Power line and resistance wire plugging machine of light-emitting device

A technology for light-emitting devices and power cords, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to guarantee assembly quality, easy to miss insertion, wrong insertion, unfavorable promotion and application, etc., to ensure assembly quality, reduce The effect of missing insertion and automatic and flexible switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

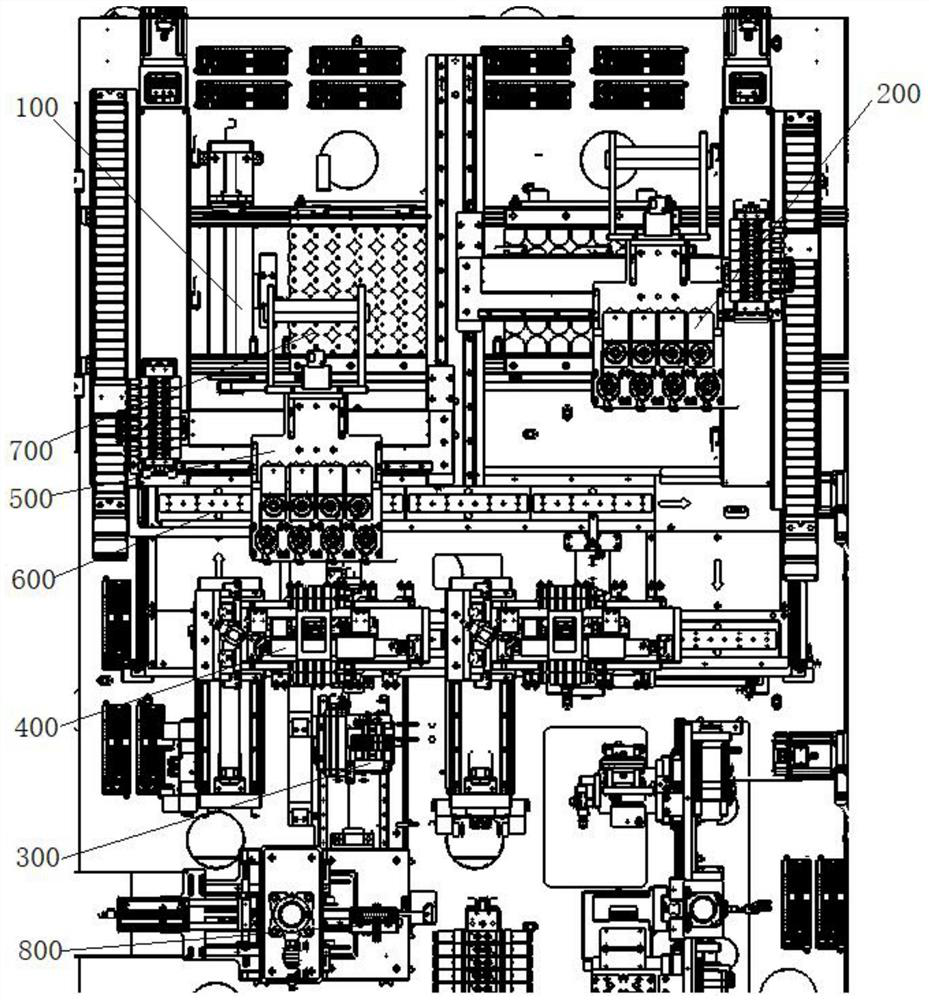

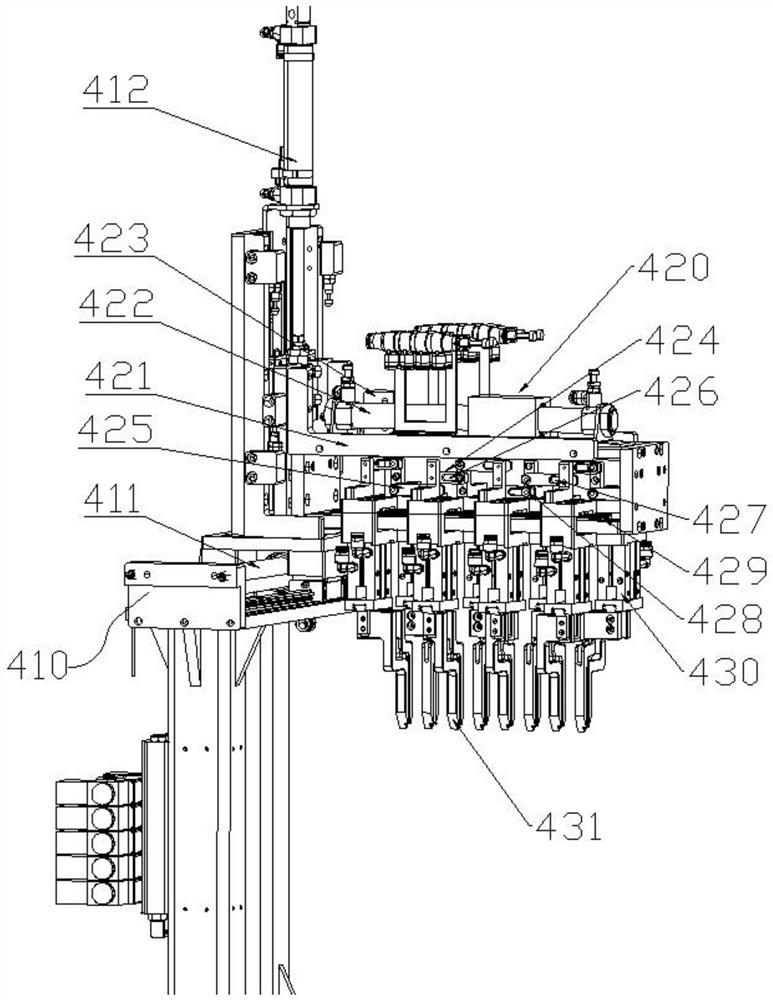

[0048] like figure 1 As shown, a power cord and resistance wire insertion machine for a light-emitting device, which installs a resistance wire insertion module 100 and a power cord insertion module 200 side by side along the X-axis direction on a frame, and the resistance