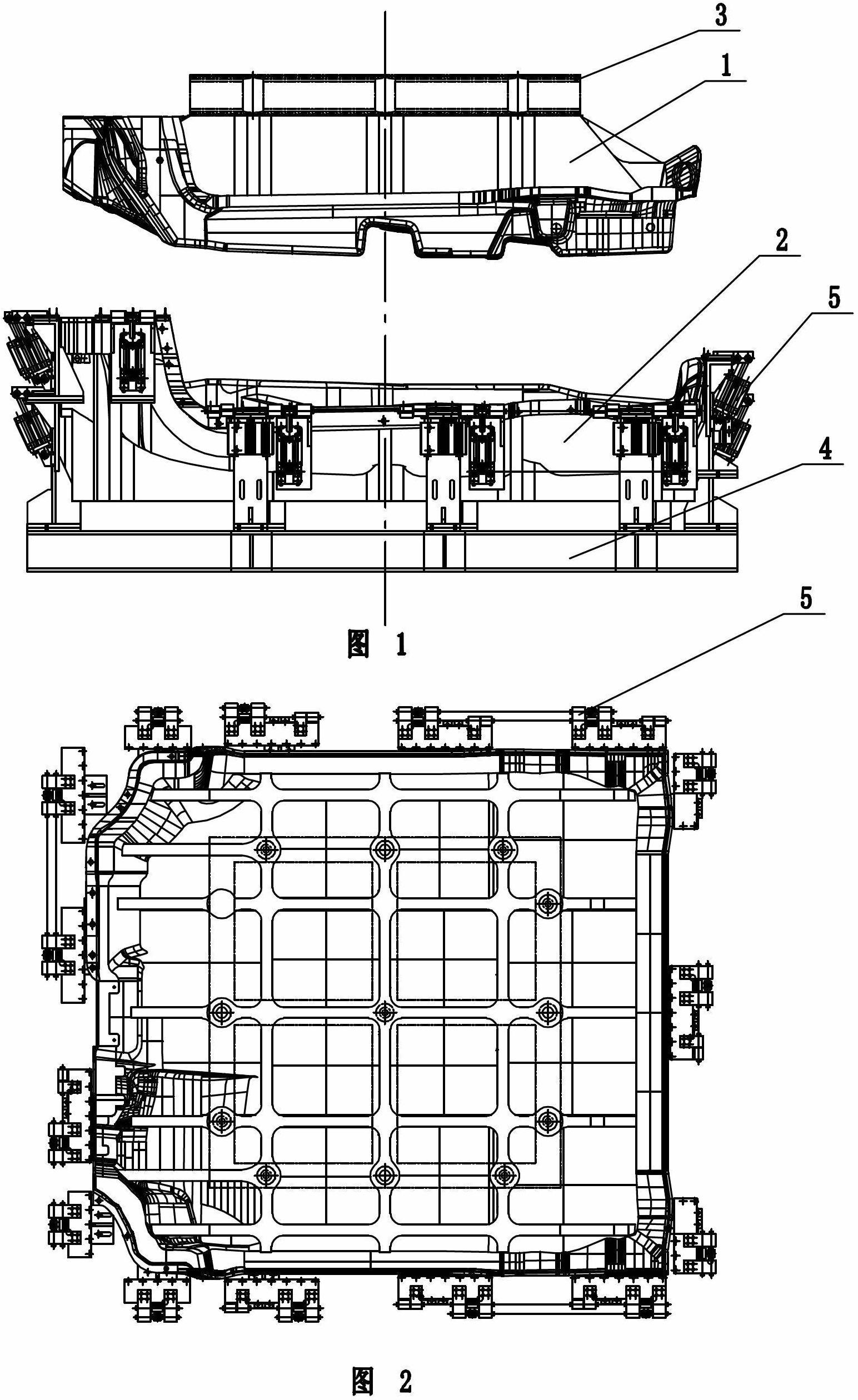

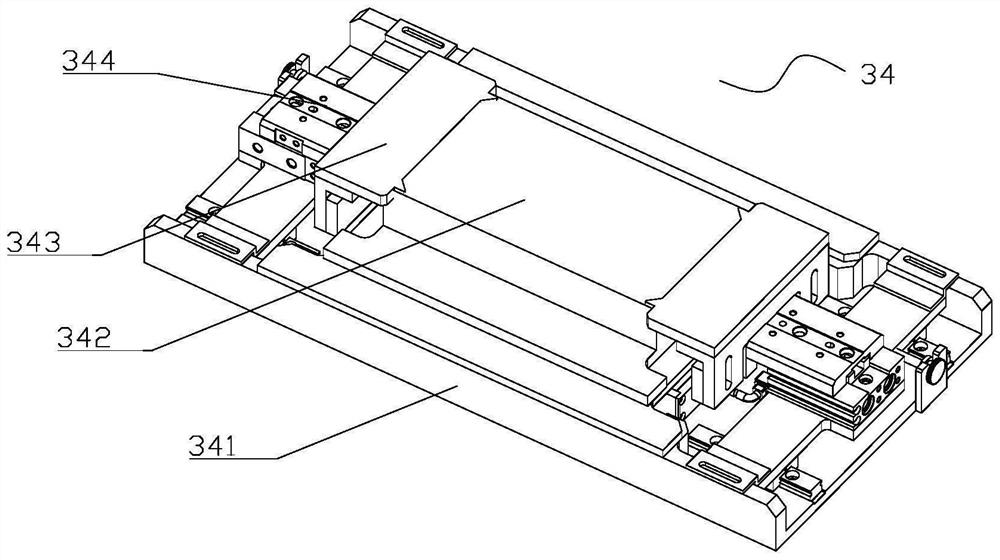

Automobile carpet step-in die structure

The invention relates to an automobile carpet step-in die structure. The automobile carpet step-in die structure comprises an upper die body clamping frame and a lower die body clamping frame, wherein an upper die body is arranged on the upper die body clamping frame; a lower die body is arranged on the lower die body clamping frame; and a plurality of material-clamping devices are arranged on the edge of the lower die body. The automobile carpet step-in die structure is characterized in that: each material-clamping device comprises a lifting cylinder and a turnover cylinder; the lifting cylinder is fixed on a lifting cylinder fixing frame; the turnover cylinder is fixed on a turnover cylinder fixing bracket; a piston rod of the lifting cylinder is fixed with a lower material-clamping plate; an upper material-clamping plate is arranged on the upper surface of the lower material-clamping plate; a rotating shaft is arranged on the end part of the piston rod of the turnover cylinder; and the rotating shaft is connected with one end of a hinge, and the other end of the hinge is fixed with the upper material-clamping plate. The automobile carpet step-in die structure has a simple, compact and reasonable structure, adapts to the flexibility of various products, guarantees that the fabric of a ceiling skylight is stable to strip, has high automation degree, is accurate in workpiece positioning, and can improve the production efficiency, reduce the labor intensity of workers, save the manufacturing cost and improve the product quality.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

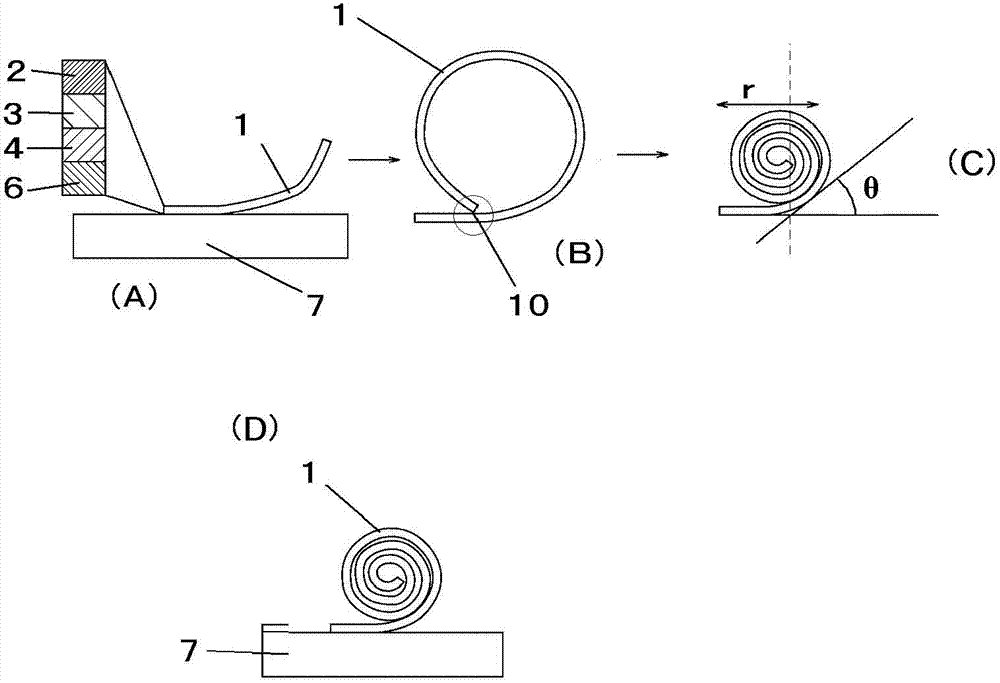

Self-rolling adhesive film

InactiveCN103289584AFull fitStable peelingLamination ancillary operationsSolid-state devicesAdhesiveThermal contraction

The invention provides a self-rolling adhesive film. An easily detachable adhesive film, which is deformed into a cylindrical shape by heating to facilitate collection, fails to be sufficiently bonded to the surface of a workpiece, if the surface of the adhesive layer is roughened by the presence of irregularities. Because of this, when water penetrates in dicing, the adhesive layer peels off from the surface of the workpiece and may fail to achieve a surface-protection purpose. In addition, when the easily detachable adhesive film is deformed into a cylindrical shape by heating, detachment stress may not uniformly applied to a workpiece, with the result that the film cannot be smoothly deformed into a cylindrical shape; at the same time, a larger amount of glue remains in the surface of a workpiece than a conventional peel-detachment. A self-rolling adhesive film composed of a multi-layered substrate including at least one thermal contraction film, an adhesive layer and a separator, in which the surface of the adhesive layer after the separator is detached has an arithmetic average roughness Ra of 1.0 [mu]m or less.

