Sucking apparatus

An adsorption device and adsorption surface technology, applied in transportation and packaging, semiconductor devices, electrical components, etc., can solve the problems of complicated device, increased number of parts, long peeling processing time, etc., to shorten processing time, improve versatility, The effect of preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

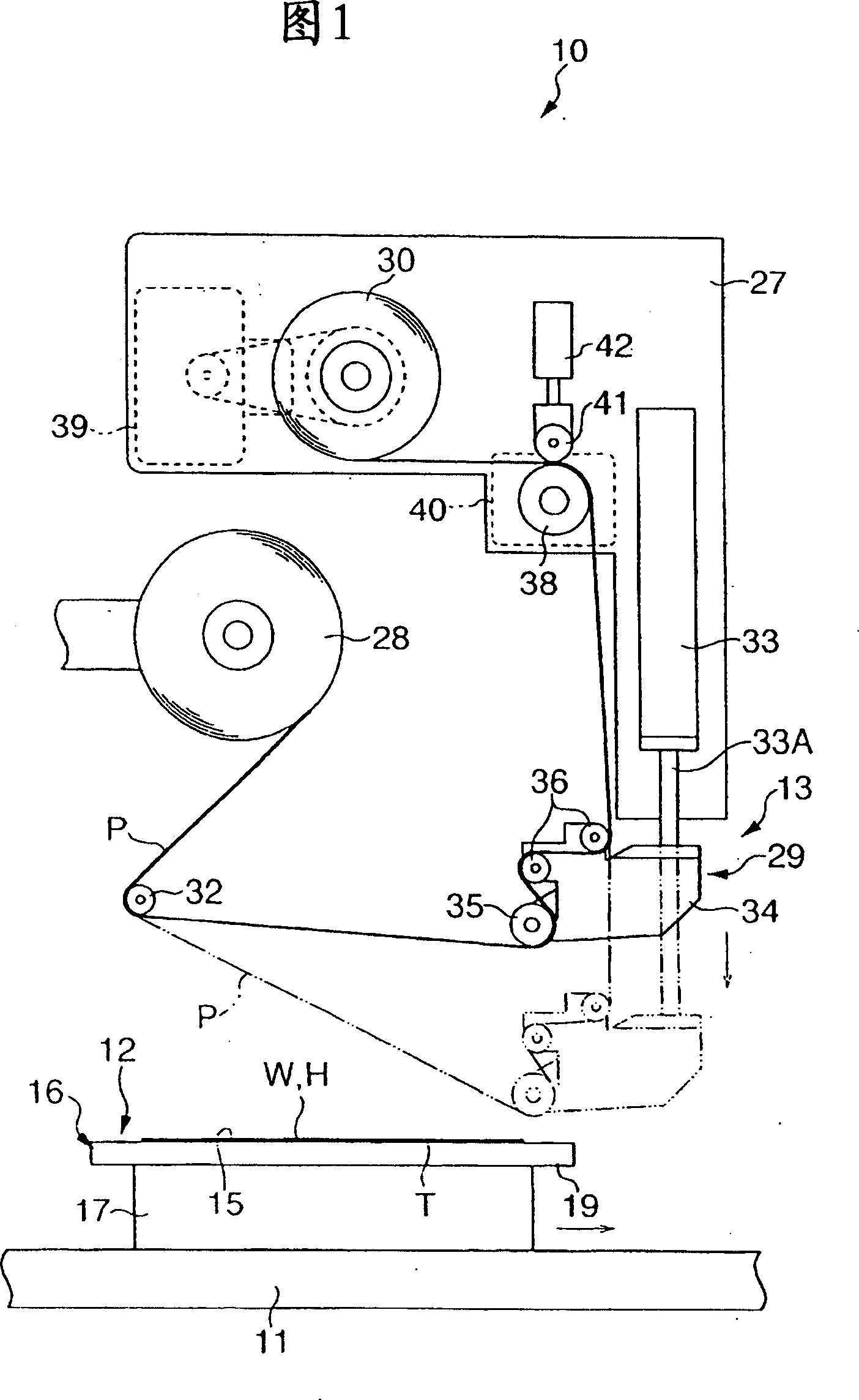

[0049] FIG. 1 shows a schematic configuration diagram of a peeling device using the suction device of the first embodiment. In this figure, the peeling device 10 includes a suction device 12 movably supported via a slider 11 extending in the left-right direction in FIG. 1 , and a peeling device 13 provided above the suction device 12 .

