SiC fiber reinforced polyurethane series skid-resistant coating and preparation method thereof

A polyurethane-based, fiber-reinforced technology, used in the field of anti-skid coatings and its preparation, can solve the problems of reduced frictional resistance, failure to meet the coating requirements of large ship decks, and coating wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0061] Preparation of SiC short fibers:

[0062] Put the SiC fiber into a high-speed crusher, crush it at a speed of 40000r / min for 9s, and screen it with a sieve for 4 times to obtain short SiC fibers with a length of 2mm.

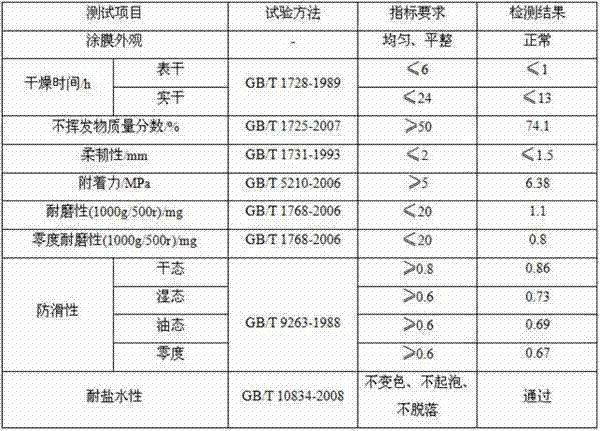

Embodiment 1

[0064] SiC fiber reinforced polyurethane anti-skid coating:

[0065] It is prepared by mixing components A, B, C and other components, wherein the mass content of component B is 3.9% of component C, and other components are mixed with components B and C, which is recorded as component D. Component A and component D are mixed at a mass ratio of 1:1.1, each component is as follows:

[0066] Component A:

[0067] Polytetrahydrofuran ether glycol: 15 parts;

[0068] Carbodiimide-uretonimine modification 4,4 _ Diphenylmethane diisocyanate: 15 parts;

[0069] E44 type epoxy resin: 2 parts;

[0070] Component B:

[0071] SiC short fiber: 6 parts;

[0072] al 2 o 3 : 15 copies;

[0073] Surface modifier (silane coupling agent KH570): 1 part;

[0074] Component C:

[0075] Carbodiimide-uretonimine modification 4,4 _ Diphenylmethane diisocyanate: 15 parts;

[0076] Chain extender (1,4-butanediol): 1.9 parts;

[0077] BaSO 4 : 2.5 copies;

[0078] Titanium dioxide: 4 part...

Embodiment 2

[0095] SiC fiber reinforced polyurethane anti-skid coating:

[0096] It is prepared by mixing components A, B, C and other components, wherein the mass content of component B is 4.6% of component C, and other components are mixed with components B and C, which is recorded as component D. Component A and component D are mixed at a mass ratio of 1:1.1, each component is as follows:

[0097] Component A:

[0098] Polytetrahydrofuran ether glycol: 13 parts;

[0099] Carbodiimide-uretonimine modification 4,4 _ Diphenylmethane diisocyanate: 13 parts;

[0100] E44 type epoxy resin: 1.5 parts;

[0101] Component B:

[0102] SiC short fiber: 3 parts;

[0103] Al 2 o 3 : 13 copies;

[0104] Surface modifier (silane coupling agent KH570): 1 part;

[0105] Component C:

[0106] Carbodiimide-uretonimine modification 4,4 _ Diphenylmethane diisocyanate: 13 parts;

[0107] Chain extender (1,4-butanediol): 1.9 parts;

[0108] BaSO 4 : 2 copies;

[0109] Titanium dioxide: 3 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

| Hard work time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com