wire insertion module 100 and The power cord insertion modules 200 each include a retrieving mechanism 300 , a clamping mechanism 400 and a wire insertion mechanism 500 , and the buffer mechanism 600 and the substrate conveying line 700 are both cyclically moved between the resistance wire insertion module 100 and the power cord insertion module 200 .

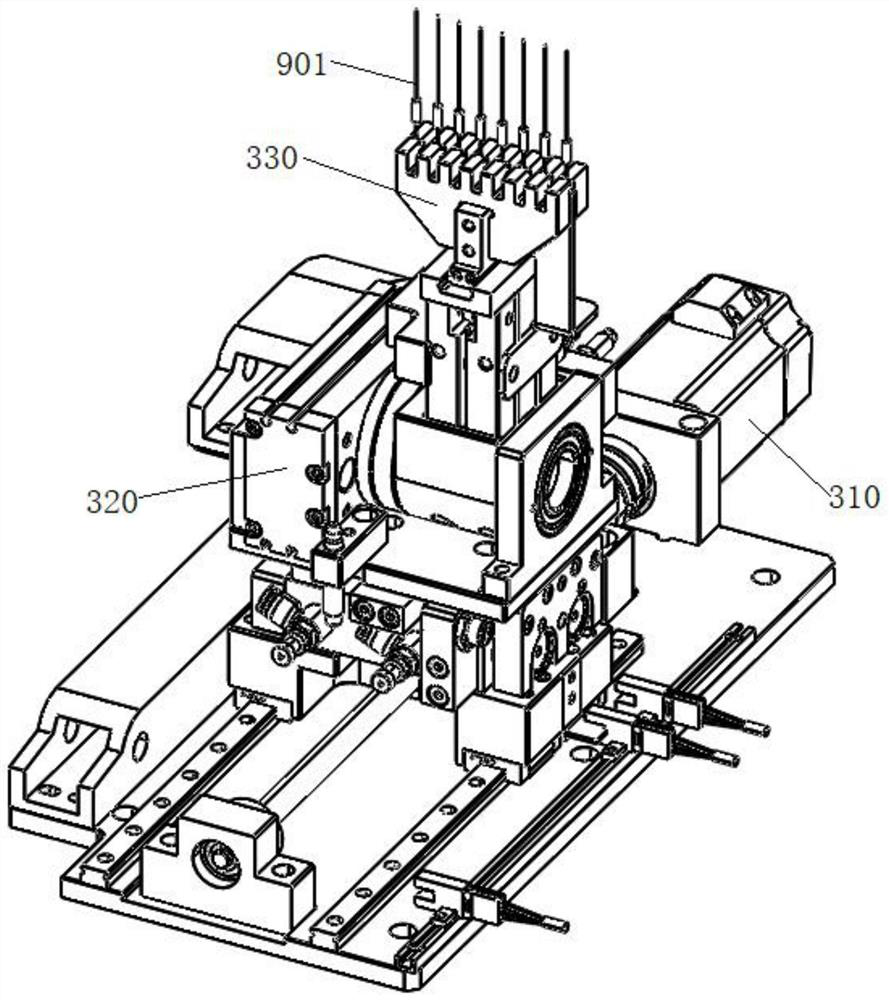

[0049] like figure 2 As shown, the retrieving mechanism 300 is used to remove a row of horizontally placed parts (resistance wires or power cords) from the waiting station 800 and convert them into a first posture, which forms an angle with the horizontal plane, Preferably, the first posture is perpendicular to the horizontal plane, so that the next proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com