Freezing-resistant acrylate suspended thickening emulsion and preparation method thereof

An acrylate and antifreeze technology, applied in the field of thickeners, can solve the problems of increased storage and transportation costs in cold regions, poor freeze-thaw stability, difficult to remove, etc., to achieve strong ability to suspend air bubbles and particles, freeze-thaw stability Good performance and stable application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

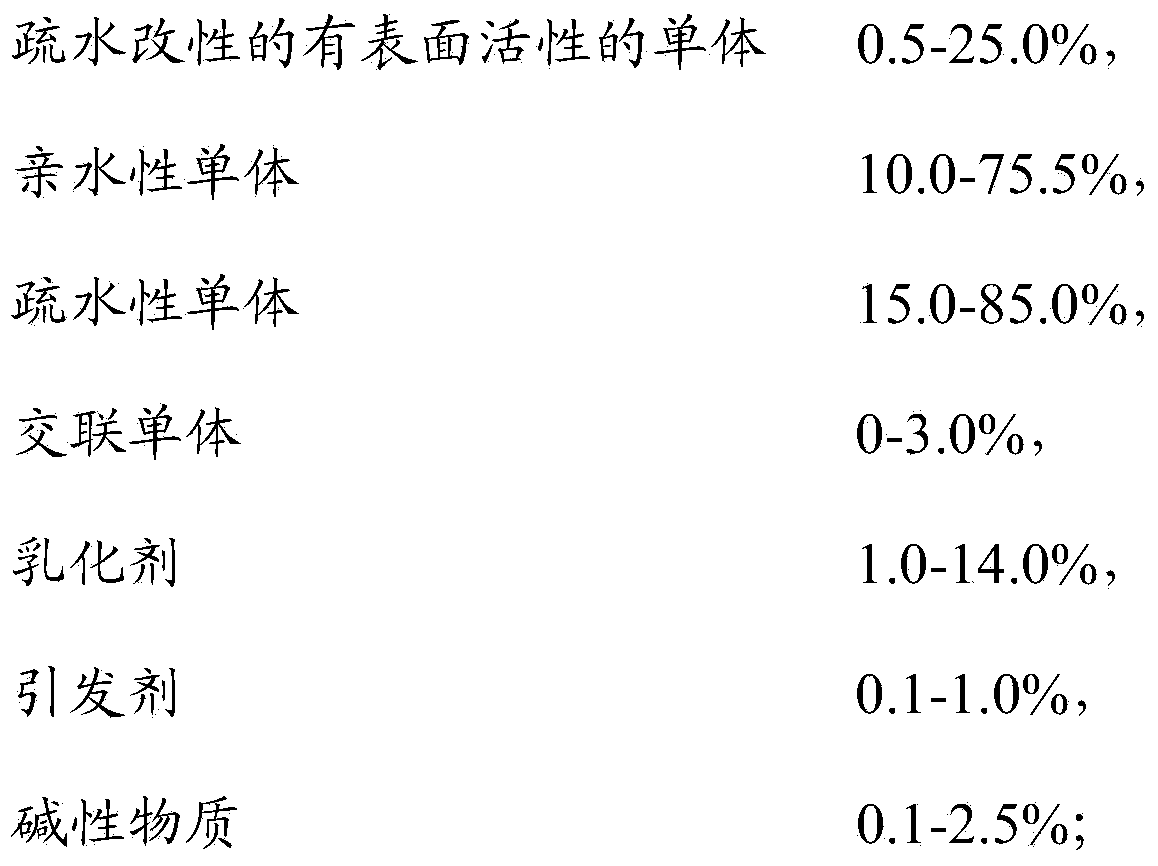

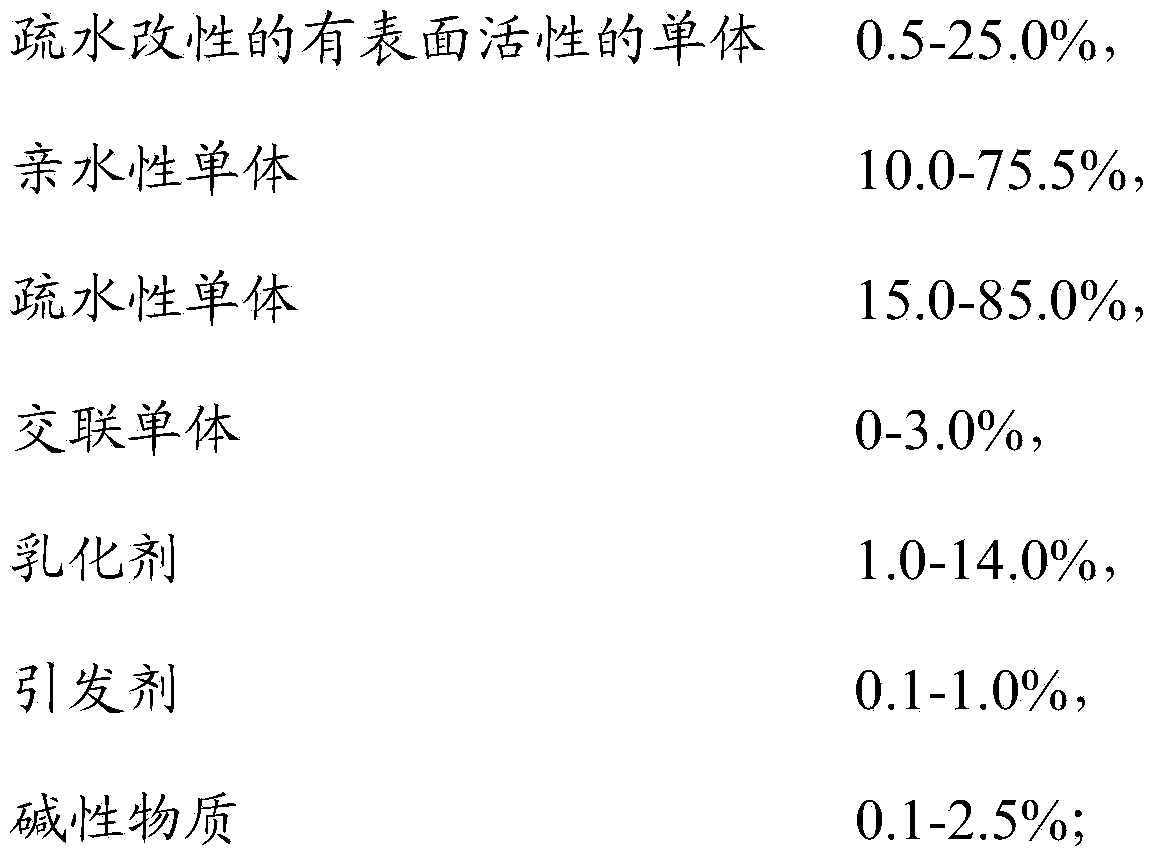

Method used

Image

Examples

Embodiment 1

[0037]Add 350g deionized water to a 1L four-neck flask, add 1.8g Span-80, 3.2g sodium dodecylbenzenesulfonate, 1.0g triethylamine and 0.5g triethanolamine at the same time, stir at a speed of 500r / min for 20min Obtain emulsifier solution; Acrylic acid 10g, methacrylic acid 90g, ethyl acrylate 60g, hydroxyethyl acrylate 10g, hydroxyethyl methacrylate 10g, butyl methacrylate 20g, fatty alcohol polyoxyethylene ether methacrylate 4.0g, 0.7g of N,N'-methylenebisacrylamide was added to the mixing tank, and stirred uniformly to obtain mixed monomer; 0.2g potassium persulfate was dissolved in 50g deionized water, and stirred uniformly to obtain an initiator solution; Add 12 g of mixed monomers into the solution, and stir for 20 min at a rotational speed of 500 r / min to obtain a seed emulsion.

[0038] Add the initiator solution dropwise to the seed emulsion heated to 80°C, and start adding the remaining mixed monomers dropwise after 30 minutes. After the mixed monomers and the initiat...

Embodiment 2

