Quartz stone board and manufacturing method of quartz stone board

A quartz stone plate and resin technology, applied in the field of quartz stone plate and its preparation, can solve the problems of obvious product appearance fluctuation, high product defect rate, low production efficiency, etc., and achieve stable product quality, stable appearance, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

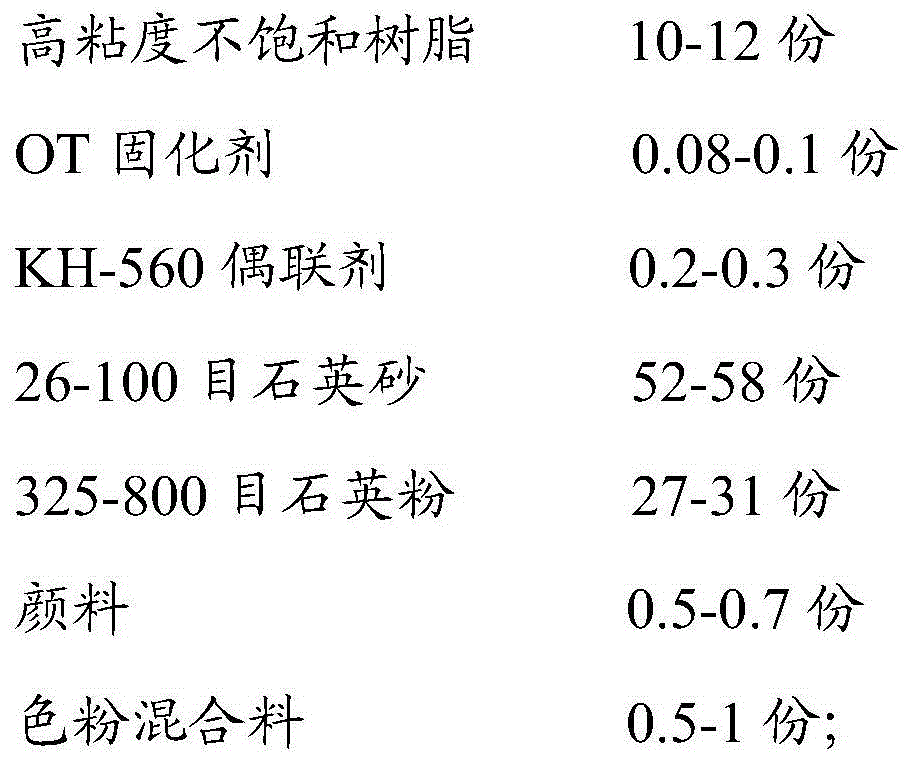

[0028] In this embodiment, a method for preparing a quartz stone plate, the quartz stone plate includes the following raw materials in parts by weight:

[0029]

[0030] The viscosity of the high-viscosity unsaturated resin is 1400 mPa·s.

[0031] The preparation method comprises the following steps:

[0032] (1) Mix and stir the high-viscosity unsaturated resin, OT curing agent, KH-560 coupling agent, 26-100 mesh quartz sand and 325-800 mesh quartz powder, and pre-press the mixed wet material, The process parameters of the pre-pressing are low frequency 20HZ, pre-pressing 5s;

[0033] (2) the wet material after step (1) is pre-pressed is carried out sieve (the size of sieve is 40mm) cutting, and the diameter scope of the group material after controlling cutting is 20mm-45mm;

[0034] (3) Spraying the mixture of pigment and toner onto the mass cut in step (2), and then performing a subsequent molding process to obtain the quartz stone plate.

[0035] The molding process ...