Owner:NITTO DENKO CORP

Preparation method of easy-to-peel ultra-thin carrier-attached copper foil with pure interface

ActiveCN112853408AUniform surfaceImprove performanceElectroforming processesPhysical chemistrySurface roughness

The invention relates to the technical field of electronic materials, in particular to a preparation method of an easy-to-peel ultra-thin carrier-attached copper foil with a pure interface. The carrier copper foil provided by the invention comprises a composite stripping layer containing an alloy layer and an organic layer, particularly, the alloy layer is obtained by electroplating an alloy liquid containing a complexing agent and at least one soluble sulfate, and the organic layer is obtained by coating organic liquid containing organic matters. Therefore, a composite stripping layer which is uniform in surface and stable in performance is formed on the upper surface of the copper foil, and the composite stripping layer has the characteristics of stable stripping performance and easy stripping after high-temperature pressing; meanwhile, the ultra-thin carrier-attached copper foil prepared by a specific method has the characteristics of easiness in stripping, fine crystal grains, compact structure, uniform thickness and pure interface, for example, the thickness of the ultra-thin copper foil is 2-6 [mu]m, the surface roughness is less than or equal to 2.5 [mu]m, and the stripping strength between the ultra-thin copper foil and the carrier copper foil is far lower than that between the ultra-thin copper foil and an insulating plate.

Owner:JIANGXI UNIV OF SCI & TECH +2

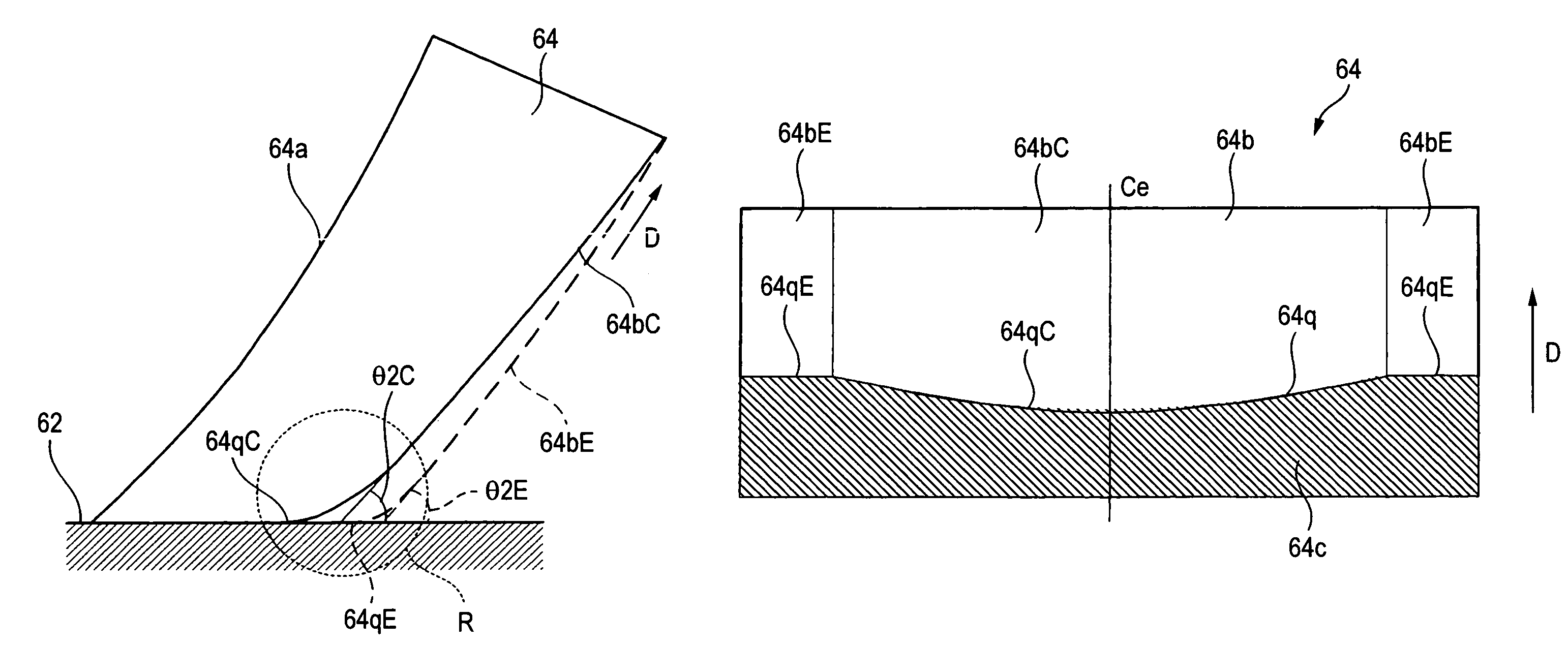

Peeling bar for peeling polarizing film from panel, peeling apparatus and peeling method using the same

ActiveUS20160207732A1Minimizes frictional forceAvoid fracturesLamination ancillary operationsLaminationEngineeringFace sheet

The present invention relates to a peeling bar, apparatus, and method for peeling a polarizing film from a panel. This invention can minimize friction between the peeling bar and the polarizing film since the peeled polarizing film is in contact with a front part of the peeling bar. The radius of a curved surface at the tip of the front part and an inclined upper surface of the front part are designed to minimize the Z-axis component of a shearing force applied to the polarizing film. Also, in order to equalize tension applied to the polarizing film in a peeling process, this invention makes both ends of the polarizing film closely adhere to the peeling bar. According to this invention, fracture of the polarizing film is prevented, and thereby the polarizing film can be stably peeled from the panel without fracture.

