Patents

Literature

178results about How to "Stable appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophobic modified associative thickener and preparation method thereof

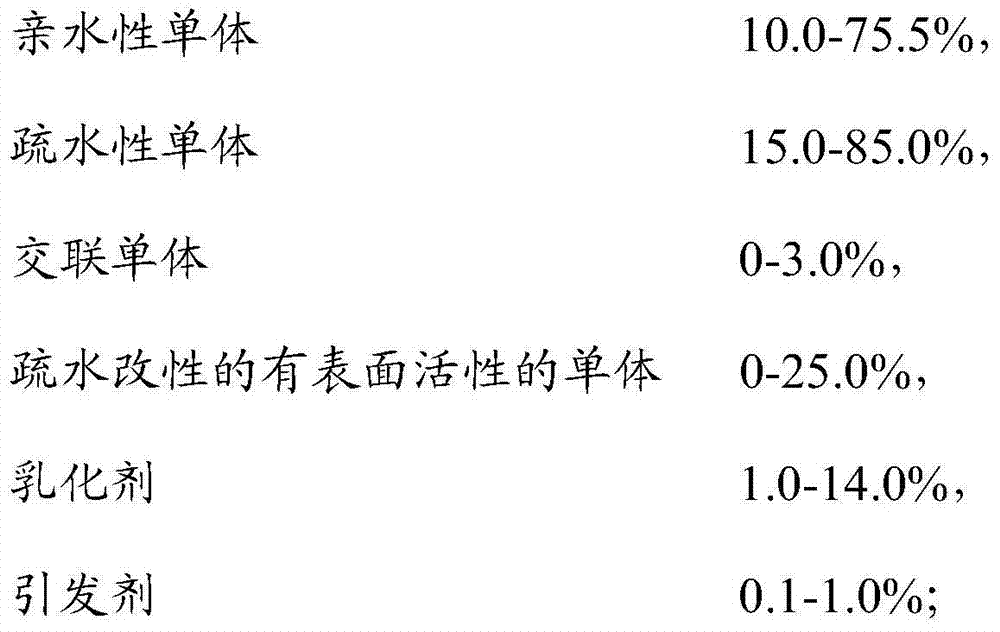

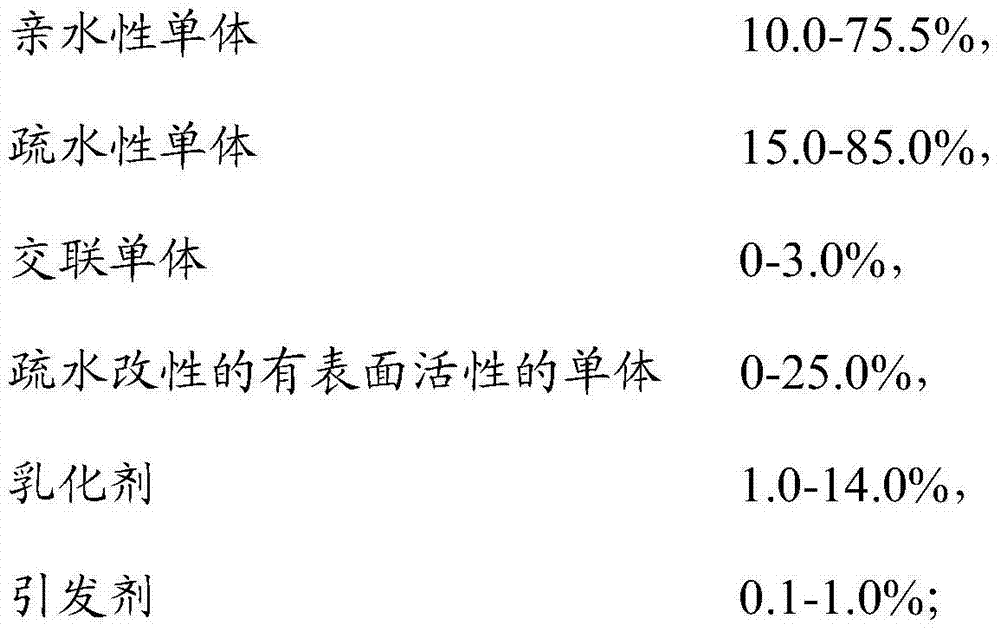

The invention relates to a hydrophobic modified associative thickener. The hydrophobic modified associative thickener is prepared from 28.0-32.0wt% of raw material and 68.0-72.0wt% of deionized water, wherein the raw material comprises following components in percentage by weight: 10.0-75.5 percent of hydrophilic monomer, 15.0-85.0 percent of hydrophobic monomer, 0-3.0 percent of crosslinking monomer, 0-25.0 percent of hydrophobic modified monomer with the surface activity, 1.0-14.0 percent of emulsifier and 0.1-1.0 percent of initiator. The invention also relates to a preparation method of the hydrophobic modified associative thickener. According to the preparation method, the hydrophobic modified associative thickener is synthesized by using a seeded emulsion polymerization method and the prepared hydrophobic modified associative thickener can satisfy the standard of the daily chemical industry and has the advantages of stable application performance and long shelf life.

Owner:GUANGZHOU DX CHEM

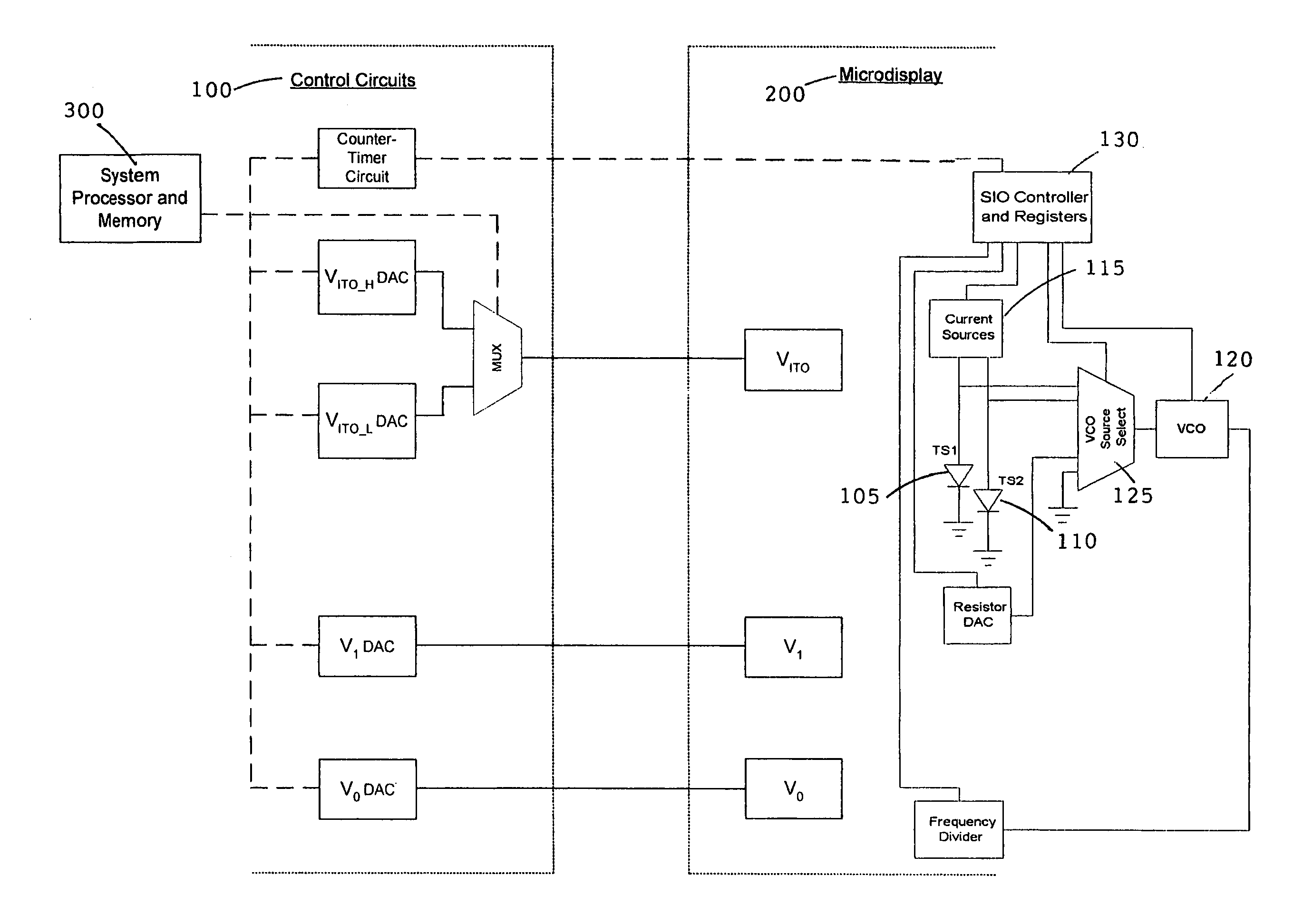

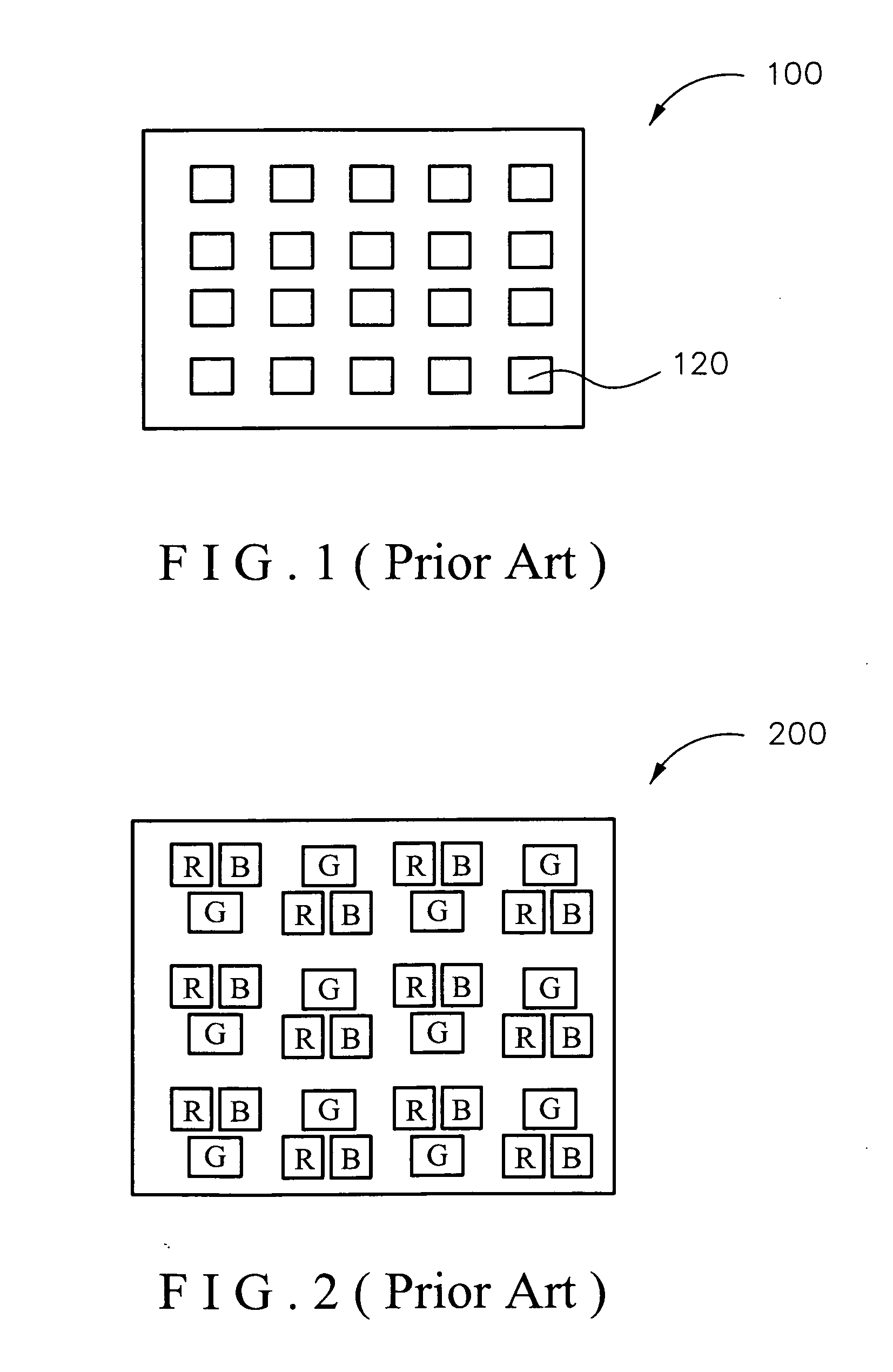

Combined temperature and color-temperature control and compensation method for microdisplay systems

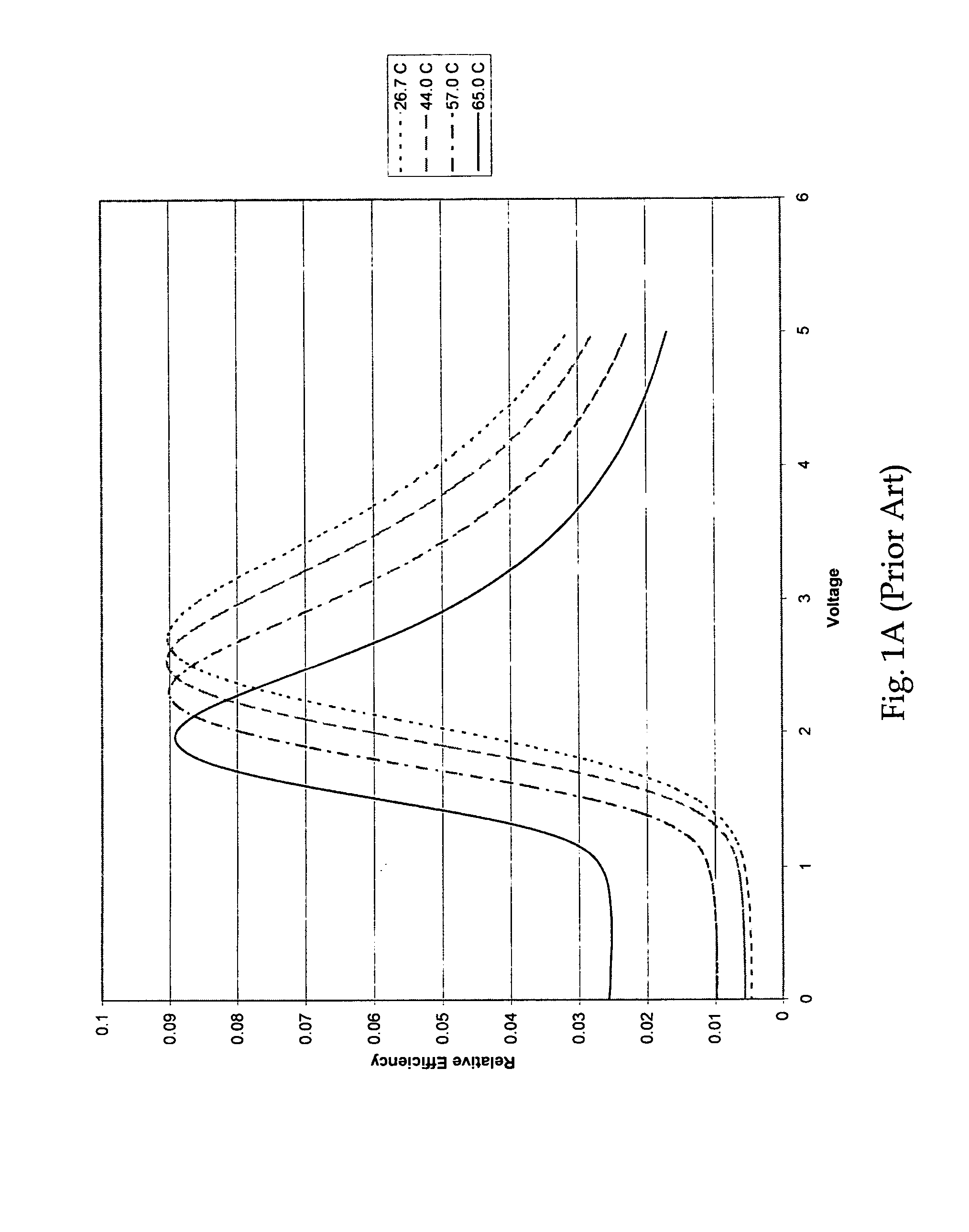

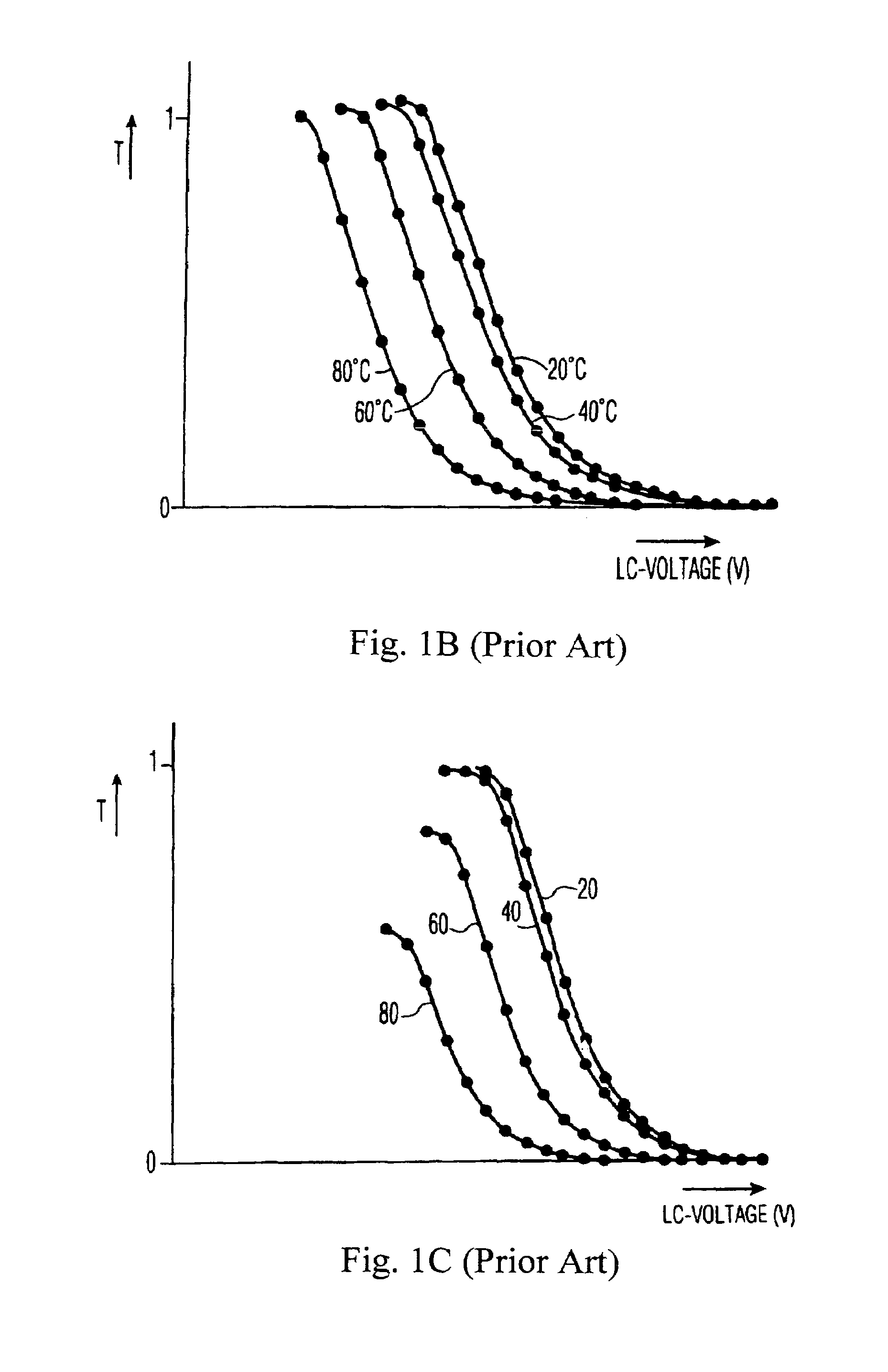

ActiveUS7271790B2Appearance of display stableStable appearanceCathode-ray tube indicatorsOperating pointDisplay device

A temperature control and compensation system is implemented by employing a closely coupled electrical architecture that applies the measured microdisplay temperature, one for each color channel, together with lookup tables preloaded with measured or predicted data for a display, to modify the liquid crystal voltage operating range of each microdisplay as required to achieve and maintain the proper white point operating point for the display. The electrical architecture includes functional blocks as required for realizing the temperature compensation and control for each color channel. The system microprocessor and control unit employs a lookup table to set the control registers on each microdisplay controller with values according to a computed value using the data retrieved from the lookup tables. The range of values in the lookup table includes setups for a number of varied conditions. One of these conditions is temperature.

