Backing welding flux used for single-side submerged arc welding and the single-side submerged arc welding method using the same

A technology of submerged arc welding and backing welding, which is applied in the direction of arc welding equipment, welding equipment, welding equipment, etc., can solve problems such as difficulty in a little strain, difficulty in tightness of the back of the groove of the backing flux and the welded steel plate, etc., and achieve The effect of stable appearance and good tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

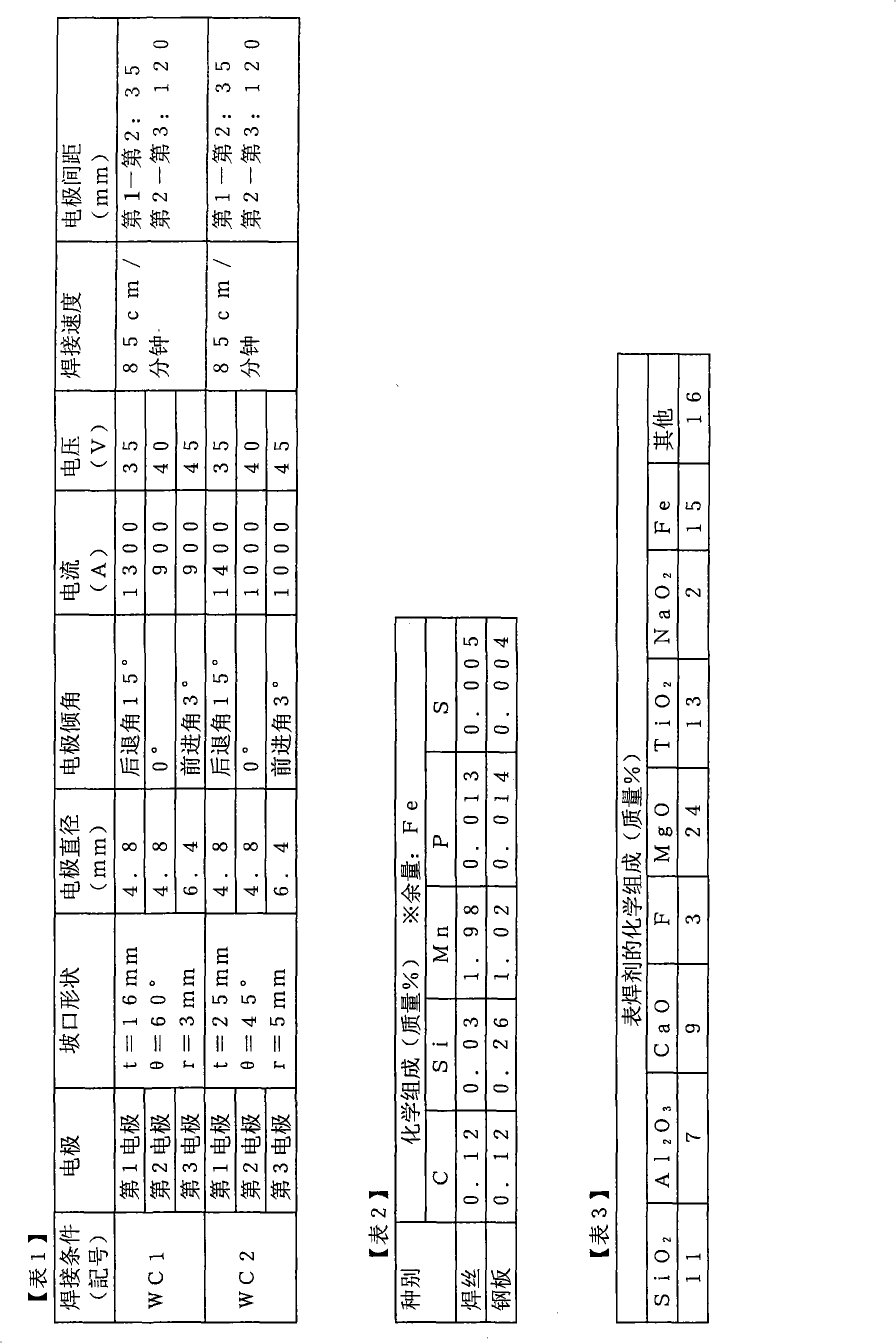

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described.