[0044] Add 360g of deionized water to a 1L four-neck flask, add 1.8g of Span-80, 3.3g of sodium dodecylbenzenesulfonate, 1.4g of triethylamine and 0.1g of sodium hydroxide at the same time, and stir at a speed of 500r / min 30min to obtain an emulsifier solution; 10g of acrylic acid, 90g of methacrylic acid, 65g of ethyl acrylate, 5g of hydroxyethyl acrylate, 10g of hydroxyethyl methacrylate, 7g of butyl acrylate, 13g of butyl methacrylate, fatty alcohol polyoxygen Add 4.2g of vinyl ether methacrylate and 0.7g of N,N'-methylene bisacrylamide into the mixing tank, and stir to obtain mixed monomers; dissolve 0.2g of potassium persulfate in 50g of deionized water, and stir to obtain the initiator Add the emulsifier solution; add 12g of mixed monomers to the emulsifier solution, and stir at a speed of 500r / min for 20min to obtain the seed emulsion.

[0045] Add the initiator solution dropwise to the seed emulsion heated to 80°C, and start adding the remaining mixed monomers dropwise...

Embodiment 3

[0051] Add 350 g of deionized water to a 1 L four-necked flask, and simultaneously add 1.9 g of Span-80, 3.3 g of sodium dodecylbenzenesulfonate, and 1.5 g of triethylamine, and stir at a speed of 400 r / min for 30 min to obtain an emulsifier solution; Acrylic acid 20g, methacrylic acid 80g, ethyl acrylate 50g, hydroxyethyl acrylate 15g, hydroxyethyl methacrylate 15g, butyl methacrylate 20g, fatty alcohol polyoxyethylene ether methacrylate 3.9g, N, Add 0.5g of N'-methylene bisacrylamide and 0.3g of ethylene glycol bismethacrylate into the mixing tank, stir well to obtain mixed monomers; dissolve 0.4g potassium persulfate in 50g deionized water, stir well to obtain initiator agent solution; add 12 g of mixed monomers to the emulsifier solution, and stir for 25 minutes at a rotational speed of 500 r / min to obtain a seed emulsion.

[0052] Add the initiator solution dropwise to the seed emulsion heated to 80°C, and start to add the remaining mixed monomers dropwise after 30 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com