Inflatable tyre

A technology for pneumatic tires and treads, which is applied to tire parts, tire edges, tire treads/tread patterns, etc., and can solve the problem of poor impact resistance of the tire side, poor comfort, and adverse effects on the overall performance of the vehicle and other issues, to achieve the effect of improving comfort, improving the overall impact resistance and comfort, and improving the shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The core of the present invention is to provide a pneumatic tire, which has a stronger side impact resistance and better driving comfort.

[0019] In order to make those skilled in the art better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

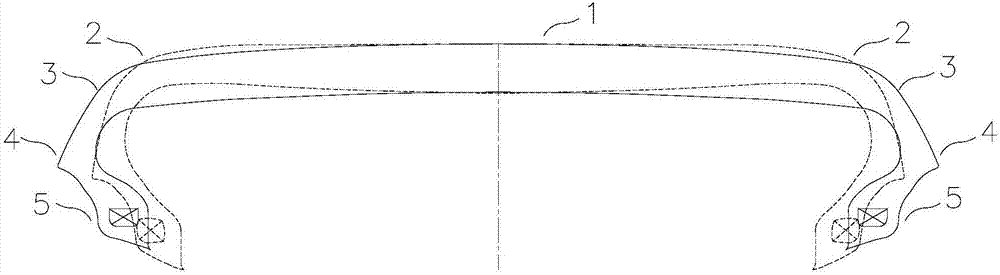

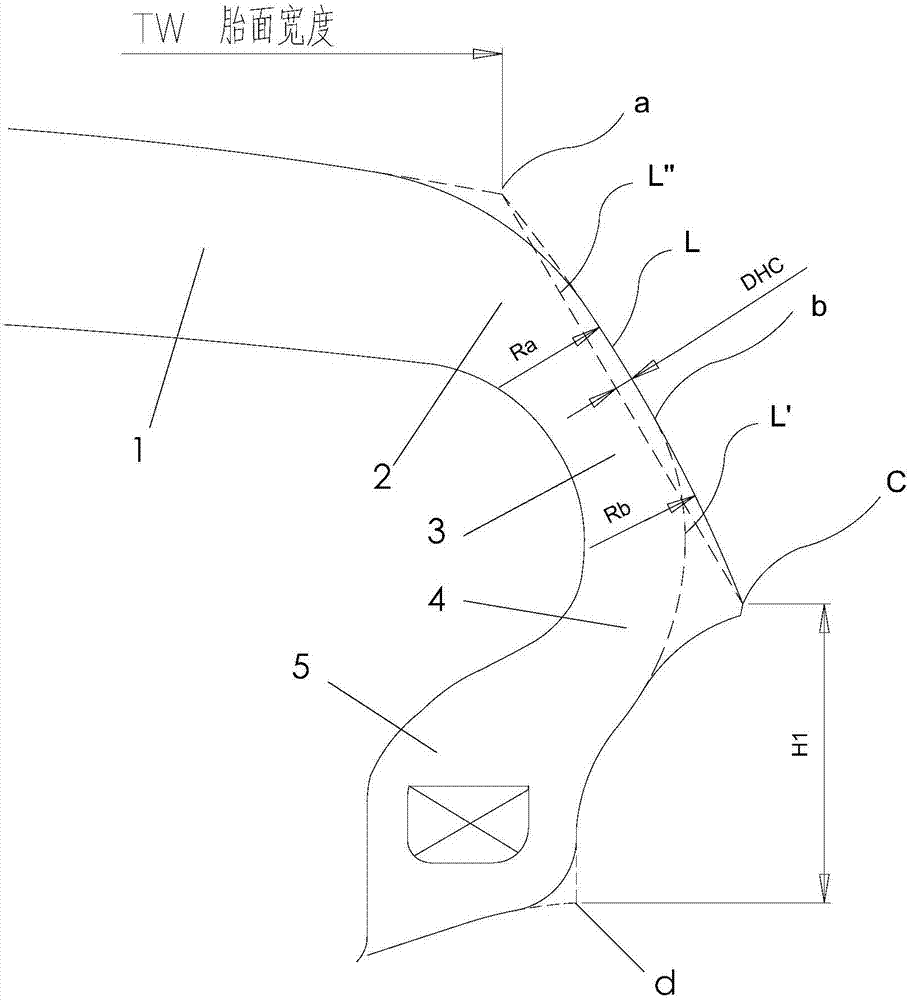

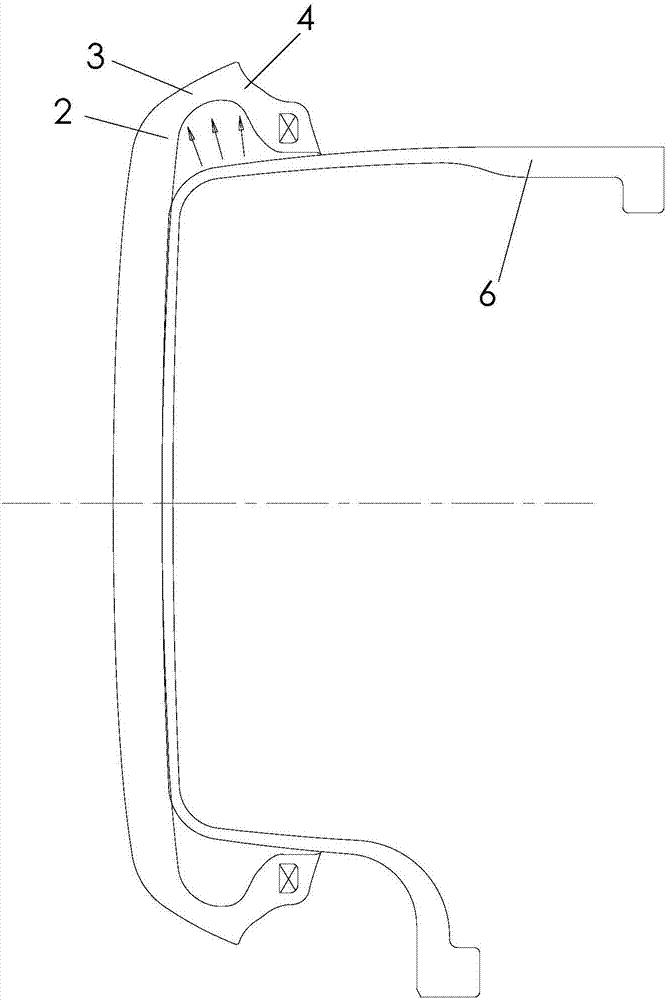

[0020] Please refer to figure 1 and figure 2 , figure 1 It is a schematic diagram of the cross-sectional structure of the difference in deformation before and after inflation of a pneumatic tire provided by a specific embodiment of the present invention; figure 2 for figure 1 Schematic diagram of the local structure.

[0021] In a specific embodiment, the pneumatic tire provided by the present invention includes a tread 1 and bead 5 located on both sides of the tread, and the tread 1 and the bead 5 are sequentially connected from the tread 1 to the bead 5 There are tire shoulders 2, sidew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com