Owner:GOOGLE LLC

Method of producing full-cotton elasticity non-ironing face fabric

InactiveCN101033570AHigh strengthSolving Yarn Strength ProblemsBiochemical fibre treatmentDrafting machinesYarnSlurry

This invention discloses a production mehod for a cotton spring permanent press cloth including the following steps: 1, spinning, 2, dyeing, 3, weaving, 4, permanent press arrangement including blank check, preparing for cloth, singeing, quiting slurry, sheening with liquid ammonia, finalizing the design through resin, stacking, washing, finalizing the design and pre-contract characterizing in applying two cotton yarns to wrap one spring silk to process spring core-wrapped yarn, which solves the problem of mightness of cotton core-wrapped yarn and increases the strength of the yarn.

Owner:宁波雅戈尔日中纺织印染有限公司

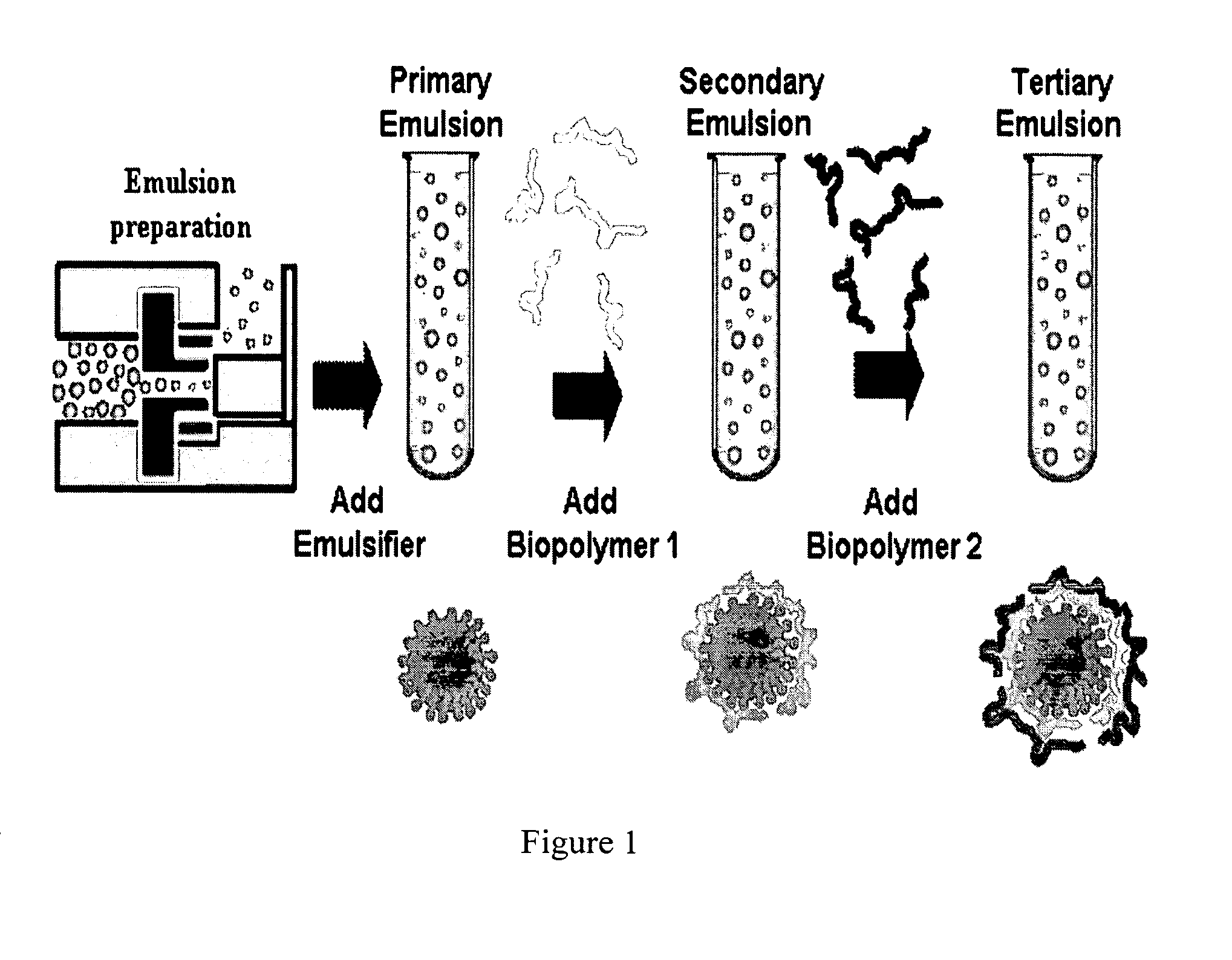

Biopolymer encapsulation and stabilization of lipid systems and methods for utilization thereof

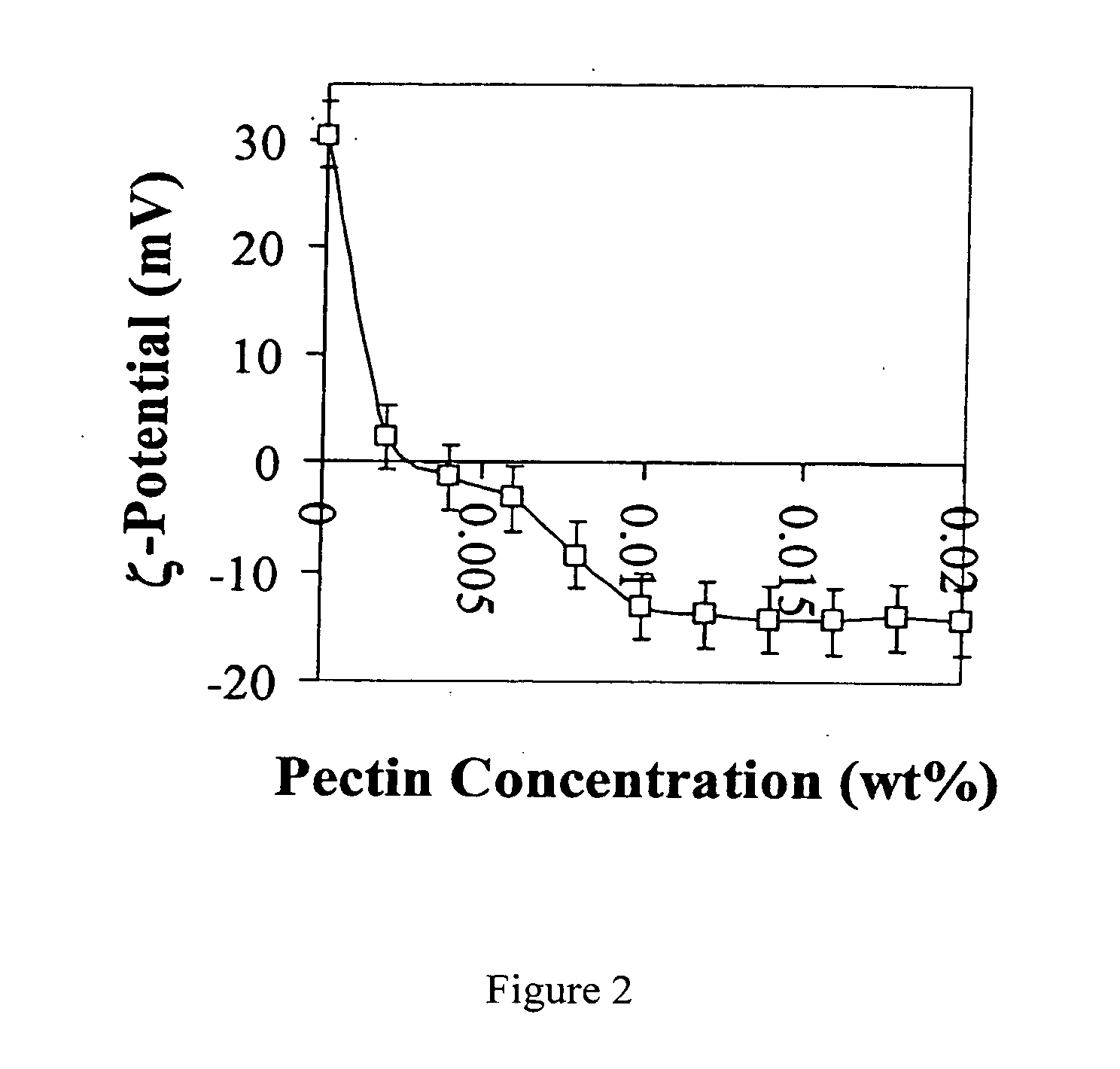

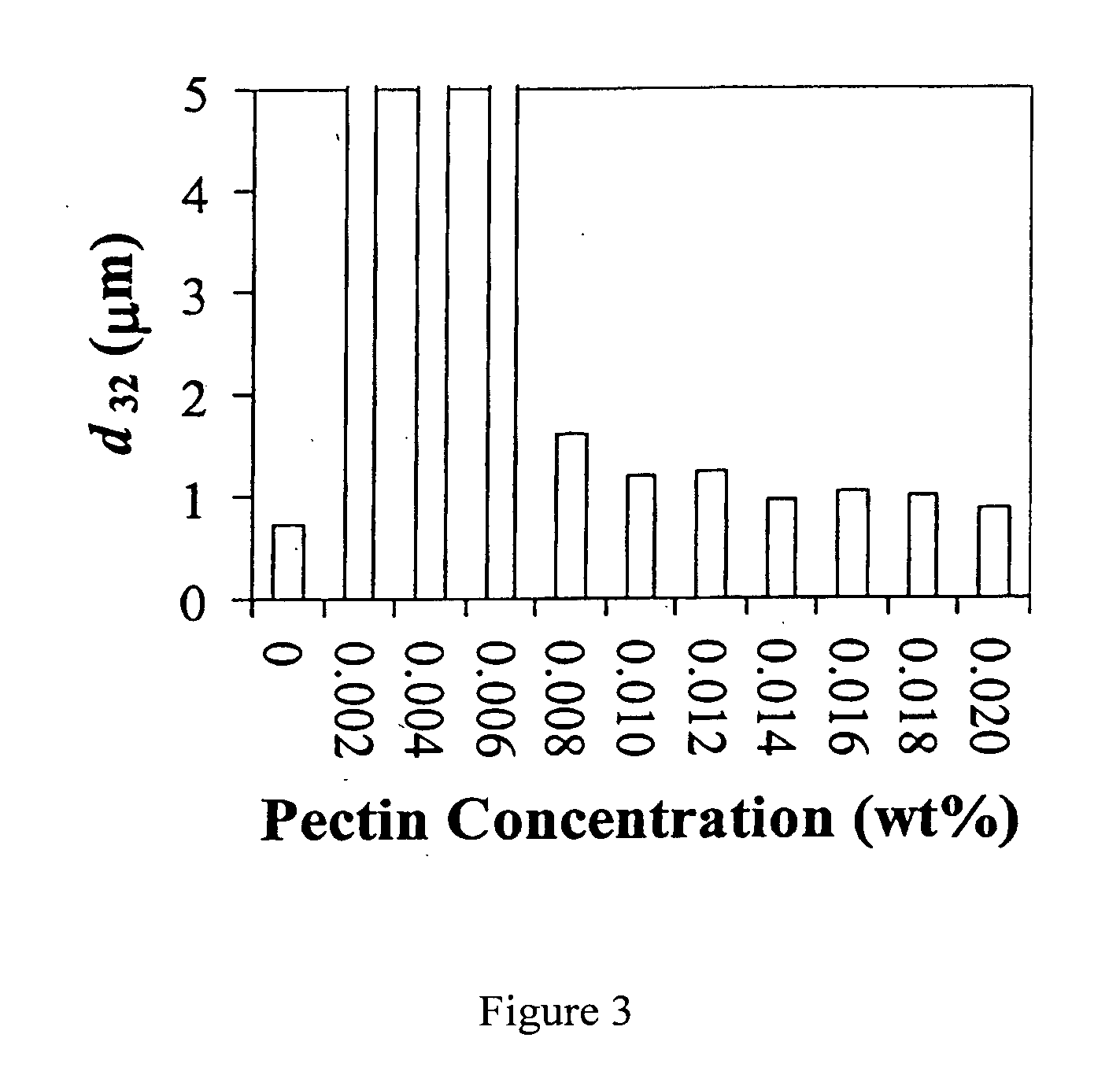

ActiveUS20050202149A1Easily substitutedImpacting tasteMicroballoon preparationFood preparationLipid formationFood grade

An emulsion system and method for controlling the digestion of a fat or an oil component is provided including a substantially hydrophobic food-grade component, and at least one of an emulsifier component, and one or more of polymeric components, wherein at least one of the emulsifier component and the polymeric component comprises a substantially indigestible food-grade material, such as an indigestible dietary fiber. The emulsifier component and / or the polymeric component can be selected so that the overall interfacial membrane is indigestible to humans and / or animals.

Owner:UNIV OF MASSACHUSETTS

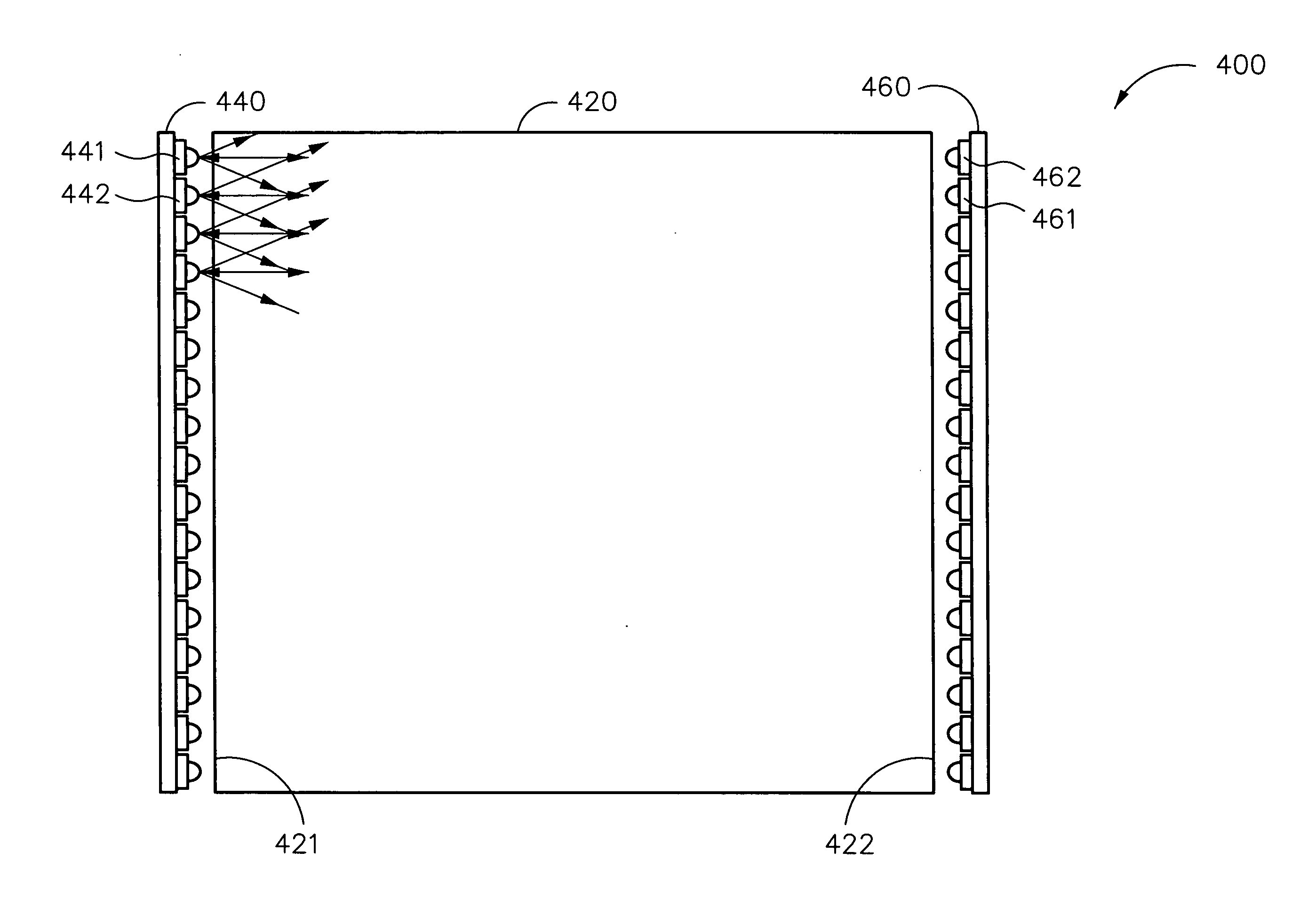

Illumination apparatus

InactiveUS20100290251A1Reduce glareOvercome glareElectrical apparatusElectric light circuit arrangementLight guideLight beam

An illumination apparatus includes a light guide plate, a first light source module, and a second light source module. The light guide plate has a first incident surface and a second incident surface opposite to the first incident surface. The first and the second light source modules provide light beams into the first and the second incident surfaces, respectively. The first light source module includes at least one first white light emitting diode (LED) and at least one second white LED neighboring with each other. The first and the second white LEDs have different color temperatures. The second light source module includes at least one third white LED and at least one forth white LED neighboring with each other. The third and the forth white LEDs have different color temperatures. The third and the forth white LEDs are located corresponding to the second and the first white LEDs, respectively.