Owner:SHANJIN OPTOELECTRONICS SUZHOU CO LTD

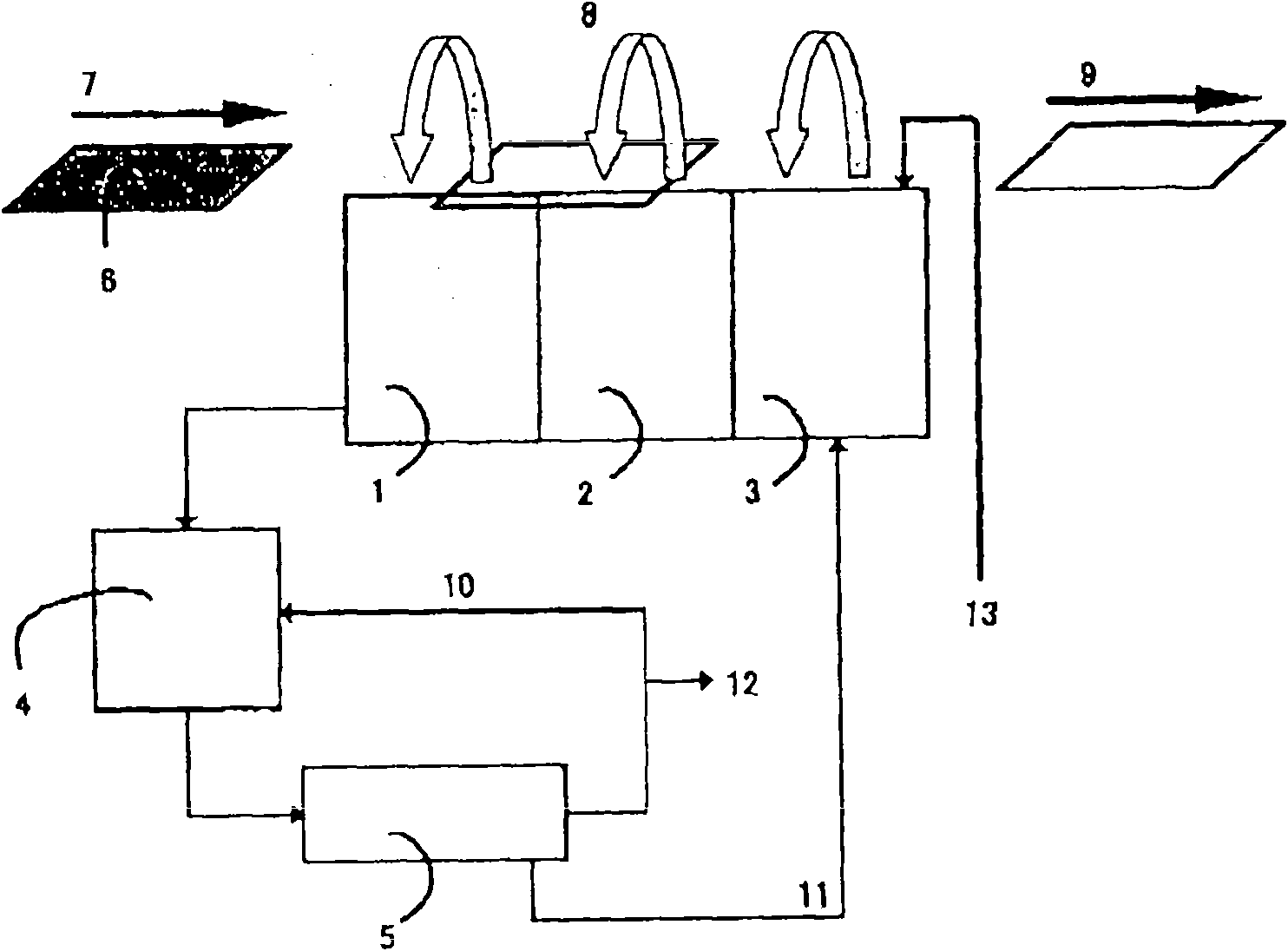

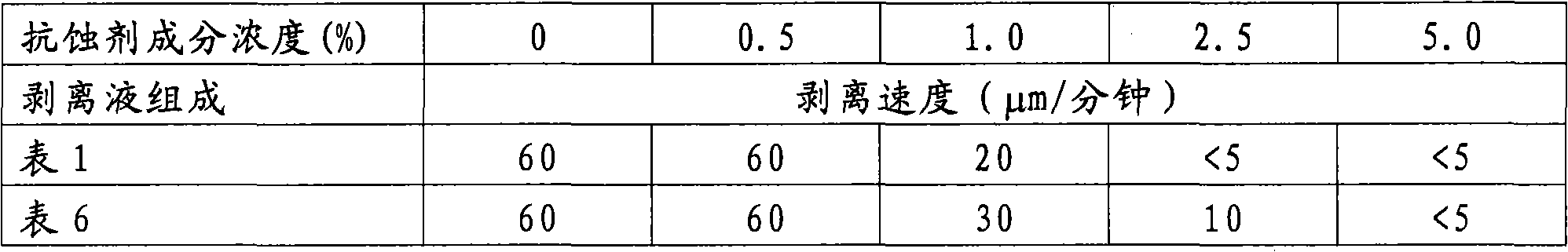

System for continuously using resist stripper liquid based on nanofiltration

InactiveCN101689480AStable peelingLow costUltrafiltrationSemiconductor/solid-state device manufacturingResistCross-flow filtration

The object of the invention is to realize a system in which a resist stripper liquid used in resist stripping is regulated so as to have a resist component concentration within a certain concentrationrange even when the resist stripper liquid is continuously used for long without replacing it. In stripping a positive resist with a stripper liquid, the resist components which have dissolved in thestripper liquid can be diminished by cross-flow filtration with a specific ceramic filter (5). In the resist stripping system, a resist-component-containing stripper liquid resulting from a strippingstep is treated in a filtration step, and the resultant concentrated stripper liquid having a heightened resist-component concentration is suitably discharged from the system. A fresh stripper liquidis suitably added to the stripper liquid from which the resist components have been removed, and the resultant stripper liquid is reused in the stripping step.

Owner:TOAGOSEI CO LTD

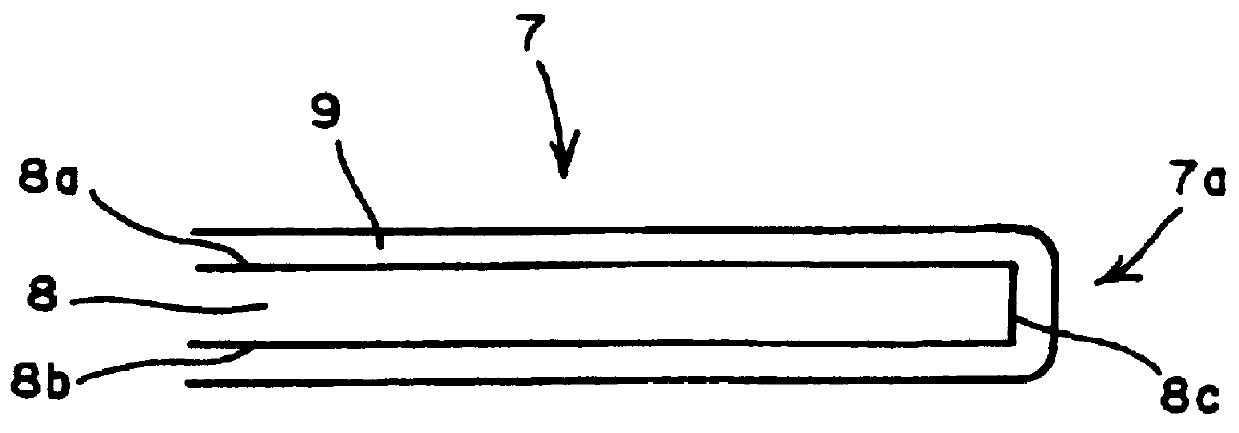

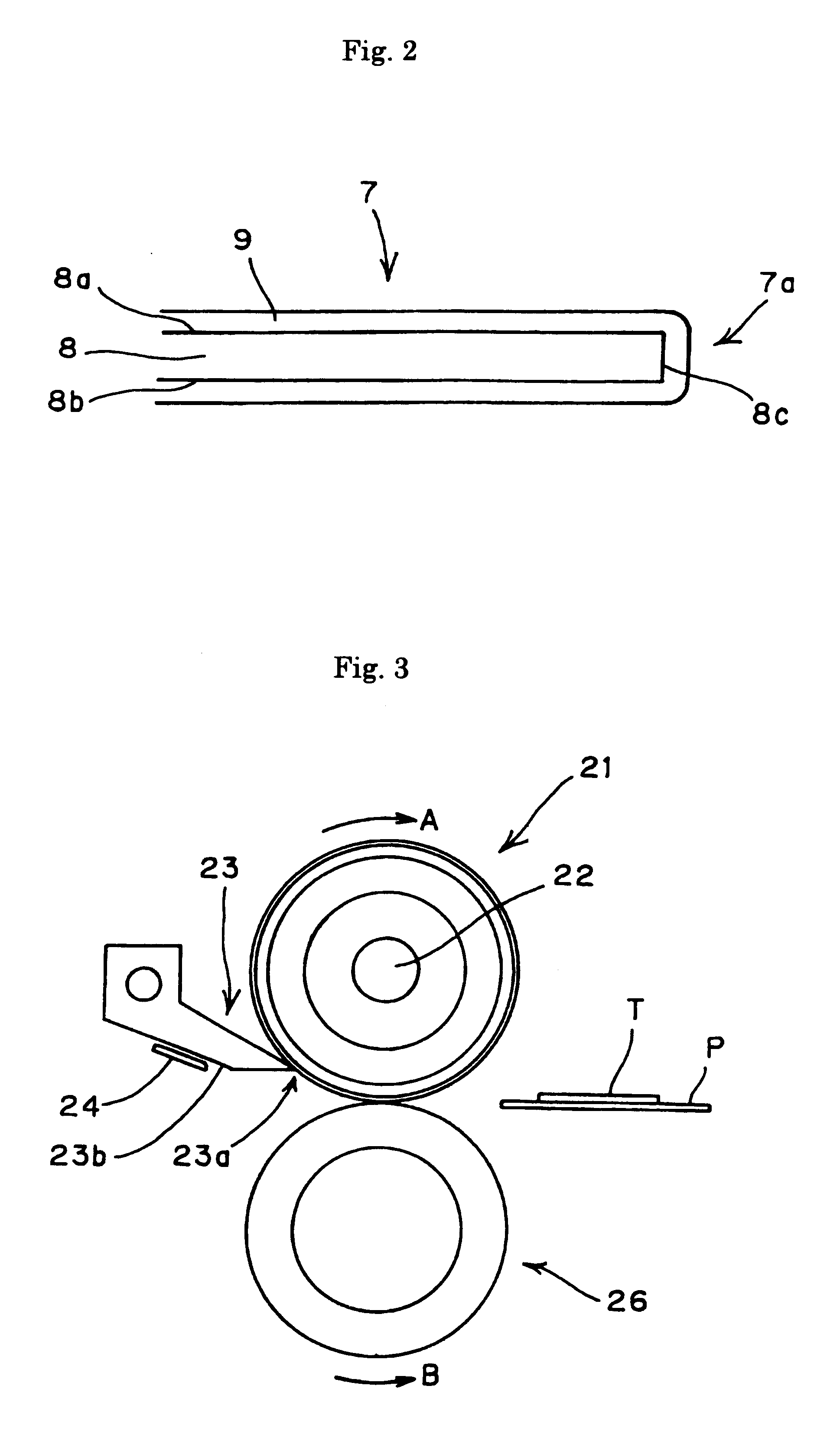

Fixing device with peeling member for an image forming apparatus

ActiveUS7463857B2Good fixabilityStable peelingElectrographic process apparatusImage formationEngineering

Owner:FUJIFILM BUSINESS INNOVATION CORP

Thermoplastic resin composition , multilayer laminate comprising the same, article obtained by allowing the thermoplastic resin composition to adhere thereto, and method for protecting surface of article

