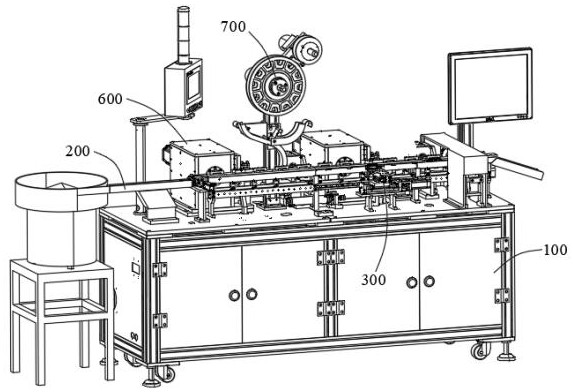

A plug-in machine for semiconductor testing and its use method

A plug-in machine and semiconductor technology, applied in the direction of semiconductor/solid-state device testing/measurement, measuring electricity, measuring devices, etc., can solve problems such as low efficiency, and achieve the effect of automatic feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0094] The present invention also provides a method of using the above-mentioned plugging machine:

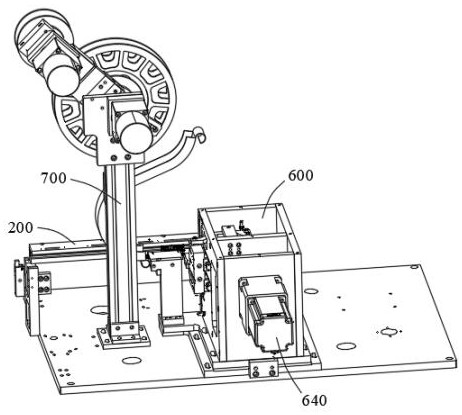

[0095] S1. The feeding part 200 transports the material to the plugging mechanism 600;

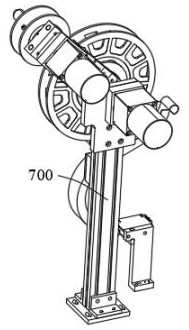

[0096] S2. The insertion mechanism 600 inserts the pin 000 into the material;

[0097] S3. The feeding part 200 sends the material inserted with the pin 000 to the detection gap 210;

[0098] S4. The horizontal cylinder 330 works to push the detection plate 310 close to the material to be detected;

[0099] S5. Insert the pin 000 of the material to be detected into the detection blind hole 321;

[0100] S6. When the material is a good product, the detection slider 320 is limited by the pin 000, the detection plate 310 continues to approach the workpiece, the push block 312 is raised, and the grooving tool 500 is offset against the pin 000; When the material is a defective product, the detection slider 320 follows the detection plate 310 to approach the workpiece, bends the pin 000, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com