Owner:CORETRONIC

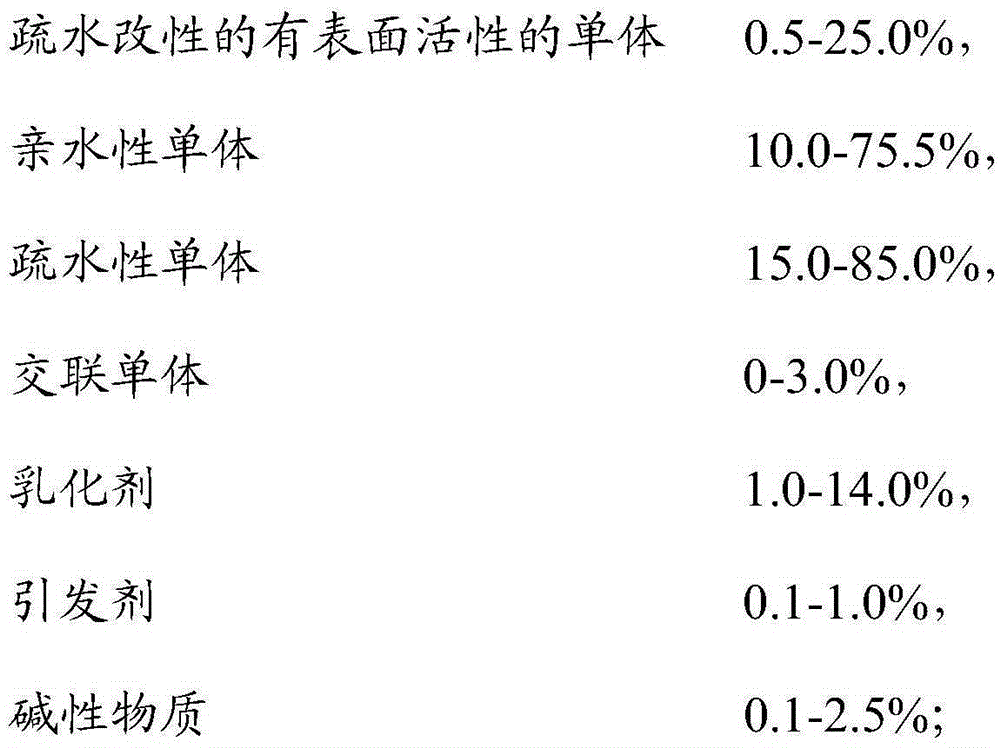

Freezing-resistant acrylate suspended thickening emulsion and preparation method thereof

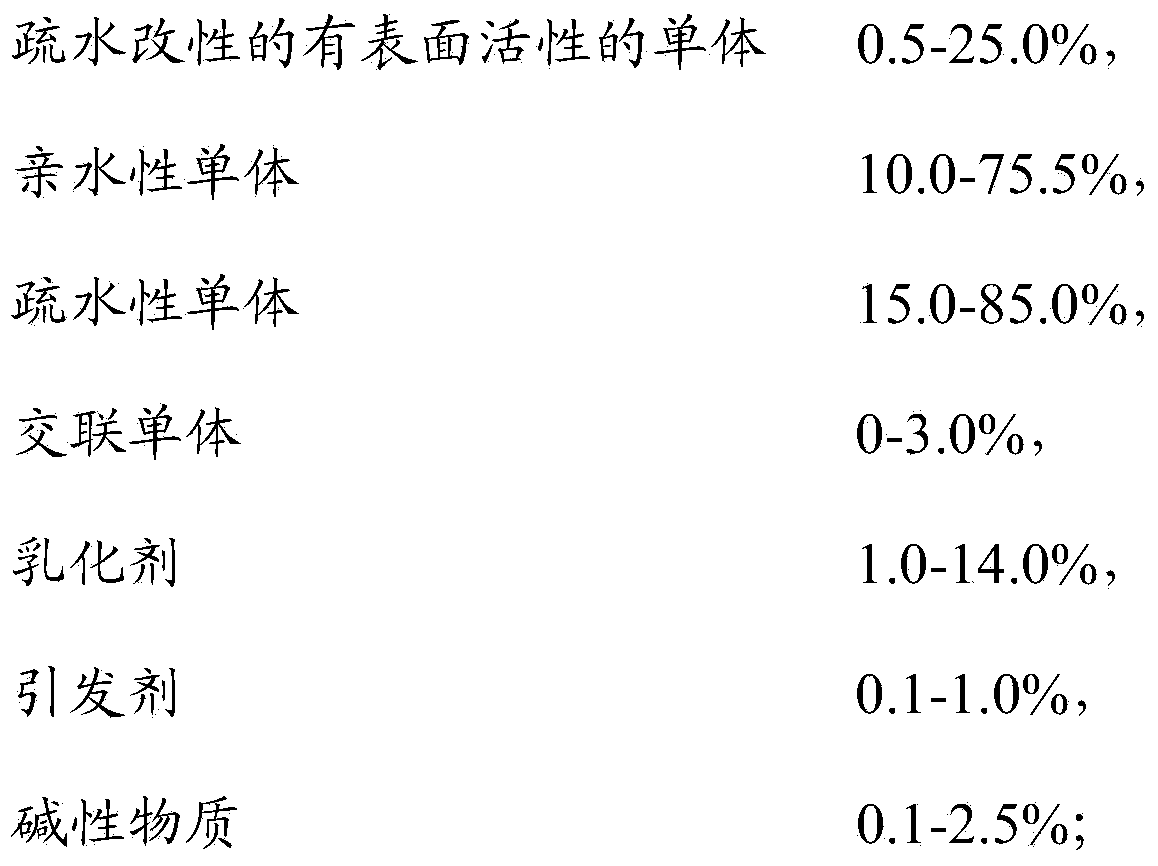

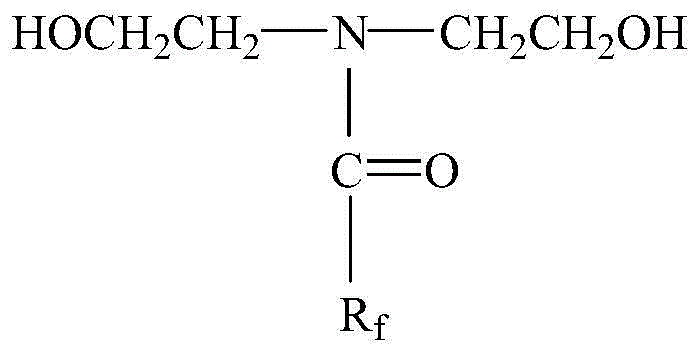

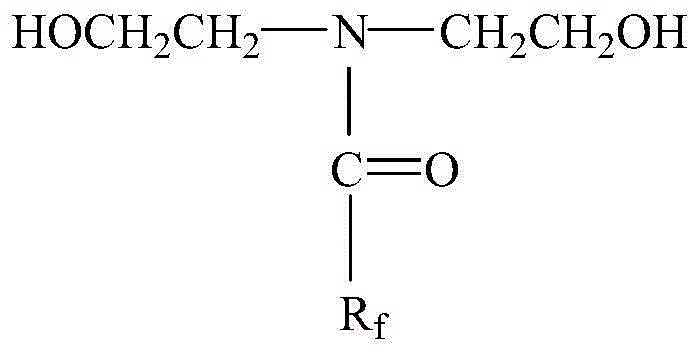

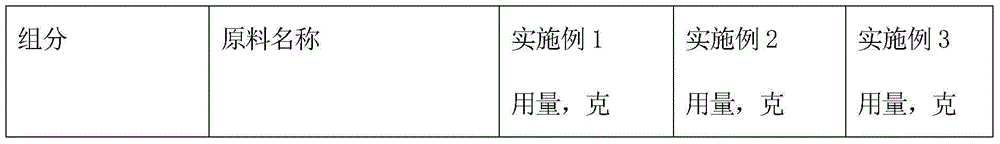

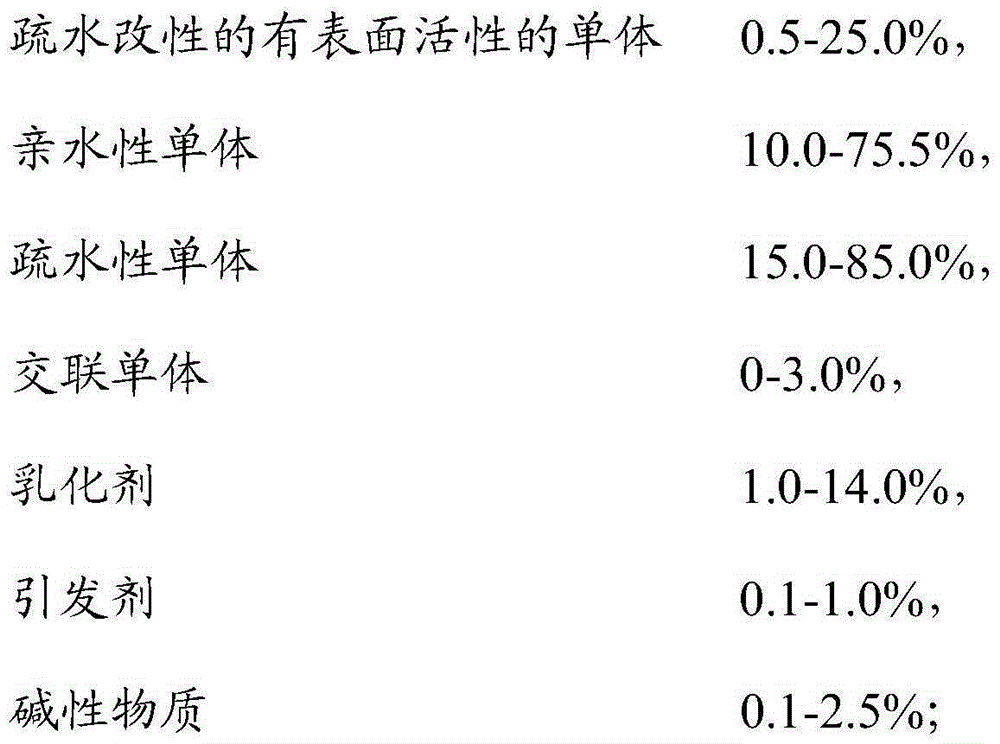

The invention relates to a freezing-resistant acrylate suspended thickening emulsion which is prepared from 28.0-32.0 wt% of raw material and 68.0-72.0 wt% of deionized water. The raw material is composed of the following components in percentage by weight: 10.0-75.5% of hydrophilic monomer, 15.0-85.0% of hydrophobic monomer, 0-3.0% of crosslinking monomer, 0.5-25.0% of hydrophobicity-modified surface-active monomer, 1.0-14.0% of emulsifier, 0.1-1.0% of initiator and 0.1-2.5% of alkaline matter. The invention also relates to a preparation method of the freezing-resistant acrylate suspended thickening emulsion. The freezing-resistant acrylate suspended thickening emulsion can satisfy the standard in daily chemical industry, and has the advantages of stable application performance, long shelf life and favorable freezing resistance.

Owner:GUANGZHOU DX CHEM

Biological skin protecting composition with tightening and whitening effects

InactiveCN105078873AIncrease elasticityImprove wrinklesCosmetic preparationsToilet preparationsMedicineSkin color

The invention provides a biological skin protecting composition with tightening and whitening effects. The biological skin protecting composition is composed of an artemia extract, a yeast extract, a saccharomyces lysate extract and yeast extracting solution. The invention also provides cosmetics containing the skin protecting composition and a production method of the cosmetics. The cosmetics have effects of tightening skin, delaying skin aging, brightening skin and whitening.