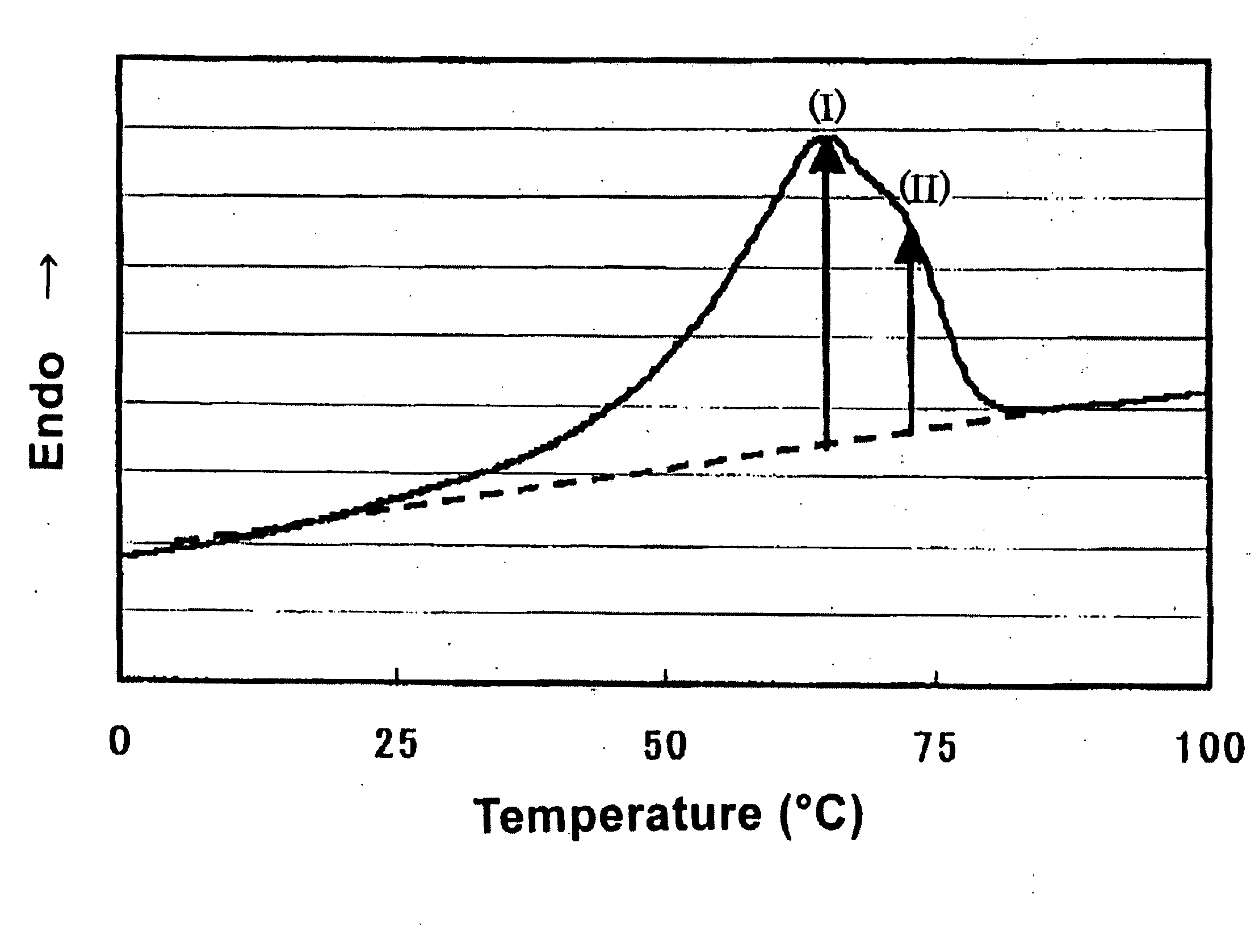

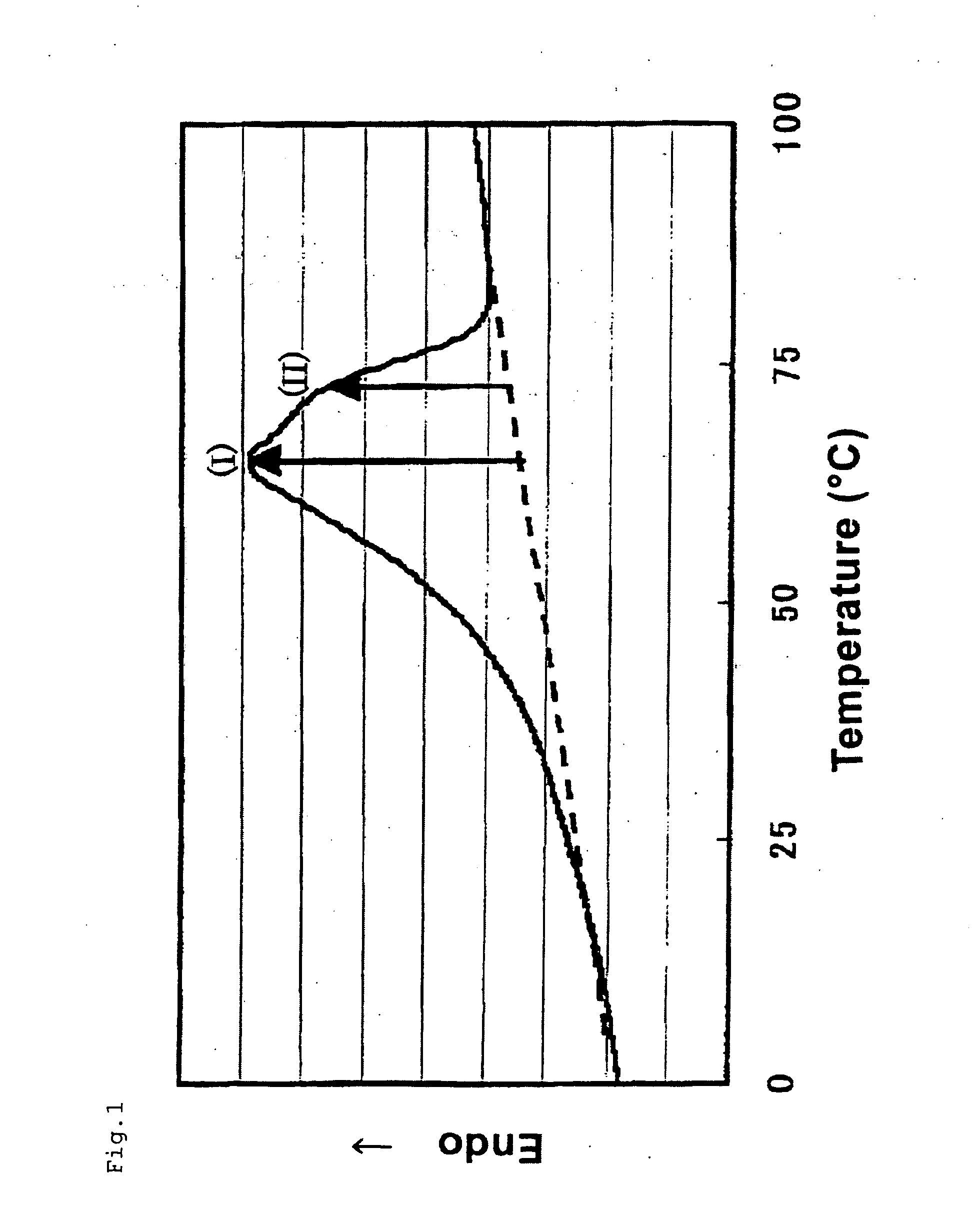

ActiveUS20090314429A1High transparencyImprove adhesionSynthetic resin layered productsLaminationButeneEthylene Homopolymers

[Problem] To provide a thermoplastic resin composition which is excellent in transparency and adhesion properties and hardly causes staining of an adherend after it is separated, a multilayer laminate using the composition, an article, and a method for protecting a surface of an article.[Means for solving problem] A thermoplastic resin composition (X) comprising the following components (A) to (C): (A) isotactic polypropylene containing not less than 90% by mol of propylene units, in an amount of 1 to 65% by weight, (B) a propylene copolymer which is a copolymer of propylene and at least one α-olefin of 2 to 20 carbon atoms (excluding propylene) and whose melting point, as measured by DSC, is lower than 65° C. or is not observed, in an amount of 30 to 94% by weight, and (C) a 1-butene-based polymer which is selected from the group consisting of a 1-butene homopolymer and a copolymer of 1-butene and an α-olefin of 2 to 20 carbon atoms (excluding 1-butene) (said copolymer containing not less than 16% by mol of 1-butene units) and whose melting point, as measured by DSC, is in the range of 65 to 135° C., in an amount of 5 to 60% by weight, the total amount of said components (A) to (C) being 100% by weight.

