Steel structure strip sticking mechanism and sticking method

A steel structure and sticking technology, applied in the directions of sending objects, packaging, thin material processing, etc., can solve the problems of difficult to control the degree of fit, time-consuming and laborious, easy to stick irregularly, etc., to achieve automatic cutting and improve work efficiency. , the effect of good tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

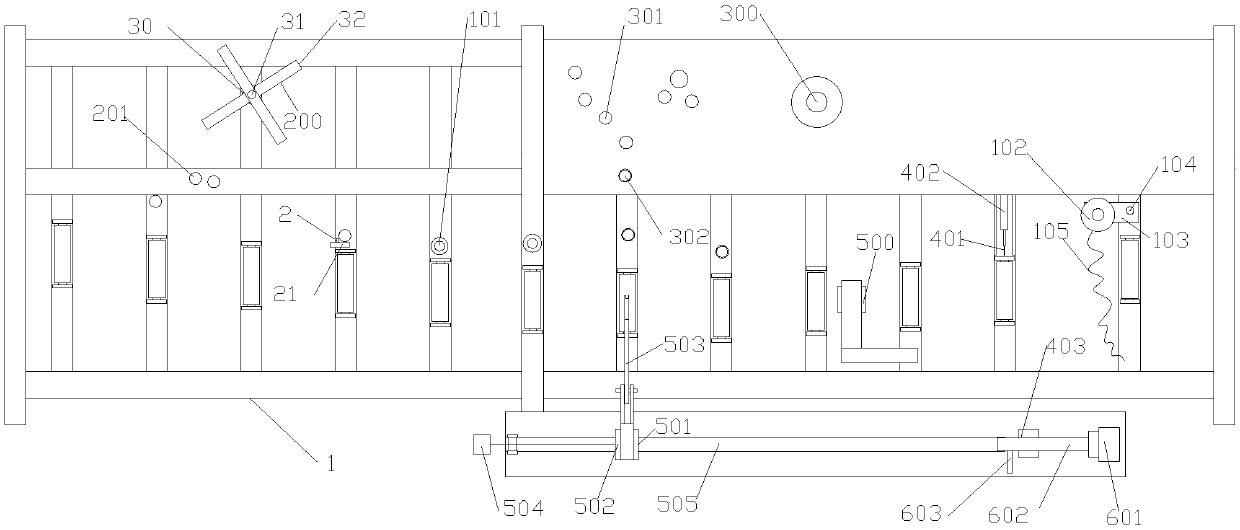

[0041] Embodiment 1, a steel structure sticking mechanism, including a frame 1, and a feeding mechanism on the frame 1, a sponge unwinding mechanism, a spraying device 2, a self-adhesive peeling mechanism, a cutting mechanism, a positioning mechanism, a reset Mechanism, sponge unwinding mechanism, self-adhesive stripping mechanism, and the edge of the feeding mechanism between are provided with a first squeeze roller 101;

[0042] The sponge unwinding mechanism includes a first rotating frame 200 and a first guide roller group 201, which are arranged along the direction of the feeding mechanism;

[0043] The spray device 2 is arranged above the guide rollers near the side of the feeding mechanism in the first guide roller group 201, the spray device 2 is fixedly installed on the column 21, and the bottom of the column 21 is fixedly installed on the frame 1;

[0044] The self-adhesive peeling mechanism includes a second rotating roller 300, a second guide roller group 301, and ...

Embodiment 2

[0054] Embodiment 2, a method for sticking strips of steel structures, the specific steps are as follows:

[0055] 1) Put the steel structure on the conveying mechanism on frame 1 for conveying;

[0056] 2) The sponge unwinding mechanism is opened to unwind the sponge roll;

[0057] 3) The spray device 2 sprays the sponge;

[0058] 4) The wetted sponge is fitted to the groove of the steel structure, and the fitted sponge moves forward with the steel structure, and the first squeeze roller 101 squeezes the sponge;

[0059] 5) The self-adhesive peeling mechanism peels off the self-adhesive;

[0060] 6) Adhering and pasting the colloidal layer of the self-adhesive to the side of the steel structure;

[0061] 7) The positioning device 403 detects that the sponge between adjacent steel structures is in place, and the cutting mechanism starts to cut;

[0062] 8) The pressing device 500 squeezes the steel structure;

[0063] 9) The reset mechanism resets the positioning mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com