Owner:天津强微特生物科技有限公司

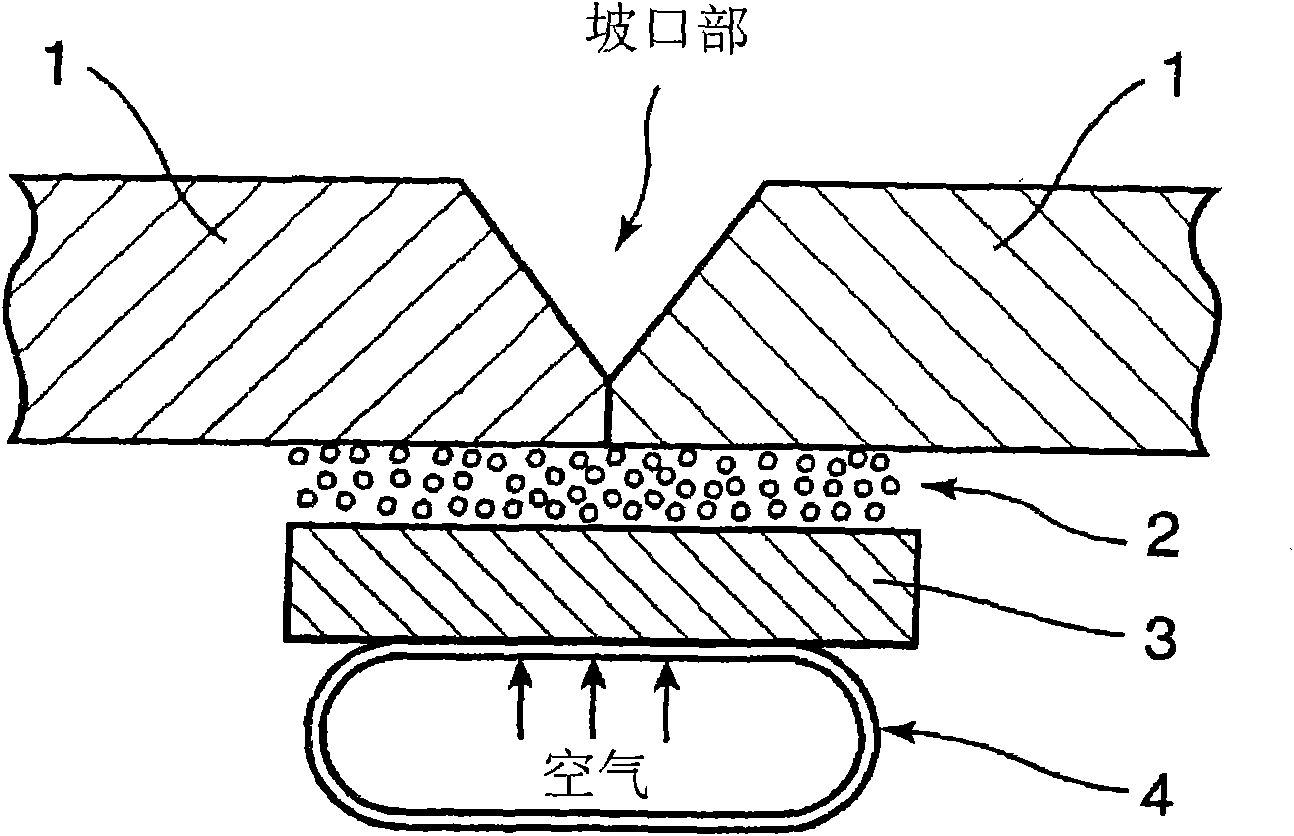

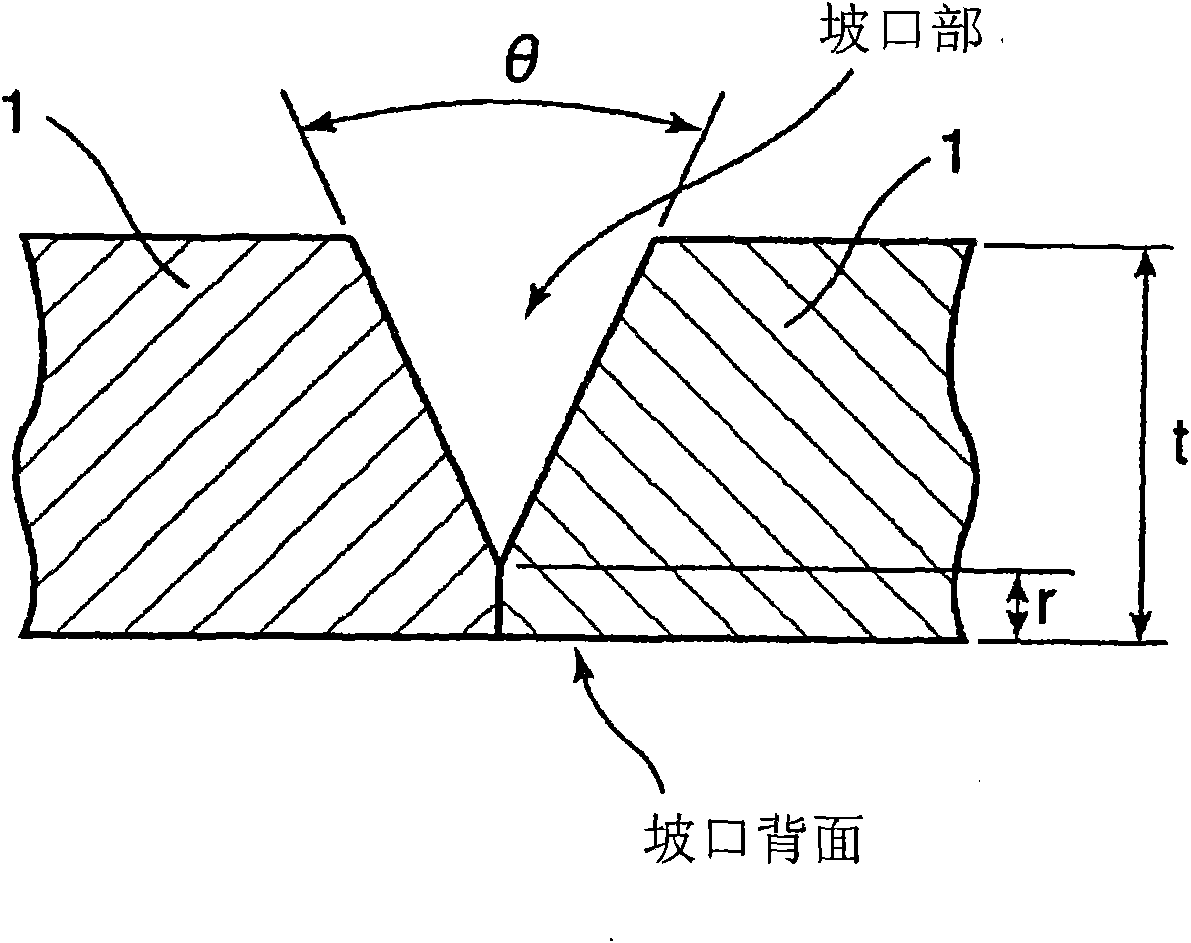

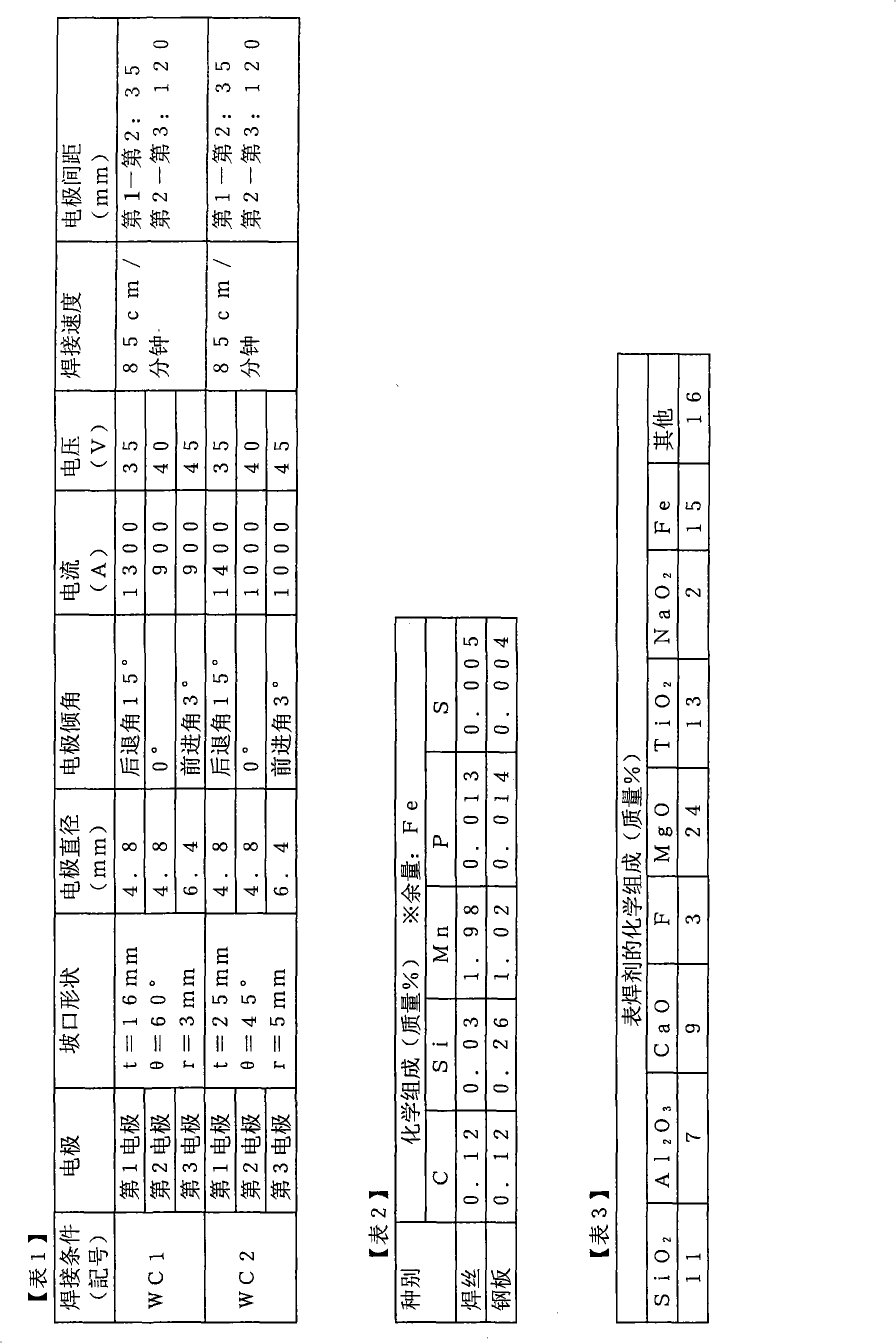

Backing welding flux used for single-side submerged arc welding and the single-side submerged arc welding method using the same

ActiveCN101564807AGood tightnessStable appearanceWelding/cutting auxillary devicesArc welding apparatusSteel platesSubmerged arc welding

A backing welding flux used for single-side submerged arc welding method is used together with the copper board as a backing; is distributed on the copper board by a certain thickness, and is pressed, together with the copper board, on the nozzle back side of the steel plate to be welded to form a back side welding channel on the nozzle surface side while performing welding; wherein, the powder ratio is 3.0-10.0%. Using the backing welding flux can ensure the excellent tightness between the backing welding flux and the nozzle back side of the steel plate to be welded, and can obtain a welding channel with stable shape and appearance, and sound back side.

Owner:KOBE STEEL LTD

Preparation method and coating method of molecular sieve coating

ActiveCN104525242AIncrease loadUniform coatingMolecular sieve catalystsCatalyst activation/preparationNitric oxideMolecular sieve

The invention discloses a preparation method of a molecular sieve type monolithic catalyst. The preparation method of the molecular sieve type monolithic catalyst has the advantage that the purposes of improving the activity of the catalyst and widening the temperature window of the catalyst are achieved by combining a plurality of molecular sieve active coatings on a catalyst due to the adoption of different activities of different molecular sieve type catalysts in NOx selective catalytic reduction reaction. The preparation method of the molecular sieve type monolithic catalyst comprises the following steps: preparing Fe modification ZSM-5 molecular sieves and NH4-ZSM-5 molecular sieves into corresponding slurries, then respectively coating the slurries on one end of a cordierite honeycomb ceramic carrier to prepare a molecular sieve type monolithic catalyst applied to selective catalytic reduction of nitric oxides. The catalyst prepared by the method has high activity of selective catalytic reduction of nitric oxides; the performance of the catalyst is superior to that of the molecular sieve type monolithic catalyst which only takes the Fe modification ZSM-5 molecular sieves and the NH4-ZSM-5 molecular sieves as active coatings; the conversation rate of NOx in a temperature zone of 190-490 DEG C can reach over 80%; and the catalyst is simple in preparation method and relatively low in production cost.

Owner:EAST CHINA UNIV OF SCI & TECH

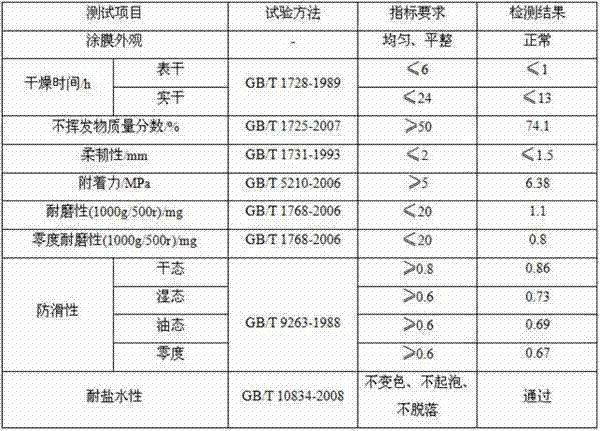

SiC fiber reinforced polyurethane series skid-resistant coating and preparation method thereof

InactiveCN104710926AUniform appearanceGood adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsDefoaming AgentsTitanium dioxide

The invention discloses a SiC fiber reinforced polyurethane series skid-resistant coating and a preparation method thereof. The skid-resistant coating is prepared from a component A, a component B, a component C, and other components through mixing, wherein the component A comprises polytetramethylene ether glycol, liquidated MDI, and E44 type epoxy resin; the B component comprises SiC short fiber, Al2O3 and a surface modifier; the component C comprises liquidated MDI, a chain extender, BaSO4, titanium dioxide and talcum powder; other components comprise a diluent, a defoaming agent and a levelling agent. The preparation method comprises the following steps: all components in the component A are mixed, so that the component A is prepared; all components in the component B are mixed, so that the component B is prepared; the component B, which accounts for 3-8% of the component C is mixed with the component C, and other components are added into the mixture so as to obtain a component D; finally, the component A and the component D are mixed according to the mass ratio of 1: (1-1.1), so that the skid-resistant coating is prepared. The skid-resistant coating disclosed by the invention is high in friction coefficient and adhesive force, excellent in comprehensive performance at low temperature and simple in preparation method.

Owner:NAT UNIV OF DEFENSE TECH

Metallic powder coating

The invention discloses a power coating strengthening metal effect, belonging to the technical field of chemical powder coating product. It adds extinction agent, polish and wax powder in the basic material (polyester / epoxy) system and then make the three matters interact to obtain the powder coating. It is adapted on all kinds of home and universal electrical apparatus and household utensils.

Owner:广州擎天粉末涂料实业有限公司

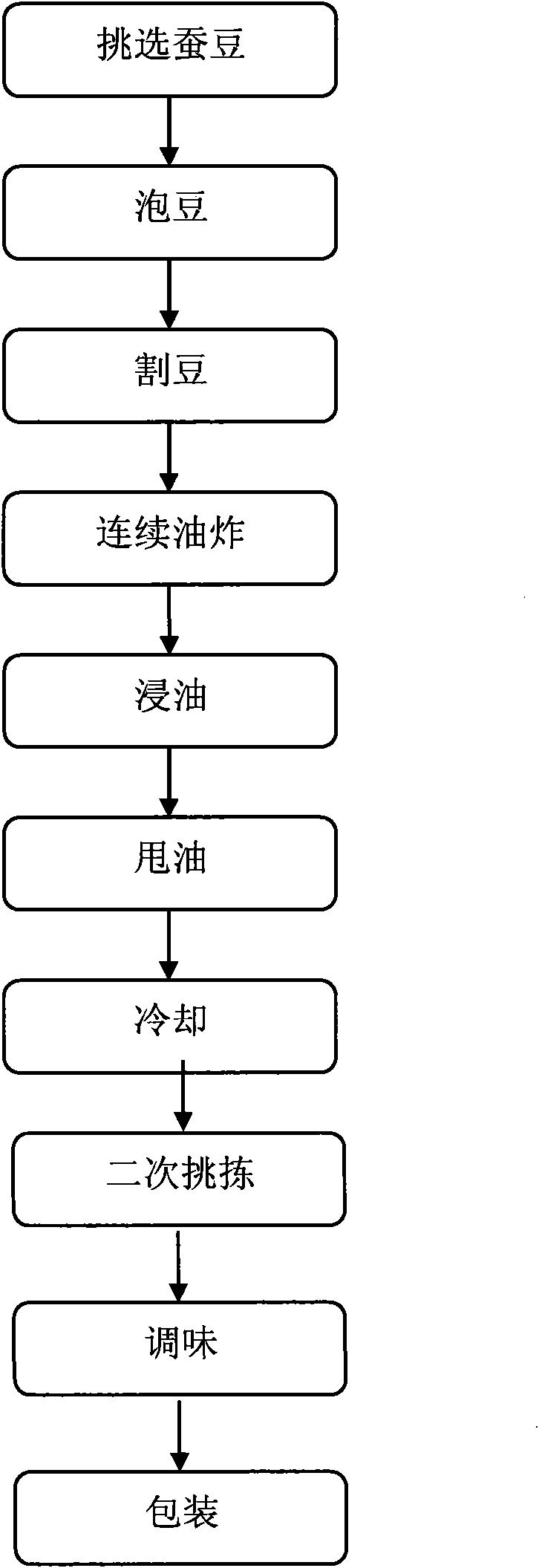

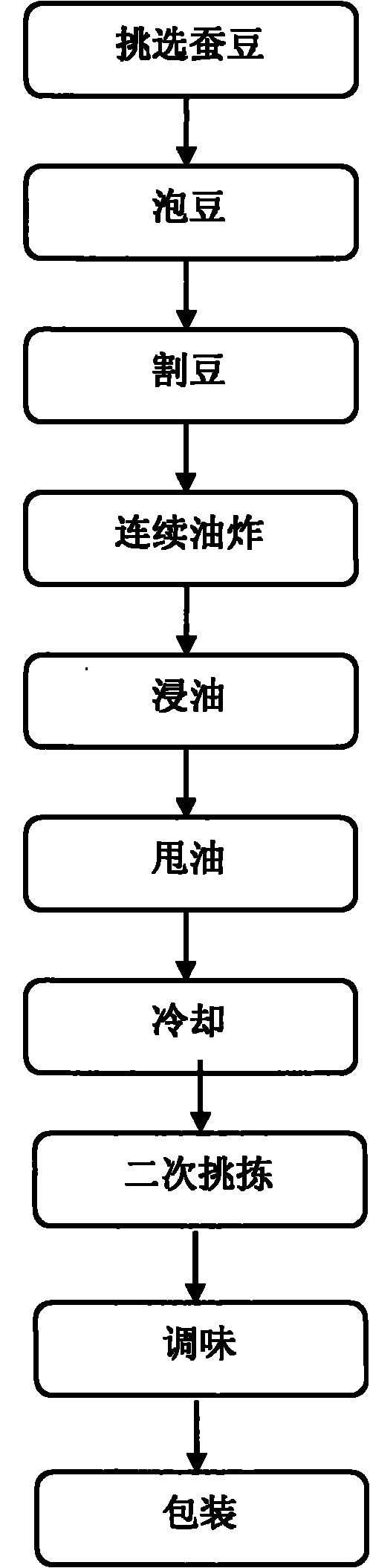

Sprouting dried broad bean and preparation method thereof

ActiveCN101933581APerformance indicators are stableGood quality consistencyFood preparationChemistryBroad beans

The invention discloses sprouting dried broad beans, which is prepared by adding the following ingredients of 2-5 parts by weight of white granulated sugar and 2-2.5 parts by weight of powder into 30 parts by weight of sprouting dried broad beans, wherein the powder comprises the following components in parts by weight: 3 parts of chili powder, 2 parts of garlic powder, 2 parts of spice, 1 part of monosodium glutamate and 1 part of sugar. The invention also discloses a preparation method of the sprouting dried broad beans. The sprouting dried broad beans have excellent appearance and quality consistency and distinctive taste and are crisp, sweet and spicy. The preparation method of the sprouting dried broad beans adopts a continuous fried production mode, the flavorings are mixed by adopting a rolling mode of an elliptical rolling pot in order to be more evenly mixed, the fried procedure adopts a pneumatic rolling mode, various indexes of appearance, rationalization, and the like of the sprouting dried broad beans have more consistency, and the development of the sprouting dried broad beans is promoted.

Owner:SUZHOU KOUSHUIWA FOOD

Double-station hot press

InactiveCN105500750AIncrease production capacityOptimize the structure of the whole machinePress ramHeat pressSingle station

The invention discloses a double-station hot press which consists of a main body frame, a control system, a mechanical device, a heating device, a hydraulic device, an electrical executive device and a safety device, wherein the main body frame consists of a rack, upright columns, cross beams, stations and a protective cover; a bottom plate is arranged below the rack; a table plate is arranged on the top surface of the rack; the protective cover is arranged above the rack; the cross beams are internally provided with the independent stations; two electric cabinets assembled side by side are arranged at the front surface of the protective cover; the control system comprises the electric cabinets and a console; the mechanical device comprises hydraulic cylinders, pistons, upper beating plates, lower beating plates and guide rods; the number of the hydraulic cylinders is two; and the heating device comprises heating rods, heating plates, heat insulating plates and heatproof covers. With the adoption of the double-station hot pressing design, the operation is simplified, the floor space is small, the pressure is stabile; the temperatures and movements of the upper heating plates and the lower heating plates are controlled separately, and alternate no-break operation is facilitated. Compared with a single-station machine, the productive capacity of the double-station hot press is increased by more than a half.

Owner:昆山力比格智能科技有限公司

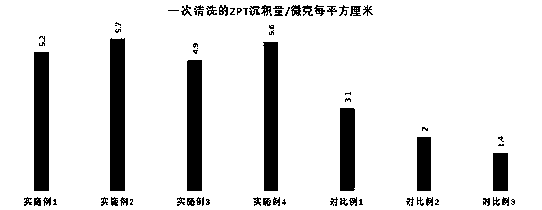

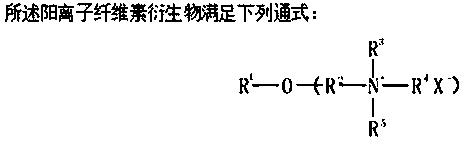

Shampooing cream composition capable of enhancing deposition of anti-dandruff agent

ActiveCN107440935AStrong flocculation strengthHelp to carryCosmetic preparationsHair cosmeticsSodium PyrithioneSuspending Agents

The invention relates to a shampooing composition, and in particular a shampooing cream composition capable of enhancing deposition of an anti-dandruff agent; the composition consists of an anionic surfactant, an ampholytic surfactant, a cationic polysaccharide polymer derivative, zinc pyrithione, a non-volatile conditioning agent, 0.01-10% of a suspending agent and the balance of purified water, wherein the cationic polysaccharide polymer derivative is any one or a compound of the following two derivatives: (i) a cationic cellulose derivative and (ii) a cationic guar gum derivative; the viscosity of a 2% pure water solution of the cationic cellulose derivative is 20000-40000cps and a nitrogen content of the cationic cellulose derivative is 0.8-3.1%; the charge density of the cationic guar gum derivative is 0.5-1.0meq / g and the molecular weight of the cationic guar gum derivative is 400000-1500000g / mol. The shampooing cream composition provided by the invention is good in flocculation phase character and excellent in anti-dandruff agent deposition capacity; and a relatively outstanding anti-dandruff effect is achieved, so that, the shampooing composition, when applied to a user for a long time, can achieve an obvious effect of removing dandruff.

