Method for preparing nalmefene hydrochloride injection and prepared nalmefene hydrochloride injection

A nalmefene and injection technology, applied in the field of nalmefene hydrochloride injection, can solve the problems of inability to achieve stable effects, poor drug stability, safety, and effectiveness risks, and achieve easy control and effective ingredient content. Stabilization, effects related to the stabilization of substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

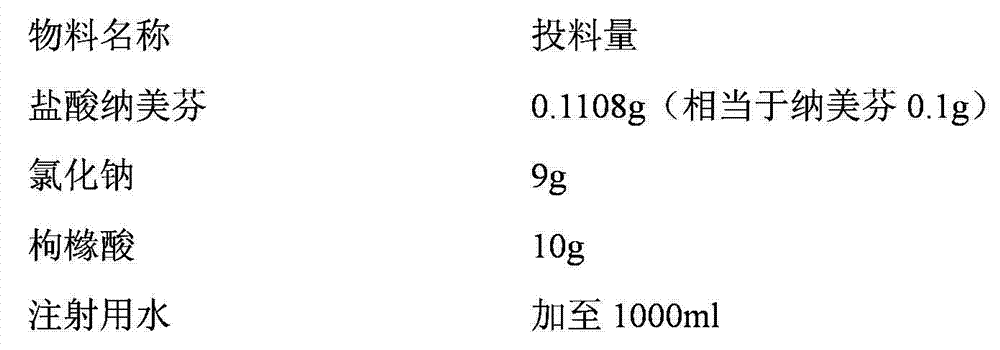

Embodiment 1

[0019] This example prepares 1000 nalmefene hydrochloride injections (specification: 1ml: 0.1mg)

[0020] Material name Feed amount

[0021] Nalmefene hydrochloride 0.1108g (equivalent to nalmefene 0.1g)

[0023] Add water for injection to 1000ml,

[0024] Preparation steps: (1) Take 9g of sodium chloride in the prescribed amount, add 500ml of water for injection to dissolve, add 0.05% (W / V) activated carbon and stir for 15 minutes, filter and decarbonize and cool to room temperature;

[0025] (2) Under the protection of nitrogen, add 0.1108g of nalmefene hydrochloride (equivalent to 0.1g of nalmefene) in the prescribed amount, stir to dissolve, add water for injection at room temperature to the full amount of 1000ml, mix well, and add 1mol / L hydrochloric acid Adjust the pH value of the solution to 3.5-4.5;

[0026] (3) After filtering with 0.45 μm and 0.22 μm filters, subpackage, fill with nitrogen, seal, and sterilize at 116°C / 40 minutes to ob...

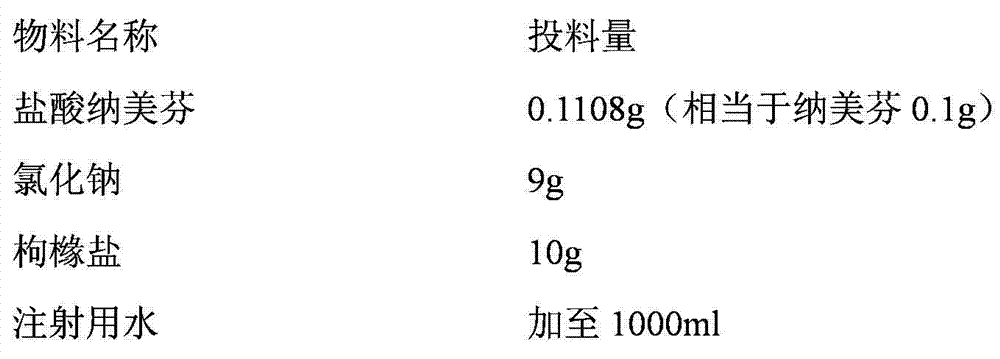

Embodiment 2

[0028] This example prepares 1000 nalmefene hydrochloride injections (specification: 1ml: 0.1mg)

[0029]

[0030] Preparation steps: (1) Take 9g of sodium chloride and 10g of citric acid as prescribed, add 500ml of water for injection to dissolve, add 0.05% (W / V) activated carbon and stir for 15 minutes, filter and decarbonize and cool to room temperature;

[0031] (2) Under the protection of nitrogen, add 0.1108g of nalmefene hydrochloride (equivalent to 0.1g of nalmefene) in the prescribed amount, stir to dissolve, add water for injection at room temperature to the full amount of 1000ml, mix well, and use 1mol / L hydrogen The sodium oxide solution adjusts the pH value to 3.5-4.5;

[0032] (3) After filtering with 0.45 μm and 0.22 μm filters, subpackage, fill with nitrogen, seal, and sterilize at 116°C / 40 minutes to obtain Nalmefene Hydrochloride Injection.

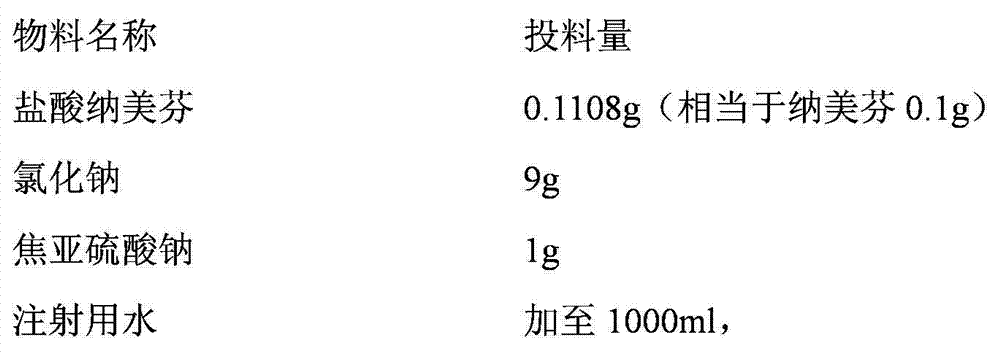

Embodiment 3

[0034] This example prepares 1000 nalmefene hydrochloride injections (specification: 1ml: 0.1mg)

[0035]

[0036] Preparation steps: (1) Take 9g of sodium chloride and 1g of sodium metabisulfite in the prescribed amount, add 500ml of water for injection to dissolve, add 0.05% (W / V) activated carbon and stir for 15 minutes, filter and decarbonize and cool to room temperature;

[0037] (2) Under the protection of nitrogen, add 0.1108g of nalmefene hydrochloride (equivalent to 0.1g of nalmefene) in the prescribed amount, stir to dissolve, add water for injection at room temperature to the full amount of 1000ml, mix well, and add 1mol / L hydrochloric acid Adjust the pH value of the solution to 3.5-4.5;

[0038] (3) After filtering with 0.45 μm and 0.22 μm filters, subpackage, fill with nitrogen, seal, and sterilize at 116°C / 40 minutes to obtain Nalmefene Hydrochloride Injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com