Self-rolling adhesive film

A film-bonding and winding technology, applied in pressure-sensitive films/sheets, film/sheet-like adhesives, adhesives, etc., can solve the problems of difficulty in recycling and easy deformation, and achieve uniform peeling stress and reliable surface protection effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

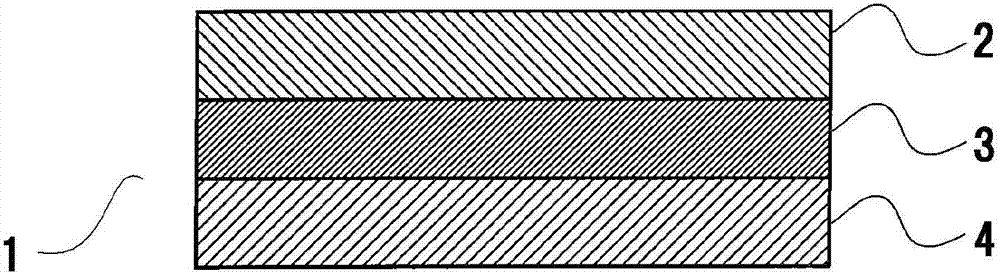

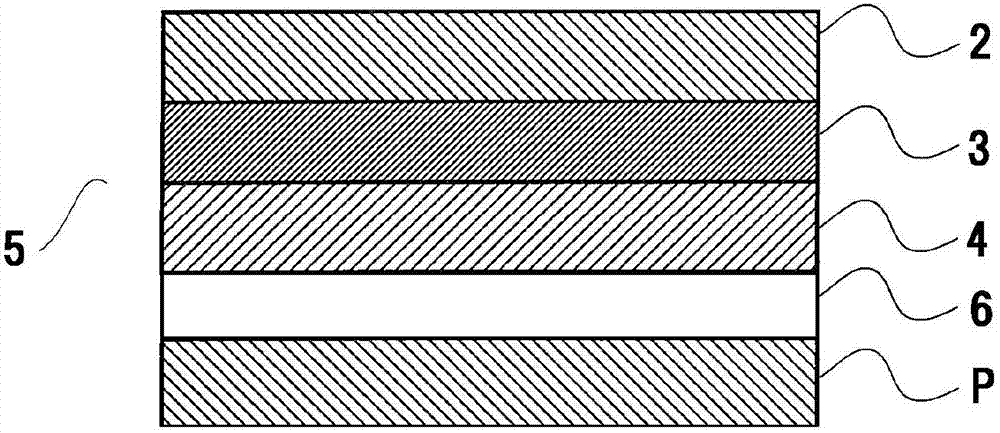

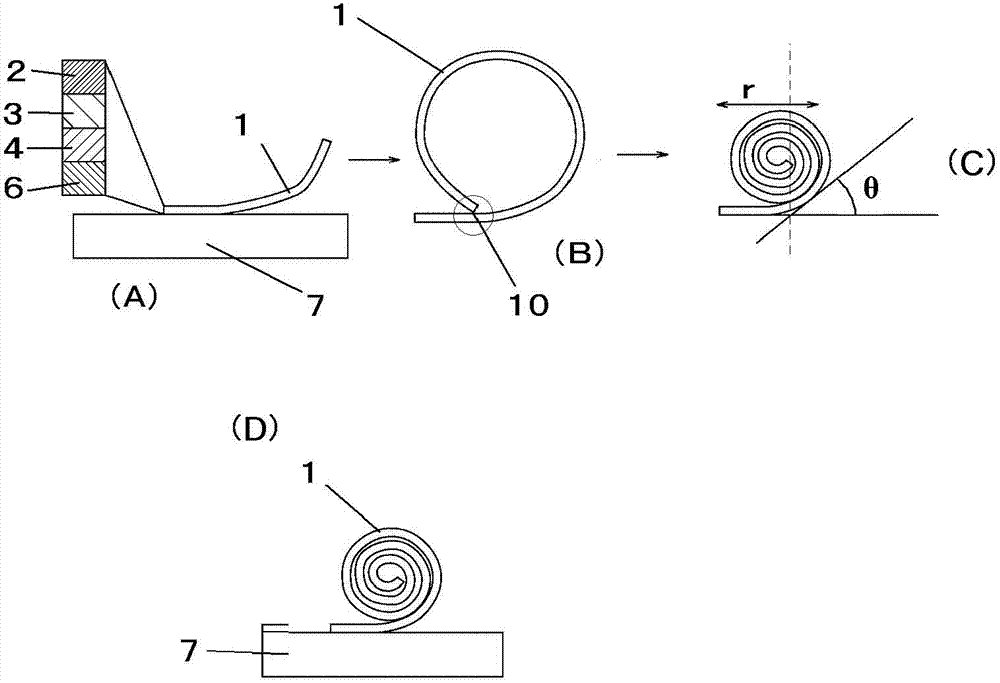

Method used

Image

Examples

manufacture example

[0172] One side of a 50 μm thick PET film "LUMIRROR S10" manufactured by Toray Industries, Inc. was coated with a 1% silicone release agent diluted with heptane (manufactured by Shin-Etsu Silicone Co., Ltd., trade name: Molding agent "KS-774" and catalysts "CAT PLR-1", "PLR-2" and "CAT PL-50T") were dried to obtain separator 1. The arithmetic mean roughness Ra of the release agent coated surface was 0.03 μm.

[0173] Production example of separator 2

[0174] One surface of a 50-μm-thick PET film "LUMIRROR S10" manufactured by Toray Industries, Inc. was sandblasted, and a silicone mold release agent (manufactured by Shin-Etsu Silicone Co., Ltd., trade name: mold release) was applied to the treated surface. agent "KS-774" and catalysts "CAT PLR-1", "PLR-2" and "CAT PL-50T"), and dried to obtain a separator 2. The arithmetic mean roughness Ra of the release agent coated surface is 0.12 μm.

[0175] Production example of separator 3

[0176] One surface of a 50-μm-thick PET f...

Embodiment 1

[0217] Using a die coater, apply the UV-curable adhesive mixture obtained in the adhesive production example to a dry film thickness of 30 μm on the release agent-applied surface of the separator 1, and then attach it to the production example The self-winding adhesive film 1 was obtained on the organic coating side of the obtained self-winding adhesive film film. In addition, the adhesive drying was pre-dried at 70°C and then completely dried at 120°C.

Embodiment 2

[0219] A self-winding adhesive film 2 was obtained in the same manner as in Example 1 except that the separator 2 was used instead of the separator 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com