Owner:OPAL COSMETICS HUIZHOU

Preparation method of cordyceps sinensis micropowder lozenges

InactiveCN103040877AReduce moisture contentEffective preservationAntinoxious agentsImmunological disordersFreeze-dryingTraditional medicine

A preparation method of cordyceps sinensis micropowder lozenges relates to a technology that the cordyceps sinensis is smashed through an ultra-low temperature smashing method and then is frozen and dried to produce the cordyceps sinensis micropowder which serves as the raw material, and then the raw material is rehydrated and pressed to obtain the cordyceps sinensis micropowder lozenges. The method comprises the following steps: first: freezing the cordyceps sinensis with water content not less than 5 percent to be below 0 DEG C, and smashing under the temperature not higher than 0 DEG C; directly freezing and drying the non-defrosting cordyceps sinensis micropowder obtained through smashing, wherein the water content of the micro powder at the moment is not higher than 3 percent (weight); forwards, rehydrating the frozen and dried cordyceps sinensis micropowder; allowing the water for rehydration to be subjected to ultrasonic atomization so as to obtain water mist which is input into the frozen and dried micro powder; meanwhile, stirring the frozen and dried micro powder so as to allow the water content to be raised to 4-20 percent (weight), and obtaining the rehydrated micro powder with the water percent of 4-20 percent (weight); and tabletting the micro powder so as to obtain the cordyceps sinensis micropowder lozenges with the water content not high than 20 percent (weight). The cordyceps sinensis micropowder with water content lower than 8 percent can be directly pressed into the lozenges with uniform water content, and the method for controlling the water content is simple and precise.

Owner:陈玉龙

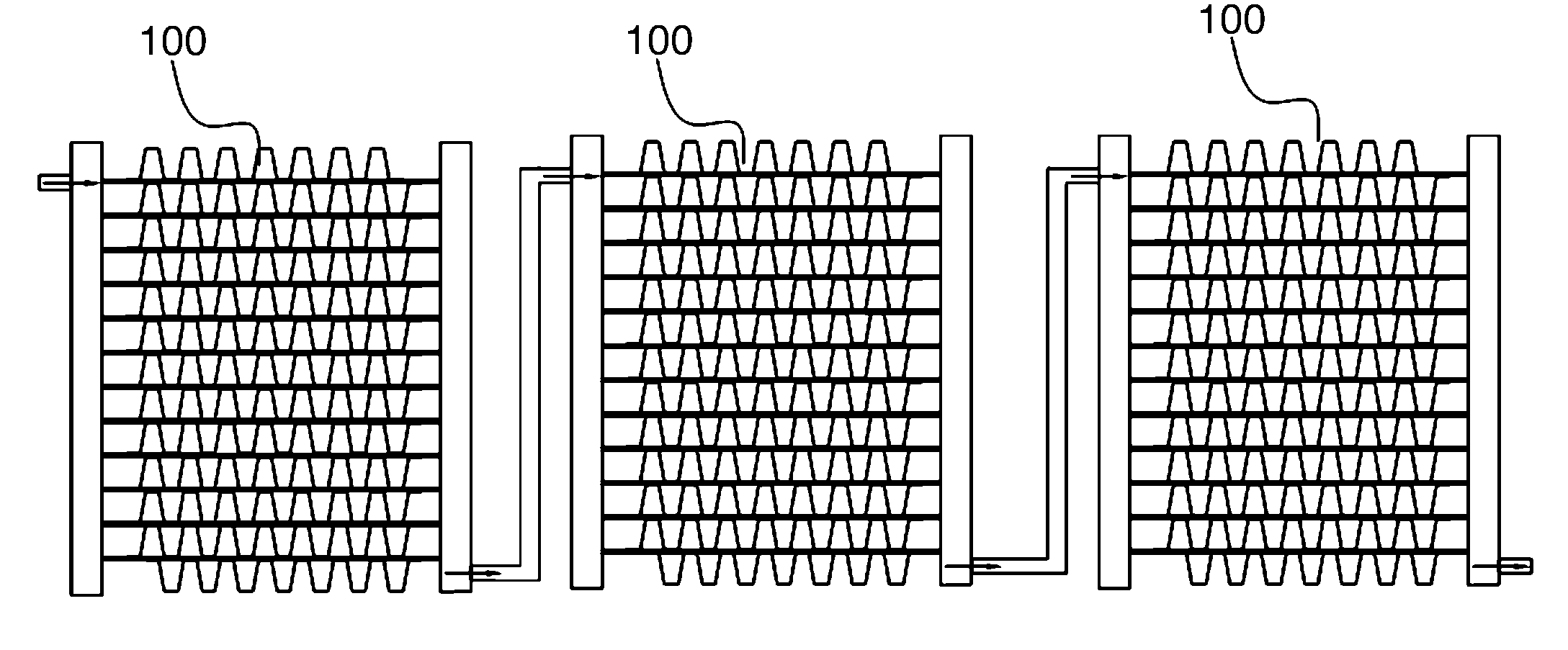

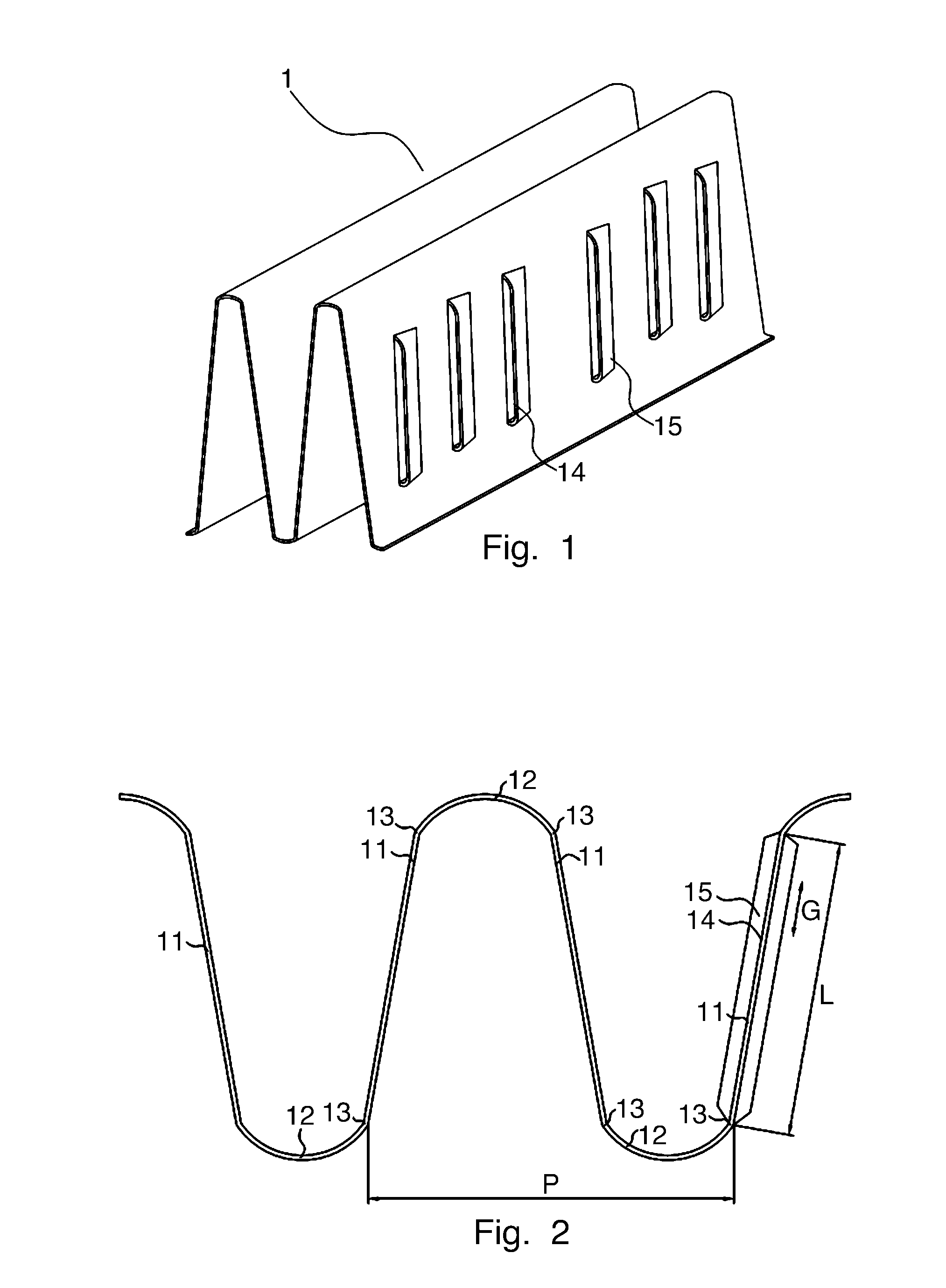

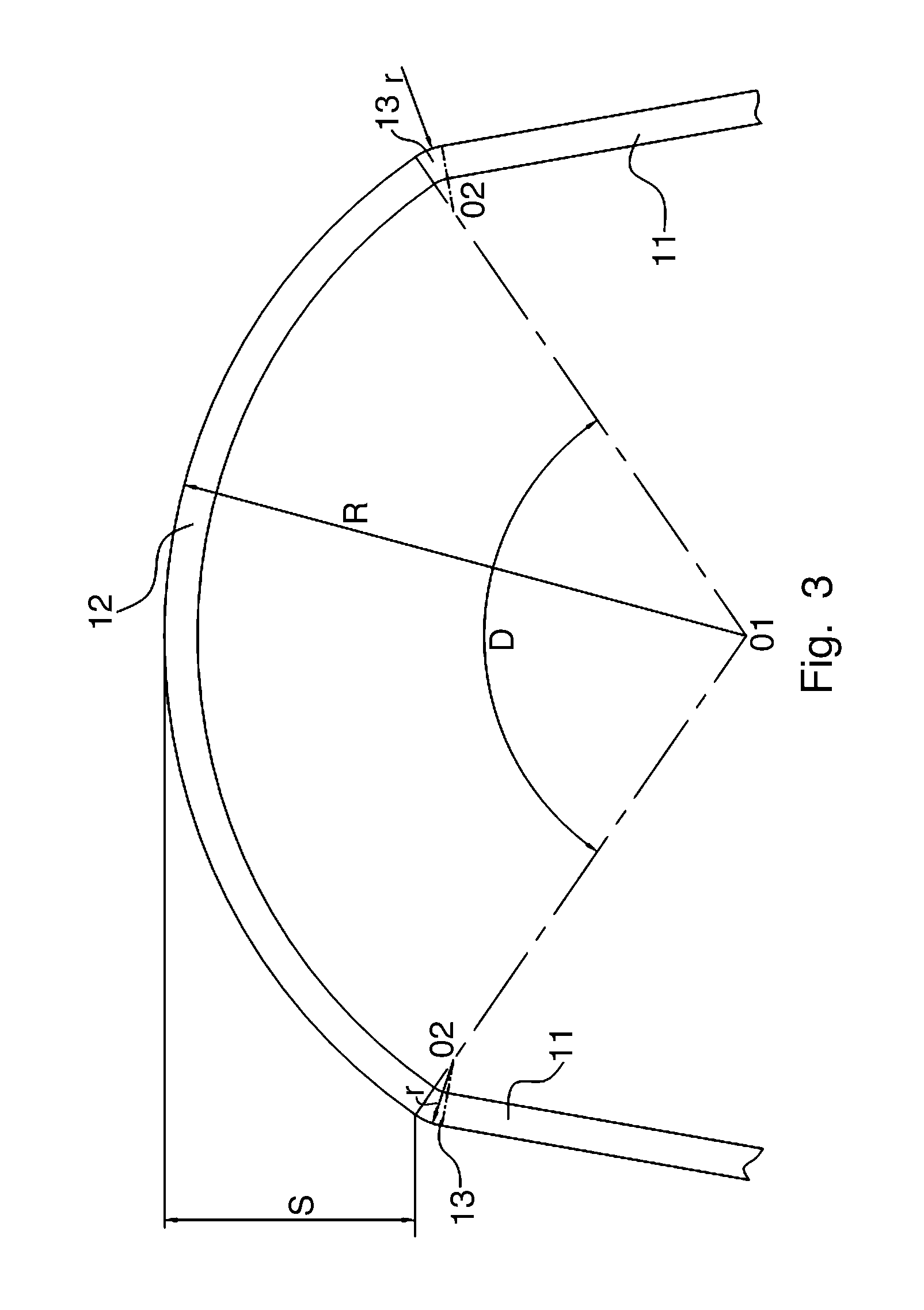

Fin, heat exchanger and heat exchanger assembly

ActiveUS20100258286A1Easy to transformEasy to controlHeat exchanger casingsTubular elementsPlate heat exchangerEngineering

The present invention discloses a fin of heat exchanger comprising a straight segment; a substantially-circular arc segment having a radius of R; and a substantially-circular arc transition segment connected between the straight segment and the substantially-circular arc segment and having a radius of r, wherein R>r. According to the present invention, after being assembled and welded to the heat exchanger, the substantially-circular arc segment is relatively easy to deform, and the shapes of the straight segment and substantially-circular arc transition segment are substantially unchanged. Therefore, the deformation of the fin is regular and easy to control. The arranging density of the fin in the heat exchanger is uniform, and the shape of the fin can meet the design requirements. In addition, the shape stability and the heat transfer coefficient of the fin are high.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER +1

Skin regenerating repair and anti-aging mask for electromagnetic radiation and fog-haze pollution

InactiveCN104971031AEfficient removalAvoid aging damageCosmetic preparationsToilet preparationsSilphium perfoliatumALPHA-ARBUTIN

The present invention relates to a skin regenerating repair and anti-aging mask for electromagnetic radiation and fog-haze pollution, and a preparation method thereof, and belongs to the field of skin care products. According to the present invention, the mask cloth is formed by weaving charcoal fibers and plant wood pulp, and the mask solution essence comprises the following raw materials 8-20% of a ganoderma lucidum extract, 4-10% of a human placenta extract, 1-3% of acetyl hexapeptide-2, 1-3% of a silphium perfoliatum extract SOD, 1-3% of tocopherol, 1-3% of tranexamic acid, 3-5% of a snail mucilage extract, 0.05-2% of a hamamelis virginiana extract, 0.3% of epidermis cell growth factor (EGF), 0.05-3% of sodium hyaluronate, 0.3% of alpha-arbutin, 0.01% of EDTA tetrasodium, 0.2% of triethanolamine, 11% of butanediol, and the balance of deionized water. According to the present invention, the mask has effects of deep absorption and removal of all dirt on skin, oxygen free radical scavenging, resistance of harm of electromagnetic radiation and fog-haze pollution on skin, moist, silky, delicate, uniform and clean skin state achieving, and young state achieving.

Owner:龚彦

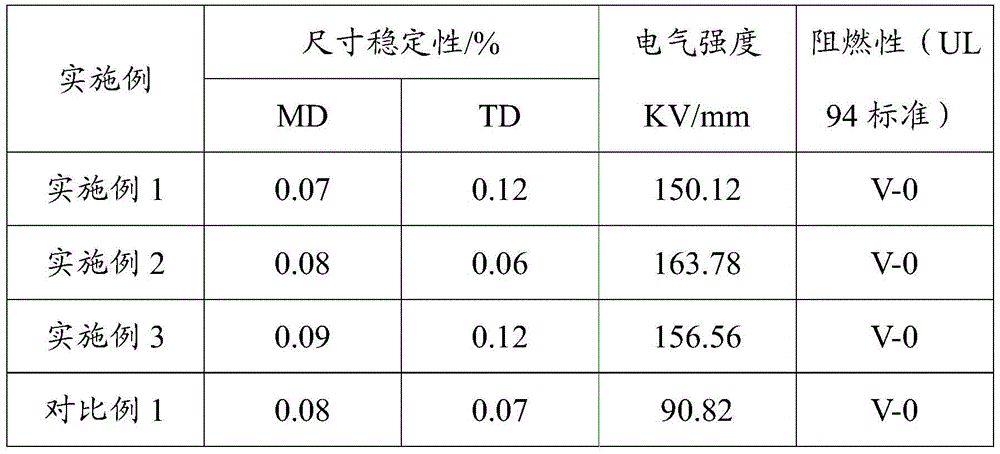

Insulating board and insulating glue sheet for laminated busbar, and production methods thereof

InactiveCN105856588ADimensionally stableFlat sizeFilm/foil adhesivesEpoxy resin adhesivesGlass fiberBusbar

The invention relates to the laminated busbar technical field, and especially relates to an insulating board for a laminated busbar; a production method includes the following steps: firstly, wire-drawing; followed by carrying out glue dipping and cloth knitting: dipping glass wires in a resin glue solution, gluing for the first time, carrying out drying semi-solidification treatment after gluing for the first time, and followed by knitting to form a glass fiber cloth blank; then roasting, and curing; and finally dipping with the glue, and curing, to obtain the insulating board. Molding cloth is adopted as a reinforcing material and is obtained through dipping with the glue; compared with a PET insulating thin film, the insulating board has better flame retardancy, and has good mechanical strength, good dimensional stability and excellent electrical stability performance in a condition of high temperature. The invention also relates to an insulating glue sheet for the laminated busbar and a production method thereof.