Owner:MITSUI CHEM INC

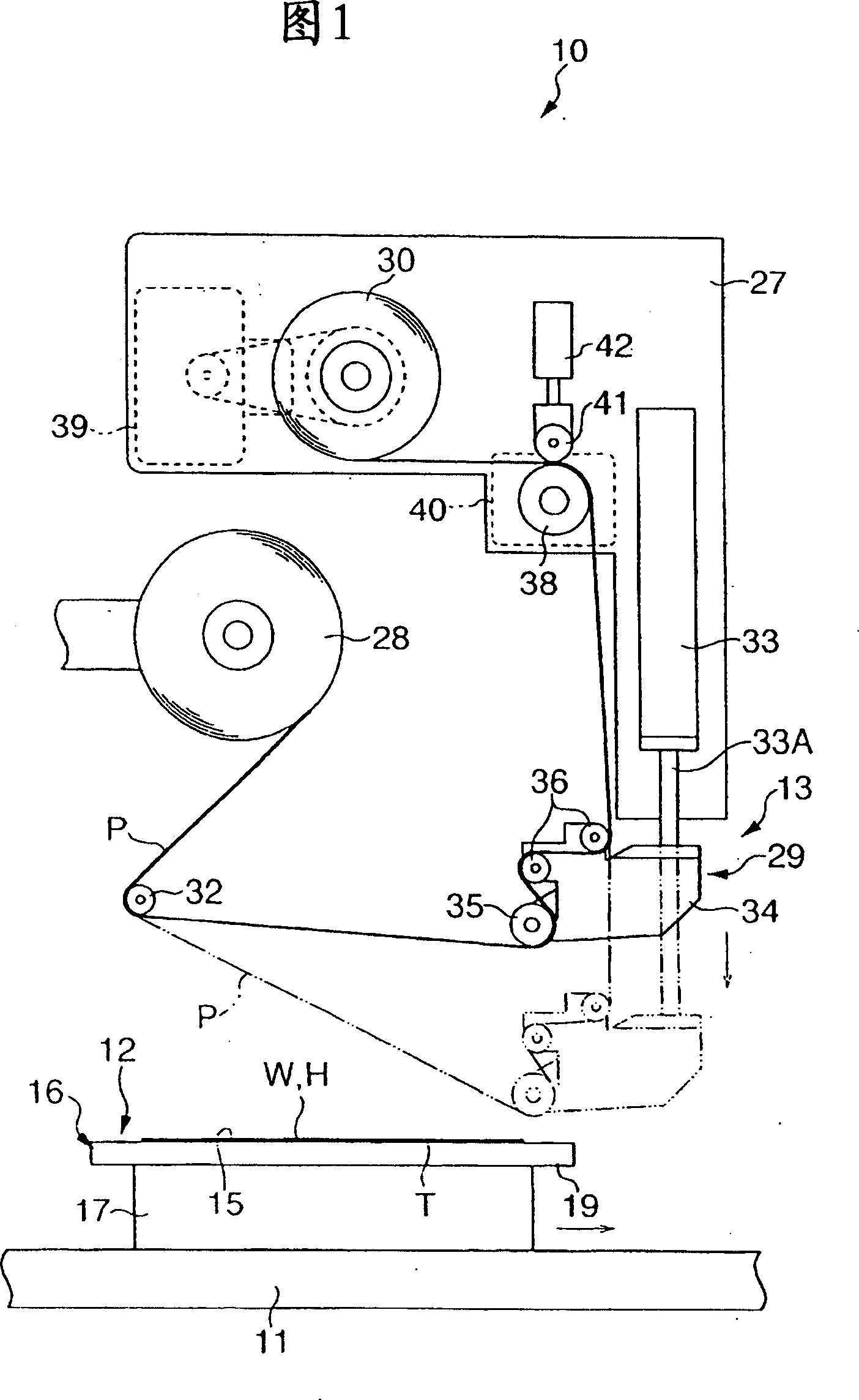

Sucking apparatus

InactiveCN1947226AAvoid bondingReduce processing timeSolid-state devicesSemiconductor/solid-state device manufacturingDicing tapeMechanical engineering

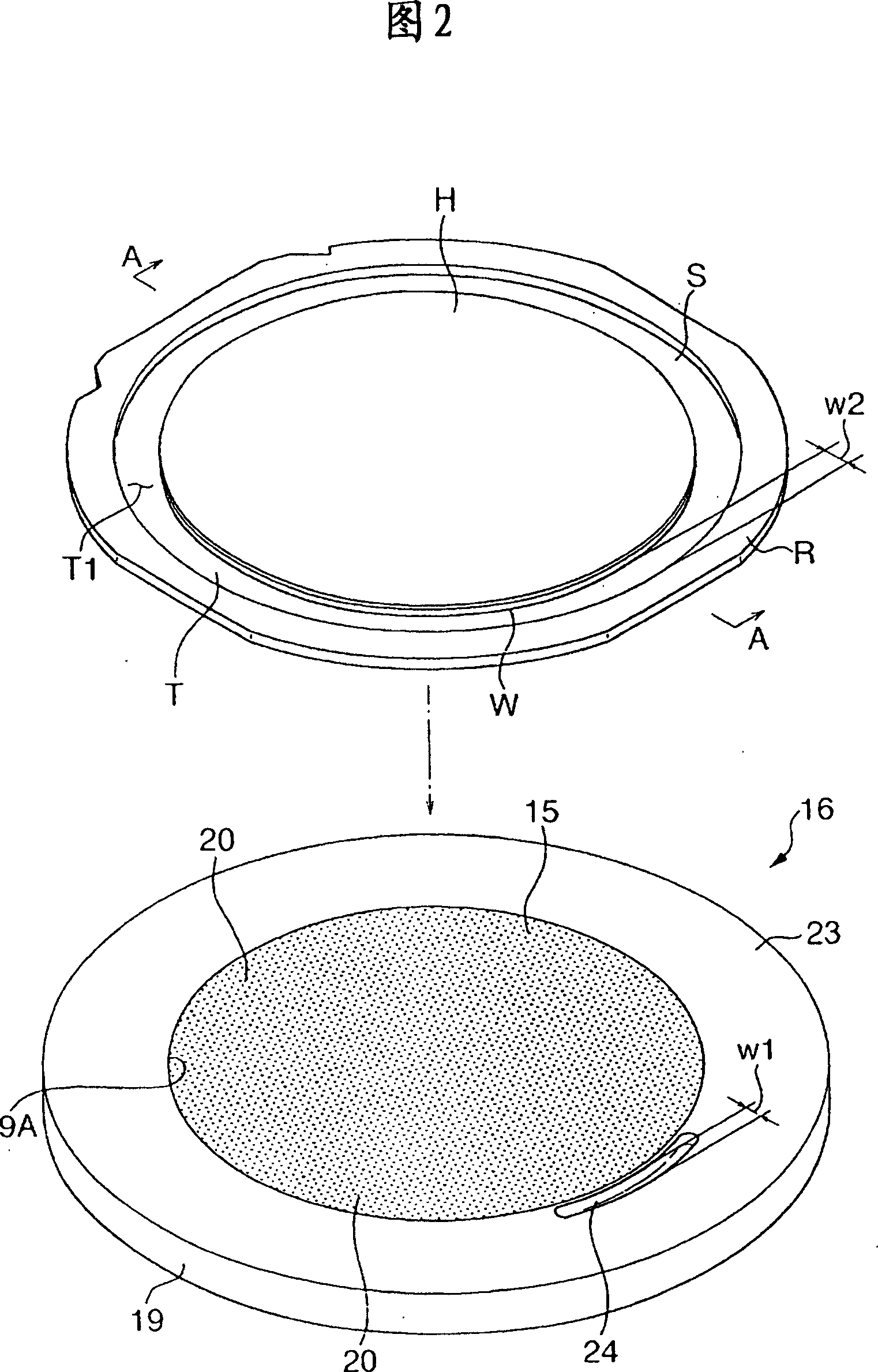

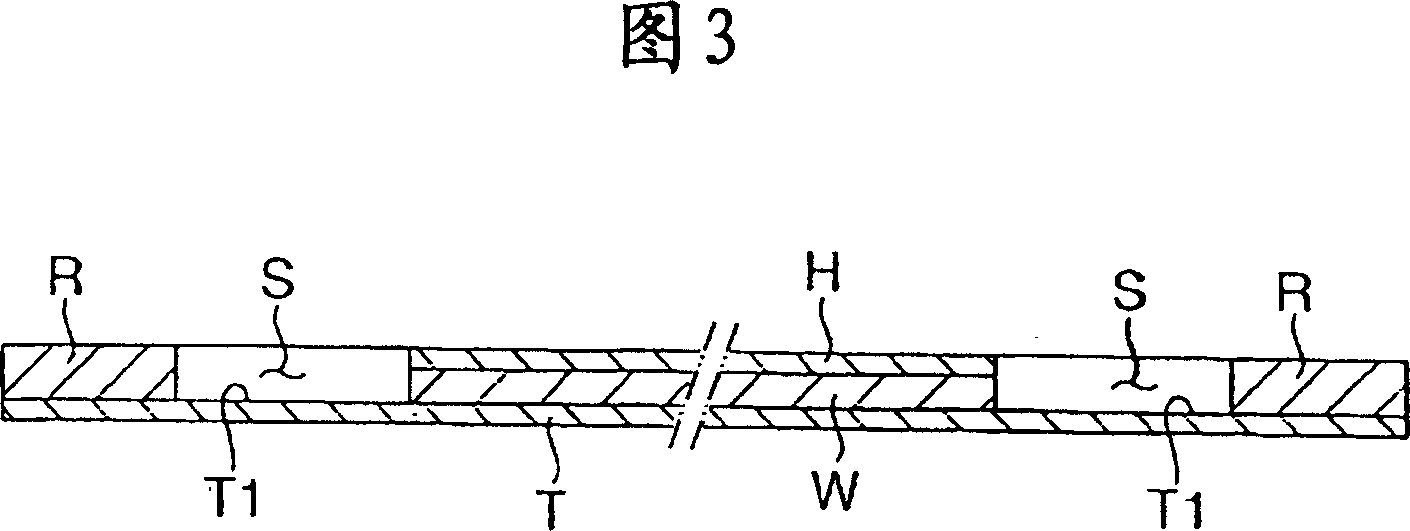

A wafer (W) is supported on a ring frame (R) from a rear side through a dicing tape (T), and a protection tape (H) is adhered on a front side of the wafer. A sucking apparatus (12) is provided with a table (16) having a sucking plane (15) on an upper surface. The sucking plane (15) sucks the dicing tape (T) by prescribed suction to hold the wafer (W). A groove (24) is formed at least in a part of an area along an outer circumference of the sucking plane (15), suction is performed by the sucking plane (15), and the dicing tape (T) is depressed by having the inside of the groove (24) depressurized.

Owner:LINTEC CORP

Electronic part feeder

InactiveCN1829434AAvoid Adsorption MistakesStable peelingElectrical componentsLine elementEngineering