Embodiment 2

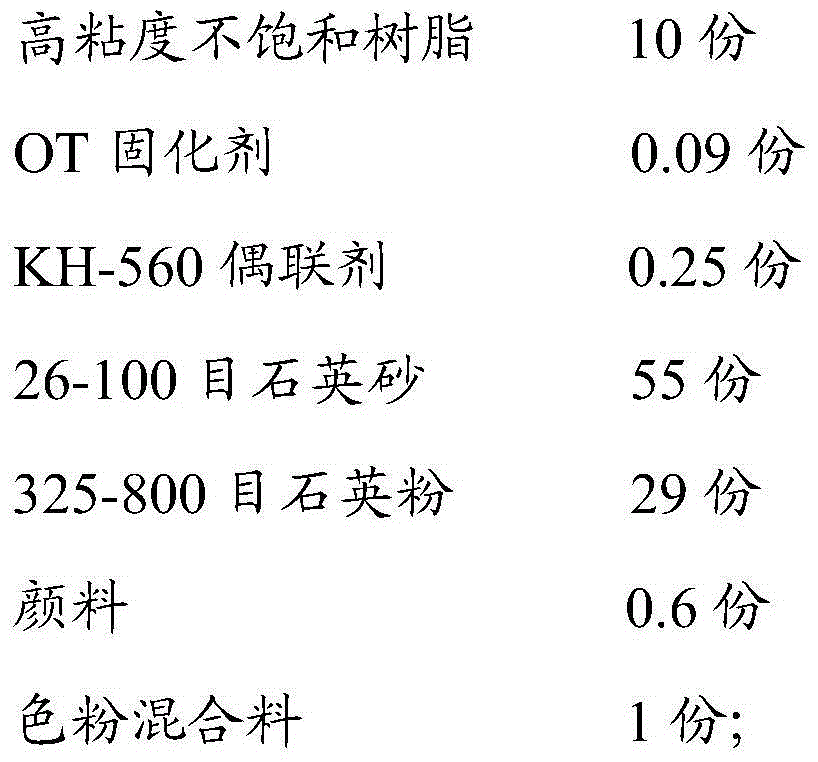

[0037] In this embodiment, a method for preparing a quartz stone plate, the quartz stone plate includes the following raw materials in parts by weight:

[0038]

[0039] The viscosity of the high-viscosity unsaturated resin is 1600 mPa·s.

[0040] The preparation method comprises the following steps:

[0041] (1) Mix and stir the high-viscosity unsaturated resin, OT curing agent, KH-560 coupling agent, 26-100 mesh quartz sand and 325-800 mesh quartz powder, and pre-press the mixed wet material, The process parameters of the pre-pressing are low frequency 20HZ, pre-pressing 6s;

[0042] (2) cutting the wet material after step (1) pre-pressing by screen (the size of the screen is 45mm), and controlling the diameter range of the cut group to be 20mm-50mm;

[0043] (3) Spraying the mixture of pigment and toner onto the mass cut in step (2), and then performing a subsequent molding process to obtain the quartz stone plate.

[0044] The molding process includes vacuum high-fre...

Embodiment 3

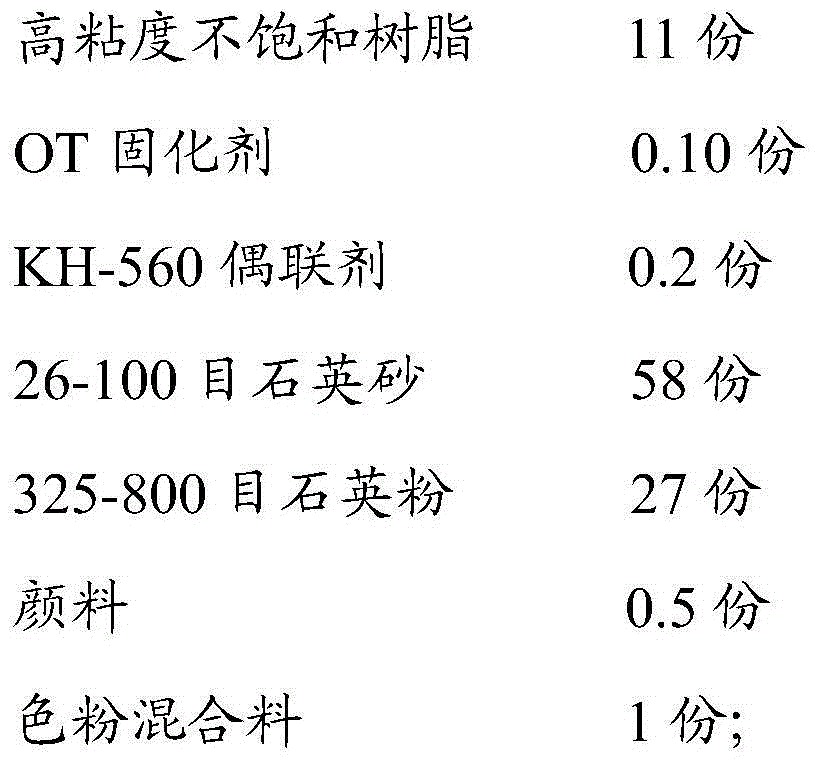

[0046] In this embodiment, a method for preparing a quartz stone plate, the quartz stone plate includes the following raw materials in parts by weight:

[0047]

[0048]

[0049] The viscosity of the high-viscosity unsaturated resin is 1800 mPa·s.

[0050] The preparation method comprises the following steps:

[0051] (1) Mix and stir the high-viscosity unsaturated resin, OT curing agent, KH-560 coupling agent, 26-100 mesh quartz sand and 325-800 mesh quartz powder, and pre-press the mixed wet material, The process parameters of the pre-pressing are low frequency 20HZ, pre-pressing 8s;

[0052] (2) cutting the wet material after step (1) preloading by screen (the size of the screen is 50mm), and controlling the diameter range of the cut group to be 20mm-60mm;

[0053] (3) Spraying the mixture of pigment and toner onto the mass cut in step (2), and then performing a subsequent molding process to obtain the quartz stone plate.

[0054] The molding process includes vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com