A method for electrochemically preparing graphene

A graphene and electrochemical technology, applied in the field of electrochemical preparation of graphene, can solve the problems of unseen graphene, etc., achieve the effect of low raw material cost, avoid oxidation, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

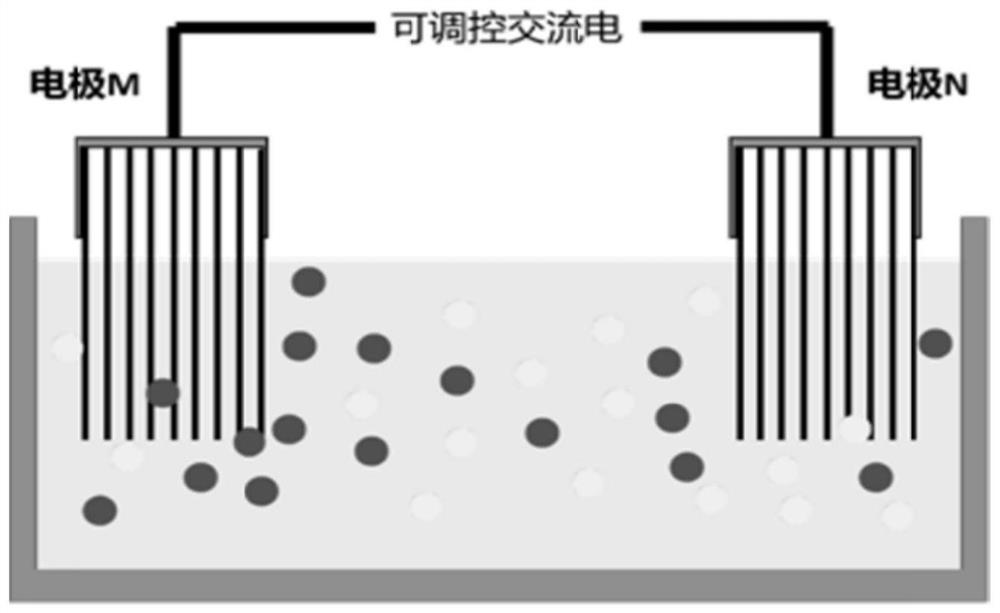

[0054] A kind of preparation method of graphene is characterized in that, the method comprises the following steps:

[0055] (1) Preparation of reactants: graphite powder is pressed into graphite flakes by tableting equipment, and the thickness of the tablet is 3mm thick electrode M and electrode N; select tetrabutylammonium bisulfate (TBAHSO 4 ), be made into the solution B of 0.5mol / L; According to 3% volume ratio in B solution, promptly every 100mL B solution adds the ammoniacal liquor of 30% mass fraction of 3mL, the pH value of regulating and controlling B solution is 9, and mixed solution Stir at a constant speed for 15 minutes; and sonicate at room temperature for 5 minutes at a power of 50W to obtain electrolyte solution C;

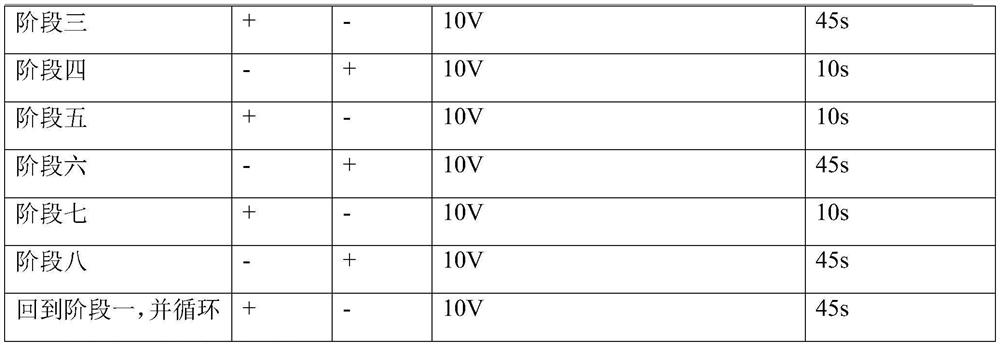

[0056] (2) Reaction stripping: place the electrolyte device in a constant temperature environment of 0°C, use the graphite sheet described in step (1) as the electrode, and solution B as the electrolyte, and keep it stable for 2 hours under a DC v...

Embodiment 2

[0061] A kind of preparation method of graphene is characterized in that, the method comprises the following steps:

[0062] (1) Preparation of reactants: graphite powder is pressed into graphite flakes by tableting equipment, and the thickness of the tablet is 3mm thick electrode M and electrode N; select tetrabutylammonium bisulfate (TBAHSO 4 ), be made into the solution B of 0.5mol / L; According to 3% volume ratio in B solution, promptly every 100mL B solution adds the ammoniacal liquor of 30% mass fraction of 3mL, the pH value of regulating and controlling B solution is 9, and mixed solution Stir at a constant speed for 15 minutes; and sonicate at room temperature for 5 minutes at a power of 50W to obtain electrolyte solution C;

[0063] (2) Reaction stripping: place the electrolyte device in a constant temperature environment of 0°C, use the graphite sheet described in step (1) as the electrode, and solution B as the electrolyte, and keep it stable for 2 hours under a DC v...

Embodiment 3

[0069] A kind of preparation method of graphene is characterized in that, the method comprises the following steps:

[0070] (1) Preparation of reactants: graphite powder is pressed into graphite flakes by tableting equipment, and the thickness of the tablet is 3mm thick electrode M and electrode N; select tetrabutylammonium bisulfate (TBAHSO 4 ), be made into the solution B of 0.5mol / L; According to 3% volume ratio in B solution, promptly every 100mL B solution adds the ammoniacal liquor of 30% mass fraction of 3mL, the pH value of regulating and controlling B solution is 9, and mixed solution Stir at a constant speed for 15 minutes; and sonicate at room temperature for 5 minutes at a power of 50W to obtain electrolyte solution C;

[0071] (2) Reaction stripping: place the electrolyte device in a constant temperature environment of 0°C, use the graphite sheet described in step (1) as the electrode, and solution B as the electrolyte, and keep it stable for 2 hours under a DC v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com