Owner:GUANGDONG SHENGYI SCI TECH

Cationic type aqueous polyurethane dispersoid and preparation method thereof

The invention relates to a cationic type aqueous polyurethane dispersoid and a preparation method thereof. The preparation method of the cationic type aqueous polyurethane dispersoid comprises the following steps: dropwise adding a special isocyanate-terminated polyurethane prepolymer solution into a backing material solution which consists of a tertamide-containing dihydroxyl compound and a dihydroxyl compound with a side chain containing fatty hydrocarbyl, reacting and subsequently obtaining the polyurethane prepolymer solution; neutralizing and emulsifying the polyurethane prepolymer solution to obtain the cationic type aqueous polyurethane dispersoid, wherein a side chain of resin molecule has long-chain fatty hydrocarbyl; the use amount of the tertamide-containing dihydroxyl compound is 6-15wt%; the use amount of the dihydroxyl compound with side chain containing fatty hydrocarbyl is 8-20wt%; the polyurethane prepolymer solution is moderate in viscosity before neutralizing; the process is easy to control; the prepared cationic type aqueous polyurethane dispersoid is good in emulsion appearance, excellent in adhesion to the base material after forming film and more excellent in water resistance and solvent resistance after coating.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

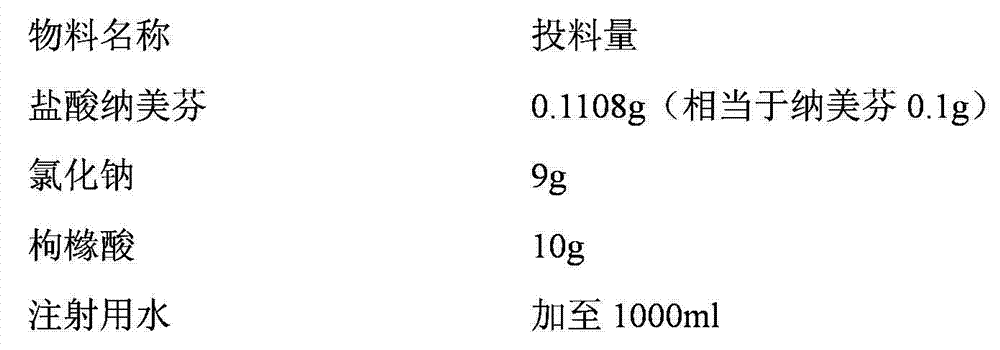

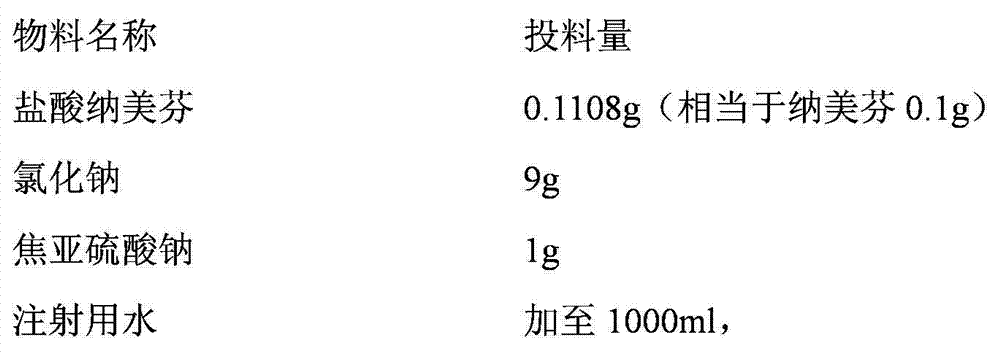

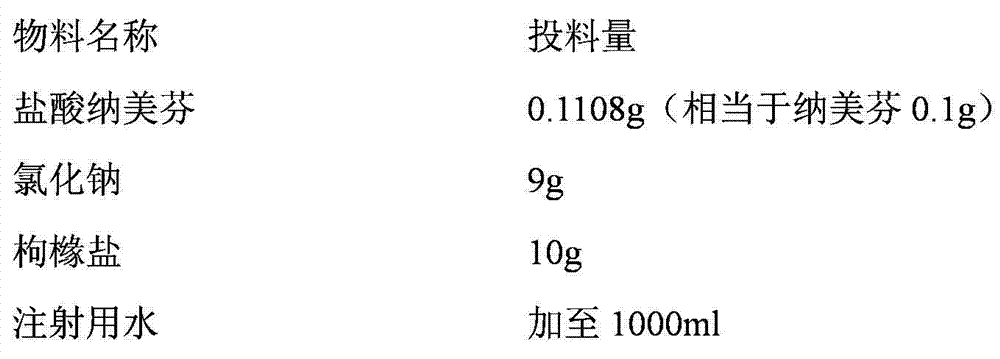

Method for preparing nalmefene hydrochloride injection and prepared nalmefene hydrochloride injection

InactiveCN103202806AExcellent pHImprove stabilityOrganic active ingredientsPharmaceutical delivery mechanismSample appearanceAdditive ingredient

The invention discloses a method for preparing nalmefene hydrochloride injection. The method comprises the steps of adding a certain amount of citric acid or citrate auxiliary material to the preparation when the nalmefene hydrochloride injection is prepared according to a common method, wherein the adding amount is 5-15g of citric acid or citrate added to each liter of injection; firstly, taking the prescribed auxiliary material in preparation, adding injection water to dissolve, adding active carbon to agitate and adsorb, filtering and removing impurities; adding the prescribed nalmefene hydrochloride under the protection of nitrogen, fully dissolving and sizing to an appointed constant volume by water, adjusting the pH value to 3.5-4.5; and finally conducting split charging, charging nitrogen, sealing and sterilizing after filtering by a filter. By adopting the method disclosed by the invention, the validity period of the nalmefene hydrochloride injection can be obviously prolonged; a specific citric acid pH value stabilizer is adopted; and the nalmefene hydrochloride injection has good stability, and stable sample appearance, pH value, effective ingredient content and related substances, and the like. Therefore, the safety of medication is ensured.

Owner:ANHUI HEALSTAR PHARM CO LTD

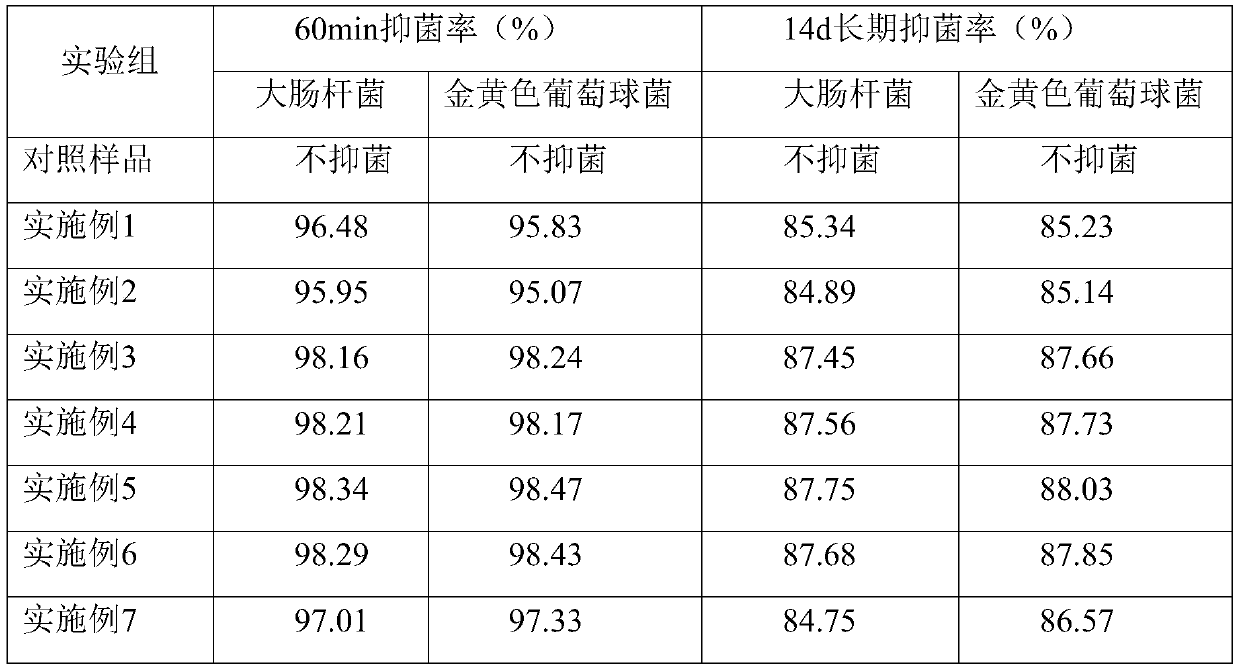

Multipurpose antibacterial non-woven fabric and production process thereof

InactiveCN110117910AEfficient and durable antibacterialStable appearanceTextiles and paperNonwoven fabricAntibacterial agent

The invention discloses a multipurpose antibacterial non-woven fabric and a production process thereof and belongs to the technical field of fiber products and composite materials. According to the technical scheme, the multipurpose antibacterial non-woven fabric comprises a base fabric layer, and the surface of the base fabric is coated with an antibacterial coating, which is composed of, by weight part, 0.1-0.2 part of natural antibacterial agent, 0.5-1.5 parts of defoaming agent, 1-2 parts of water absorbent, 1-2 parts of dispersing agent, 3-6 parts of binding agent and water as balance. The multipurpose antibacterial non-woven fabric has the advantages of being efficient and durable in antibacterial performance, stable in appearance and free from toxicity and pollution. The invention also discloses the production process of the multipurpose antibacterial non-woven fabric. The production process mainly comprises performing a spunlacing procedure and applying the antibacterial coating. The production process avoids affecting the original features of fibers and damaging the fibers, the produced non-woven fabric has the advantages of high strength, low fluffiness, soft hand feelingand the like, besides, the production process is high in production efficiency and utilization rate of raw materials.

Owner:HANGZHOU XINFUHUA NONWOVENS

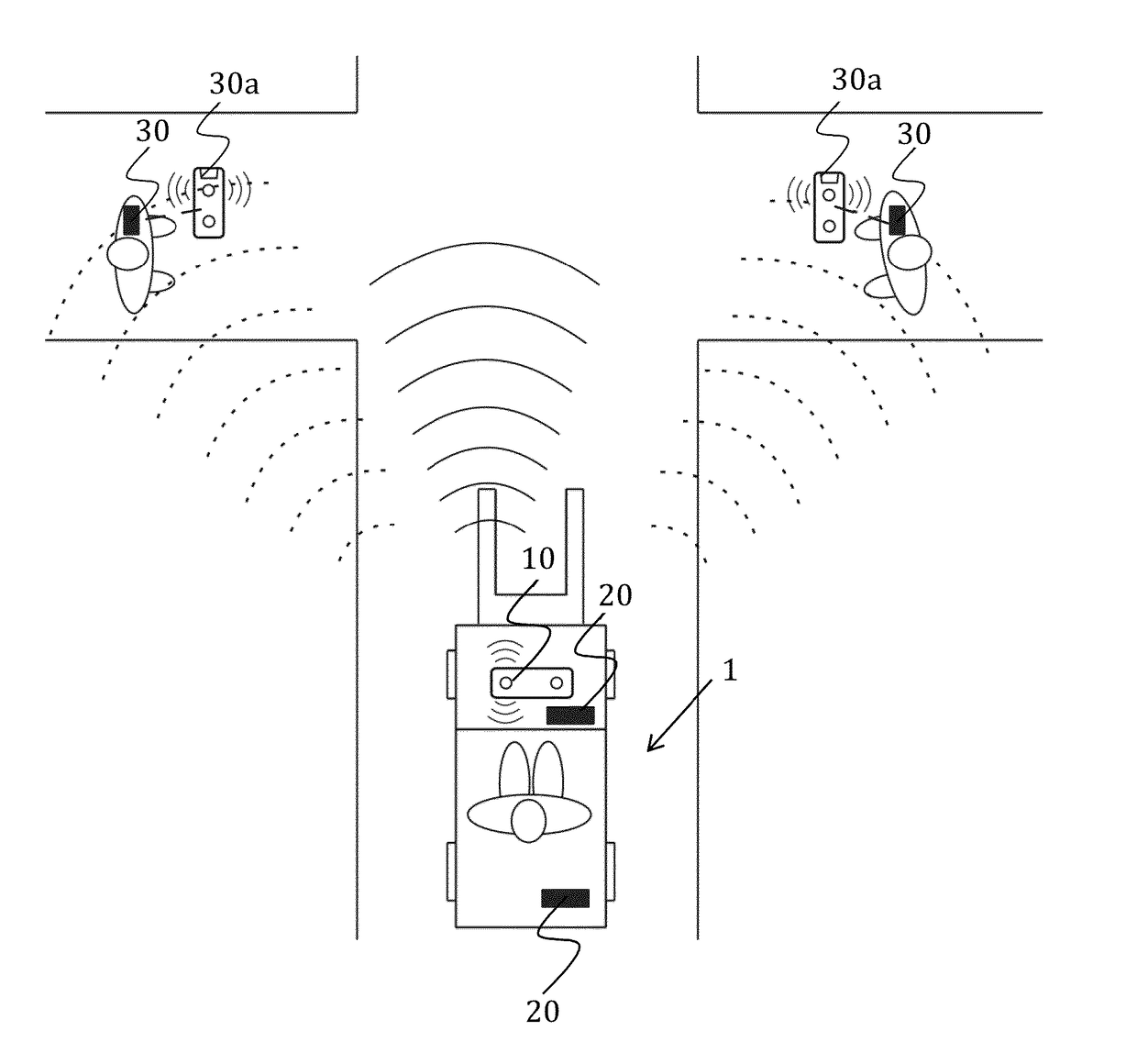

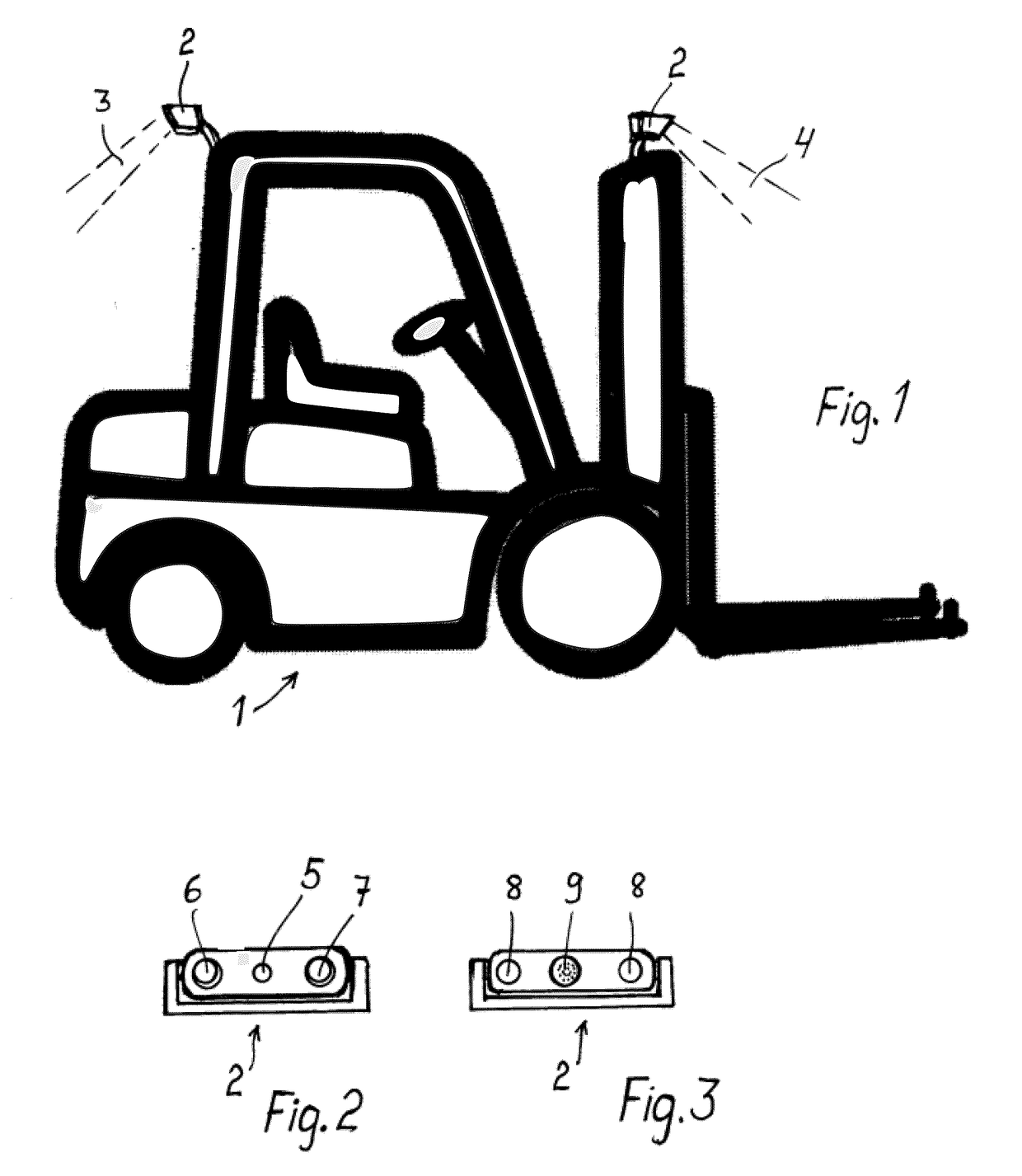

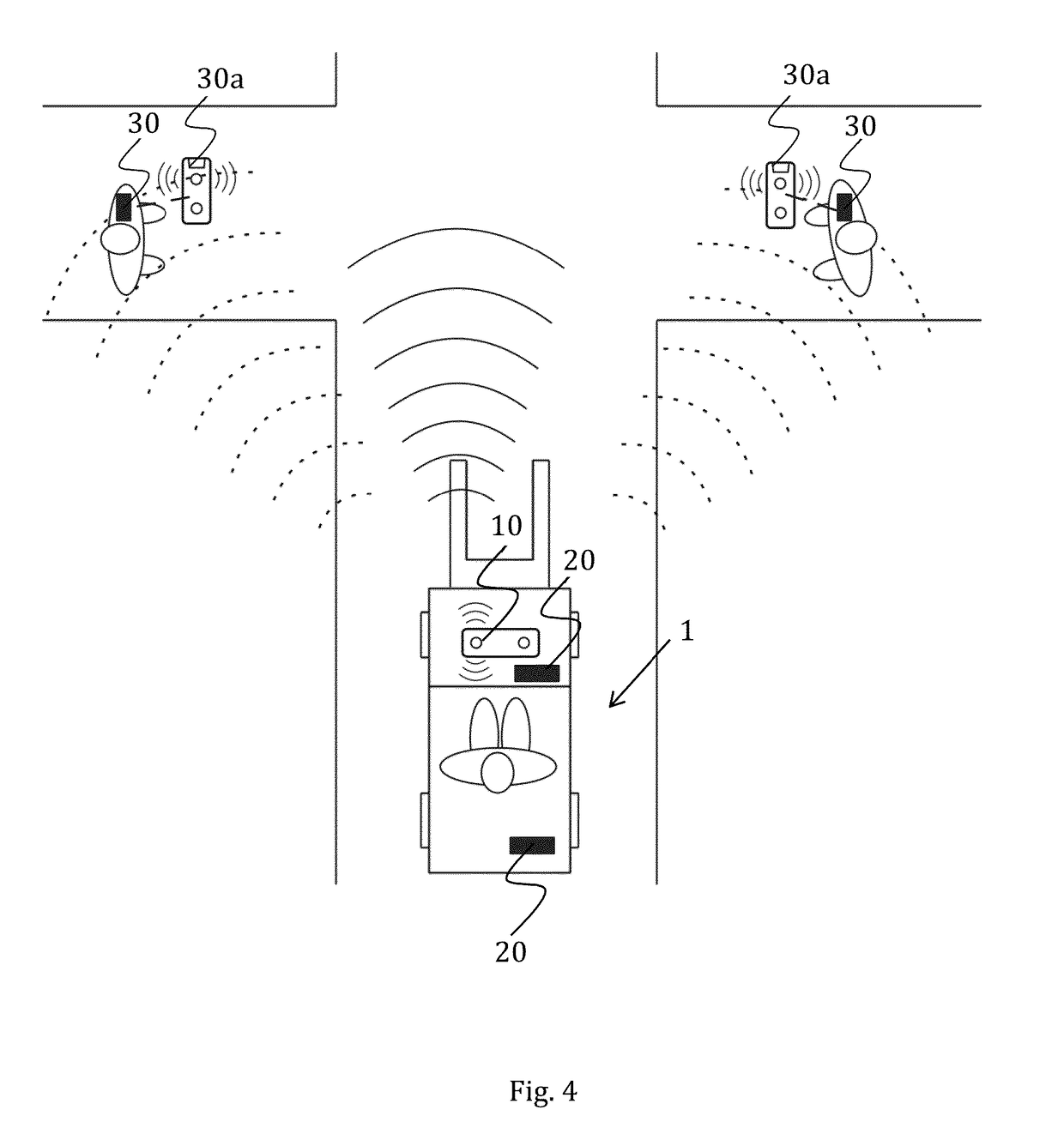

Safety arrangement

ActiveUS20180170250A1Stable appearanceReduce the amount requiredSafety devices for lifting equipmentsControl with pedestrian guidance indicatorMobile vehicleEngineering

The invention comprises a safety system comprising a vehicle identifier (10) arranged to a moving vehicle or work machine (1) and capable of radio communication and, arranged in an operating connection therewith, an alarm unit (20), and a personal identifier (30, 30a) arranged in connection with the moving unit and capable of radio communication, the personal identifier (30, 30a) comprising an alerting device for warning of vehicles or work machines in the area. In addition, said alarm unit (20) comprises warning equipment for warning of units moving in the area. The vehicle identifier and / or the personal identifier of the safety system are configured to determine a distance between the vehicle identifier and the personal identifier on the basis of at least one signal transmitted between the vehicle identifier and the personal identifier. The vehicle identifier is configured to activate the warning equipment if the distance between the vehicle identifier and the personal identifier is less than a threshold value determined in advance for the vehicle identifier, and the personal identifier is configured to activate the alerting device if the predetermined distance between the vehicle identifier and the personal identifier is less than a threshold value determined in advance for the personal identifier.