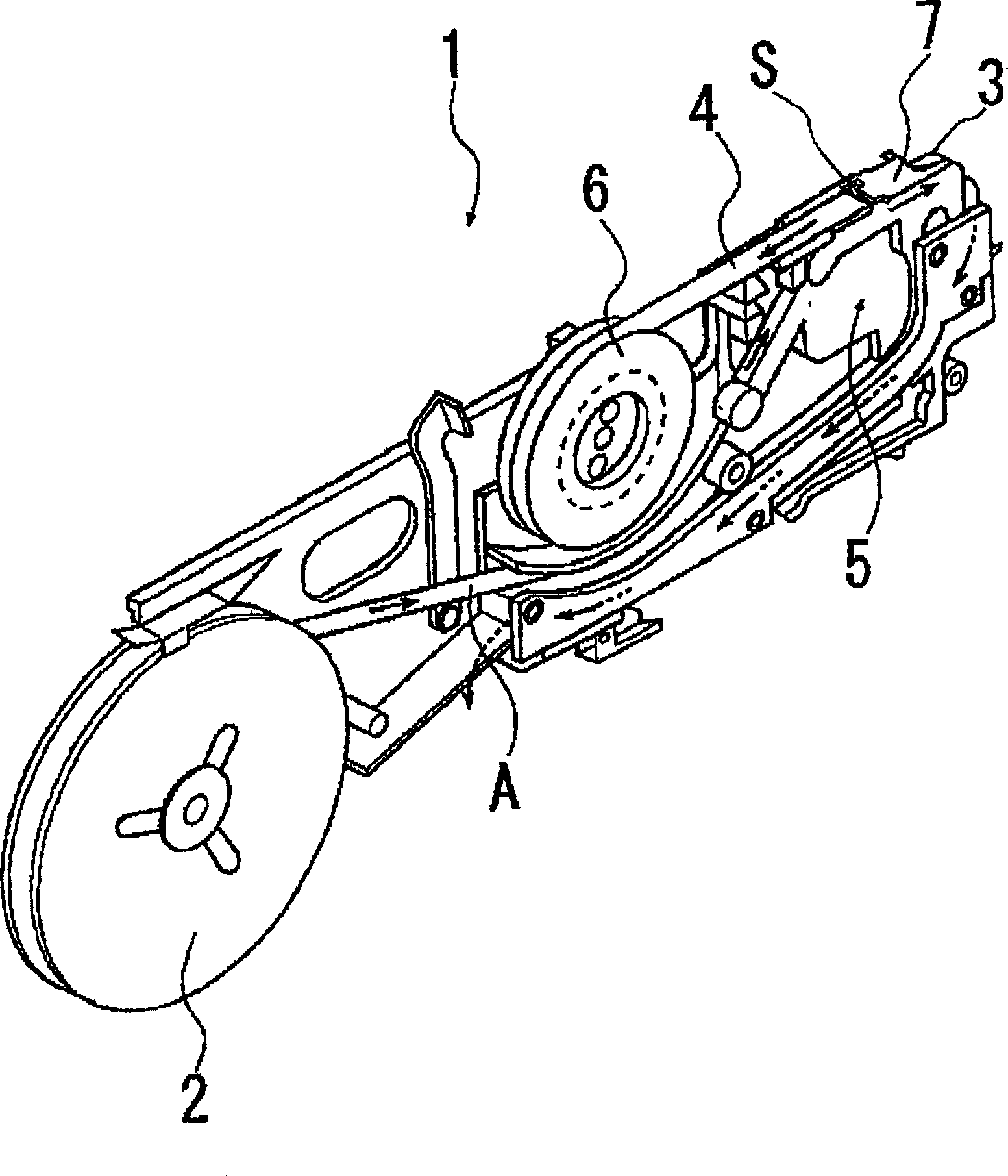

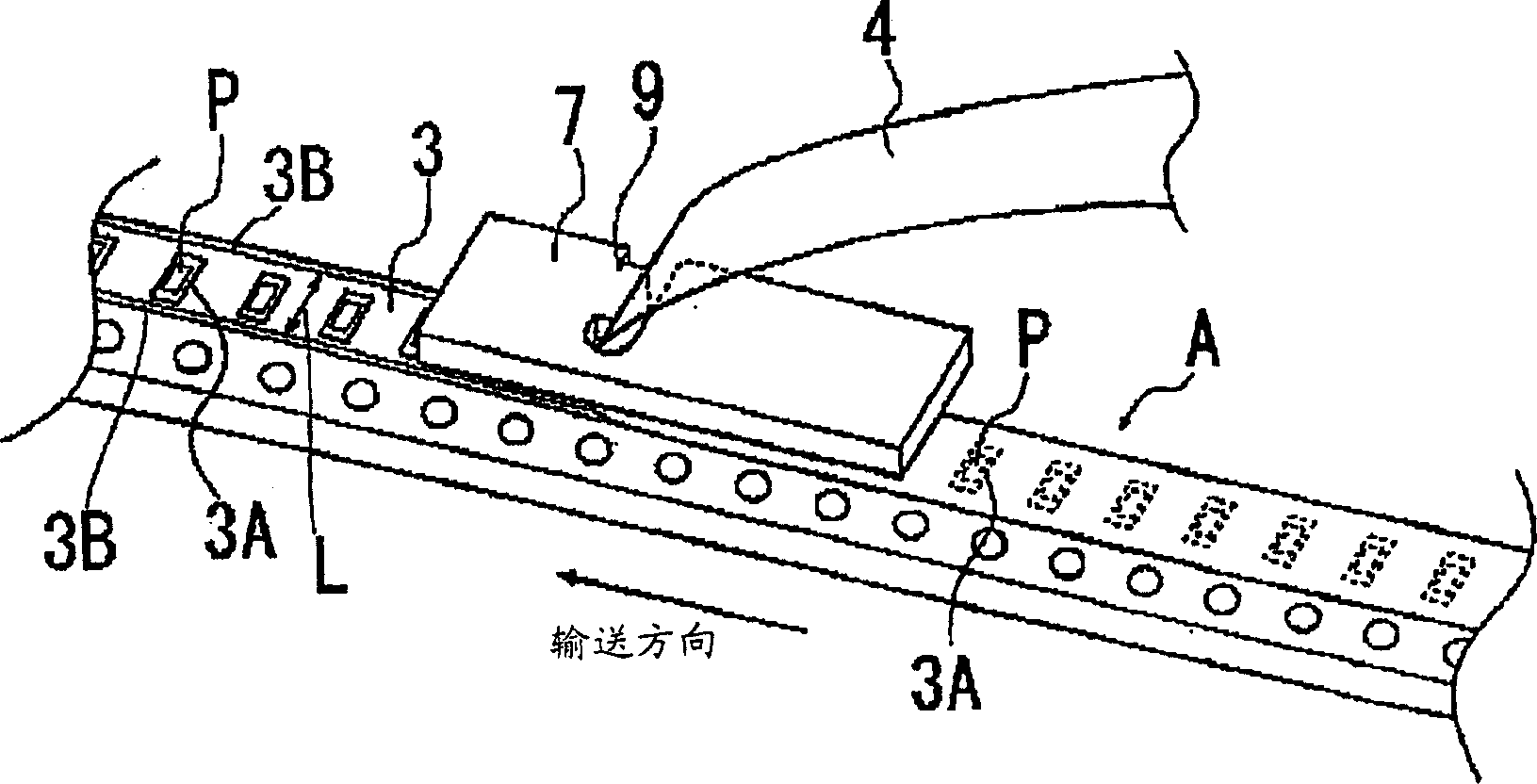

An electron-unit supply arrangement can prevent the paperfibre attached on the driving belt and the covering belt when detaching the covering belt from clinging to the projecting part. Accordingly, the covering belt can be smoothly detached from the driving belt, which can avoid the adsorptive error to the electron unit. The electron-unit supply arrangement includes: driving belt which takes in the units with equal interval and forms the bonding unit on the two edges along the direction of length with predetermined interval; covering belt which bonds with the said bonding unit of the driving belt; driver element which intermittently transports the driving belt; stripping element which detaches the covering belt from the driving belt; and winding element which can coil the covering belt separated from the driving belt. In the said electron-unit supply arrangement, the said stripping element includes a marginal element which detaches the covering belt from the driving belt; and a projecting part, in which the gap between the said projecting part and the said marginal element is set along the transfer direction of the driving belt and a straight-line element with a smaller gap than the said bonding unit of the driving belt is formed on the relative margin of the said marginal element.

Owner:JUKI CORP

Preparation method of ultrathin carrier copper foil

ActiveCN106757181AImprove conductivityEasy to operateElectroforming processesOrganic filmElectrolysis

The invention relates to a preparation method of ultrathin carrier copper foil. The preparation method specifically comprises the following steps that (1) a plating solution is prepared, specifically, a complexing agent sodium gluconate, potassium dichromate, an additive A and an additive B are dissolved in water correspondingly and mixed after being clarified, and the pH value of the solution is adjusted; (2) carrier foil is soaked into an organic solution of a silane coupling agent, and a layer of organic film is formed through adsorption; and (3) the carrier foil is placed into the plating solution in the step (1), a layer of novel nanoscale composite chrome plating layer is formed through electroplating to serve as a peeling layer, then ultrathin electrolytic copper foil which is 2-5 microns thick is electroplated on the peeling layer, and the ultrathin carrier copper foil is obtained. The ultrathin carrier copper foil is subjected to high-temperature pressing and cured on an insulating substrate, and then the carrier foil can be completely removed through peeling by means of a mechanical method. The peeling layer prepared through the method is ultrathin and uniform, the carrier foil can be peeled easily, completely and stably, and the preparation method has great application prospects.