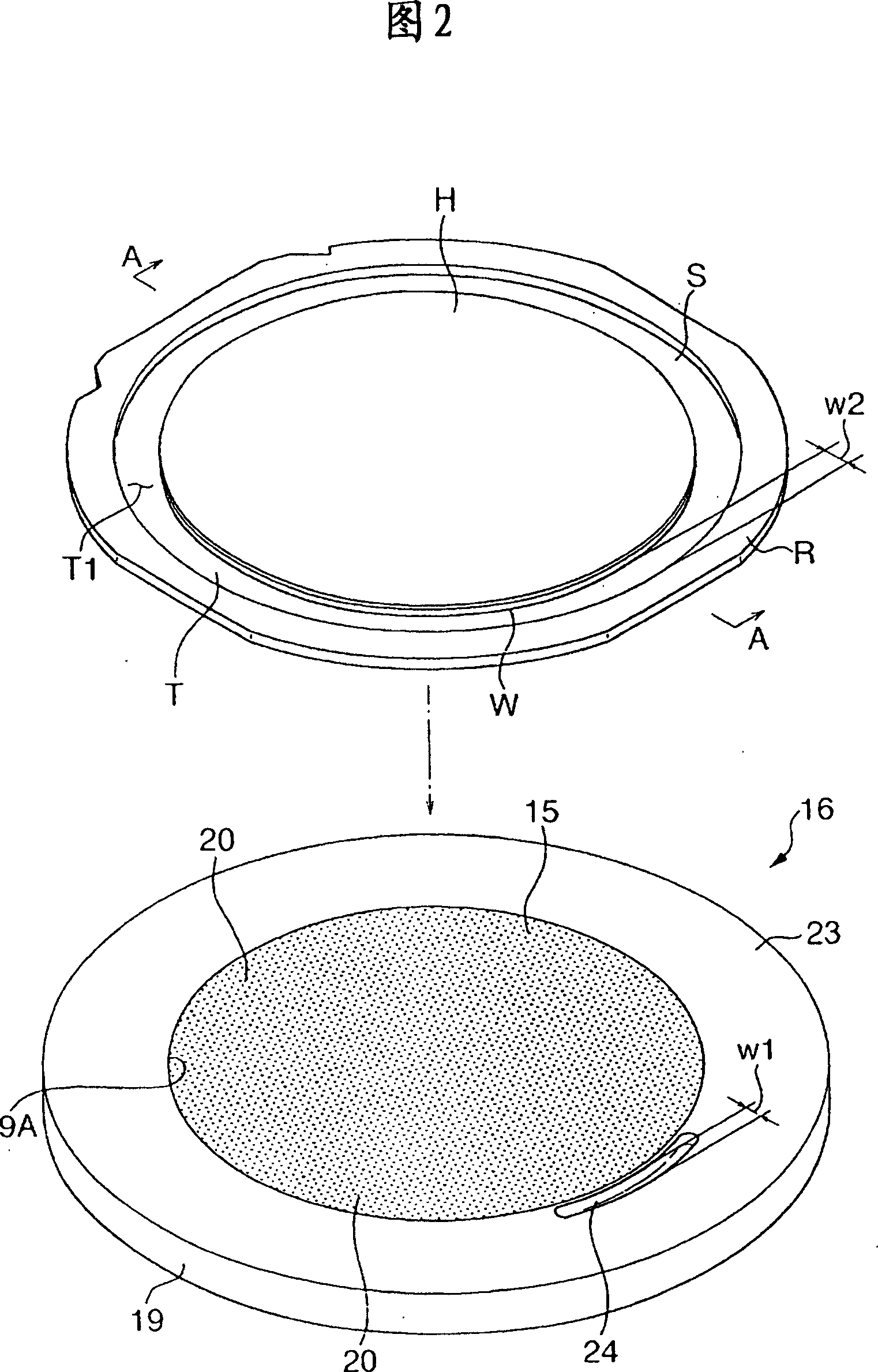

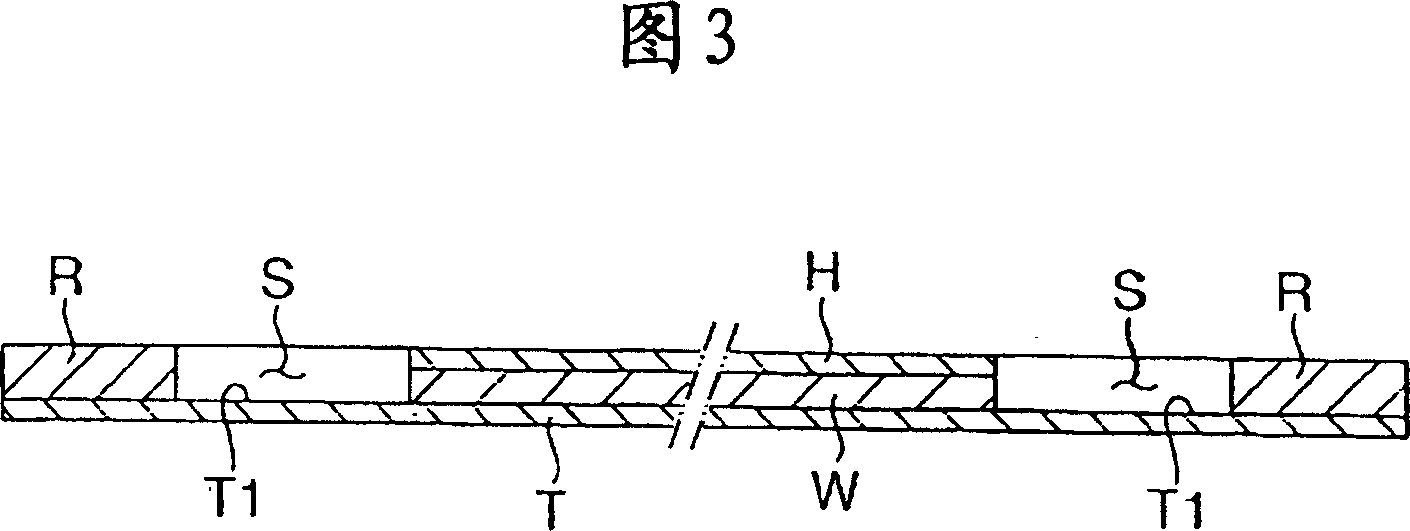

[0050] A wafer W as a plate-shaped member held by the suction device 12 has a substantially disc shape as shown in FIGS. 2 and 3 and is supported on a ring frame R via a dicing tape T as an adhesive sheet. Specifically, the dicing tape T has an adhesive surface T1 on its upper surface, and is stuck to the back surface (lower surface) of the wafer W via the adhesive surface T1. The dicing tape T has a planar area larger than that of the wafer W, and has a planar shape exposed from the outer periphery of the wafer W, and the outer peripheral side is attached to the ring frame R (lower surface). A substantially annular gap S exists between the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com