Owner:INNOTRAFIK

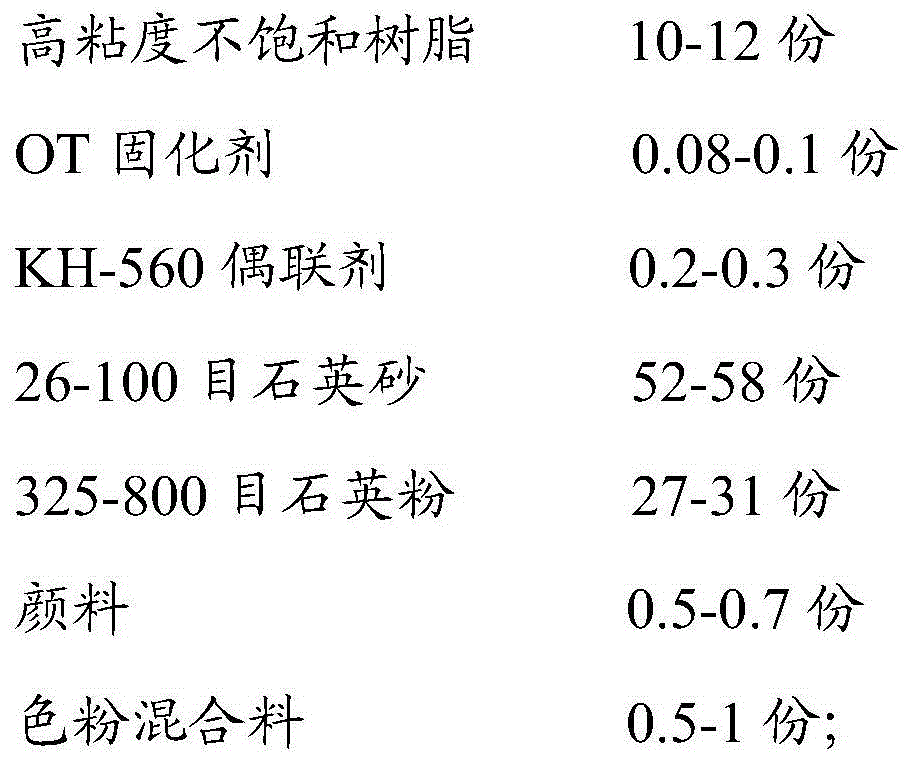

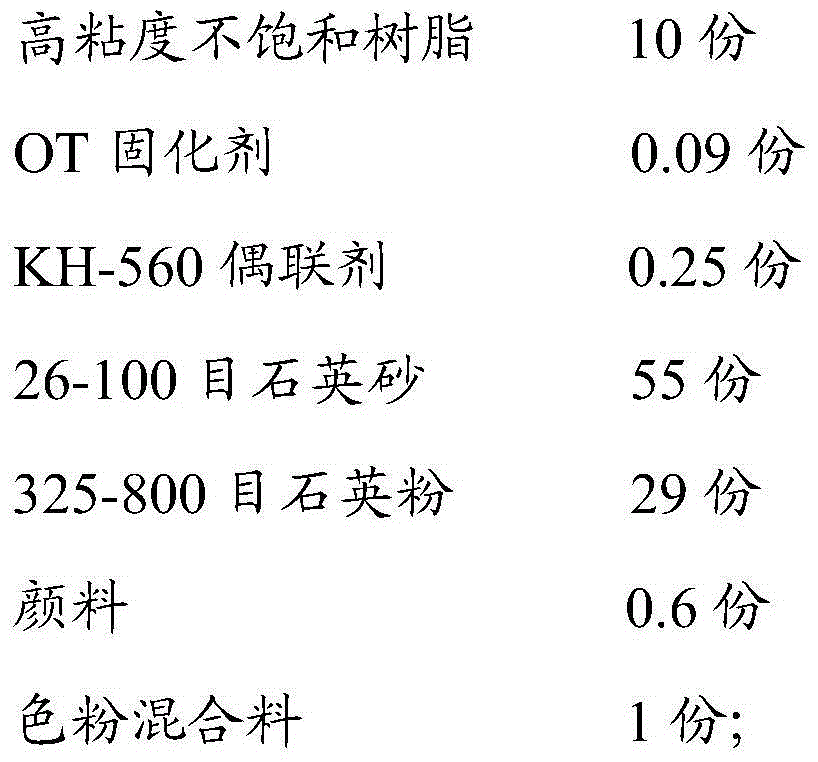

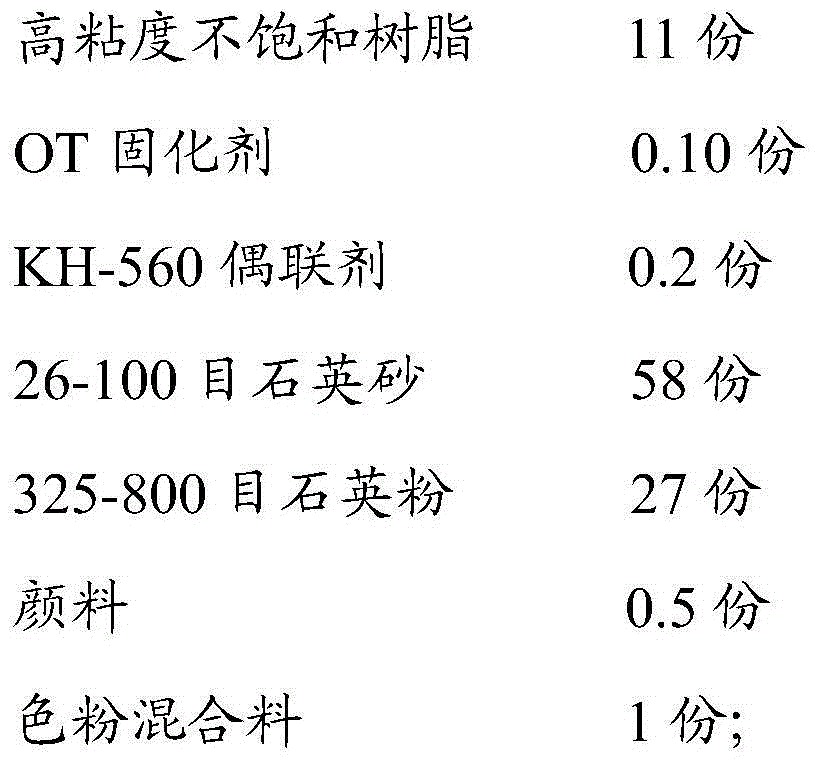

Quartz stone board and manufacturing method of quartz stone board

ActiveCN104529240AStable appearanceProduct quality and appearance are stableMaximum diameterBatch Number

The invention discloses a quartz stone board and a manufacturing method of the quartz stone board. High-viscosity unsaturated polyester resin is adopted in raw materials in proportion. The manufacturing method includes the following steps: (1) wet materials obtained after the raw materials are mixed are pre-pressed; (2) screen cutting is carried out on the wet materials pre-pressed in the step (1); (3) pigments and toner mixing materials are sprayed to cluster materials cut in the step (2), and then the follow-up molding work procedure is carried out to obtain the quartz stone board. By means of the quartz stone board and the manufacturing method, the high-viscosity resin and the wet materials are introduced into a formula to be pre-pressed, so that a foundation is laid for large-figure line board face appearance; the maximum diameter of the clustered wet materials is controlled through the large-screen quantitative cutting, and the quantitative toner mixing materials are sprayed, so that the appearance quality of the board face is guaranteed; the obtained product is stable in quality and appearance, the batch number is larger than 50, and the percent of pass of the board is higher than 98%.

Owner:OPPEIN HOME GRP

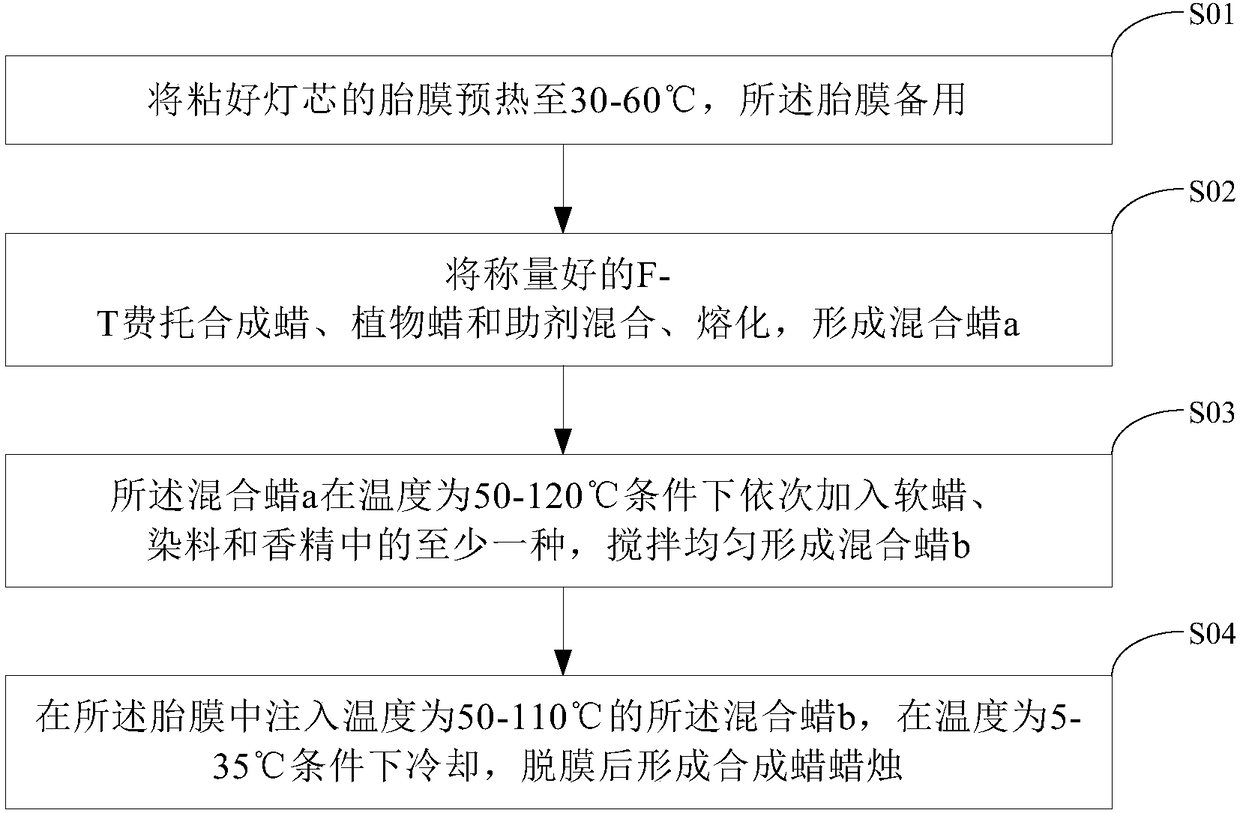

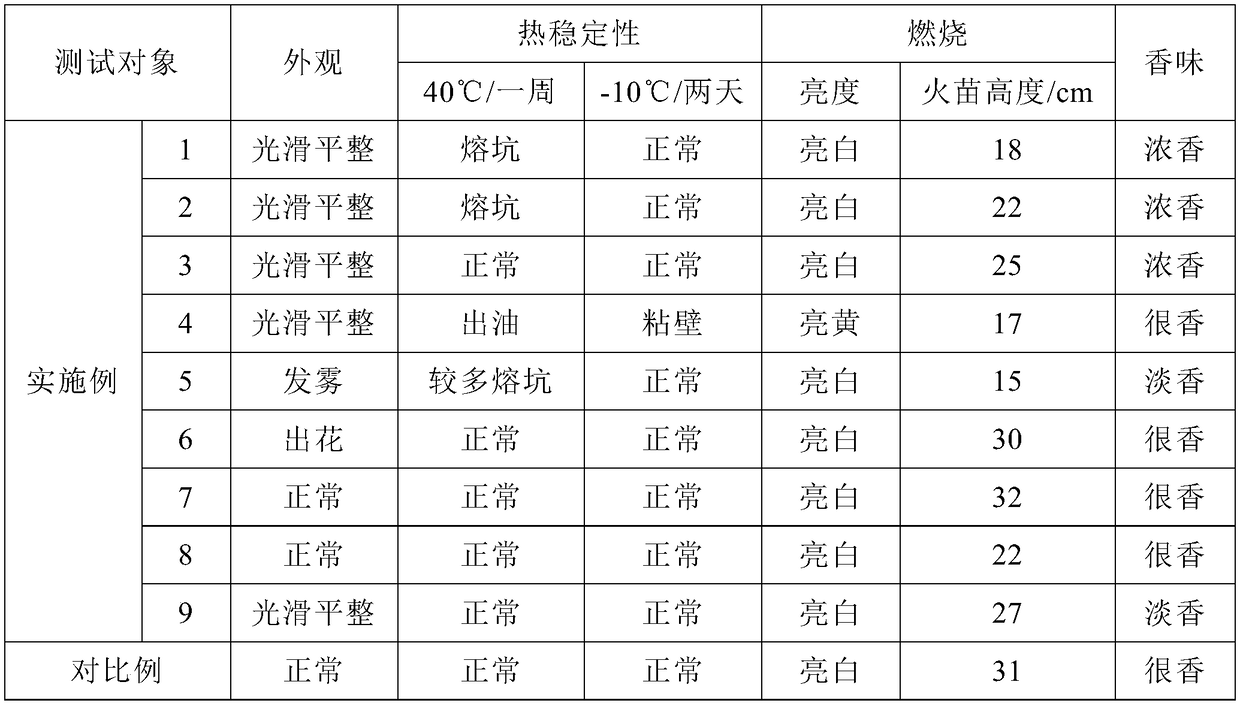

Synthetic wax candle and preparation method thereof

The invention provides a synthetic wax candle and a preparation method thereof, wherein the synthetic wax candle includes, by weight, 5-80% of Fischer-Tropsch synthesis wax, 11-75% of plant wax, and 4-20% of a candle making additive including an additive, and at least one of soft wax, a dye and an essence. During preparation of the synthetic wax candle, original paraffin is replaced by the Fischer-Tropsch synthesis wax, which is then mixed with the plant wax and the candle making additive in order to produce the candle. The synthetic wax candle has stable performances of appearance, combustionand fragrance, is produced from environment-friendly and pollution-free raw materials, and is free of raw material exhaustion.

Owner:QINGDAO KINGKING APPL CHEM CO LTD

Wax-containing 3D printing light-cured cast resin and preparation method thereof

InactiveCN109880272ALow viscosityImprove mechanical propertiesAdditive manufacturing apparatusMechanical propertyDefoaming Agents

The invention discloses wax-containing 3D printing light-cured cast resin and a preparation method thereof. The wax-containing 3D printing light-cured cast resin comprises the following components inparts by weight: 30-80 parts of oligomer resin, 15-60 parts of a reactive diluent, 1-10 parts of a photoinitiator, 1-10 parts of micro-powder wax, 0.1-5 parts of an organic pigment, 0.01-2 parts of adispersing agent, 0.1-5 parts of a defoaming agent and 0.1-5 parts of a flatting agent. The wax-containing 3D printing light-cured cast resin disclosed by the invention has the multiple advantages oflow viscosity, excellent mechanical property, low ash content, small linear shrinkage rate and the like, and can effectively ensure the dimensional precision and clean and smooth appearance of a casting. The invention provides the light-cured material with high printing precision, rapid casting and stable performance for the field of 3D printing and casting, greatly expands the advantages of a laser rapid prototyping technology in the field of casting, and remarkably improves the market competitiveness of products.

Owner:HANS LASER TECH IND GRP CO LTD

LED display screen for outdoor advertisement

InactiveCN106782113APlay the role of anti-collision protectionAvoid damageBatteries circuit arrangementsCasings/cabinets/drawers detailsLED displayLightning rod

The invention discloses an LED display screen for outdoor advertisement. The LED display screen comprises a display screen body, wherein an aluminum alloy frame is inlaid in the periphery of the display screen body; stainless steel supporting stand columns are respectively welded to two sides of the top of the aluminum alloy frame; a rainproof cover is mounted above the aluminum alloy frame; a solar photovoltaic module is mounted on the upper surface of the rainproof cover; and a lightning rod is mounted on one side of the solar photovoltaic module. The rainproof cover is mounted above the aluminum alloy frame, rainproof, dustproof and anti-exposure effects on the display screen body can be achieved, the solar photovoltaic module is mounted on the rainproof cover, and the LED display screen can be powered by fully using solar energy in the environment. The LED display screen is energy-saving and environmentally friendly. The running cost of the LED display screen is greatly reduced. The LED display screen for outdoor advertisement is simple in structure and attractive in appearance, has a lightningproof function. The LED display screen can be effectively prevented from being attacked by thunder and is long in service life.