Owner:SHANDONG JINBAO ELECTRONICS

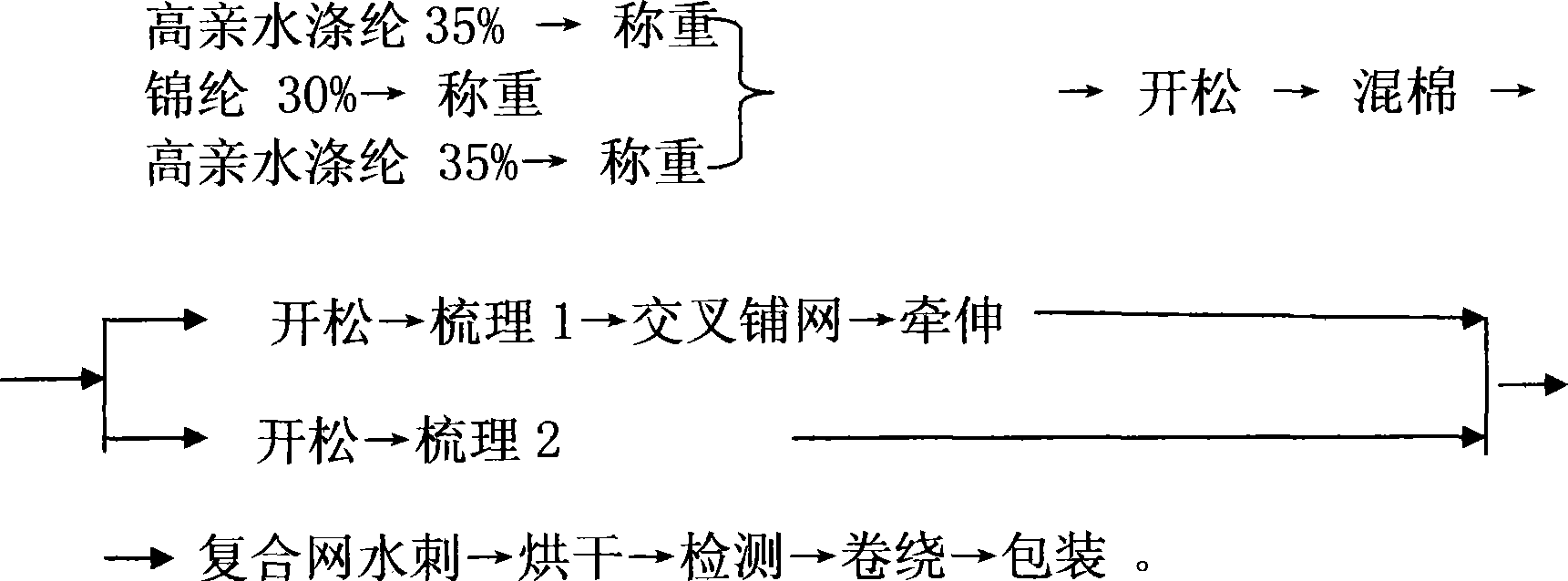

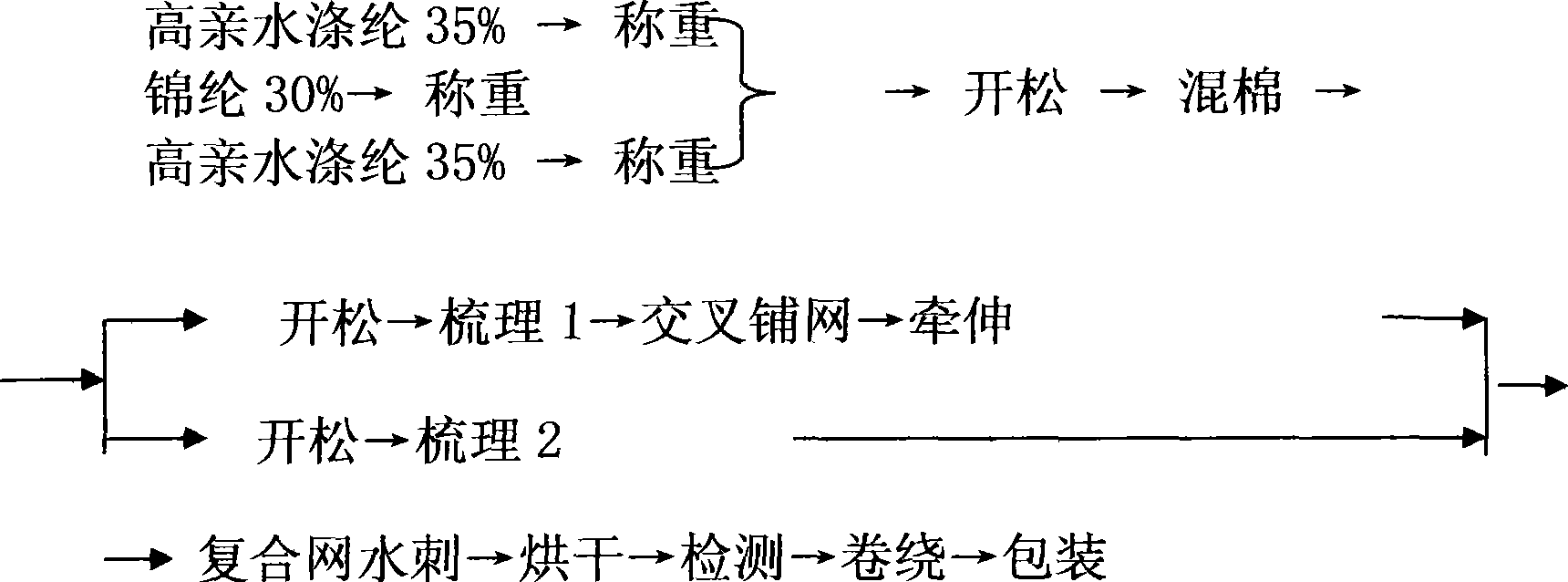

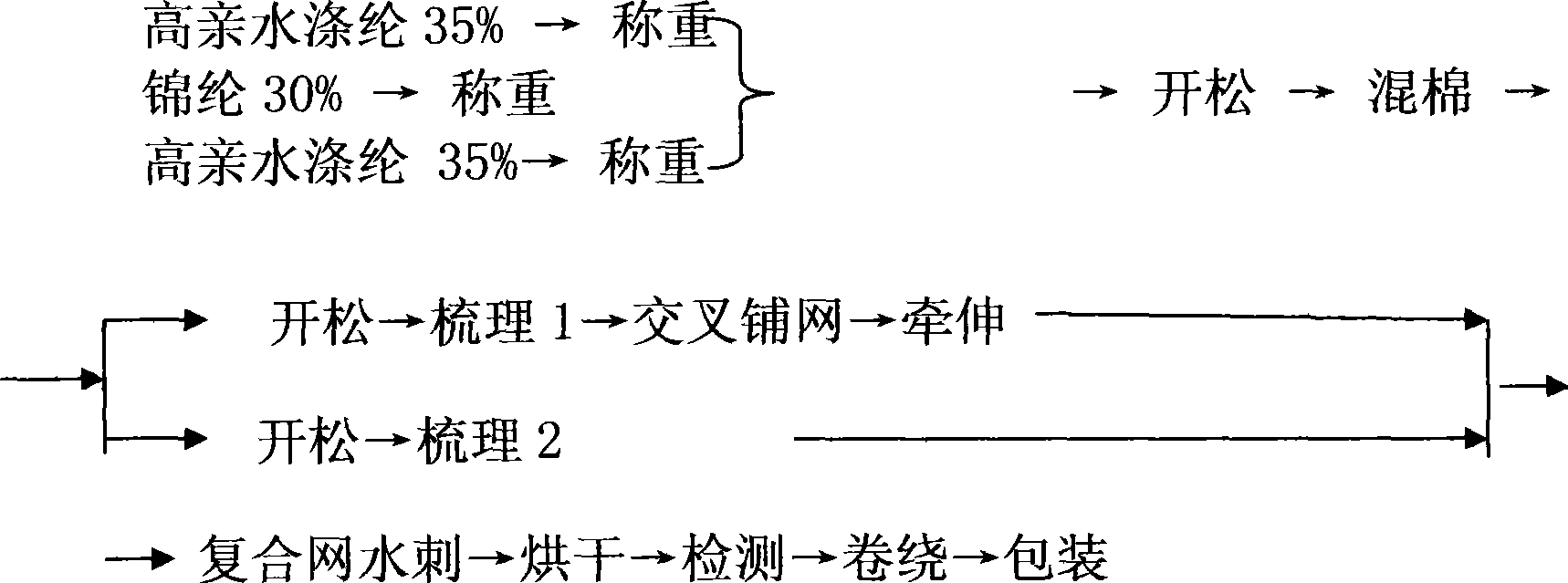

High breathable and high tearing fine denier spun-laced novel material and process for its production

InactiveCN101397722AImprove tensile strengthImprove flatnessCarding machinesNon-woven fabricsPolyesterYarn

The invention discloses a highly air permeable and highly tearing fine denier yarn spunlace novel material and a production technique thereof, which pertains to the technical field of textile materials. The novel material is produced by the following components according to weight percentage: 70 percent of highly hydrophilic polyester with the specification of 1.56dtex multiplied by 38mm and 30 percent of nylon with the specification of 1.56dtex multiplied by 38mm. The highly air permeable and highly tearing fine denier yarn spunlace novel material has good stretching strength, the ratio of MD to CD equal to 1:1, even vertical and horizontal tearing strength, good uniformity, even thickness, no fuzz, stable peeling, good winding effect, comfortable touch feeling and low formaldehyde content, and improves the simulation quality and the air permeability of a product after becoming finished leather; the product is mainly used as the base fabric of PU leather.

Owner:SHAOXING RONGLIDA TEXTILE TECH

Making method of mixed dried beancurd sticks

The invention discloses a making method of mixed dried beancurd sticks. The making method comprises the following steps of step 1, performing selecting treatment on qualified soybeans; step 2, performing selecting treatment on auxiliary materials; step 3, performing peeling treatment on the soybeans; step 4, performing a soaking operation on the soybeans; step 5, performing refining on the soybeans, and boiling pulp; and step 6, boiling the soybeans to obtain skin. The invention relates to the technical field of making of dried beancurd sticks. According to the making method of the mixed driedbeancurd sticks, relevant nutrients of purple sweet potatoes, black beans and mint are added in the production process of the dried beancurd sticks, and can complement mutually with nutrients of thesoybeans, soybean ketone of peas and beans can interact with purple sweet potato pasty powder, absorption of bodies can be promoted, through slow grinding, the soybean pulp can be sufficiently ground,and the yield of the dried beancurd sticks can be indirectly increased; and the soybeans are subjected to peeling treatment, effective substances of the soybeans can be completely soaked in water, and the soaking efficiency can be improved. The peeling operation is simple and convenient, and easy for workers to operate.

