Plating solution for carrier copper foil stripping layer and preparation method of stripping layer

A technology of carrier copper foil and peeling layer, which is applied in the field of preparation of plating solution and peeling layer, and achieves the effects of good conductivity, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

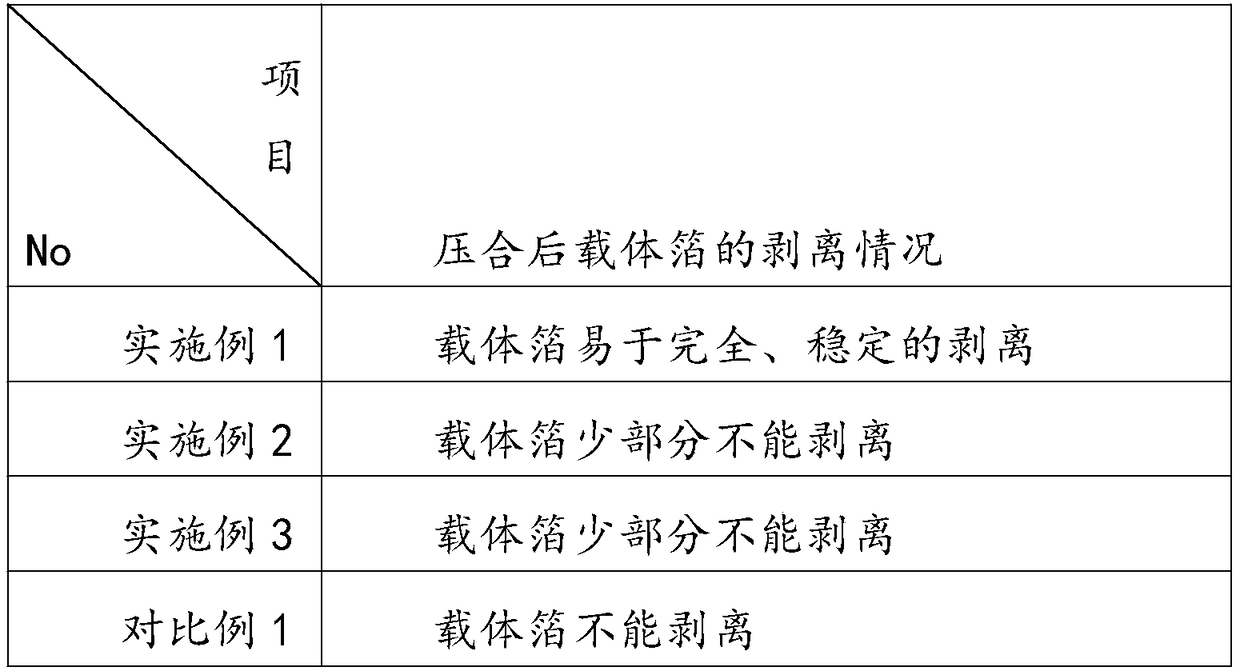

Examples

Embodiment 1

[0018] A kind of plating solution of carrier copper foil peeling layer, comprises following component: the content of potassium hydrogen tartrate is 40g / L, and the content of zinc sulfate is 12g / L, and the content of additive A is 12g / L, and additive A is 3-( Methacryloyloxy)propyltrimethoxysilane, potassium thiocyanate and potassium dihydrogen phosphate are mixed at a mass ratio of 1:5:5, pH=3.8-4.2.

[0019] The method for preparing the peeling layer of the carrier copper foil using the above-mentioned plating solution includes the following steps: controlling the temperature of the plating solution to be 35°C, and then putting the carrier copper foil into the plating solution, under the action of a direct current with a voltage of 20V and a current of 5A , electroplating a layer of new nano-composite zinc coating as the peeling layer, the electroplating time is 3s, and the peeling layer is obtained.

Embodiment 2

[0021] A kind of plating solution of carrier copper foil peeling layer, comprises following component: the content of potassium hydrogen tartrate is 60g / L, and the content of zinc sulfate is 16g / L, and the content of additive A is 20g / L, and additive A is 3-( 2,3-Glycidoxy)propyltrimethoxysilane, 3-(2,3-Glycidoxy)propyltriethoxysilane and sodium acetate are mixed at a mass ratio of 2:2:8 , pH=3.0~3.6.

[0022] The method for preparing the peeling layer of the carrier copper foil using the above-mentioned plating solution comprises the following steps: controlling the temperature of the plating solution to be 25°C, and then putting the carrier copper foil into the plating solution, under the action of a direct current with a voltage of 20V and a current of 5A , electroplating a layer of new nano-composite zinc coating as the peeling layer, the electroplating time is 3s, and the peeling layer is obtained.

Embodiment 3

[0024] A kind of plating solution of carrier copper foil peeling layer, comprises following component: the content of potassium hydrogen tartrate is 20g / L, and the content of zinc sulfate is 8g / L, and the content of additive A is 5g / L, and additive A is 3-( 2,3-glycidoxy)propylmethoxydiethoxysilane, 3-(methacryloyloxy)propyltrimethoxysilane, sodium acetate, ammonium sulfate in a mass ratio of 1:1:3: 5 mixed, pH=4.5~5.0.

[0025] The method for preparing the peeling layer of the carrier copper foil using the above-mentioned plating solution includes the following steps: controlling the temperature of the plating solution to be 45°C, and then putting the carrier copper foil into the plating solution, under the action of a direct current with a voltage of 20V and a current of 5A , electroplating a layer of new nano-composite zinc coating as the stripping layer, the electroplating time is 5s, and the stripping layer is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com