Owner:重庆英洛凡科技有限公司

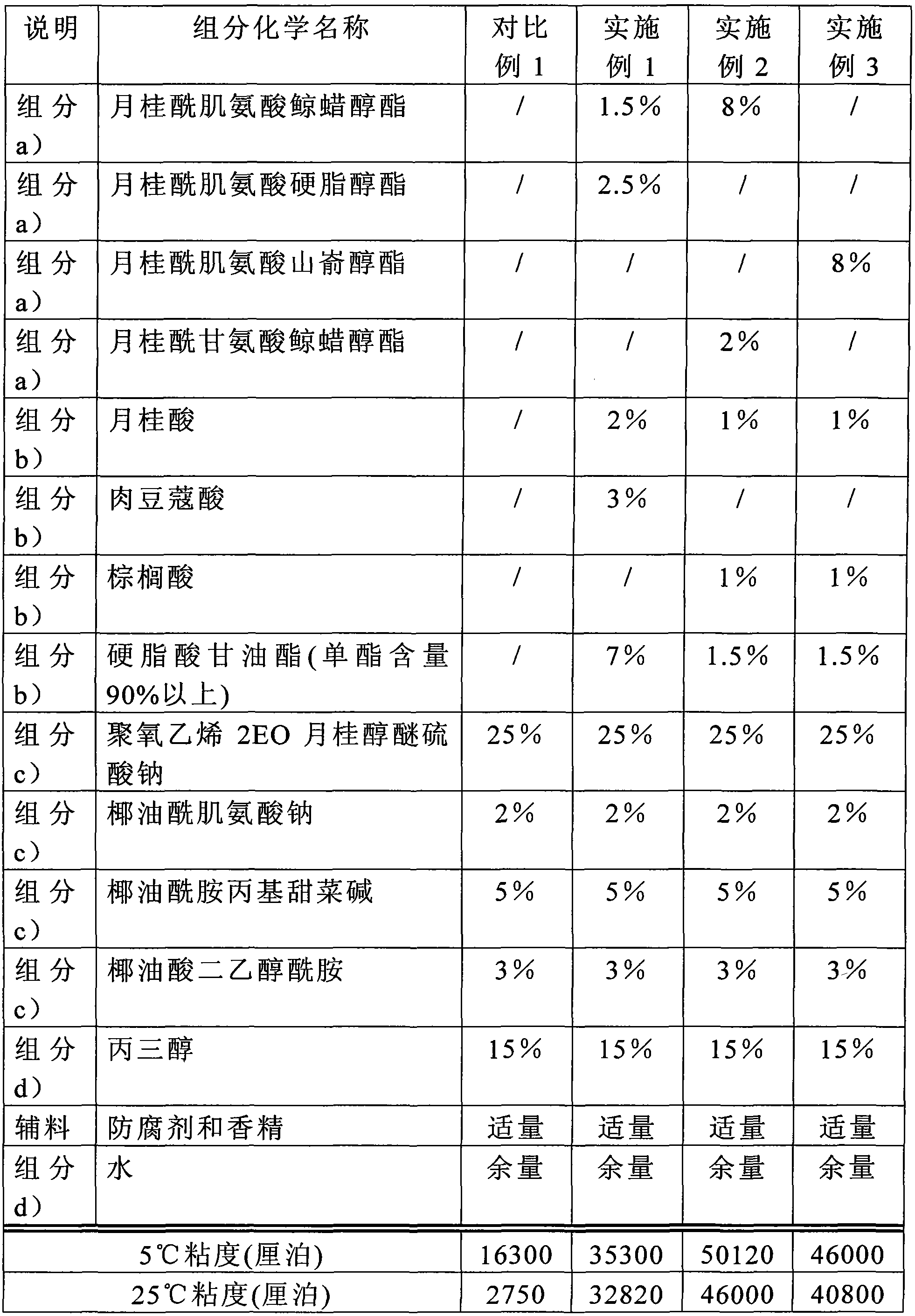

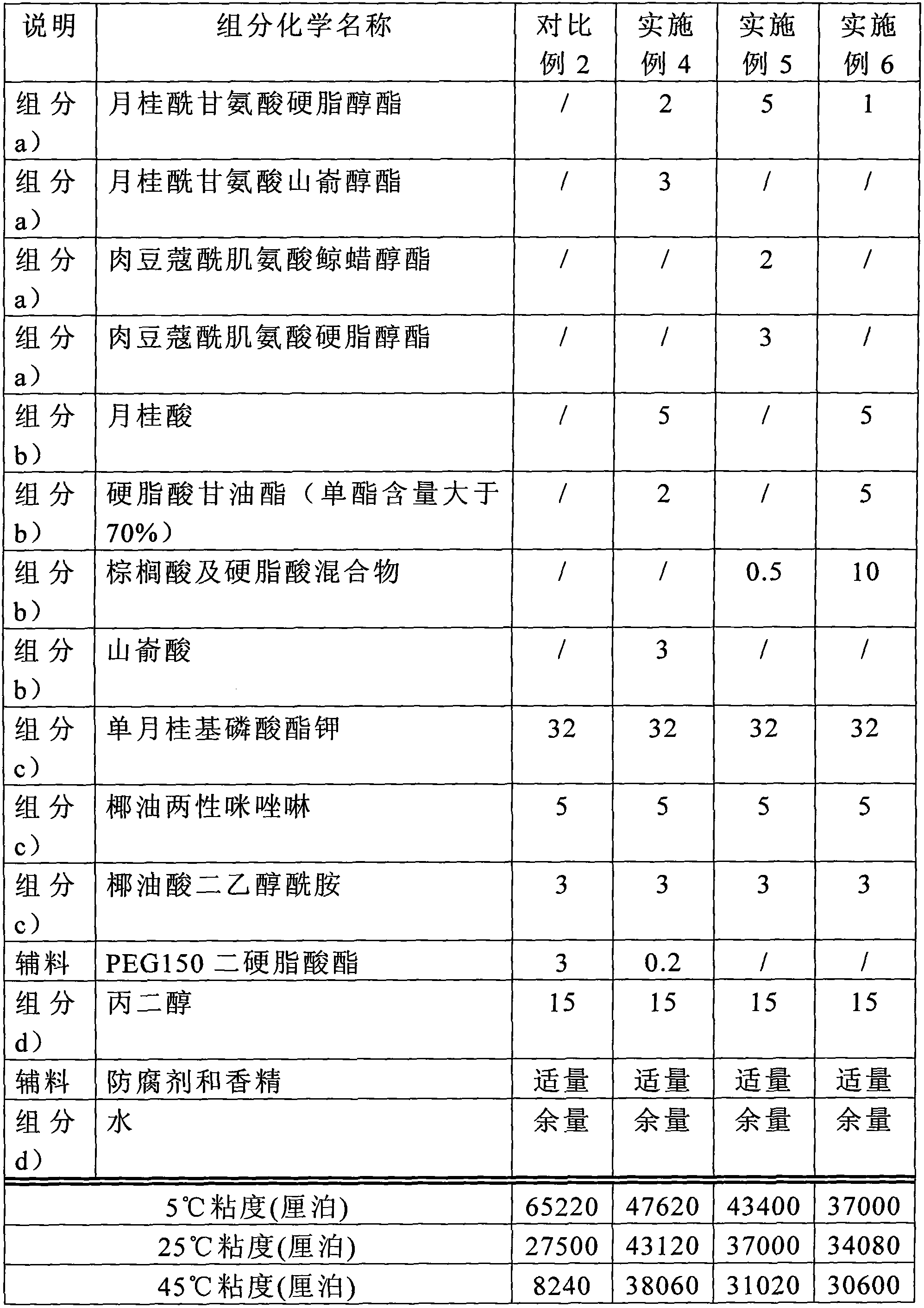

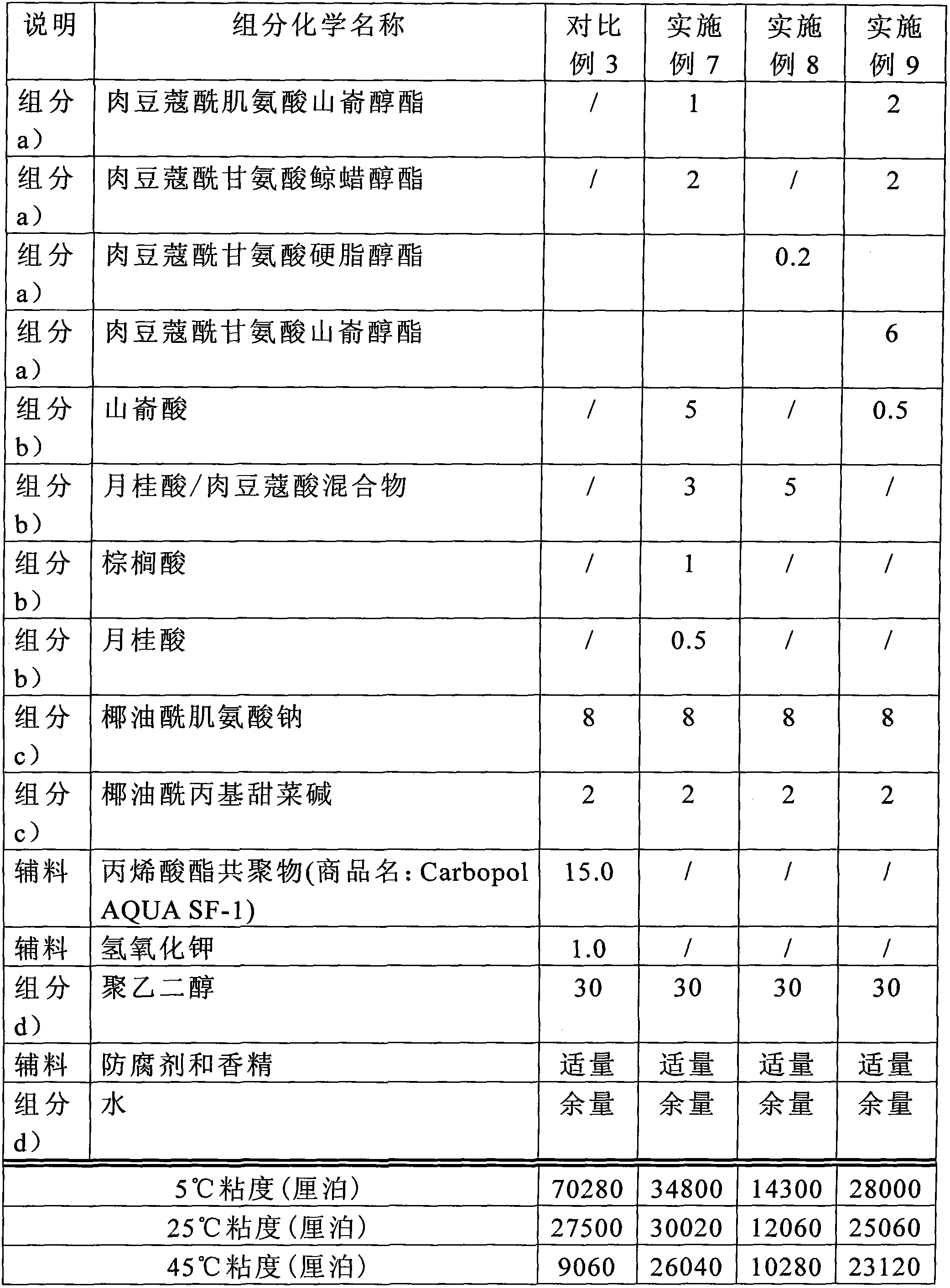

Stiff cleaning composite

ActiveCN102058489AHigh viscosityFoaming fastCosmetic preparationsHair cosmeticsNeutral Amino AcidsAlcohol

The invention discloses a stiff cleaning composite, relating to a stiff cleaning composition used for cleaning skin, eyes, teeth and hair in the field of personal care products. The cleaning composite comprises long-chain fatty acyl neutral amino-acid ester, a fatty compound, surfactant, solvent and beautifying and cleaning assistant solvent, wherein the fatty compound is one of fatty acid, fatty alcohol, fatty alcohol ether or polyol fatty acid ester; the solvent is composed of water, lower alcohol, polyalcohol and polyalcohol ether; and the beautifying and cleaning assistant solvent is used for skin, eyes, teeth and hair. The cleaning composite can obtain satisfactory stiff appearance when being used for cleaning skin and hair, can maintain stable viscosity at different temperatures, is easy to smear and quick to foam and has good foaming quality when being used by consumers.

Owner:SUZHOU ELECO CHEM IND

Method for processing sea cucumber soaked in water

InactiveCN101023800ALong storage timeExtended storage timeMeat/fish preservation by heatingMeat/fish preservation using chemicalsIrradiationHigh heat

The present invention discloses a processing method of dried sea cucumber. Said processing method mainly is characterized by that it utilizes a fresh-keeping liquor whose concentration is 0.01-0.1% to treat packaging bag of dried sea cucumber or adopts an irradiation sterilization method to kill the bacteria on the packaging bag so as to prolong the storage time of dried sea cucumber.

Owner:NINGBO UNIV

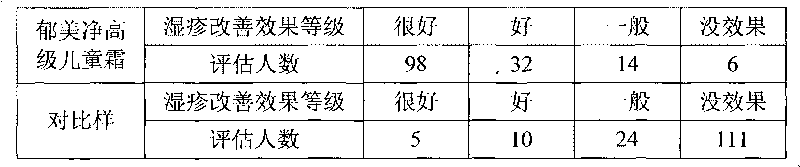

Composite for cosmetics, cosmetic product containing same and preparation method thereof

ActiveCN101695470AStability impactReduce dosageCosmetic preparationsToilet preparationsChrysanthemum FlowerCleaning product

The invention provides a composite for cosmetics, a cosmetic product containing the same and a preparation method thereof. The composite for cosmetics comprises phellodendron essential oil, wild chrysanthemum flower essential oil, chamomile essential oil and fresh milk, wherein composite essential oil is formed by the phellodendron essential oil, the wild chrysanthemum flower essential oil and the chamomile essential oil; the weight ratio of the composite essential oil to the fresh milk is 0.2-0.8 to 5-20; the weight ratio of the phellodendron essential oil to the wild chrysanthemum flower essential oil to the chamomile essential oil is 1:1.5-2.5:2.5-3.5. The composite can be used as an addition phase for manufacturing cosmetic products, particularly skin care products and cleaning products so that the products have the efficacy of antianaphylaxis, antiphlogosis, eczema elimination, and the like.

Owner:TIANJIN YU MEI JING GRP

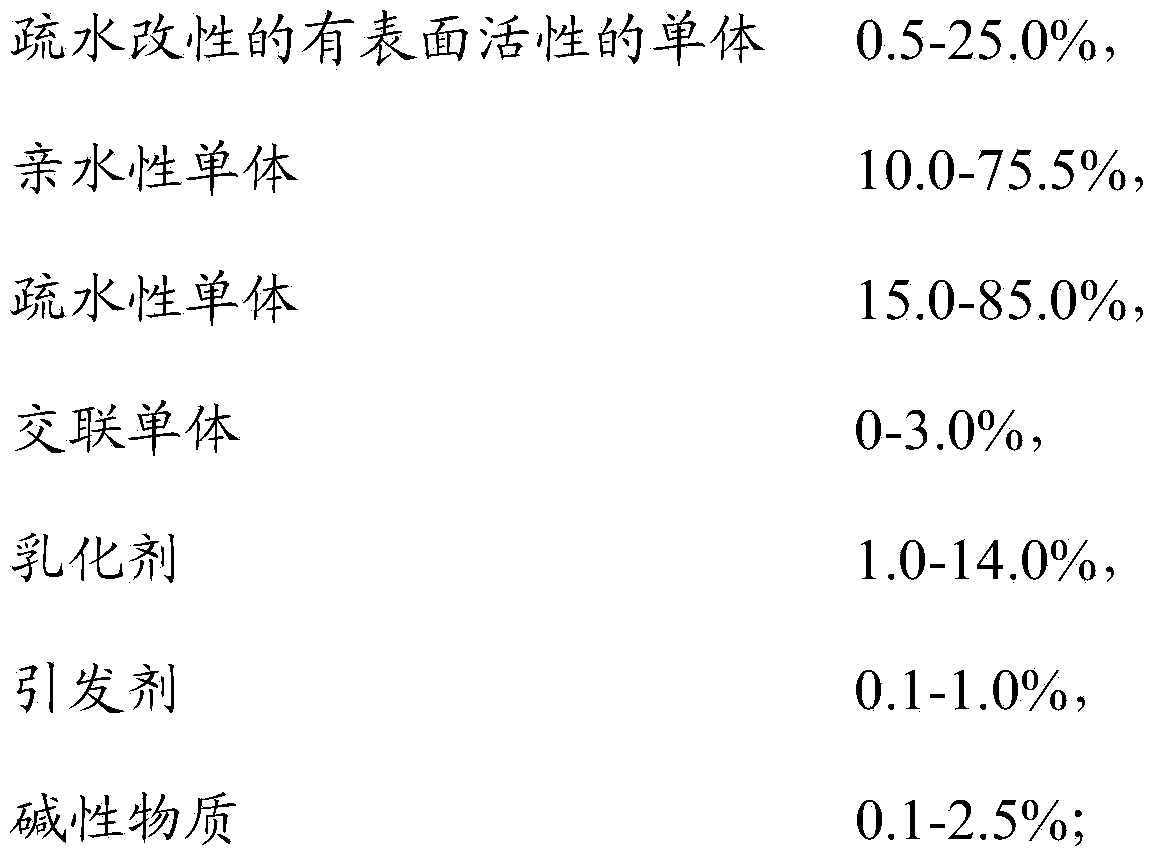

A kind of frost-resistant acrylate suspension thickening emulsion and preparation method thereof

The invention relates to a freezing-resistant acrylate suspended thickening emulsion which is prepared from 28.0-32.0 wt% of raw material and 68.0-72.0 wt% of deionized water. The raw material is composed of the following components in percentage by weight: 10.0-75.5% of hydrophilic monomer, 15.0-85.0% of hydrophobic monomer, 0-3.0% of crosslinking monomer, 0.5-25.0% of hydrophobicity-modified surface-active monomer, 1.0-14.0% of emulsifier, 0.1-1.0% of initiator and 0.1-2.5% of alkaline matter. The invention also relates to a preparation method of the freezing-resistant acrylate suspended thickening emulsion. The freezing-resistant acrylate suspended thickening emulsion can satisfy the standard in daily chemical industry, and has the advantages of stable application performance, long shelf life and favorable freezing resistance.

Owner:GUANGZHOU DX CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com