Owner:淮北市铚康食品有限公司

Preparation method of high-performance release paper

ActiveCN111691218AExcellent anti-oxidative aging abilityPrevent agingWater-repelling agents additionPulp beating methodsEmulsionPapermaking

The invention discloses a preparation method of high-performance release paper, which relates to the technical field of papermaking. The method comprises the following steps: (1) selecting ground bleached sulfate softwood pulp as raw material pulp; (2) adding an internal sizing agent into the raw material pulp; (3) carrying out papermaking on a fourdrinier machine, and carrying out squeezing dehydration; (4) performing semi-wet drying and pressurizing treatment; (5) performing surface sizing and drying; (6) performing spray wetting, super calendaring, coiling and slitting to prepare raw paper;and (7) carrying out corona discharge treatment on the raw paper, then coating the raw paper with an antioxidant organosilicon emulsion, and drying to prepare the high-performance release paper. According to the method, the release layer prepared by coating the raw paper with the antioxidant organosilicon emulsion has excellent antioxidant aging resistance, so that the aging problem caused by long-time storage and high-temperature use of the coating layer on the release paper is prevented, meanwhile, the stripping performance is more stable, and the use frequency of the release paper is higher.

Owner:XIANHE CO LTD

Emulsion type silicone pressure sensitive adhesive composition and process for the production thereof

ActiveUS10077387B2Small particle sizeStable appearanceMacromolecular adhesive additivesPolymer scienceEmulsion

Disclosed is an emulsion type silicone pressure sensitive adhesive composition and a process for the production thereof. Also provided is an emulsion type silicone pressure sensitive adhesive composition, comprising: (A) 100 parts by weight of a silicone pressure sensitive adhesive; (B) 1-30 parts by weight of an emulsifier selected from the group consisting of a polyvinylalcohol and a polyether modified MQ resin wherein M is R 3SiO 1 / 2, and Q is SiO 4 / 2, wherein R represents C 1-20 alkyl; (C) water; and (D) catalyst.

Owner:DOW (SHANGHAI) HOLDING CO LTD +1

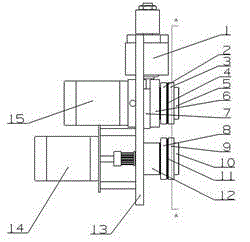

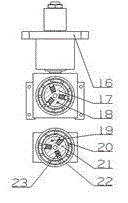

Apparatus for peeling middle of wire

Provided is an apparatus for peeling the middle of a wire. The apparatus comprises a skin cutting device, a wire feeding device, and a panel. The skin cutting device is mainly composed of a cylinder, a wire protecting device, a top circular cutter, a top end cover, a top case body, a slide rail, a bottom end cover, a bottom circular cutter, a bottom case body, a bottom motor, a top motor, a top main shaft, a top main shaft cylindrical pin, a bottom main shaft cylindrical pin, a deep groove ball bearing, and a bottom main shaft. The wire feeding device comprises a wire outlet wheel, a wire-cutting peeling cutter, a cutter stand, a conduit, a wire inlet wheel, a wire inlet wheel tensioning regulator, and a wire outlet wheel tensioning regulator. The apparatus may stably peel the middle of the wire, achieve high efficiency, and does not damage the wire.

Owner:蔡君路

Cover film

ActiveUS8652601B2Stable peelingMaintain stable propertiesWrappersSemiconductor/solid-state device detailsLow-density polyethyleneLinear low-density polyethylene

A cover film comprising a substrate layer, an intermediate layer comprising a resin composition containing 50% by mass or more of a metallocene linear low-density polyethylene resin having a density of 0.900 to 0.940×103 kg / m3, and a sealant layer comprising an ethylene-type copolymerized resin containing 50 to 85% by mass of an olefin component.

Owner:DENKA CO LTD

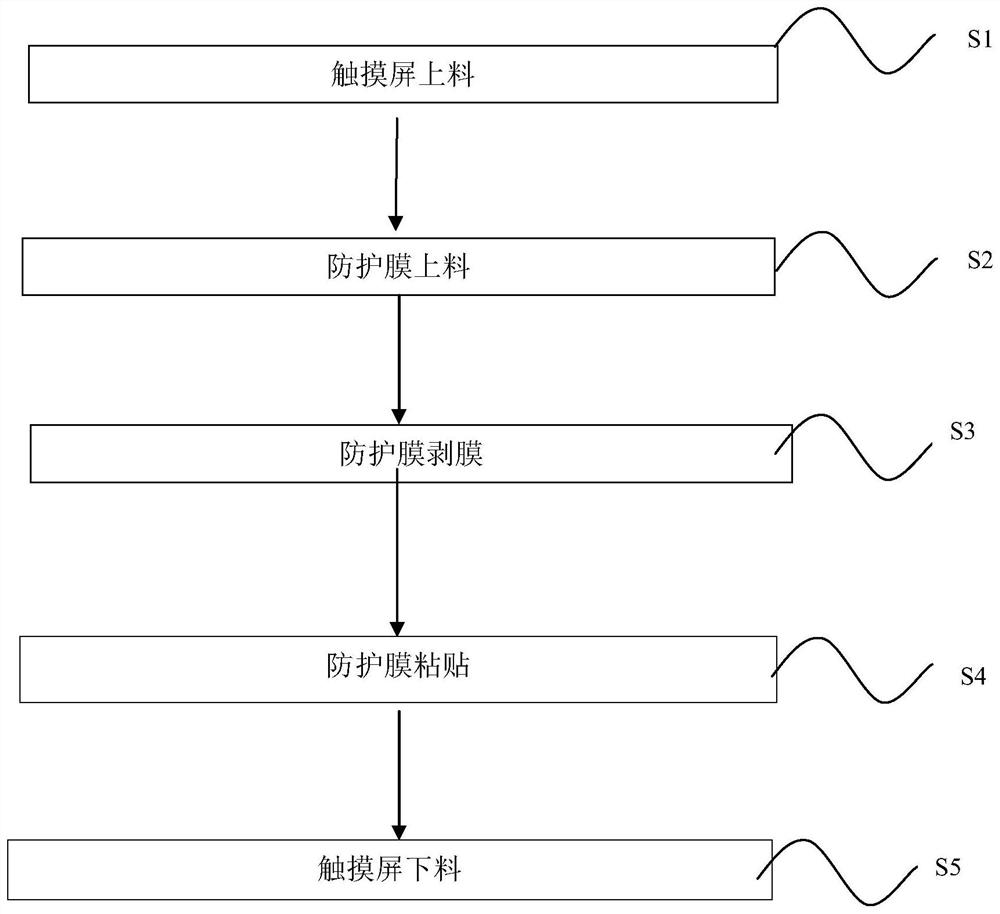

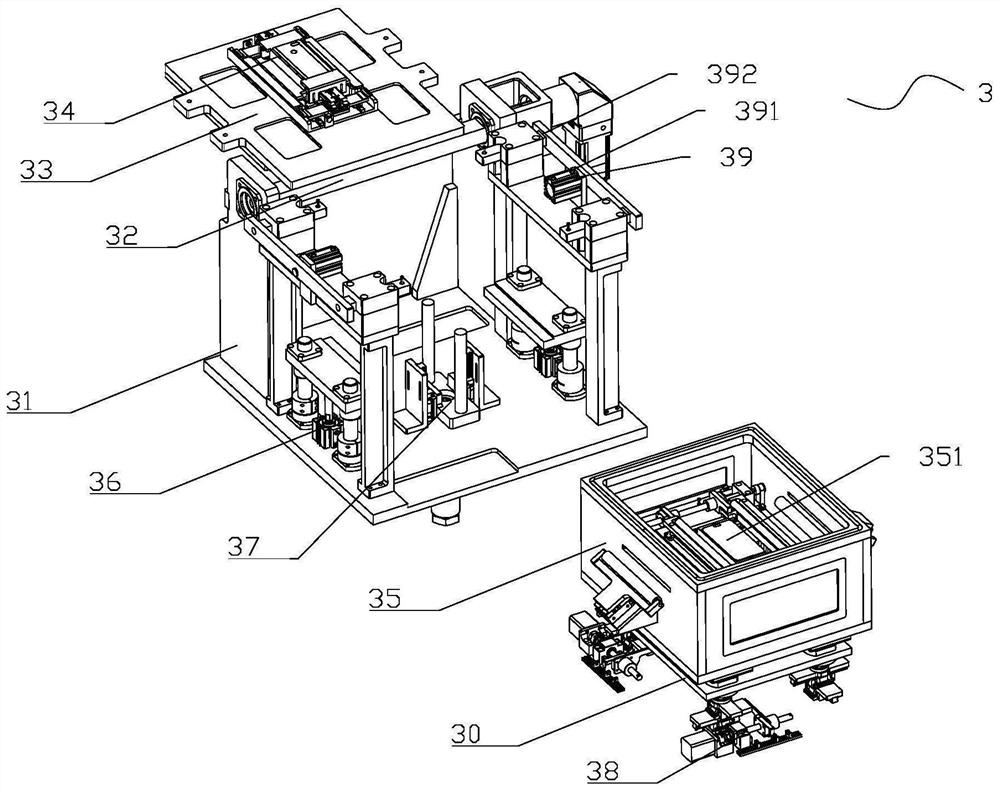

Touch screen protective film pasting equipment and film pasting process

The invention discloses touch screen protective film pasting equipment. The touch screen protective film pasting equipment comprises a rack, and further comprises a touch screen feeding device, a vacuum film pasting device, a protective film feeding device, a touch screen feeding carrying device, a film stripping device, a discharging carrying device and a discharging device which are installed onthe rack; the touch screen feeding device and the discharging device are located on the same straight line, and the protective film feeding device is located between the touch screen feeding device and the discharging device during feeding; the vacuum film pasting device is located in the middle of the protective film feeding device, and the film stripping device is located above the vacuum filmpasting device; and the discharging carrying device is connected with the discharging end of the protective film feeding device and the discharging device. The touch screen protective film pasting equipment has the advantages of being efficient in workpiece circulation, high in production efficiency and high in automation degree.

Owner:NINGBO YINZHOU TEERFEI ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com