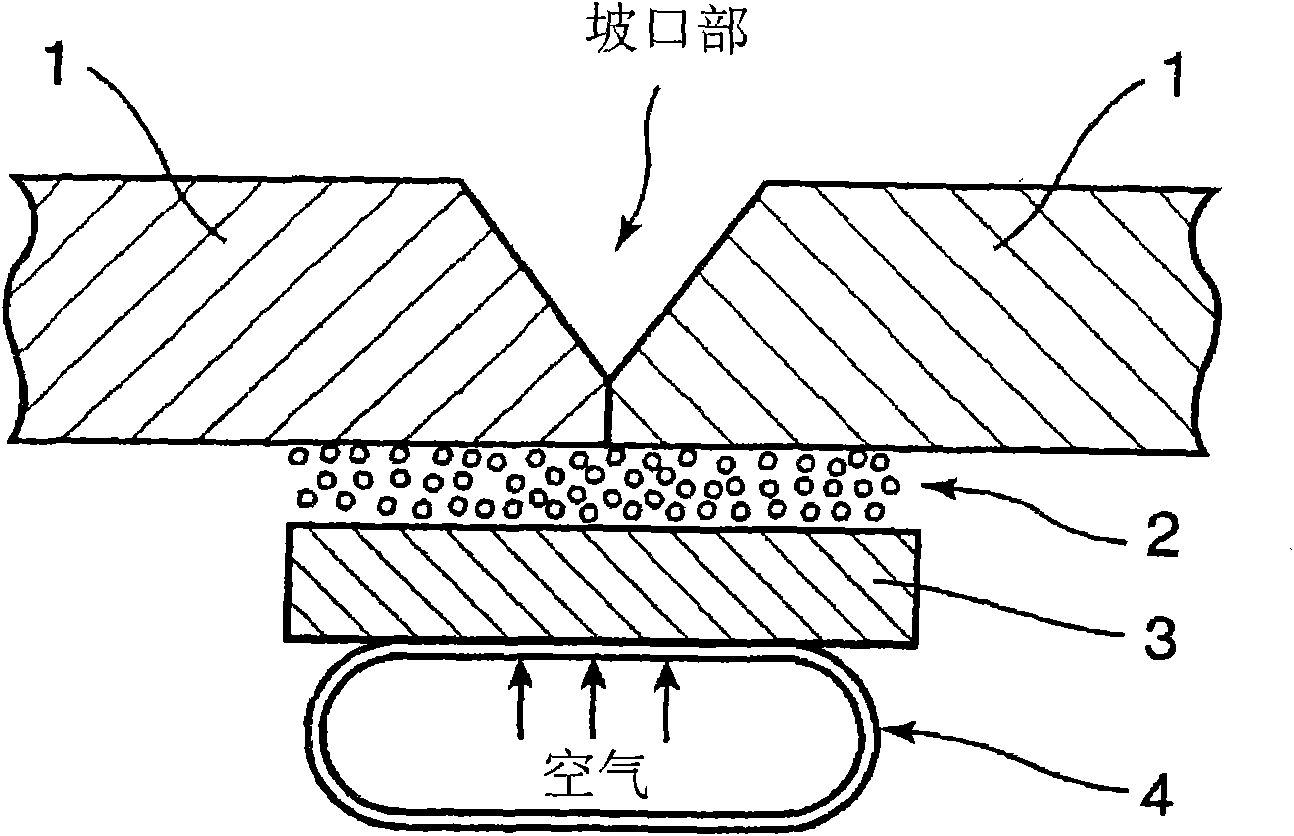

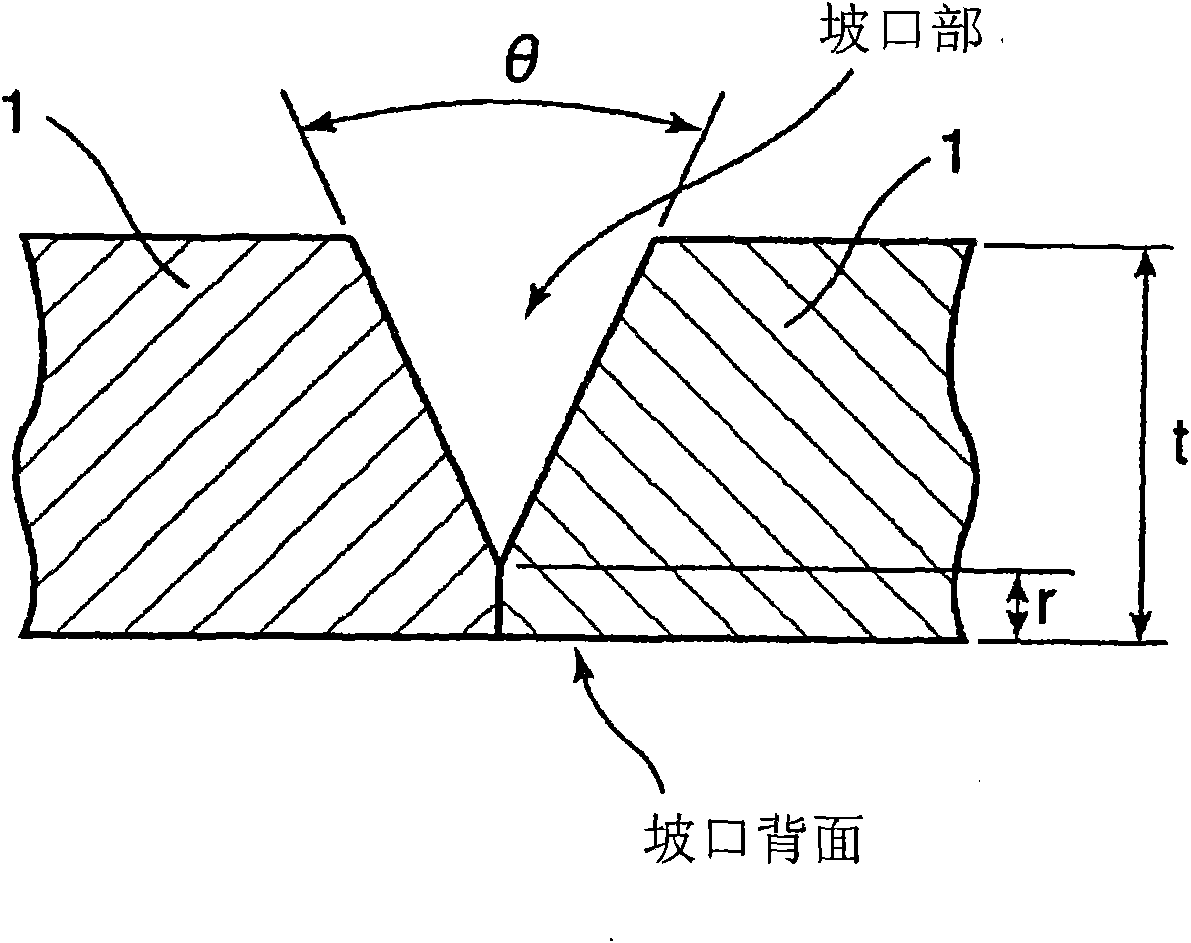

[0024] In single-side submerged arc welding using copper plate and flux as a backing, in order to ensure good tightness between the backing flux and the back of the groove of the welded steel plate, it is important to In the post-strike state, minimize the gaps between the flux particles of the backing flux.

[0025] At this time, if the backing flux spread on the copper plate with a certain thickness is close to the state of solid flux with extremely small gaps in the flux, then fill the air hose with air and press the copper plate on the backing. When the groove back of the steel plate is welded, it hardly follows the strain or the like on the groove back of the steel plate to be welded, and the adhesion between the pad flux and the groove back becomes poor. Therefore, in the state where the pad flux is dispersed with a constant thickness on the copper plate, it is necessary to achieve a state in which a certain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com