Insulating board and insulating glue sheet for laminated busbar, and production methods thereof

A technology of laminated busbars and insulating films, which is applied in the direction of adhesives, epoxy resin adhesives, film/sheet adhesives, etc., can solve the problem of insulation film bonding performance and moisture resistance decline, mechanical strength and electrical performance. Good, insulation board electrical performance decline and other problems, to avoid poor impregnation, reduce production difficulty, good electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

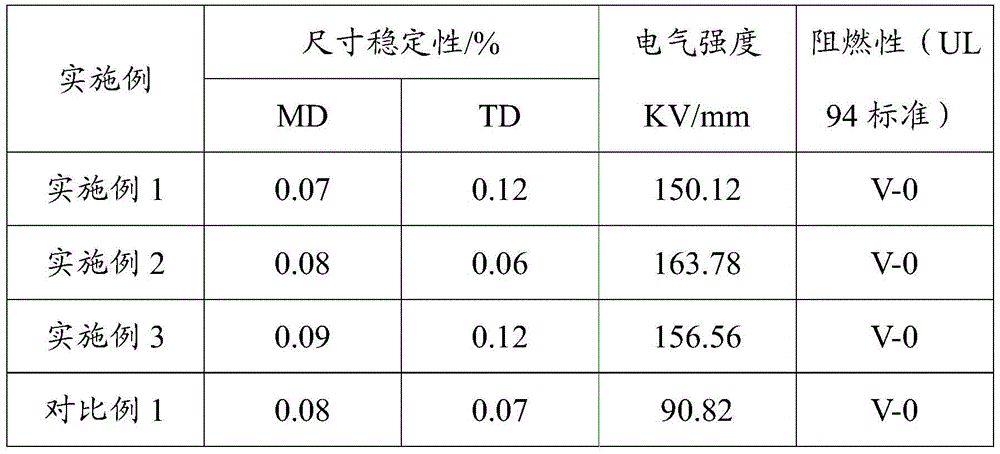

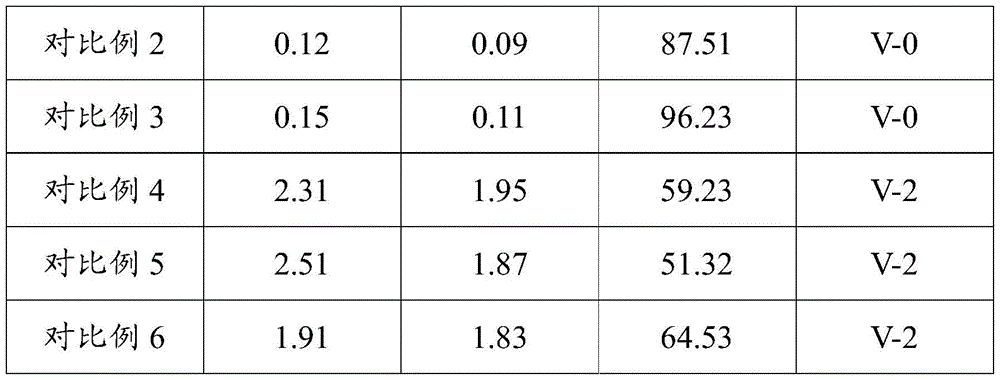

Embodiment 1

[0050] An insulating board for laminated busbars. Firstly, the shaped cloth is produced through the first embodiment, that is, the glass raw materials are first drawn and paralleled, and then the glass strands are impregnated with epoxy resin glue. Bake at 100°C for 3 minutes to perform semi-curing treatment, then twist, warp and weave according to the specifications of 104 glass fiber cloth. After weaving, bake in an oven at 180°C for 90 minutes to cure. Obtain a shaped cloth, the weight content of resin in the shaped cloth is no more than 30%;

[0051] Then immerse the obtained shaped cloth in the epoxy resin glue again, take it out and bake and cure it in an oven at 180°C to 250°C for 5 to 10 minutes to completely cure the resin glue to obtain an insulating board;

[0052] An insulating film for laminated busbars: the surface of the insulating board obtained above is coated with a modified polyester adhesive, and baked in an oven at 120-150°C for 3-5 minutes to obtain a lam...

Embodiment 2

[0055] An insulating board for laminated busbars. Firstly, the sizing cloth is made through the second embodiment, that is, the glass raw materials are drawn, paralleled, twisted and warped, and the warped yarns are impregnated with epoxy resin glue. Glue treatment, get the dipped warp yarn and bake it at 150°C for 3 minutes to perform semi-curing treatment, then weave it according to the specifications of 104 glass fiber cloth, and bake it in an oven at 200°C for 50 minutes after weaving After curing, a shaped cloth is obtained, and the resin weight content in the shaped cloth is no more than 30%;

[0056] Then immerse the obtained shaped cloth in the epoxy resin glue again, take it out and bake and cure it in an oven at 180°C to 250°C for 5 to 10 minutes to completely cure the resin glue to obtain an insulating board;

[0057] An insulating film for laminated busbars: the surface of the insulating board obtained above is coated with a modified epoxy adhesive, and baked in an...

Embodiment 3

[0060] An insulating board for laminated busbars. Firstly, the sizing cloth is made through the second embodiment, that is, the glass raw materials are drawn, paralleled, twisted and warped, and the warped yarns are impregnated with epoxy resin glue. Glue treatment, get the dipped warp yarn and bake it at 150°C for 3 minutes to perform semi-curing treatment, then weave it according to the specifications of 104 glass fiber cloth, and bake it in an oven at 200°C for 50 minutes after weaving After curing, a shaped cloth is obtained, and the resin weight content in the shaped cloth is no more than 30%;

[0061] Then immerse the obtained shaped cloth in the epoxy resin glue again, take it out and bake and cure it in an oven at 180°C to 250°C for 5 to 10 minutes to completely cure the resin glue to obtain an insulating board;

[0062] An insulating film for laminated busbars: the surface of the insulating board obtained above is coated with a modified acrylic adhesive, and baked in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com